How Ethyl Acetate Strengthens Bio-Based Industry Collaborations?

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Bio-Based Industry: Background and Objectives

Ethyl acetate has emerged as a key player in the bio-based industry, marking a significant shift towards sustainable and environmentally friendly practices. This versatile organic compound, traditionally derived from petrochemical sources, is now increasingly produced through biological processes, aligning with the growing demand for green alternatives in various industrial applications.

The evolution of ethyl acetate production and utilization in the bio-based industry reflects a broader trend towards circular economy principles and reduced reliance on fossil fuels. Initially used primarily as a solvent in traditional industries, ethyl acetate has found new applications and production methods that leverage renewable resources and biotechnological advancements.

The bio-based industry's interest in ethyl acetate stems from its wide range of applications, including its use as a solvent in paints, coatings, and adhesives, as well as its role in the food and pharmaceutical sectors. The shift towards bio-based ethyl acetate production addresses environmental concerns and meets the increasing consumer demand for sustainable products.

Recent technological developments have focused on improving the efficiency and sustainability of ethyl acetate production. Fermentation processes using renewable feedstocks such as sugarcane, corn, and other agricultural residues have been developed, offering a more environmentally friendly alternative to traditional petrochemical routes.

The objectives of ethyl acetate research and development in the bio-based industry are multifaceted. Primarily, there is a drive to optimize production processes, enhancing yield and reducing costs to make bio-based ethyl acetate economically competitive with its petrochemical counterpart. Additionally, researchers aim to expand the range of renewable feedstocks that can be used in production, thereby increasing the flexibility and resilience of supply chains.

Another key objective is to explore and develop new applications for ethyl acetate in various industries, leveraging its unique properties and green credentials. This includes investigating its potential in advanced materials, biodegradable plastics, and as a platform chemical for the synthesis of other valuable compounds.

The pursuit of these objectives has led to increased collaboration between academic institutions, biotechnology firms, and traditional chemical companies. These partnerships aim to bridge the gap between fundamental research and industrial application, accelerating the development and commercialization of bio-based ethyl acetate technologies.

As the bio-based industry continues to evolve, ethyl acetate stands as a prime example of how traditional chemicals can be reimagined and produced through sustainable means. The ongoing research and development in this field not only contribute to the growth of the bio-based economy but also pave the way for broader adoption of green chemistry principles across various industrial sectors.

The evolution of ethyl acetate production and utilization in the bio-based industry reflects a broader trend towards circular economy principles and reduced reliance on fossil fuels. Initially used primarily as a solvent in traditional industries, ethyl acetate has found new applications and production methods that leverage renewable resources and biotechnological advancements.

The bio-based industry's interest in ethyl acetate stems from its wide range of applications, including its use as a solvent in paints, coatings, and adhesives, as well as its role in the food and pharmaceutical sectors. The shift towards bio-based ethyl acetate production addresses environmental concerns and meets the increasing consumer demand for sustainable products.

Recent technological developments have focused on improving the efficiency and sustainability of ethyl acetate production. Fermentation processes using renewable feedstocks such as sugarcane, corn, and other agricultural residues have been developed, offering a more environmentally friendly alternative to traditional petrochemical routes.

The objectives of ethyl acetate research and development in the bio-based industry are multifaceted. Primarily, there is a drive to optimize production processes, enhancing yield and reducing costs to make bio-based ethyl acetate economically competitive with its petrochemical counterpart. Additionally, researchers aim to expand the range of renewable feedstocks that can be used in production, thereby increasing the flexibility and resilience of supply chains.

Another key objective is to explore and develop new applications for ethyl acetate in various industries, leveraging its unique properties and green credentials. This includes investigating its potential in advanced materials, biodegradable plastics, and as a platform chemical for the synthesis of other valuable compounds.

The pursuit of these objectives has led to increased collaboration between academic institutions, biotechnology firms, and traditional chemical companies. These partnerships aim to bridge the gap between fundamental research and industrial application, accelerating the development and commercialization of bio-based ethyl acetate technologies.

As the bio-based industry continues to evolve, ethyl acetate stands as a prime example of how traditional chemicals can be reimagined and produced through sustainable means. The ongoing research and development in this field not only contribute to the growth of the bio-based economy but also pave the way for broader adoption of green chemistry principles across various industrial sectors.

Market Demand Analysis for Bio-Based Ethyl Acetate

The market demand for bio-based ethyl acetate has been steadily increasing in recent years, driven by growing environmental concerns and the shift towards sustainable products. This trend is particularly evident in industries such as coatings, adhesives, pharmaceuticals, and food processing, where ethyl acetate is widely used as a solvent and flavoring agent.

In the coatings industry, bio-based ethyl acetate is gaining traction as manufacturers seek eco-friendly alternatives to traditional petroleum-based solvents. The global green coatings market, which includes bio-based solvents, is expected to grow significantly in the coming years, creating a substantial demand for bio-based ethyl acetate.

The adhesives sector is another key market for bio-based ethyl acetate. As consumers and industries prioritize sustainable packaging solutions, the demand for bio-based adhesives is rising. This trend is particularly strong in the food packaging industry, where bio-based ethyl acetate offers a safer and more environmentally friendly option for laminating films and other packaging materials.

In the pharmaceutical industry, bio-based ethyl acetate is finding applications in the production of various medications and as a solvent in drug formulations. The increasing focus on green chemistry and sustainable pharmaceutical manufacturing processes is driving the adoption of bio-based solvents, including ethyl acetate.

The food and beverage industry represents another significant market for bio-based ethyl acetate. As a flavoring agent and processing aid, ethyl acetate derived from renewable sources aligns with the growing consumer demand for natural and clean label products. This trend is particularly strong in the production of fruit flavors, where bio-based ethyl acetate can replace synthetic alternatives.

The market potential for bio-based ethyl acetate is further enhanced by regulatory support and sustainability initiatives. Many countries have implemented policies to promote the use of bio-based chemicals, creating a favorable environment for market growth. Additionally, companies across various industries are setting ambitious sustainability targets, which often include increasing the use of bio-based materials in their supply chains.

Despite the positive market outlook, challenges remain in scaling up production and ensuring cost-competitiveness with conventional ethyl acetate. However, ongoing research and development efforts, coupled with increasing collaborations between bio-based industry players, are expected to address these challenges and further drive market growth.

In the coatings industry, bio-based ethyl acetate is gaining traction as manufacturers seek eco-friendly alternatives to traditional petroleum-based solvents. The global green coatings market, which includes bio-based solvents, is expected to grow significantly in the coming years, creating a substantial demand for bio-based ethyl acetate.

The adhesives sector is another key market for bio-based ethyl acetate. As consumers and industries prioritize sustainable packaging solutions, the demand for bio-based adhesives is rising. This trend is particularly strong in the food packaging industry, where bio-based ethyl acetate offers a safer and more environmentally friendly option for laminating films and other packaging materials.

In the pharmaceutical industry, bio-based ethyl acetate is finding applications in the production of various medications and as a solvent in drug formulations. The increasing focus on green chemistry and sustainable pharmaceutical manufacturing processes is driving the adoption of bio-based solvents, including ethyl acetate.

The food and beverage industry represents another significant market for bio-based ethyl acetate. As a flavoring agent and processing aid, ethyl acetate derived from renewable sources aligns with the growing consumer demand for natural and clean label products. This trend is particularly strong in the production of fruit flavors, where bio-based ethyl acetate can replace synthetic alternatives.

The market potential for bio-based ethyl acetate is further enhanced by regulatory support and sustainability initiatives. Many countries have implemented policies to promote the use of bio-based chemicals, creating a favorable environment for market growth. Additionally, companies across various industries are setting ambitious sustainability targets, which often include increasing the use of bio-based materials in their supply chains.

Despite the positive market outlook, challenges remain in scaling up production and ensuring cost-competitiveness with conventional ethyl acetate. However, ongoing research and development efforts, coupled with increasing collaborations between bio-based industry players, are expected to address these challenges and further drive market growth.

Current Status and Challenges in Bio-Based Ethyl Acetate Production

The production of bio-based ethyl acetate has gained significant traction in recent years, driven by the growing demand for sustainable alternatives to petrochemical-derived products. Currently, the global bio-based ethyl acetate market is experiencing steady growth, with an increasing number of companies investing in research and development to improve production processes and expand capacity.

The primary feedstocks for bio-based ethyl acetate production include renewable resources such as sugarcane, corn, and cellulosic biomass. These raw materials are converted into ethanol through fermentation processes, which is then further processed to produce ethyl acetate. The current production methods predominantly rely on esterification reactions between ethanol and acetic acid, catalyzed by various enzymes or chemical catalysts.

Despite the progress made in bio-based ethyl acetate production, several challenges persist. One of the main hurdles is the high production cost compared to conventional petrochemical-derived ethyl acetate. This cost differential is primarily attributed to the higher prices of bio-based feedstocks and the additional processing steps required for conversion.

Another significant challenge is the optimization of production processes to improve yield and efficiency. Current bio-based methods often result in lower yields and slower reaction rates compared to traditional petrochemical processes. This necessitates ongoing research to develop more efficient catalysts and reaction conditions to enhance productivity and reduce energy consumption.

The scalability of bio-based ethyl acetate production also presents a challenge. While small-scale production has been successfully demonstrated, scaling up to commercial levels while maintaining consistent quality and cost-effectiveness remains a hurdle for many producers. This is particularly evident in the purification and separation stages of the production process.

Environmental concerns, although less prominent than in petrochemical production, still exist in bio-based processes. Issues such as water consumption, waste management, and the potential competition with food crops for agricultural land need to be addressed to ensure the long-term sustainability of bio-based ethyl acetate production.

Regulatory frameworks and certification standards for bio-based products are still evolving, creating uncertainty for producers and potential barriers to market entry. The lack of harmonized global standards for bio-based content and sustainability claims can hinder market growth and consumer acceptance.

Despite these challenges, the bio-based ethyl acetate industry continues to advance, driven by technological innovations and increasing collaborations between academic institutions, research organizations, and industrial partners. These collaborations are crucial for addressing the current limitations and paving the way for more efficient and cost-effective production methods in the future.

The primary feedstocks for bio-based ethyl acetate production include renewable resources such as sugarcane, corn, and cellulosic biomass. These raw materials are converted into ethanol through fermentation processes, which is then further processed to produce ethyl acetate. The current production methods predominantly rely on esterification reactions between ethanol and acetic acid, catalyzed by various enzymes or chemical catalysts.

Despite the progress made in bio-based ethyl acetate production, several challenges persist. One of the main hurdles is the high production cost compared to conventional petrochemical-derived ethyl acetate. This cost differential is primarily attributed to the higher prices of bio-based feedstocks and the additional processing steps required for conversion.

Another significant challenge is the optimization of production processes to improve yield and efficiency. Current bio-based methods often result in lower yields and slower reaction rates compared to traditional petrochemical processes. This necessitates ongoing research to develop more efficient catalysts and reaction conditions to enhance productivity and reduce energy consumption.

The scalability of bio-based ethyl acetate production also presents a challenge. While small-scale production has been successfully demonstrated, scaling up to commercial levels while maintaining consistent quality and cost-effectiveness remains a hurdle for many producers. This is particularly evident in the purification and separation stages of the production process.

Environmental concerns, although less prominent than in petrochemical production, still exist in bio-based processes. Issues such as water consumption, waste management, and the potential competition with food crops for agricultural land need to be addressed to ensure the long-term sustainability of bio-based ethyl acetate production.

Regulatory frameworks and certification standards for bio-based products are still evolving, creating uncertainty for producers and potential barriers to market entry. The lack of harmonized global standards for bio-based content and sustainability claims can hinder market growth and consumer acceptance.

Despite these challenges, the bio-based ethyl acetate industry continues to advance, driven by technological innovations and increasing collaborations between academic institutions, research organizations, and industrial partners. These collaborations are crucial for addressing the current limitations and paving the way for more efficient and cost-effective production methods in the future.

Current Bio-Based Ethyl Acetate Production Methods

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The production methods aim to optimize the reaction conditions and separation processes to obtain high-quality ethyl acetate efficiently.

- Applications of ethyl acetate in industrial processes: Ethyl acetate finds diverse applications in industrial processes. It is used as a solvent in various industries, including pharmaceuticals, coatings, and electronics. The compound is also employed in extraction processes, as a reaction medium, and in the production of other chemicals. Its versatility makes it a valuable component in many manufacturing processes.

- Ethyl acetate in polymer and material science: Ethyl acetate plays a significant role in polymer and material science. It is used in the synthesis and processing of various polymers, as well as in the development of advanced materials. The compound's properties make it suitable for use in coating formulations, adhesives, and as a processing aid in the production of plastics and other materials.

- Environmental and safety considerations for ethyl acetate: The use of ethyl acetate in industrial processes requires consideration of environmental and safety aspects. Research focuses on developing environmentally friendly production methods, reducing emissions, and improving handling and storage practices. Safety measures for working with ethyl acetate, including proper ventilation and personal protective equipment, are also emphasized.

- Novel synthesis routes and derivatives of ethyl acetate: Research explores novel synthesis routes for ethyl acetate and the development of its derivatives. These include new catalytic processes, alternative feedstocks, and the creation of functionalized ethyl acetate compounds. The aim is to expand the range of applications and improve the properties of ethyl acetate-based products for various industrial uses.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other compounds. Its versatility makes it valuable in industries such as pharmaceuticals, coatings, and adhesives.Expand Specific Solutions03 Ethyl acetate in extraction and separation processes

Ethyl acetate is employed in extraction and separation processes for various substances, including natural products, pharmaceuticals, and other chemicals. Its properties make it suitable for liquid-liquid extraction and chromatographic techniques.Expand Specific Solutions04 Environmental and safety considerations for ethyl acetate

Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling procedures.Expand Specific Solutions05 Novel applications and formulations of ethyl acetate

Innovative applications and formulations of ethyl acetate are being explored, including its use in advanced materials, specialty chemicals, and consumer products. These developments aim to expand the utility of ethyl acetate in various industries.Expand Specific Solutions

Key Players in Bio-Based Ethyl Acetate Industry

The ethyl acetate market is in a growth phase, driven by increasing demand in bio-based industries. The market size is expanding, with projections indicating significant growth in the coming years. Technologically, ethyl acetate production is mature, but innovations in bio-based manufacturing are emerging. Key players like Celanese, Eastman Chemical, and Sekisui Chemical are leading traditional production, while companies such as Xyleco and Cemvita Factory are pioneering bio-based approaches. Research institutions like the University of Florida and East China University of Science & Technology are contributing to advancements in sustainable production methods, strengthening industry-academia collaborations and driving the shift towards more environmentally friendly processes.

Celanese International Corp.

Technical Solution: Celanese has developed a proprietary process for producing ethyl acetate from sustainable sources. Their bio-based ethyl acetate is manufactured using ethanol derived from renewable feedstocks, such as corn or sugarcane. The company employs a continuous esterification process that combines ethanol with acetic acid in the presence of a catalyst. This method achieves high yields and purity levels comparable to traditional petrochemical-based production[1]. Celanese's bio-based ethyl acetate maintains the same chemical properties and performance characteristics as conventional ethyl acetate, making it a drop-in replacement for various applications[2]. The company has also implemented advanced purification techniques to ensure product quality meets stringent industry standards.

Strengths: Renewable feedstock usage, drop-in replacement capability, established production infrastructure. Weaknesses: Potential higher production costs compared to petrochemical routes, dependence on agricultural feedstock availability.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed a novel approach to bio-based ethyl acetate production through its proprietary GEM Technology™. This process utilizes a mixed feedstock of bio-based and recycled content to create ethyl acetate with a significantly reduced carbon footprint. The technology employs a gasification process to convert biomass and plastic waste into syngas, which is then converted into acetic acid and subsequently ethyl acetate[3]. Eastman's method allows for the incorporation of difficult-to-recycle plastics, contributing to circular economy goals. The company has optimized catalyst systems and reaction conditions to achieve high selectivity and yield in the ethyl acetate synthesis step[4]. Additionally, Eastman has implemented advanced separation techniques to ensure the final product meets the highest purity standards required for various industrial applications.

Strengths: Utilization of mixed feedstocks including plastic waste, contribution to circular economy, reduced carbon footprint. Weaknesses: Complex process requiring significant capital investment, potential variability in feedstock composition.

Key Innovations in Bio-Based Ethyl Acetate Synthesis

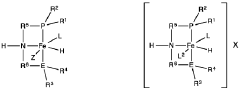

Homogeneous iron catalysts for the conversion of ethanol to ethyl acetate and hydrogen

PatentWO2019027965A1

Innovation

- A process utilizing a homogeneous iron catalyst with a tridentate pincer ligand for dehydrogenative coupling of ethanol at moderate temperatures, producing ethyl acetate efficiently and selectively, with iron loadings as low as 0.001 mol%, allowing for continuous operation and easy separation of ethyl acetate from the catalyst.

Patent

Innovation

- Ethyl acetate serves as a bio-based solvent that facilitates cross-industry collaborations in the bio-based economy.

- Ethyl acetate acts as a bridge between agricultural and industrial sectors, promoting the utilization of renewable resources.

- The use of ethyl acetate in various industries demonstrates the versatility of bio-based chemicals, encouraging further research and development.

Environmental Impact of Bio-Based Ethyl Acetate Production

The production of bio-based ethyl acetate has significant environmental implications, offering both advantages and challenges compared to traditional petrochemical-based production methods. One of the primary benefits is the reduction in greenhouse gas emissions. Bio-based ethyl acetate production utilizes renewable resources, such as agricultural waste or dedicated biomass crops, which can lead to a lower carbon footprint throughout the product lifecycle. Studies have shown that the carbon dioxide emissions from bio-based ethyl acetate production can be up to 50% lower than those from fossil-based alternatives.

Water consumption is another critical environmental factor to consider. While bio-based production processes generally require water for biomass cultivation and fermentation, innovative technologies are being developed to optimize water usage. Closed-loop systems and water recycling techniques are increasingly being implemented to minimize the overall water footprint of bio-based ethyl acetate production.

Land use changes associated with biomass cultivation for ethyl acetate production can have both positive and negative environmental impacts. On one hand, the use of marginal lands or agricultural residues can provide additional income for farmers and reduce pressure on food crops. On the other hand, if not managed sustainably, it could lead to deforestation or competition with food production.

The production of bio-based ethyl acetate also contributes to reduced dependence on fossil fuels, which can have far-reaching environmental benefits. By utilizing renewable feedstocks, the industry helps conserve non-renewable resources and reduces the environmental risks associated with oil extraction and transportation.

Waste management is an essential aspect of the environmental impact assessment. Bio-based production processes generate organic waste, which can be composted or used for biogas production, creating additional value streams and reducing overall waste. However, proper handling and treatment of these byproducts are crucial to prevent soil and water pollution.

Air quality is another consideration in bio-based ethyl acetate production. While the process generally emits fewer volatile organic compounds (VOCs) compared to petrochemical methods, careful monitoring and control of fermentation off-gases are necessary to minimize local air pollution.

Biodiversity impacts must also be evaluated, particularly when large-scale biomass cultivation is involved. Sustainable farming practices and the use of diverse crop rotations can help maintain ecosystem balance and protect local flora and fauna.

In conclusion, while bio-based ethyl acetate production offers significant environmental advantages, particularly in terms of greenhouse gas reduction and resource conservation, it is essential to address potential challenges related to land use, water management, and biodiversity. Ongoing research and development in process efficiency and sustainability practices are crucial to maximizing the environmental benefits of bio-based ethyl acetate production.

Water consumption is another critical environmental factor to consider. While bio-based production processes generally require water for biomass cultivation and fermentation, innovative technologies are being developed to optimize water usage. Closed-loop systems and water recycling techniques are increasingly being implemented to minimize the overall water footprint of bio-based ethyl acetate production.

Land use changes associated with biomass cultivation for ethyl acetate production can have both positive and negative environmental impacts. On one hand, the use of marginal lands or agricultural residues can provide additional income for farmers and reduce pressure on food crops. On the other hand, if not managed sustainably, it could lead to deforestation or competition with food production.

The production of bio-based ethyl acetate also contributes to reduced dependence on fossil fuels, which can have far-reaching environmental benefits. By utilizing renewable feedstocks, the industry helps conserve non-renewable resources and reduces the environmental risks associated with oil extraction and transportation.

Waste management is an essential aspect of the environmental impact assessment. Bio-based production processes generate organic waste, which can be composted or used for biogas production, creating additional value streams and reducing overall waste. However, proper handling and treatment of these byproducts are crucial to prevent soil and water pollution.

Air quality is another consideration in bio-based ethyl acetate production. While the process generally emits fewer volatile organic compounds (VOCs) compared to petrochemical methods, careful monitoring and control of fermentation off-gases are necessary to minimize local air pollution.

Biodiversity impacts must also be evaluated, particularly when large-scale biomass cultivation is involved. Sustainable farming practices and the use of diverse crop rotations can help maintain ecosystem balance and protect local flora and fauna.

In conclusion, while bio-based ethyl acetate production offers significant environmental advantages, particularly in terms of greenhouse gas reduction and resource conservation, it is essential to address potential challenges related to land use, water management, and biodiversity. Ongoing research and development in process efficiency and sustainability practices are crucial to maximizing the environmental benefits of bio-based ethyl acetate production.

Collaborative Opportunities in Bio-Based Ethyl Acetate Industry

The bio-based ethyl acetate industry presents numerous collaborative opportunities that can strengthen partnerships and drive innovation across the value chain. One key area for collaboration is in feedstock sourcing and supply. Producers of bio-based ethyl acetate can partner with agricultural companies and biomass suppliers to secure a stable and sustainable supply of raw materials. This collaboration can lead to the development of dedicated biomass crops optimized for ethyl acetate production, as well as improved logistics and processing methods.

Research and development collaborations between industry players and academic institutions can accelerate technological advancements in bio-based ethyl acetate production. These partnerships can focus on developing more efficient fermentation processes, novel catalysts for esterification, and improved separation techniques. Such collaborations can also explore new applications for bio-based ethyl acetate, expanding its market potential.

Downstream collaborations with end-users in various industries, such as coatings, adhesives, and pharmaceuticals, can drive product innovation and market adoption. By working closely with customers, ethyl acetate producers can develop tailored solutions that meet specific performance requirements and sustainability goals. This co-development approach can lead to the creation of new bio-based products and applications, fostering growth in the broader bio-economy.

Cross-industry collaborations can also emerge, linking the bio-based ethyl acetate sector with other bio-based industries. For instance, partnerships with bio-refineries can create synergies in feedstock utilization and process integration. Collaborations with bioplastics manufacturers can explore the use of bio-based ethyl acetate as a solvent or additive in their production processes, further expanding the market for this versatile compound.

Sustainability-focused collaborations are another crucial area for the bio-based ethyl acetate industry. Producers can partner with environmental organizations, certification bodies, and government agencies to develop and implement sustainability standards and life cycle assessment methodologies. These collaborations can enhance the credibility of bio-based ethyl acetate as a sustainable alternative to petrochemical-derived products and support its market acceptance.

Lastly, industry-wide collaborations through consortia or trade associations can address common challenges and promote the benefits of bio-based ethyl acetate. These collective efforts can focus on regulatory advocacy, public awareness campaigns, and the development of industry standards. By working together, stakeholders can create a more favorable business environment and accelerate the growth of the bio-based ethyl acetate market.

Research and development collaborations between industry players and academic institutions can accelerate technological advancements in bio-based ethyl acetate production. These partnerships can focus on developing more efficient fermentation processes, novel catalysts for esterification, and improved separation techniques. Such collaborations can also explore new applications for bio-based ethyl acetate, expanding its market potential.

Downstream collaborations with end-users in various industries, such as coatings, adhesives, and pharmaceuticals, can drive product innovation and market adoption. By working closely with customers, ethyl acetate producers can develop tailored solutions that meet specific performance requirements and sustainability goals. This co-development approach can lead to the creation of new bio-based products and applications, fostering growth in the broader bio-economy.

Cross-industry collaborations can also emerge, linking the bio-based ethyl acetate sector with other bio-based industries. For instance, partnerships with bio-refineries can create synergies in feedstock utilization and process integration. Collaborations with bioplastics manufacturers can explore the use of bio-based ethyl acetate as a solvent or additive in their production processes, further expanding the market for this versatile compound.

Sustainability-focused collaborations are another crucial area for the bio-based ethyl acetate industry. Producers can partner with environmental organizations, certification bodies, and government agencies to develop and implement sustainability standards and life cycle assessment methodologies. These collaborations can enhance the credibility of bio-based ethyl acetate as a sustainable alternative to petrochemical-derived products and support its market acceptance.

Lastly, industry-wide collaborations through consortia or trade associations can address common challenges and promote the benefits of bio-based ethyl acetate. These collective efforts can focus on regulatory advocacy, public awareness campaigns, and the development of industry standards. By working together, stakeholders can create a more favorable business environment and accelerate the growth of the bio-based ethyl acetate market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!