How to Achieve Cost Efficiency with Ethyl Acetate?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Background

Ethyl acetate, a versatile organic compound with the chemical formula CH3COOC2H5, has been a staple in various industries for decades. This colorless liquid, known for its characteristic sweet smell, is produced through the esterification of ethanol and acetic acid. Its history dates back to the early 19th century when it was first synthesized in laboratory settings.

The compound's unique properties, including its low toxicity, high solvency power, and pleasant odor, have made it an indispensable component in numerous applications. From its use as a solvent in paints and coatings to its role in the production of pharmaceuticals and fragrances, ethyl acetate has become a cornerstone in modern industrial processes.

In recent years, the global demand for ethyl acetate has seen steady growth, driven by expanding applications in emerging economies and the increasing need for environmentally friendly solvents. The market has witnessed a shift towards bio-based ethyl acetate production methods, aligning with the growing emphasis on sustainability and green chemistry principles.

The production of ethyl acetate has evolved significantly over time. Traditional methods relied heavily on petrochemical feedstocks, but recent advancements have introduced more sustainable approaches. These include the use of bioethanol as a raw material and the development of novel catalytic processes that enhance efficiency and reduce environmental impact.

Cost efficiency in ethyl acetate production and utilization has become a critical focus for industry players. This emphasis stems from fluctuating raw material prices, increasing competition, and the need to maintain profitability in a dynamic market landscape. Manufacturers are continuously exploring innovative technologies and process optimizations to reduce production costs while maintaining product quality.

The quest for cost efficiency in ethyl acetate production encompasses various strategies. These include improving catalytic systems to increase yield and selectivity, implementing energy-efficient distillation techniques, and exploring alternative feedstocks. Additionally, the integration of circular economy principles, such as recycling and waste valorization, is gaining traction as a means to enhance overall cost-effectiveness and sustainability.

As industries strive to balance economic viability with environmental responsibility, the future of ethyl acetate production is likely to see further innovations. These may include the development of novel bio-based production routes, the implementation of advanced process control systems, and the adoption of green chemistry principles to minimize waste and energy consumption.

The compound's unique properties, including its low toxicity, high solvency power, and pleasant odor, have made it an indispensable component in numerous applications. From its use as a solvent in paints and coatings to its role in the production of pharmaceuticals and fragrances, ethyl acetate has become a cornerstone in modern industrial processes.

In recent years, the global demand for ethyl acetate has seen steady growth, driven by expanding applications in emerging economies and the increasing need for environmentally friendly solvents. The market has witnessed a shift towards bio-based ethyl acetate production methods, aligning with the growing emphasis on sustainability and green chemistry principles.

The production of ethyl acetate has evolved significantly over time. Traditional methods relied heavily on petrochemical feedstocks, but recent advancements have introduced more sustainable approaches. These include the use of bioethanol as a raw material and the development of novel catalytic processes that enhance efficiency and reduce environmental impact.

Cost efficiency in ethyl acetate production and utilization has become a critical focus for industry players. This emphasis stems from fluctuating raw material prices, increasing competition, and the need to maintain profitability in a dynamic market landscape. Manufacturers are continuously exploring innovative technologies and process optimizations to reduce production costs while maintaining product quality.

The quest for cost efficiency in ethyl acetate production encompasses various strategies. These include improving catalytic systems to increase yield and selectivity, implementing energy-efficient distillation techniques, and exploring alternative feedstocks. Additionally, the integration of circular economy principles, such as recycling and waste valorization, is gaining traction as a means to enhance overall cost-effectiveness and sustainability.

As industries strive to balance economic viability with environmental responsibility, the future of ethyl acetate production is likely to see further innovations. These may include the development of novel bio-based production routes, the implementation of advanced process control systems, and the adoption of green chemistry principles to minimize waste and energy consumption.

Market Analysis

The global market for ethyl acetate has been experiencing steady growth, driven by its versatile applications across various industries. The compound's widespread use in coatings, adhesives, pharmaceuticals, and food packaging has contributed to its increasing demand. Market analysis indicates that the Asia-Pacific region, particularly China and India, has emerged as a significant consumer and producer of ethyl acetate, owing to rapid industrialization and economic growth.

The cost efficiency of ethyl acetate production is a critical factor influencing market dynamics. As raw material prices fluctuate, manufacturers are constantly seeking ways to optimize their production processes and reduce costs. The primary feedstocks for ethyl acetate production, ethanol and acetic acid, are subject to price volatility, which directly impacts the overall production costs. This has led to a growing emphasis on developing more efficient synthesis routes and exploring alternative raw materials.

In recent years, there has been a noticeable shift towards bio-based ethyl acetate production, driven by increasing environmental concerns and the push for sustainable manufacturing practices. This trend has opened up new market opportunities for companies investing in green technologies. However, the cost-competitiveness of bio-based ethyl acetate compared to its conventional counterparts remains a challenge that needs to be addressed to gain wider market acceptance.

The demand for ethyl acetate in the pharmaceutical industry has been particularly strong, with the compound being used as a solvent in drug formulations and as a reagent in various chemical processes. This sector's growth is expected to continue, driven by increasing healthcare expenditure and the development of new drugs. Additionally, the food and beverage industry's use of ethyl acetate as a flavoring agent and in fruit extracts has contributed to market expansion.

Market analysis also reveals that the packaging industry, especially flexible packaging, has been a significant driver of ethyl acetate demand. The compound's excellent solvent properties make it ideal for use in printing inks and adhesives, which are essential in packaging applications. As e-commerce continues to grow, the demand for packaging materials is expected to rise, further boosting the ethyl acetate market.

To achieve cost efficiency in ethyl acetate production, manufacturers are exploring various strategies. These include process intensification, waste heat recovery, and the implementation of advanced catalysts to improve yield and selectivity. Additionally, some companies are investing in vertical integration to secure a stable supply of raw materials and reduce dependency on external suppliers, thereby mitigating the impact of price fluctuations.

The cost efficiency of ethyl acetate production is a critical factor influencing market dynamics. As raw material prices fluctuate, manufacturers are constantly seeking ways to optimize their production processes and reduce costs. The primary feedstocks for ethyl acetate production, ethanol and acetic acid, are subject to price volatility, which directly impacts the overall production costs. This has led to a growing emphasis on developing more efficient synthesis routes and exploring alternative raw materials.

In recent years, there has been a noticeable shift towards bio-based ethyl acetate production, driven by increasing environmental concerns and the push for sustainable manufacturing practices. This trend has opened up new market opportunities for companies investing in green technologies. However, the cost-competitiveness of bio-based ethyl acetate compared to its conventional counterparts remains a challenge that needs to be addressed to gain wider market acceptance.

The demand for ethyl acetate in the pharmaceutical industry has been particularly strong, with the compound being used as a solvent in drug formulations and as a reagent in various chemical processes. This sector's growth is expected to continue, driven by increasing healthcare expenditure and the development of new drugs. Additionally, the food and beverage industry's use of ethyl acetate as a flavoring agent and in fruit extracts has contributed to market expansion.

Market analysis also reveals that the packaging industry, especially flexible packaging, has been a significant driver of ethyl acetate demand. The compound's excellent solvent properties make it ideal for use in printing inks and adhesives, which are essential in packaging applications. As e-commerce continues to grow, the demand for packaging materials is expected to rise, further boosting the ethyl acetate market.

To achieve cost efficiency in ethyl acetate production, manufacturers are exploring various strategies. These include process intensification, waste heat recovery, and the implementation of advanced catalysts to improve yield and selectivity. Additionally, some companies are investing in vertical integration to secure a stable supply of raw materials and reduce dependency on external suppliers, thereby mitigating the impact of price fluctuations.

Technical Challenges

The production and utilization of ethyl acetate face several technical challenges that impact cost efficiency. One of the primary issues is the energy-intensive nature of the traditional production process, which relies on esterification of ethanol and acetic acid. This reaction requires high temperatures and pressures, leading to significant energy consumption and operational costs.

Another challenge lies in the purification of ethyl acetate. The azeotropic mixture formed with water during production necessitates complex separation techniques, such as azeotropic distillation or extractive distillation. These processes are not only energy-intensive but also require specialized equipment, contributing to higher capital and operational expenses.

Raw material costs pose a significant challenge to cost efficiency. The price volatility of ethanol and acetic acid, the primary feedstocks for ethyl acetate production, can substantially impact production costs. Fluctuations in these raw material prices make it difficult for manufacturers to maintain consistent profit margins and plan long-term production strategies.

The recovery and recycling of ethyl acetate in various industrial applications present another technical hurdle. Many industries use ethyl acetate as a solvent, and efficient recovery systems are crucial for cost-effective operations. However, designing and implementing effective solvent recovery systems that maintain high purity levels while minimizing energy consumption remains a challenge.

Environmental regulations and sustainability concerns add another layer of complexity to ethyl acetate production and use. Stricter emission controls and waste management requirements necessitate investments in advanced pollution control technologies and more sustainable production methods. These regulatory compliance measures often lead to increased production costs.

Catalyst efficiency in the production process is another area of technical challenge. While catalysts are essential for improving reaction rates and selectivity, developing catalysts that maintain high activity and selectivity over extended periods while being cost-effective remains an ongoing research focus. The need for frequent catalyst replacement or regeneration can significantly impact operational costs.

Lastly, the scale-up of novel production technologies from laboratory to industrial scale presents considerable technical challenges. Promising alternative production routes, such as the direct addition of acetic acid to ethylene or the use of bio-based feedstocks, often face difficulties in maintaining efficiency and product quality when scaled up to commercial production levels. Overcoming these scale-up challenges is crucial for implementing more cost-effective and sustainable production methods.

Another challenge lies in the purification of ethyl acetate. The azeotropic mixture formed with water during production necessitates complex separation techniques, such as azeotropic distillation or extractive distillation. These processes are not only energy-intensive but also require specialized equipment, contributing to higher capital and operational expenses.

Raw material costs pose a significant challenge to cost efficiency. The price volatility of ethanol and acetic acid, the primary feedstocks for ethyl acetate production, can substantially impact production costs. Fluctuations in these raw material prices make it difficult for manufacturers to maintain consistent profit margins and plan long-term production strategies.

The recovery and recycling of ethyl acetate in various industrial applications present another technical hurdle. Many industries use ethyl acetate as a solvent, and efficient recovery systems are crucial for cost-effective operations. However, designing and implementing effective solvent recovery systems that maintain high purity levels while minimizing energy consumption remains a challenge.

Environmental regulations and sustainability concerns add another layer of complexity to ethyl acetate production and use. Stricter emission controls and waste management requirements necessitate investments in advanced pollution control technologies and more sustainable production methods. These regulatory compliance measures often lead to increased production costs.

Catalyst efficiency in the production process is another area of technical challenge. While catalysts are essential for improving reaction rates and selectivity, developing catalysts that maintain high activity and selectivity over extended periods while being cost-effective remains an ongoing research focus. The need for frequent catalyst replacement or regeneration can significantly impact operational costs.

Lastly, the scale-up of novel production technologies from laboratory to industrial scale presents considerable technical challenges. Promising alternative production routes, such as the direct addition of acetic acid to ethylene or the use of bio-based feedstocks, often face difficulties in maintaining efficiency and product quality when scaled up to commercial production levels. Overcoming these scale-up challenges is crucial for implementing more cost-effective and sustainable production methods.

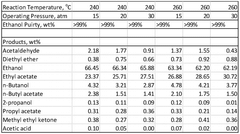

Current Methods

01 Production process optimization

Improving the production process of ethyl acetate can lead to cost efficiency. This includes optimizing reaction conditions, developing more efficient catalysts, and implementing continuous flow processes. These improvements can result in higher yields, reduced energy consumption, and lower production costs.- Production process optimization: Improving the production process of ethyl acetate can lead to cost efficiency. This may involve optimizing reaction conditions, enhancing catalysts, or developing new synthesis routes. Such improvements can result in higher yields, reduced energy consumption, and lower raw material costs.

- Recycling and recovery systems: Implementing efficient recycling and recovery systems for ethyl acetate can significantly reduce costs. This includes developing advanced separation techniques, designing closed-loop systems, and improving solvent recovery methods. These approaches minimize waste and decrease the need for fresh raw materials.

- Alternative raw materials: Exploring alternative, more cost-effective raw materials for ethyl acetate production can improve overall cost efficiency. This may involve using bio-based feedstocks, waste products from other industries, or developing new precursors that are more economical or readily available.

- Energy-efficient equipment and processes: Incorporating energy-efficient equipment and processes in ethyl acetate production can lead to significant cost savings. This includes using advanced heat exchangers, implementing process intensification techniques, and adopting more efficient separation technologies to reduce energy consumption.

- Supply chain optimization: Optimizing the supply chain for ethyl acetate production and distribution can improve cost efficiency. This involves streamlining logistics, reducing transportation costs, implementing just-in-time inventory systems, and developing strategic partnerships with suppliers and customers to minimize overall expenses.

02 Recycling and recovery methods

Implementing effective recycling and recovery methods for ethyl acetate can significantly reduce costs. This involves developing advanced separation techniques, such as membrane technology or distillation processes, to recover and reuse ethyl acetate from waste streams or byproducts.Expand Specific Solutions03 Alternative raw materials

Exploring alternative, more cost-effective raw materials for ethyl acetate production can improve overall cost efficiency. This may include using bio-based feedstocks, waste materials, or developing new synthetic routes that utilize less expensive starting materials.Expand Specific Solutions04 Energy-efficient equipment

Utilizing energy-efficient equipment and technologies in the production and handling of ethyl acetate can lead to significant cost savings. This includes implementing heat integration systems, using high-efficiency reactors, and optimizing storage and transportation methods.Expand Specific Solutions05 Process control and automation

Implementing advanced process control and automation systems can enhance the cost efficiency of ethyl acetate production. This involves using real-time monitoring, predictive modeling, and artificial intelligence to optimize process parameters, reduce waste, and improve overall productivity.Expand Specific Solutions

Industry Players

The market for ethyl acetate cost efficiency is in a mature stage, with a global market size exceeding $3 billion annually. The technology is well-established, with major players like Celanese, Eastman Chemical, and INEOS dominating production. However, emerging companies such as Nantong Baichuan and Jiangsu Baichuan are introducing innovative processes to improve efficiency. Research institutions like Nanjing Tech University and Dalian Institute of Chemical Physics are actively developing new catalysts and green synthesis methods. The industry is focusing on sustainable production techniques and bio-based feedstocks to meet growing environmental concerns and reduce costs.

Celanese International Corp.

Technical Solution: Celanese has developed an innovative process for ethyl acetate production using ethylene and acetic acid as raw materials. This method, known as the Celanese VA-EA process, integrates vinyl acetate monomer (VAM) and ethyl acetate production, significantly reducing production costs[1]. The process utilizes a unique catalyst system that allows for high selectivity and conversion rates, resulting in a more efficient use of raw materials. Additionally, Celanese has implemented advanced process control systems and energy recovery techniques to further optimize the production process, leading to reduced energy consumption and improved overall cost efficiency[2].

Strengths: Integrated production process, high selectivity and conversion rates, reduced energy consumption. Weaknesses: Dependence on ethylene availability, potential sensitivity to raw material price fluctuations.

Daicel Corp.

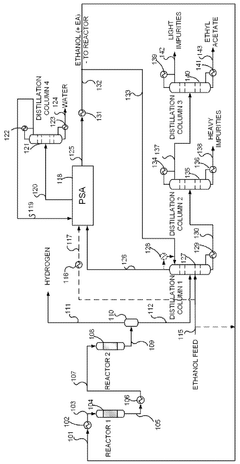

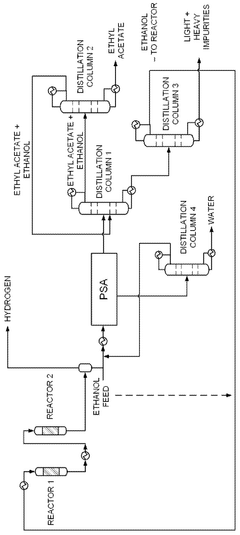

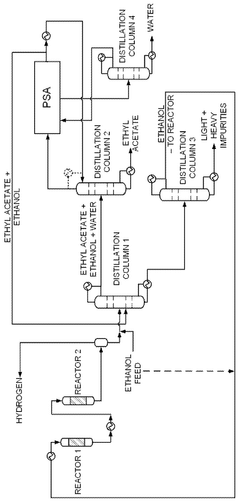

Technical Solution: Daicel has developed a novel approach to ethyl acetate production using bioethanol as a feedstock. This bio-based process involves the dehydrogenation of bioethanol to acetaldehyde, followed by the Tishchenko reaction to form ethyl acetate[3]. The company has optimized the catalyst system to achieve high yields and selectivity, reducing byproduct formation and improving overall efficiency. Daicel has also implemented advanced separation and purification techniques, such as pressure swing distillation, to minimize energy consumption during the product recovery stage[4]. Furthermore, the company has integrated its production facilities with bioethanol plants to create a more sustainable and cost-effective supply chain.

Strengths: Sustainable bio-based process, reduced carbon footprint, potential for lower feedstock costs. Weaknesses: Dependence on bioethanol availability, potential quality variations in bio-based feedstock.

Key Innovations

Process for production of ethyl acetate

PatentWO2025072073A1

Innovation

- A novel process that converts ethanol to ethyl acetate through dehydrogenation, followed by selective hydrogenation of byproducts to facilitate easier separation, and utilizes pressure swing adsorption to minimize water content and protect the catalyst.

Process of low energy consumption for preparing a carboxylic acid ester

PatentInactiveEP2686292A1

Innovation

- A process involving the reaction of ethyl alcohol with acetic acid in the presence of a solid acid catalyst, using a reactive distillation system with a molar ratio of acetic acid to ethyl alcohol between 0.85 and 0.97, and a reflux ratio between 1.0 and 1.5, which allows for simultaneous reaction and separation in multiple zones, reducing energy costs and acetic acid content.

Economic Factors

The economic factors surrounding ethyl acetate production and usage play a crucial role in achieving cost efficiency. Raw material costs, particularly ethanol and acetic acid, significantly impact the overall production expenses. Fluctuations in these feedstock prices can directly affect the profitability of ethyl acetate manufacturing. Energy costs also contribute substantially to the production expenses, as the esterification process requires heat input. Implementing energy-efficient technologies and optimizing process conditions can lead to considerable cost savings.

Scale of production is another critical economic factor. Larger production volumes generally result in lower unit costs due to economies of scale. This aspect encourages manufacturers to maximize plant capacity utilization and seek opportunities for expansion. However, market demand and competition must be carefully considered to avoid oversupply situations that could negatively impact prices and profitability.

Transportation and logistics costs are significant, especially when raw materials or finished products need to be moved over long distances. Locating production facilities strategically near raw material sources or major markets can help minimize these expenses. Additionally, efficient supply chain management and inventory control practices can further reduce costs associated with storage and distribution.

The global market dynamics of ethyl acetate also influence cost efficiency. Price variations in different regions, driven by local supply-demand balances and regulatory environments, can create opportunities for cost-effective sourcing or market expansion. Understanding these global trends and leveraging them in procurement and sales strategies can contribute to overall cost efficiency.

Regulatory compliance costs are an important consideration, particularly in regions with stringent environmental and safety regulations. Investments in emission control technologies, safety measures, and waste management systems are necessary to meet regulatory requirements. While these investments increase initial capital costs, they can lead to long-term cost savings by avoiding penalties and improving operational efficiency.

Technological advancements in production processes can significantly impact cost efficiency. Innovations in catalysts, reactor designs, and separation technologies can improve yield, reduce energy consumption, and enhance product quality. Continuous investment in research and development is essential to stay competitive and achieve sustained cost efficiency in ethyl acetate production.

Scale of production is another critical economic factor. Larger production volumes generally result in lower unit costs due to economies of scale. This aspect encourages manufacturers to maximize plant capacity utilization and seek opportunities for expansion. However, market demand and competition must be carefully considered to avoid oversupply situations that could negatively impact prices and profitability.

Transportation and logistics costs are significant, especially when raw materials or finished products need to be moved over long distances. Locating production facilities strategically near raw material sources or major markets can help minimize these expenses. Additionally, efficient supply chain management and inventory control practices can further reduce costs associated with storage and distribution.

The global market dynamics of ethyl acetate also influence cost efficiency. Price variations in different regions, driven by local supply-demand balances and regulatory environments, can create opportunities for cost-effective sourcing or market expansion. Understanding these global trends and leveraging them in procurement and sales strategies can contribute to overall cost efficiency.

Regulatory compliance costs are an important consideration, particularly in regions with stringent environmental and safety regulations. Investments in emission control technologies, safety measures, and waste management systems are necessary to meet regulatory requirements. While these investments increase initial capital costs, they can lead to long-term cost savings by avoiding penalties and improving operational efficiency.

Technological advancements in production processes can significantly impact cost efficiency. Innovations in catalysts, reactor designs, and separation technologies can improve yield, reduce energy consumption, and enhance product quality. Continuous investment in research and development is essential to stay competitive and achieve sustained cost efficiency in ethyl acetate production.

Sustainability Aspects

Sustainability is a critical aspect of cost efficiency in ethyl acetate production and usage. The environmental impact of ethyl acetate manufacturing and its applications has become increasingly important in recent years, driving the industry to seek more sustainable practices.

One key area of focus is the raw material sourcing for ethyl acetate production. Traditional methods rely heavily on petroleum-based feedstocks, which are non-renewable and contribute to carbon emissions. To address this, researchers are exploring bio-based alternatives, such as using ethanol derived from renewable sources like corn or sugarcane. This shift not only reduces dependency on fossil fuels but also potentially lowers the overall carbon footprint of ethyl acetate production.

Energy consumption during the manufacturing process is another significant factor affecting both cost and sustainability. Implementing energy-efficient technologies and optimizing production processes can lead to substantial reductions in energy use. For instance, advanced distillation techniques and heat integration systems can minimize energy waste and improve overall efficiency. Additionally, the use of renewable energy sources in production facilities can further enhance the sustainability profile of ethyl acetate manufacturing.

Waste reduction and recycling initiatives play a crucial role in achieving cost efficiency while promoting sustainability. Closed-loop systems that recover and reuse ethyl acetate in industrial processes can significantly reduce raw material costs and minimize environmental impact. Furthermore, developing more efficient catalysts for ethyl acetate synthesis can improve yield and selectivity, reducing waste generation and the need for extensive purification steps.

The end-of-life considerations for ethyl acetate-based products are also gaining attention. Designing products for easier recycling or biodegradability can enhance the overall sustainability of ethyl acetate use. This approach not only addresses environmental concerns but can also open up new markets and applications for ethyl acetate in eco-friendly products.

Regulatory compliance and voluntary sustainability certifications are becoming increasingly important for ethyl acetate producers. Meeting stringent environmental standards and obtaining certifications like ISO 14001 can improve market access and customer trust. While initially costly, these measures often lead to long-term cost savings through improved efficiency and risk management.

In conclusion, achieving cost efficiency with ethyl acetate is intrinsically linked to improving its sustainability profile. By focusing on renewable feedstocks, energy efficiency, waste reduction, and lifecycle considerations, companies can simultaneously reduce costs and environmental impact, positioning themselves favorably in an increasingly eco-conscious market.

One key area of focus is the raw material sourcing for ethyl acetate production. Traditional methods rely heavily on petroleum-based feedstocks, which are non-renewable and contribute to carbon emissions. To address this, researchers are exploring bio-based alternatives, such as using ethanol derived from renewable sources like corn or sugarcane. This shift not only reduces dependency on fossil fuels but also potentially lowers the overall carbon footprint of ethyl acetate production.

Energy consumption during the manufacturing process is another significant factor affecting both cost and sustainability. Implementing energy-efficient technologies and optimizing production processes can lead to substantial reductions in energy use. For instance, advanced distillation techniques and heat integration systems can minimize energy waste and improve overall efficiency. Additionally, the use of renewable energy sources in production facilities can further enhance the sustainability profile of ethyl acetate manufacturing.

Waste reduction and recycling initiatives play a crucial role in achieving cost efficiency while promoting sustainability. Closed-loop systems that recover and reuse ethyl acetate in industrial processes can significantly reduce raw material costs and minimize environmental impact. Furthermore, developing more efficient catalysts for ethyl acetate synthesis can improve yield and selectivity, reducing waste generation and the need for extensive purification steps.

The end-of-life considerations for ethyl acetate-based products are also gaining attention. Designing products for easier recycling or biodegradability can enhance the overall sustainability of ethyl acetate use. This approach not only addresses environmental concerns but can also open up new markets and applications for ethyl acetate in eco-friendly products.

Regulatory compliance and voluntary sustainability certifications are becoming increasingly important for ethyl acetate producers. Meeting stringent environmental standards and obtaining certifications like ISO 14001 can improve market access and customer trust. While initially costly, these measures often lead to long-term cost savings through improved efficiency and risk management.

In conclusion, achieving cost efficiency with ethyl acetate is intrinsically linked to improving its sustainability profile. By focusing on renewable feedstocks, energy efficiency, waste reduction, and lifecycle considerations, companies can simultaneously reduce costs and environmental impact, positioning themselves favorably in an increasingly eco-conscious market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!