How to Apply Ethyl Acetate in Advanced Material Science?

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate in Materials Science: Background and Objectives

Ethyl acetate, a versatile organic compound, has been gaining significant attention in the field of advanced material science. This ester, with its unique chemical properties, has emerged as a promising candidate for various applications in materials development and processing. The evolution of ethyl acetate's role in material science can be traced back to its initial use as a solvent in traditional industries such as paints and coatings.

Over time, researchers and material scientists have recognized the potential of ethyl acetate beyond its conventional applications. The compound's low toxicity, high solvency power, and moderate volatility have made it an attractive option for developing eco-friendly and high-performance materials. As the focus on sustainable and green chemistry intensifies, ethyl acetate has become a key player in the pursuit of environmentally benign material synthesis and processing methods.

The current technological landscape presents numerous opportunities for ethyl acetate in advanced material science. Its ability to dissolve a wide range of organic compounds makes it an excellent medium for the synthesis of polymers, nanoparticles, and composite materials. Furthermore, ethyl acetate's role in surface modification and functionalization of materials has opened new avenues for creating advanced coatings and smart materials with tailored properties.

One of the primary objectives in applying ethyl acetate to advanced material science is to develop novel synthesis routes for high-performance materials. This includes exploring its potential in sol-gel processes, electrospinning techniques, and controlled precipitation methods. Researchers aim to leverage ethyl acetate's unique solvent properties to create materials with enhanced mechanical, thermal, and chemical characteristics.

Another crucial goal is to utilize ethyl acetate in the development of sustainable and biodegradable materials. As the world moves towards circular economy models, there is a growing need for materials that can be easily recycled or naturally decomposed. Ethyl acetate's biodegradability and its potential as a bio-based solvent align well with these sustainability objectives.

The application of ethyl acetate in advanced material science also aims to address challenges in energy storage and conversion technologies. Its role in the synthesis of electrode materials for batteries and supercapacitors, as well as in the fabrication of membranes for fuel cells and separation processes, is an area of active research. Scientists are exploring how ethyl acetate can contribute to the development of more efficient and durable energy-related materials.

As we look towards the future, the integration of ethyl acetate into advanced manufacturing processes, such as 3D printing and additive manufacturing, presents exciting possibilities. The compound's potential to act as a carrier for functional materials and its compatibility with various printing technologies could revolutionize the production of complex, multi-functional structures.

Over time, researchers and material scientists have recognized the potential of ethyl acetate beyond its conventional applications. The compound's low toxicity, high solvency power, and moderate volatility have made it an attractive option for developing eco-friendly and high-performance materials. As the focus on sustainable and green chemistry intensifies, ethyl acetate has become a key player in the pursuit of environmentally benign material synthesis and processing methods.

The current technological landscape presents numerous opportunities for ethyl acetate in advanced material science. Its ability to dissolve a wide range of organic compounds makes it an excellent medium for the synthesis of polymers, nanoparticles, and composite materials. Furthermore, ethyl acetate's role in surface modification and functionalization of materials has opened new avenues for creating advanced coatings and smart materials with tailored properties.

One of the primary objectives in applying ethyl acetate to advanced material science is to develop novel synthesis routes for high-performance materials. This includes exploring its potential in sol-gel processes, electrospinning techniques, and controlled precipitation methods. Researchers aim to leverage ethyl acetate's unique solvent properties to create materials with enhanced mechanical, thermal, and chemical characteristics.

Another crucial goal is to utilize ethyl acetate in the development of sustainable and biodegradable materials. As the world moves towards circular economy models, there is a growing need for materials that can be easily recycled or naturally decomposed. Ethyl acetate's biodegradability and its potential as a bio-based solvent align well with these sustainability objectives.

The application of ethyl acetate in advanced material science also aims to address challenges in energy storage and conversion technologies. Its role in the synthesis of electrode materials for batteries and supercapacitors, as well as in the fabrication of membranes for fuel cells and separation processes, is an area of active research. Scientists are exploring how ethyl acetate can contribute to the development of more efficient and durable energy-related materials.

As we look towards the future, the integration of ethyl acetate into advanced manufacturing processes, such as 3D printing and additive manufacturing, presents exciting possibilities. The compound's potential to act as a carrier for functional materials and its compatibility with various printing technologies could revolutionize the production of complex, multi-functional structures.

Market Analysis for Ethyl Acetate-Based Advanced Materials

The market for ethyl acetate-based advanced materials is experiencing significant growth, driven by the increasing demand for sustainable and high-performance materials across various industries. Ethyl acetate, a versatile organic compound, has found applications in the development of advanced materials due to its unique properties and eco-friendly nature.

In the polymer industry, ethyl acetate-based materials are gaining traction as alternatives to traditional petroleum-based polymers. These materials offer improved biodegradability and reduced environmental impact, aligning with the growing consumer preference for sustainable products. The packaging sector, in particular, has shown keen interest in ethyl acetate-based films and coatings, which provide excellent barrier properties and recyclability.

The electronics industry is another key market for ethyl acetate-based advanced materials. With the miniaturization of electronic devices and the need for flexible electronics, ethyl acetate-derived materials are being explored for their potential in developing thin-film transistors, organic light-emitting diodes (OLEDs), and flexible displays. These materials offer advantages such as improved conductivity, flexibility, and durability.

In the healthcare and biomedical sectors, ethyl acetate-based materials are finding applications in drug delivery systems, tissue engineering scaffolds, and biocompatible implants. The biocompatibility and controlled degradation properties of these materials make them attractive for use in medical devices and regenerative medicine.

The construction industry is also exploring the potential of ethyl acetate-based advanced materials. These materials are being developed for use in high-performance coatings, adhesives, and sealants, offering improved durability, weather resistance, and energy efficiency in building applications.

The global market for ethyl acetate-based advanced materials is expected to grow steadily in the coming years. Factors contributing to this growth include increasing research and development activities, growing awareness of environmental sustainability, and stringent regulations promoting the use of eco-friendly materials.

However, challenges remain in the widespread adoption of ethyl acetate-based advanced materials. These include the need for further optimization of material properties, scaling up production processes, and addressing cost competitiveness compared to traditional materials. Overcoming these challenges will be crucial for realizing the full market potential of ethyl acetate-based advanced materials across various industries.

In the polymer industry, ethyl acetate-based materials are gaining traction as alternatives to traditional petroleum-based polymers. These materials offer improved biodegradability and reduced environmental impact, aligning with the growing consumer preference for sustainable products. The packaging sector, in particular, has shown keen interest in ethyl acetate-based films and coatings, which provide excellent barrier properties and recyclability.

The electronics industry is another key market for ethyl acetate-based advanced materials. With the miniaturization of electronic devices and the need for flexible electronics, ethyl acetate-derived materials are being explored for their potential in developing thin-film transistors, organic light-emitting diodes (OLEDs), and flexible displays. These materials offer advantages such as improved conductivity, flexibility, and durability.

In the healthcare and biomedical sectors, ethyl acetate-based materials are finding applications in drug delivery systems, tissue engineering scaffolds, and biocompatible implants. The biocompatibility and controlled degradation properties of these materials make them attractive for use in medical devices and regenerative medicine.

The construction industry is also exploring the potential of ethyl acetate-based advanced materials. These materials are being developed for use in high-performance coatings, adhesives, and sealants, offering improved durability, weather resistance, and energy efficiency in building applications.

The global market for ethyl acetate-based advanced materials is expected to grow steadily in the coming years. Factors contributing to this growth include increasing research and development activities, growing awareness of environmental sustainability, and stringent regulations promoting the use of eco-friendly materials.

However, challenges remain in the widespread adoption of ethyl acetate-based advanced materials. These include the need for further optimization of material properties, scaling up production processes, and addressing cost competitiveness compared to traditional materials. Overcoming these challenges will be crucial for realizing the full market potential of ethyl acetate-based advanced materials across various industries.

Current Applications and Challenges in Ethyl Acetate Usage

Ethyl acetate has found widespread applications in advanced material science, particularly in the development of novel polymers, coatings, and adhesives. Its unique properties as a solvent and reactant have made it an invaluable component in various industrial processes. In the field of polymer synthesis, ethyl acetate serves as an effective medium for polymerization reactions, enabling the production of high-performance materials with tailored properties.

One of the primary applications of ethyl acetate in advanced materials is in the formulation of specialty coatings. Its excellent solvency and low boiling point make it ideal for creating fast-drying, high-gloss finishes. These coatings find use in automotive, aerospace, and electronics industries, where durability and aesthetic appeal are crucial. Additionally, ethyl acetate-based coatings have shown promise in developing anti-corrosion and self-healing materials, addressing long-standing challenges in material protection.

In the realm of adhesives, ethyl acetate plays a vital role in the production of pressure-sensitive adhesives (PSAs) and hot-melt adhesives. Its ability to dissolve a wide range of polymers allows for the creation of adhesives with specific bonding characteristics, catering to diverse industrial needs. The use of ethyl acetate in adhesive formulations has led to improvements in bond strength, durability, and environmental resistance.

Despite its versatility, the application of ethyl acetate in advanced material science faces several challenges. One significant issue is its volatility, which can lead to rapid evaporation during processing and application. This necessitates careful handling and storage procedures to maintain product consistency and quality. Moreover, the flammability of ethyl acetate poses safety concerns in manufacturing environments, requiring stringent safety measures and specialized equipment.

Environmental considerations also present challenges in the use of ethyl acetate. As a volatile organic compound (VOC), its emissions are subject to increasingly strict regulations. This has prompted research into alternative solvents and the development of low-VOC formulations. Additionally, the petrochemical origin of ethyl acetate raises sustainability concerns, driving efforts to explore bio-based alternatives derived from renewable resources.

Another challenge lies in the optimization of ethyl acetate-based processes for large-scale production. Achieving consistent material properties and performance across different batches and production scales remains a complex task. This is particularly evident in the synthesis of advanced polymers and nanocomposites, where precise control over reaction conditions is crucial.

The integration of ethyl acetate into emerging technologies, such as 3D printing and smart materials, presents both opportunities and challenges. While its solvent properties make it suitable for certain additive manufacturing processes, ensuring compatibility with a wide range of printing materials and maintaining dimensional stability of printed objects are ongoing areas of research.

One of the primary applications of ethyl acetate in advanced materials is in the formulation of specialty coatings. Its excellent solvency and low boiling point make it ideal for creating fast-drying, high-gloss finishes. These coatings find use in automotive, aerospace, and electronics industries, where durability and aesthetic appeal are crucial. Additionally, ethyl acetate-based coatings have shown promise in developing anti-corrosion and self-healing materials, addressing long-standing challenges in material protection.

In the realm of adhesives, ethyl acetate plays a vital role in the production of pressure-sensitive adhesives (PSAs) and hot-melt adhesives. Its ability to dissolve a wide range of polymers allows for the creation of adhesives with specific bonding characteristics, catering to diverse industrial needs. The use of ethyl acetate in adhesive formulations has led to improvements in bond strength, durability, and environmental resistance.

Despite its versatility, the application of ethyl acetate in advanced material science faces several challenges. One significant issue is its volatility, which can lead to rapid evaporation during processing and application. This necessitates careful handling and storage procedures to maintain product consistency and quality. Moreover, the flammability of ethyl acetate poses safety concerns in manufacturing environments, requiring stringent safety measures and specialized equipment.

Environmental considerations also present challenges in the use of ethyl acetate. As a volatile organic compound (VOC), its emissions are subject to increasingly strict regulations. This has prompted research into alternative solvents and the development of low-VOC formulations. Additionally, the petrochemical origin of ethyl acetate raises sustainability concerns, driving efforts to explore bio-based alternatives derived from renewable resources.

Another challenge lies in the optimization of ethyl acetate-based processes for large-scale production. Achieving consistent material properties and performance across different batches and production scales remains a complex task. This is particularly evident in the synthesis of advanced polymers and nanocomposites, where precise control over reaction conditions is crucial.

The integration of ethyl acetate into emerging technologies, such as 3D printing and smart materials, presents both opportunities and challenges. While its solvent properties make it suitable for certain additive manufacturing processes, ensuring compatibility with a wide range of printing materials and maintaining dimensional stability of printed objects are ongoing areas of research.

Existing Methodologies for Ethyl Acetate Application

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and separation methods. These processes aim to improve the yield and purity of ethyl acetate for industrial applications.- Production and purification of ethyl acetate: Various methods and processes for producing and purifying ethyl acetate are described. These include esterification reactions, distillation techniques, and the use of specific catalysts or reactants to improve yield and purity.

- Applications of ethyl acetate in industrial processes: Ethyl acetate is utilized in diverse industrial applications, including as a solvent in chemical reactions, as a component in coatings and adhesives, and in the production of various materials such as plastics and textiles.

- Ethyl acetate in pharmaceutical and cosmetic formulations: The use of ethyl acetate in pharmaceutical and cosmetic products is explored, including its role as a solvent for active ingredients, as a component in drug delivery systems, and in the preparation of various personal care products.

- Environmental and safety considerations for ethyl acetate: Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, reducing emissions, and enhancing handling and storage practices.

- Novel synthesis routes and catalysts for ethyl acetate: Innovative approaches to synthesizing ethyl acetate are presented, including the development of new catalysts, alternative feedstocks, and improved reaction conditions to enhance efficiency and selectivity in the production process.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in diverse chemical processes, such as solvent extraction, as a reaction medium, and in the production of other chemicals. Its properties make it suitable for various industrial applications, including pharmaceuticals and polymer synthesis.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is employed in the formulation of coatings, adhesives, and related products. Its solvent properties and compatibility with various resins make it valuable in these applications, contributing to improved product performance and characteristics.Expand Specific Solutions04 Ethyl acetate in environmental and sustainable processes

Research focuses on developing environmentally friendly processes involving ethyl acetate, including its use in green solvents, bio-based production methods, and sustainable chemical transformations. These efforts aim to reduce environmental impact and improve process efficiency.Expand Specific Solutions05 Ethyl acetate in analytical and separation techniques

Ethyl acetate plays a role in various analytical and separation techniques, such as chromatography, extraction processes, and sample preparation methods. Its properties make it suitable for isolating and purifying compounds in laboratory and industrial settings.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The application of ethyl acetate in advanced material science is in a growth phase, with increasing market size and technological advancements. The global market for ethyl acetate is projected to expand significantly, driven by its versatile applications in various industries. The technology's maturity is evolving, with companies like Celanese International Corp., Eastman Chemical Co., and LyondellBasell Acetyls LLC leading in production and innovation. Research institutions such as Nanjing Tech University and Tianjin University are contributing to the development of novel applications. Emerging players like Nantong Baichuan New Material Co., Ltd. and Jiangsu Baichuan High-Tech New Materials Co., Ltd. are also entering the market, indicating growing competition and technological progress in this field.

Celanese International Corp.

Technical Solution: Celanese has developed advanced material solutions using ethyl acetate as a key component. Their approach involves incorporating ethyl acetate into polymer matrices to enhance properties such as flexibility, durability, and chemical resistance. The company has successfully applied this technology in the production of high-performance films and coatings for various industries, including automotive and electronics[1]. Celanese's research has also focused on using ethyl acetate as a green solvent in the synthesis of specialty polymers, reducing environmental impact while maintaining product quality[2]. Their innovative use of ethyl acetate extends to the development of bio-based materials, where it serves as a crucial intermediate in the production of sustainable plastics and fibers[3].

Strengths: Extensive experience in polymer chemistry, strong R&D capabilities, and a wide range of industrial applications. Weaknesses: Potential dependence on petroleum-based feedstocks for ethyl acetate production, which may face sustainability challenges in the long term.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has pioneered the use of ethyl acetate in advanced material science through its proprietary esterification technology. The company has developed a process that utilizes ethyl acetate as both a reactant and solvent in the production of specialty esters, which are crucial components in high-performance coatings, adhesives, and plasticizers[1]. Eastman's approach allows for the creation of materials with enhanced durability, weather resistance, and low VOC emissions. Additionally, they have innovated in the field of cellulose esters, using ethyl acetate as a key ingredient to produce biodegradable materials with applications in packaging and textiles[2]. The company has also explored the use of ethyl acetate in the development of advanced membrane technologies for gas separation and water purification[3].

Strengths: Strong expertise in esterification processes, diverse product portfolio, and focus on sustainable solutions. Weaknesses: Potential vulnerability to fluctuations in ethyl acetate prices and availability of raw materials.

Innovative Research on Ethyl Acetate in Advanced Materials

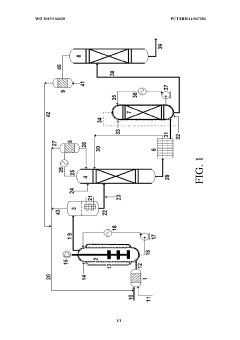

Process and system for production of alkylene glycol acetates

PatentWO2015104620A1

Innovation

- A process involving the oxidation of acetaldehyde to produce peracetic acid in a non-aqueous solvent, followed by reaction with an alkylene in the presence of a catalyst, using a system that includes a bubble column reactor, solvent recovery, and catalytic reactors to efficiently produce alkylene glycol mono- and diacetates with minimal byproducts.

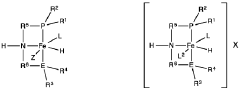

Homogeneous iron catalysts for the conversion of ethanol to ethyl acetate and hydrogen

PatentWO2019027965A1

Innovation

- A process utilizing a homogeneous iron catalyst with a tridentate pincer ligand for dehydrogenative coupling of ethanol at moderate temperatures, producing ethyl acetate efficiently and selectively, with iron loadings as low as 0.001 mol%, allowing for continuous operation and easy separation of ethyl acetate from the catalyst.

Environmental Impact and Sustainability Considerations

The application of ethyl acetate in advanced material science necessitates a thorough examination of its environmental impact and sustainability considerations. As a widely used solvent in various industries, ethyl acetate's production and utilization have significant implications for environmental sustainability.

From a production standpoint, ethyl acetate is primarily synthesized through the esterification of ethanol and acetic acid. This process, while efficient, relies on petrochemical feedstocks, raising concerns about resource depletion and carbon footprint. However, recent advancements in green chemistry have led to the development of bio-based ethyl acetate production methods, utilizing renewable resources such as biomass-derived ethanol and acetic acid. These sustainable production routes show promise in reducing the environmental burden associated with ethyl acetate manufacturing.

In terms of its use in advanced material science, ethyl acetate's volatile organic compound (VOC) status is a critical consideration. VOCs contribute to air pollution and can have adverse effects on human health and the environment. Consequently, material scientists must carefully evaluate the potential atmospheric emissions during ethyl acetate-based processes and implement appropriate control measures to minimize environmental impact.

Water pollution is another environmental concern associated with ethyl acetate usage. Although ethyl acetate has limited water solubility, improper handling or disposal can lead to contamination of water bodies. Advanced material science applications must incorporate robust waste management protocols to prevent the release of ethyl acetate into aquatic ecosystems.

From a lifecycle perspective, the biodegradability of ethyl acetate is a positive attribute. Unlike some persistent organic solvents, ethyl acetate readily breaks down in the environment, reducing its long-term ecological impact. This characteristic aligns well with the principles of green chemistry and sustainable material design.

Energy consumption during ethyl acetate-based processes is another crucial sustainability factor. Material scientists should focus on developing energy-efficient methodologies that minimize the overall carbon footprint of ethyl acetate applications. This may involve optimizing reaction conditions, exploring low-temperature processes, or integrating renewable energy sources into production systems.

Recycling and recovery of ethyl acetate present opportunities for enhancing the sustainability of its use in advanced materials. Implementing closed-loop systems and efficient solvent recovery techniques can significantly reduce waste generation and raw material consumption, contributing to a more circular economy approach in material science.

As regulations surrounding environmental protection and chemical use continue to evolve, material scientists must stay abreast of compliance requirements related to ethyl acetate. This includes adhering to emission standards, implementing proper handling and storage protocols, and conducting thorough environmental impact assessments for new applications.

From a production standpoint, ethyl acetate is primarily synthesized through the esterification of ethanol and acetic acid. This process, while efficient, relies on petrochemical feedstocks, raising concerns about resource depletion and carbon footprint. However, recent advancements in green chemistry have led to the development of bio-based ethyl acetate production methods, utilizing renewable resources such as biomass-derived ethanol and acetic acid. These sustainable production routes show promise in reducing the environmental burden associated with ethyl acetate manufacturing.

In terms of its use in advanced material science, ethyl acetate's volatile organic compound (VOC) status is a critical consideration. VOCs contribute to air pollution and can have adverse effects on human health and the environment. Consequently, material scientists must carefully evaluate the potential atmospheric emissions during ethyl acetate-based processes and implement appropriate control measures to minimize environmental impact.

Water pollution is another environmental concern associated with ethyl acetate usage. Although ethyl acetate has limited water solubility, improper handling or disposal can lead to contamination of water bodies. Advanced material science applications must incorporate robust waste management protocols to prevent the release of ethyl acetate into aquatic ecosystems.

From a lifecycle perspective, the biodegradability of ethyl acetate is a positive attribute. Unlike some persistent organic solvents, ethyl acetate readily breaks down in the environment, reducing its long-term ecological impact. This characteristic aligns well with the principles of green chemistry and sustainable material design.

Energy consumption during ethyl acetate-based processes is another crucial sustainability factor. Material scientists should focus on developing energy-efficient methodologies that minimize the overall carbon footprint of ethyl acetate applications. This may involve optimizing reaction conditions, exploring low-temperature processes, or integrating renewable energy sources into production systems.

Recycling and recovery of ethyl acetate present opportunities for enhancing the sustainability of its use in advanced materials. Implementing closed-loop systems and efficient solvent recovery techniques can significantly reduce waste generation and raw material consumption, contributing to a more circular economy approach in material science.

As regulations surrounding environmental protection and chemical use continue to evolve, material scientists must stay abreast of compliance requirements related to ethyl acetate. This includes adhering to emission standards, implementing proper handling and storage protocols, and conducting thorough environmental impact assessments for new applications.

Regulatory Framework for Ethyl Acetate in Materials

The regulatory framework for ethyl acetate in materials science is a complex and evolving landscape that significantly impacts its application in advanced materials. Globally, ethyl acetate is classified as a volatile organic compound (VOC), subject to various environmental and safety regulations. In the United States, the Environmental Protection Agency (EPA) regulates ethyl acetate under the Clean Air Act, setting limits on emissions and requiring permits for large-scale industrial use. The Occupational Safety and Health Administration (OSHA) has established permissible exposure limits for workers handling ethyl acetate in material production processes.

In the European Union, ethyl acetate falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Manufacturers and importers must register ethyl acetate with the European Chemicals Agency (ECHA) and provide safety data sheets detailing its properties and potential risks. The EU's VOC Solvents Emissions Directive also imposes restrictions on the use of ethyl acetate in certain products and industrial processes.

Japan's regulatory approach includes the Chemical Substances Control Law (CSCL) and the Industrial Safety and Health Law (ISHL), which govern the manufacture, import, and use of ethyl acetate in material applications. These regulations require proper labeling, risk assessment, and adherence to specific handling and storage guidelines.

In the context of advanced material science, researchers and manufacturers must navigate these regulatory frameworks when developing new applications for ethyl acetate. This includes considering its use as a solvent in polymer processing, as a component in adhesive formulations, or as a reagent in the synthesis of advanced materials. Compliance with these regulations often necessitates the implementation of emission control technologies, such as solvent recovery systems or catalytic oxidizers, to minimize environmental impact.

Furthermore, the regulatory landscape is continuously evolving, with increasing focus on sustainability and circular economy principles. This trend is driving the development of bio-based alternatives to ethyl acetate and promoting research into more environmentally friendly production methods. As a result, material scientists must stay informed about regulatory changes and adapt their research and development strategies accordingly to ensure compliance and maintain market competitiveness.

In the European Union, ethyl acetate falls under the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Manufacturers and importers must register ethyl acetate with the European Chemicals Agency (ECHA) and provide safety data sheets detailing its properties and potential risks. The EU's VOC Solvents Emissions Directive also imposes restrictions on the use of ethyl acetate in certain products and industrial processes.

Japan's regulatory approach includes the Chemical Substances Control Law (CSCL) and the Industrial Safety and Health Law (ISHL), which govern the manufacture, import, and use of ethyl acetate in material applications. These regulations require proper labeling, risk assessment, and adherence to specific handling and storage guidelines.

In the context of advanced material science, researchers and manufacturers must navigate these regulatory frameworks when developing new applications for ethyl acetate. This includes considering its use as a solvent in polymer processing, as a component in adhesive formulations, or as a reagent in the synthesis of advanced materials. Compliance with these regulations often necessitates the implementation of emission control technologies, such as solvent recovery systems or catalytic oxidizers, to minimize environmental impact.

Furthermore, the regulatory landscape is continuously evolving, with increasing focus on sustainability and circular economy principles. This trend is driving the development of bio-based alternatives to ethyl acetate and promoting research into more environmentally friendly production methods. As a result, material scientists must stay informed about regulatory changes and adapt their research and development strategies accordingly to ensure compliance and maintain market competitiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!