How To Succeed Using Atomic Force Microscopy For Rough Surface Analysis

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Rough Surface Analysis Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. This scanning probe microscopy technique has revolutionized surface characterization by enabling three-dimensional topographical imaging at the nanoscale with minimal sample preparation. Initially developed for atomic-level imaging of flat surfaces, AFM technology has progressively expanded its capabilities to address increasingly complex surface structures, including rough surfaces that present unique analytical challenges.

The evolution of AFM technology has been marked by several key advancements, including the development of various operational modes (contact, non-contact, and tapping modes), improvements in probe design, and enhanced data processing algorithms. These innovations have collectively expanded AFM's applicability across diverse scientific and industrial domains, from materials science and semiconductor manufacturing to biological research and nanotechnology.

Despite these advancements, rough surface analysis remains one of the most challenging applications for AFM. Conventional AFM techniques often encounter limitations when characterizing surfaces with high aspect ratios, steep slopes, or significant height variations. These challenges stem from physical constraints of the probe-surface interaction, including tip convolution effects, feedback loop limitations, and data interpretation complexities that can compromise measurement accuracy and reproducibility.

The primary objective of this technical research is to comprehensively evaluate current methodologies and emerging techniques for optimizing AFM performance in rough surface analysis. We aim to identify best practices, technological innovations, and analytical approaches that can overcome existing limitations and enhance measurement reliability. This includes examining specialized probe designs, advanced operational modes, optimal scanning parameters, and sophisticated data processing algorithms specifically tailored for rough surface characterization.

Additionally, this research seeks to establish standardized protocols for rough surface analysis across different AFM platforms, ensuring consistency and comparability of results. By addressing these technical challenges, we intend to expand the practical applications of AFM in fields where rough surface characterization is critical, such as tribology, corrosion science, biomaterial development, and advanced manufacturing processes.

The findings from this technical research will provide valuable insights for both academic researchers and industrial practitioners seeking to leverage AFM capabilities for comprehensive rough surface analysis, ultimately contributing to advancements in surface engineering, quality control processes, and the development of novel materials with tailored surface properties.

The evolution of AFM technology has been marked by several key advancements, including the development of various operational modes (contact, non-contact, and tapping modes), improvements in probe design, and enhanced data processing algorithms. These innovations have collectively expanded AFM's applicability across diverse scientific and industrial domains, from materials science and semiconductor manufacturing to biological research and nanotechnology.

Despite these advancements, rough surface analysis remains one of the most challenging applications for AFM. Conventional AFM techniques often encounter limitations when characterizing surfaces with high aspect ratios, steep slopes, or significant height variations. These challenges stem from physical constraints of the probe-surface interaction, including tip convolution effects, feedback loop limitations, and data interpretation complexities that can compromise measurement accuracy and reproducibility.

The primary objective of this technical research is to comprehensively evaluate current methodologies and emerging techniques for optimizing AFM performance in rough surface analysis. We aim to identify best practices, technological innovations, and analytical approaches that can overcome existing limitations and enhance measurement reliability. This includes examining specialized probe designs, advanced operational modes, optimal scanning parameters, and sophisticated data processing algorithms specifically tailored for rough surface characterization.

Additionally, this research seeks to establish standardized protocols for rough surface analysis across different AFM platforms, ensuring consistency and comparability of results. By addressing these technical challenges, we intend to expand the practical applications of AFM in fields where rough surface characterization is critical, such as tribology, corrosion science, biomaterial development, and advanced manufacturing processes.

The findings from this technical research will provide valuable insights for both academic researchers and industrial practitioners seeking to leverage AFM capabilities for comprehensive rough surface analysis, ultimately contributing to advancements in surface engineering, quality control processes, and the development of novel materials with tailored surface properties.

Market Applications and Demand for Rough Surface Characterization

The global market for surface characterization technologies has witnessed substantial growth, driven by increasing demands across multiple industries for precise surface analysis capabilities. Rough surface characterization, in particular, has become a critical requirement in sectors ranging from semiconductor manufacturing to biomedical implants, where surface topography directly impacts product performance and functionality.

The semiconductor industry represents one of the largest markets for atomic force microscopy (AFM) in rough surface analysis. As device dimensions continue to shrink below 5nm, manufacturers require increasingly precise characterization of surface roughness to ensure optimal electrical performance and reliability. Market research indicates that semiconductor surface metrology tools, including AFM systems, constitute approximately 30% of the total surface analysis market.

Materials science and engineering form another significant market segment. The development of advanced materials with tailored surface properties—such as superhydrophobic coatings, anti-fouling surfaces, and wear-resistant layers—necessitates comprehensive roughness analysis. These applications have expanded the demand for high-resolution AFM systems capable of characterizing multi-scale roughness parameters.

The biomedical sector has emerged as a rapidly growing market for rough surface characterization. Medical implant manufacturers require precise control over surface topography to optimize cell adhesion, reduce bacterial colonization, and enhance osseointegration. The correlation between nanoscale surface roughness and biological response has driven increased adoption of AFM technologies in this sector.

Energy applications represent another expanding market segment. Solar cell efficiency is directly influenced by surface roughness at multiple scales, while battery electrode surfaces impact charge transfer kinetics. As renewable energy technologies mature, the demand for precise surface characterization continues to grow steadily.

Consumer electronics manufacturers increasingly rely on surface roughness analysis to optimize tribological properties, optical characteristics, and tactile feel of products. This has created a substantial market for portable and automated AFM systems capable of high-throughput analysis in production environments.

The automotive industry utilizes rough surface characterization for developing advanced coatings, optimizing friction in engine components, and enhancing paint adhesion and appearance. With the transition toward electric vehicles, new applications are emerging related to battery interfaces and lightweight materials.

Market forecasts project the global surface analysis equipment market to grow at a CAGR of 6-7% through 2028, with AFM systems for rough surface analysis representing a significant portion of this growth. Regional analysis indicates particularly strong demand growth in Asia-Pacific countries, driven by semiconductor manufacturing and advanced materials development.

The semiconductor industry represents one of the largest markets for atomic force microscopy (AFM) in rough surface analysis. As device dimensions continue to shrink below 5nm, manufacturers require increasingly precise characterization of surface roughness to ensure optimal electrical performance and reliability. Market research indicates that semiconductor surface metrology tools, including AFM systems, constitute approximately 30% of the total surface analysis market.

Materials science and engineering form another significant market segment. The development of advanced materials with tailored surface properties—such as superhydrophobic coatings, anti-fouling surfaces, and wear-resistant layers—necessitates comprehensive roughness analysis. These applications have expanded the demand for high-resolution AFM systems capable of characterizing multi-scale roughness parameters.

The biomedical sector has emerged as a rapidly growing market for rough surface characterization. Medical implant manufacturers require precise control over surface topography to optimize cell adhesion, reduce bacterial colonization, and enhance osseointegration. The correlation between nanoscale surface roughness and biological response has driven increased adoption of AFM technologies in this sector.

Energy applications represent another expanding market segment. Solar cell efficiency is directly influenced by surface roughness at multiple scales, while battery electrode surfaces impact charge transfer kinetics. As renewable energy technologies mature, the demand for precise surface characterization continues to grow steadily.

Consumer electronics manufacturers increasingly rely on surface roughness analysis to optimize tribological properties, optical characteristics, and tactile feel of products. This has created a substantial market for portable and automated AFM systems capable of high-throughput analysis in production environments.

The automotive industry utilizes rough surface characterization for developing advanced coatings, optimizing friction in engine components, and enhancing paint adhesion and appearance. With the transition toward electric vehicles, new applications are emerging related to battery interfaces and lightweight materials.

Market forecasts project the global surface analysis equipment market to grow at a CAGR of 6-7% through 2028, with AFM systems for rough surface analysis representing a significant portion of this growth. Regional analysis indicates particularly strong demand growth in Asia-Pacific countries, driven by semiconductor manufacturing and advanced materials development.

Current AFM Capabilities and Technical Challenges

Atomic Force Microscopy (AFM) has evolved significantly since its invention in the 1980s, becoming a powerful tool for surface characterization at the nanoscale. Current AFM systems offer remarkable capabilities for analyzing surface topography with sub-nanometer resolution in three dimensions. Modern instruments can operate in various modes including contact, tapping, and non-contact modes, each offering distinct advantages for different surface types and measurement requirements.

Despite these advancements, AFM faces significant challenges when applied to rough surface analysis. The primary technical limitation stems from the physical interaction between the probe tip and the sample surface. On rough surfaces with high aspect ratio features, conventional AFM tips often cannot access deep trenches or accurately trace steep walls, resulting in what is known as "tip convolution artifacts" that distort measurement accuracy.

Vertical measurement range presents another substantial challenge. Standard AFM systems typically have a Z-range limited to 10-15 μm, which becomes insufficient when analyzing surfaces with height variations exceeding this range. This limitation forces researchers to compromise between measurement area and the ability to capture the full topographical profile of rough surfaces.

Scan speed remains a persistent constraint in AFM technology. Traditional AFM scanning is relatively slow, with high-resolution scans of rough surfaces often taking tens of minutes to complete. This time-intensive process limits throughput and makes dynamic surface analysis challenging, particularly for industrial applications requiring rapid quality control.

Data processing and interpretation present additional complexities. Rough surface analysis generates enormous datasets that require sophisticated algorithms for proper filtering, analysis, and interpretation. Current software solutions often struggle with automatically distinguishing between actual surface features and measurement artifacts on highly irregular surfaces.

Environmental factors significantly impact measurement quality. Vibration, acoustic noise, and thermal drift can severely compromise data integrity, particularly during long-duration scans necessary for rough surface characterization. While isolation systems have improved, they remain imperfect for the most demanding applications.

Recent technological innovations have begun addressing these challenges. High-aspect-ratio tips with carbon nanotube terminations offer improved access to deep surface features. Fast-scanning AFM technologies have reduced imaging times from hours to minutes. Advanced algorithms incorporating machine learning approaches are enhancing data processing capabilities for complex surface topographies.

Despite these advances, significant gaps remain between current capabilities and the ideal requirements for comprehensive rough surface analysis across diverse material systems and industrial applications. The field continues to evolve toward more robust, faster, and more accurate measurement methodologies.

Despite these advancements, AFM faces significant challenges when applied to rough surface analysis. The primary technical limitation stems from the physical interaction between the probe tip and the sample surface. On rough surfaces with high aspect ratio features, conventional AFM tips often cannot access deep trenches or accurately trace steep walls, resulting in what is known as "tip convolution artifacts" that distort measurement accuracy.

Vertical measurement range presents another substantial challenge. Standard AFM systems typically have a Z-range limited to 10-15 μm, which becomes insufficient when analyzing surfaces with height variations exceeding this range. This limitation forces researchers to compromise between measurement area and the ability to capture the full topographical profile of rough surfaces.

Scan speed remains a persistent constraint in AFM technology. Traditional AFM scanning is relatively slow, with high-resolution scans of rough surfaces often taking tens of minutes to complete. This time-intensive process limits throughput and makes dynamic surface analysis challenging, particularly for industrial applications requiring rapid quality control.

Data processing and interpretation present additional complexities. Rough surface analysis generates enormous datasets that require sophisticated algorithms for proper filtering, analysis, and interpretation. Current software solutions often struggle with automatically distinguishing between actual surface features and measurement artifacts on highly irregular surfaces.

Environmental factors significantly impact measurement quality. Vibration, acoustic noise, and thermal drift can severely compromise data integrity, particularly during long-duration scans necessary for rough surface characterization. While isolation systems have improved, they remain imperfect for the most demanding applications.

Recent technological innovations have begun addressing these challenges. High-aspect-ratio tips with carbon nanotube terminations offer improved access to deep surface features. Fast-scanning AFM technologies have reduced imaging times from hours to minutes. Advanced algorithms incorporating machine learning approaches are enhancing data processing capabilities for complex surface topographies.

Despite these advances, significant gaps remain between current capabilities and the ideal requirements for comprehensive rough surface analysis across diverse material systems and industrial applications. The field continues to evolve toward more robust, faster, and more accurate measurement methodologies.

Existing Methodologies for AFM Rough Surface Analysis

01 AFM techniques for surface roughness measurement

Atomic Force Microscopy (AFM) provides high-resolution techniques for measuring surface roughness at the nanoscale. These techniques involve scanning a probe across a sample surface to create topographical maps that can quantify roughness parameters. The methodology allows for precise characterization of surface features, enabling researchers to analyze surface morphology with exceptional accuracy and resolution compared to conventional methods.- AFM techniques for surface roughness measurement: Atomic Force Microscopy (AFM) provides high-resolution techniques for measuring surface roughness at the nanoscale. These techniques involve scanning a probe across a sample surface to create topographical maps that can quantify roughness parameters. Advanced scanning modes and data processing algorithms enhance the accuracy and reliability of surface roughness measurements, allowing for precise characterization of material surfaces.

- AFM probe design and optimization for roughness analysis: Specialized probe designs are crucial for accurate surface roughness measurements. These probes are engineered with specific tip geometries and materials to interact optimally with various surface types. Innovations in probe technology include wear-resistant coatings, flexible cantilevers, and specialized tip shapes that can access narrow features, improving the resolution and reliability of roughness measurements across different material surfaces.

- Data processing and analysis methods for AFM roughness measurements: Advanced algorithms and software solutions are developed to process and analyze AFM data for surface roughness characterization. These methods include statistical analysis techniques, filtering algorithms to remove artifacts, and specialized software for calculating roughness parameters such as Ra, Rq, and Rz. Machine learning approaches are increasingly being applied to improve the accuracy and efficiency of roughness data interpretation from AFM measurements.

- AFM calibration and standardization for roughness measurements: Calibration methods and standards are essential for ensuring the accuracy and reproducibility of AFM surface roughness measurements. These include reference materials with known roughness values, calibration procedures for probe tip characterization, and standardized protocols for measurement and data analysis. Regular calibration helps compensate for instrument drift, tip wear, and environmental factors that can affect measurement accuracy.

- Industry-specific AFM applications for surface roughness analysis: AFM surface roughness analysis is applied across various industries with specialized requirements. In semiconductor manufacturing, it's used to inspect wafer surfaces and thin films. In materials science, it characterizes coatings and composite materials. Biomedical applications include analyzing implant surfaces and biomaterials. Each application area has developed specific AFM methodologies optimized for their particular surface types and roughness requirements.

02 Advanced AFM probe designs for roughness analysis

Specialized probe designs enhance the capability of AFM systems to measure surface roughness. These include modified cantilevers, specialized tip geometries, and functionalized probes that improve measurement accuracy and reduce artifacts. Advanced probe technologies allow for better interaction with various surface types and enable more precise characterization of surface roughness across different materials and environmental conditions.Expand Specific Solutions03 Data processing algorithms for roughness characterization

Sophisticated algorithms and software solutions are employed to process AFM data for accurate surface roughness characterization. These computational methods include filtering techniques, statistical analysis, and mathematical models that transform raw AFM measurements into meaningful roughness parameters. Advanced data processing enables the extraction of various roughness metrics such as average roughness, root mean square roughness, and peak-to-valley measurements from topographical data.Expand Specific Solutions04 Environmental and operational factors affecting AFM roughness measurements

Various environmental and operational factors influence the accuracy of AFM surface roughness measurements. These include temperature fluctuations, humidity, vibration, scan rate, and feedback parameters. Controlling these factors is essential for obtaining reliable and reproducible roughness data. Specialized environmental chambers and vibration isolation systems are often employed to minimize external influences on measurement quality.Expand Specific Solutions05 Industry-specific AFM roughness measurement applications

AFM surface roughness measurement techniques are adapted for specific industry applications, including semiconductor manufacturing, materials science, and biomedical research. These specialized applications involve customized sample preparation methods, measurement protocols, and interpretation frameworks tailored to the requirements of each field. Industry-specific implementations often focus on particular surface characteristics relevant to product performance or research objectives.Expand Specific Solutions

Leading Manufacturers and Research Institutions in AFM Development

Atomic Force Microscopy (AFM) for rough surface analysis is in a growth phase, with increasing market adoption across research and industrial applications. The global AFM market is projected to expand significantly, driven by demands in materials science, semiconductor, and biomedical sectors. Technologically, the field shows varying maturity levels, with companies like Bruker Nano and Nanosurf AG leading in specialized AFM instrumentation, while research institutions such as Fraunhofer-Gesellschaft and CNRS advance fundamental methodologies. Industrial players including Samsung Electronics, GLOBALFOUNDRIES, and Texas Instruments are integrating AFM techniques into quality control processes. Academic-industrial collaborations between universities (Technical University of Denmark, Yokohama National University) and commercial entities are accelerating innovation in rough surface characterization techniques, particularly for semiconductor and advanced materials applications.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced AFM technologies specifically designed for rough surface analysis, including their PeakForce Tapping® mode which allows for high-resolution imaging of samples with significant height variations. Their proprietary algorithms automatically adjust scanning parameters in real-time to maintain tip-sample interaction even on highly irregular surfaces. The company's MultiMode 8-HR system incorporates adaptive scan control that dynamically responds to surface topography changes, preventing tip damage while maintaining nanometer-scale resolution on rough samples. Bruker's ScanAsyst® technology further enhances rough surface analysis by automatically optimizing imaging parameters during scanning, reducing artifacts and improving data quality. Their systems also feature specialized probes with reinforced tips designed specifically for rough surface characterization, offering extended tip life and consistent imaging quality across varied topographies[1][3].

Strengths: Industry-leading resolution on rough surfaces; automated parameter optimization reduces user expertise requirements; robust tip designs minimize wear during rough surface scanning. Weaknesses: Premium pricing compared to competitors; complex systems may require significant training; some specialized applications may require custom modifications.

NanoFocus AG

Technical Solution: NanoFocus AG has pioneered confocal microscopy integration with AFM for comprehensive rough surface analysis. Their μsurf technology combines optical and atomic force measurements to characterize surfaces across multiple scales, from macro to nano. The company's approach addresses a fundamental challenge in rough surface analysis by first using optical confocal scanning to identify regions of interest before deploying high-resolution AFM for detailed characterization. This multi-scale methodology significantly improves efficiency when analyzing large rough samples. NanoFocus systems incorporate specialized software algorithms that process 3D topographical data to extract meaningful roughness parameters according to international standards (ISO 25178). Their technology enables non-destructive measurement of surface roughness parameters including Sa, Sq, and functional volume parameters critical for industrial applications. The company has also developed specialized holders and vibration isolation systems specifically designed to stabilize rough samples during measurement, improving data reliability[2][5].

Strengths: Multi-scale measurement capability bridges the macro-to-nano gap; specialized software provides standardized roughness parameters; efficient workflow for industrial applications. Weaknesses: Lower resolution than pure AFM systems; optical component limitations in certain sample types; requires careful calibration between measurement modes.

Key Technical Innovations in AFM Probe and Feedback Systems

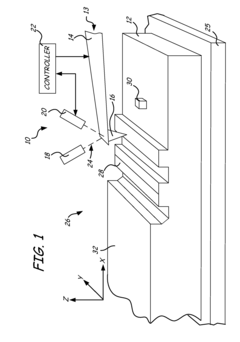

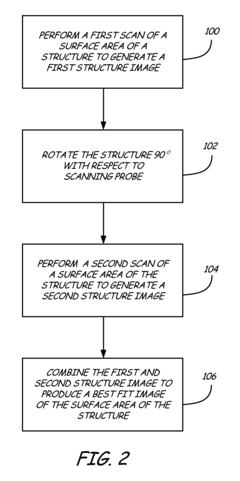

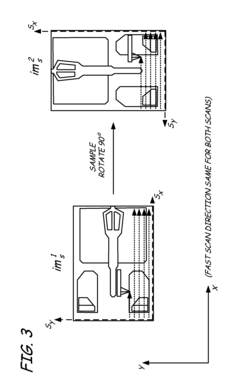

Atomic force microscopy true shape measurement method

PatentInactiveUS8296860B2

Innovation

- The method involves scanning a structure and a flat standard surface twice, each time rotated 90°, and combining the images to produce best fit images. These best fit images are then subtracted to eliminate thermal drift and Zrr errors, allowing for the generation of a true topographical image.

Method for producing a high quality useful layer on a substrate utilizing helium and hydrogen implantations

PatentInactiveUS7081399B2

Innovation

- A method involving the sequential implantation of helium and hydrogen species into a donor substrate to create a weakened zone, followed by bonding to a support substrate and thermal treatment using rapid thermal annealing (RTA) and stabilized oxidation (StabOx) processes to minimize both high-frequency and low-frequency roughness, eliminating the need for chemical mechanical polishing.

Data Processing and Analysis Algorithms for Rough Surface Imaging

The evolution of data processing algorithms for Atomic Force Microscopy (AFM) has been critical in addressing the challenges of rough surface analysis. Traditional image processing techniques often fail when confronted with the complex topographical data generated by rough surfaces, necessitating specialized approaches that can handle high-frequency spatial variations and large height differentials.

Statistical methods form the foundation of modern AFM data processing for rough surfaces. These include advanced filtering techniques such as adaptive Gaussian filters, wavelet transforms, and Fourier-based methods that effectively separate roughness from waviness while preserving critical surface features. The implementation of these filters must be carefully calibrated to the specific scale of roughness being investigated, as inappropriate filter parameters can lead to data artifacts or loss of meaningful surface characteristics.

Machine learning algorithms have emerged as powerful tools for AFM data interpretation, particularly for complex rough surfaces. Convolutional neural networks (CNNs) and support vector machines (SVMs) have demonstrated remarkable capabilities in feature recognition and classification of surface anomalies. These approaches can identify patterns in roughness data that might be overlooked by conventional analytical methods, providing deeper insights into surface properties and behaviors.

Fractal analysis techniques have proven especially valuable for quantifying self-similar rough surfaces across multiple scales. The calculation of fractal dimensions and Hurst exponents offers meaningful metrics for characterizing surface complexity beyond traditional roughness parameters. These methods are particularly effective when analyzing natural surfaces or engineered materials with hierarchical roughness structures.

Real-time processing algorithms represent the cutting edge of AFM data analysis for rough surfaces. These systems incorporate feedback mechanisms that dynamically adjust scanning parameters based on detected surface features, optimizing data acquisition for challenging topographies. Parallel processing architectures and GPU acceleration have made it possible to implement computationally intensive algorithms during the scanning process rather than in post-processing.

Correlation analysis between multiple data channels (topography, phase, amplitude) provides complementary information that enhances the interpretation of rough surface characteristics. By integrating these data streams through multivariate statistical techniques, researchers can distinguish between topographical features and variations in material properties, critical for heterogeneous rough surfaces.

The standardization of data formats and processing pipelines remains an ongoing challenge in the field. Efforts to develop open-source platforms like Gwyddion and OpenFovea have improved accessibility and reproducibility of AFM data analysis, though further work is needed to establish universal protocols for rough surface characterization across different instrument platforms and analysis software.

Statistical methods form the foundation of modern AFM data processing for rough surfaces. These include advanced filtering techniques such as adaptive Gaussian filters, wavelet transforms, and Fourier-based methods that effectively separate roughness from waviness while preserving critical surface features. The implementation of these filters must be carefully calibrated to the specific scale of roughness being investigated, as inappropriate filter parameters can lead to data artifacts or loss of meaningful surface characteristics.

Machine learning algorithms have emerged as powerful tools for AFM data interpretation, particularly for complex rough surfaces. Convolutional neural networks (CNNs) and support vector machines (SVMs) have demonstrated remarkable capabilities in feature recognition and classification of surface anomalies. These approaches can identify patterns in roughness data that might be overlooked by conventional analytical methods, providing deeper insights into surface properties and behaviors.

Fractal analysis techniques have proven especially valuable for quantifying self-similar rough surfaces across multiple scales. The calculation of fractal dimensions and Hurst exponents offers meaningful metrics for characterizing surface complexity beyond traditional roughness parameters. These methods are particularly effective when analyzing natural surfaces or engineered materials with hierarchical roughness structures.

Real-time processing algorithms represent the cutting edge of AFM data analysis for rough surfaces. These systems incorporate feedback mechanisms that dynamically adjust scanning parameters based on detected surface features, optimizing data acquisition for challenging topographies. Parallel processing architectures and GPU acceleration have made it possible to implement computationally intensive algorithms during the scanning process rather than in post-processing.

Correlation analysis between multiple data channels (topography, phase, amplitude) provides complementary information that enhances the interpretation of rough surface characteristics. By integrating these data streams through multivariate statistical techniques, researchers can distinguish between topographical features and variations in material properties, critical for heterogeneous rough surfaces.

The standardization of data formats and processing pipelines remains an ongoing challenge in the field. Efforts to develop open-source platforms like Gwyddion and OpenFovea have improved accessibility and reproducibility of AFM data analysis, though further work is needed to establish universal protocols for rough surface characterization across different instrument platforms and analysis software.

Standards and Metrology Considerations for AFM Surface Measurements

Standardization in Atomic Force Microscopy (AFM) measurements is crucial for ensuring reproducibility and comparability of surface roughness data across different instruments and laboratories. The International Organization for Standardization (ISO) has developed several standards specifically for AFM measurements, including ISO 11039 and ISO 25178, which provide guidelines for calibration procedures, measurement protocols, and data reporting formats. These standards establish common terminology and methodologies that enable consistent characterization of surface topography across diverse research environments.

Calibration represents a fundamental metrological consideration when conducting AFM analysis on rough surfaces. Regular calibration of the AFM probe's lateral and vertical sensitivity using certified reference materials is essential for accurate quantitative measurements. For rough surface analysis, calibration becomes particularly critical as the probe-surface interaction dynamics change significantly across varying topographical features. Height calibration standards with certified step heights and lateral calibration gratings with known pitch dimensions should be employed before measurement campaigns to ensure dimensional accuracy.

Measurement uncertainty analysis must be systematically incorporated into AFM roughness measurements. Sources of uncertainty include probe geometry effects, scanner nonlinearities, thermal drift, and environmental vibrations. When analyzing rough surfaces, the probe-surface convolution effect becomes more pronounced, potentially leading to underestimation of deep valleys or sharp peaks. Quantifying these uncertainties through repeated measurements and statistical analysis provides confidence intervals for reported roughness parameters and enhances the reliability of comparative studies.

Traceability to national measurement standards ensures that AFM measurements can be linked to the International System of Units (SI). National metrology institutes such as NIST (USA), PTB (Germany), and NPL (UK) maintain primary standards that provide the foundation for traceable measurements. For rough surface analysis, reference artifacts with certified roughness values across different spatial wavelengths enable validation of measurement procedures and instrument performance.

Data processing protocols significantly impact the interpretation of AFM roughness measurements. Standardized approaches to filtering, leveling, and parameter calculation are necessary to obtain comparable results. The selection of appropriate cut-off wavelengths for separating roughness from waviness becomes particularly important when analyzing multi-scale rough surfaces. ISO standards recommend specific mathematical procedures for calculating common roughness parameters such as Ra, Rq, and Rz from AFM height data, ensuring consistency in reported values.

Interlaboratory comparison studies have revealed that even with standardized protocols, significant variations can occur in AFM roughness measurements of identical samples. These studies highlight the importance of establishing robust measurement procedures and uncertainty budgets. For rough surfaces with high aspect ratios or complex morphologies, consensus on best practices continues to evolve through collaborative research efforts and round-robin testing programs organized by standards bodies and professional organizations.

Calibration represents a fundamental metrological consideration when conducting AFM analysis on rough surfaces. Regular calibration of the AFM probe's lateral and vertical sensitivity using certified reference materials is essential for accurate quantitative measurements. For rough surface analysis, calibration becomes particularly critical as the probe-surface interaction dynamics change significantly across varying topographical features. Height calibration standards with certified step heights and lateral calibration gratings with known pitch dimensions should be employed before measurement campaigns to ensure dimensional accuracy.

Measurement uncertainty analysis must be systematically incorporated into AFM roughness measurements. Sources of uncertainty include probe geometry effects, scanner nonlinearities, thermal drift, and environmental vibrations. When analyzing rough surfaces, the probe-surface convolution effect becomes more pronounced, potentially leading to underestimation of deep valleys or sharp peaks. Quantifying these uncertainties through repeated measurements and statistical analysis provides confidence intervals for reported roughness parameters and enhances the reliability of comparative studies.

Traceability to national measurement standards ensures that AFM measurements can be linked to the International System of Units (SI). National metrology institutes such as NIST (USA), PTB (Germany), and NPL (UK) maintain primary standards that provide the foundation for traceable measurements. For rough surface analysis, reference artifacts with certified roughness values across different spatial wavelengths enable validation of measurement procedures and instrument performance.

Data processing protocols significantly impact the interpretation of AFM roughness measurements. Standardized approaches to filtering, leveling, and parameter calculation are necessary to obtain comparable results. The selection of appropriate cut-off wavelengths for separating roughness from waviness becomes particularly important when analyzing multi-scale rough surfaces. ISO standards recommend specific mathematical procedures for calculating common roughness parameters such as Ra, Rq, and Rz from AFM height data, ensuring consistency in reported values.

Interlaboratory comparison studies have revealed that even with standardized protocols, significant variations can occur in AFM roughness measurements of identical samples. These studies highlight the importance of establishing robust measurement procedures and uncertainty budgets. For rough surfaces with high aspect ratios or complex morphologies, consensus on best practices continues to evolve through collaborative research efforts and round-robin testing programs organized by standards bodies and professional organizations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!