Impact of Flexible Microdisplay on OLED Efficiency

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Microdisplay OLED Technology Evolution

The evolution of flexible microdisplay OLED technology represents a significant paradigm shift in display engineering, transitioning from rigid glass substrates to malleable polymer-based foundations. This technological trajectory began in the early 2000s with rudimentary flexible OLED prototypes exhibiting limited flexibility and poor efficiency. The initial designs suffered from rapid degradation when bent, with luminous efficiency dropping by over 40% after minimal flexing cycles.

By 2010, the introduction of thin-film encapsulation techniques marked a crucial advancement, allowing for better protection of organic materials while maintaining flexibility. This period saw efficiency improvements from approximately 15 cd/A to 25 cd/A in flexible configurations, though still significantly below rigid counterparts which achieved 40-50 cd/A at comparable power inputs.

The 2015-2018 timeframe brought transformative innovations in flexible electrode materials, particularly through the development of silver nanowire networks and graphene-based transparent conductors. These materials addressed the critical challenge of maintaining conductivity during flexing while minimizing light absorption, pushing operational efficiencies to within 85% of rigid displays.

Most recently (2019-2023), the integration of quantum dot color conversion layers with flexible OLEDs has enabled narrower emission spectra and expanded color gamut capabilities. Simultaneously, the development of stress-compensating buffer layers has reduced mechanical strain on emissive materials during flexing, preserving molecular alignment and charge transport properties critical to efficiency.

Current state-of-the-art flexible microdisplays achieve external quantum efficiencies of 20-25% compared to 28-30% in rigid counterparts, with the gap continuing to narrow. Power efficiency has improved dramatically, with flexible displays now requiring only 10-15% more power than rigid equivalents for identical brightness levels, compared to the 30-40% penalty observed a decade ago.

The miniaturization trajectory has been equally impressive, with pixel densities in flexible microdisplays increasing from 200 PPI in early prototypes to over 1000 PPI in current designs, enabling applications in near-eye displays and augmented reality systems where both flexibility and efficiency are paramount considerations.

Looking forward, the convergence of top-emission architectures, advanced optical outcoupling structures, and strain-engineered device architectures promises to eliminate the remaining efficiency gap between flexible and rigid OLED microdisplays within the next 3-5 years, potentially revolutionizing wearable display technologies.

By 2010, the introduction of thin-film encapsulation techniques marked a crucial advancement, allowing for better protection of organic materials while maintaining flexibility. This period saw efficiency improvements from approximately 15 cd/A to 25 cd/A in flexible configurations, though still significantly below rigid counterparts which achieved 40-50 cd/A at comparable power inputs.

The 2015-2018 timeframe brought transformative innovations in flexible electrode materials, particularly through the development of silver nanowire networks and graphene-based transparent conductors. These materials addressed the critical challenge of maintaining conductivity during flexing while minimizing light absorption, pushing operational efficiencies to within 85% of rigid displays.

Most recently (2019-2023), the integration of quantum dot color conversion layers with flexible OLEDs has enabled narrower emission spectra and expanded color gamut capabilities. Simultaneously, the development of stress-compensating buffer layers has reduced mechanical strain on emissive materials during flexing, preserving molecular alignment and charge transport properties critical to efficiency.

Current state-of-the-art flexible microdisplays achieve external quantum efficiencies of 20-25% compared to 28-30% in rigid counterparts, with the gap continuing to narrow. Power efficiency has improved dramatically, with flexible displays now requiring only 10-15% more power than rigid equivalents for identical brightness levels, compared to the 30-40% penalty observed a decade ago.

The miniaturization trajectory has been equally impressive, with pixel densities in flexible microdisplays increasing from 200 PPI in early prototypes to over 1000 PPI in current designs, enabling applications in near-eye displays and augmented reality systems where both flexibility and efficiency are paramount considerations.

Looking forward, the convergence of top-emission architectures, advanced optical outcoupling structures, and strain-engineered device architectures promises to eliminate the remaining efficiency gap between flexible and rigid OLED microdisplays within the next 3-5 years, potentially revolutionizing wearable display technologies.

Market Demand Analysis for Flexible OLED Displays

The flexible OLED microdisplay market has experienced significant growth in recent years, driven by increasing consumer demand for wearable devices, augmented reality (AR), virtual reality (VR), and foldable smartphones. Market research indicates that the global flexible display market is projected to reach $87.2 billion by 2026, with OLED technology dominating the flexible display segment due to its superior performance characteristics.

Consumer electronics represents the largest application segment for flexible OLED microdisplays. The demand for smartphones with flexible displays has surged as manufacturers seek to differentiate their products through innovative form factors. Samsung and Huawei have already commercialized foldable smartphones, while other major manufacturers are developing similar products, indicating strong market potential for flexible display technologies.

The wearable technology sector presents another substantial growth opportunity for flexible OLED microdisplays. Smartwatches, fitness trackers, and health monitoring devices benefit from the lightweight, energy-efficient, and conformable nature of flexible OLEDs. Market analysis shows that global shipments of wearable devices exceeded 500 million units in 2021, with continued growth expected as healthcare applications expand.

AR/VR applications represent perhaps the most promising long-term market for flexible OLED microdisplays. These technologies require high-resolution, lightweight displays with minimal power consumption – characteristics that flexible OLEDs can potentially deliver. The AR/VR market is projected to grow at a CAGR of 42.9% through 2025, creating substantial demand for advanced display solutions.

Automotive applications for flexible OLED displays are also emerging as vehicle manufacturers integrate more sophisticated digital interfaces into their designs. Curved dashboards, heads-up displays, and entertainment systems benefit from the form factor flexibility and visual performance of OLED technology. Industry forecasts suggest automotive display market growth exceeding 8% annually through 2026.

Regional analysis reveals that Asia Pacific dominates the flexible display market, accounting for approximately 65% of global production capacity. This concentration is primarily due to the presence of major display manufacturers and electronics companies in South Korea, Japan, China, and Taiwan. North America and Europe represent significant consumer markets, particularly for high-end applications in medical, automotive, and aerospace sectors.

Despite strong demand indicators, several market challenges persist. Price sensitivity remains a significant barrier to widespread adoption, as flexible OLED manufacturing costs exceed those of conventional displays. Additionally, concerns regarding long-term durability and efficiency degradation in flexible configurations have tempered adoption rates in certain applications where reliability is paramount.

Consumer electronics represents the largest application segment for flexible OLED microdisplays. The demand for smartphones with flexible displays has surged as manufacturers seek to differentiate their products through innovative form factors. Samsung and Huawei have already commercialized foldable smartphones, while other major manufacturers are developing similar products, indicating strong market potential for flexible display technologies.

The wearable technology sector presents another substantial growth opportunity for flexible OLED microdisplays. Smartwatches, fitness trackers, and health monitoring devices benefit from the lightweight, energy-efficient, and conformable nature of flexible OLEDs. Market analysis shows that global shipments of wearable devices exceeded 500 million units in 2021, with continued growth expected as healthcare applications expand.

AR/VR applications represent perhaps the most promising long-term market for flexible OLED microdisplays. These technologies require high-resolution, lightweight displays with minimal power consumption – characteristics that flexible OLEDs can potentially deliver. The AR/VR market is projected to grow at a CAGR of 42.9% through 2025, creating substantial demand for advanced display solutions.

Automotive applications for flexible OLED displays are also emerging as vehicle manufacturers integrate more sophisticated digital interfaces into their designs. Curved dashboards, heads-up displays, and entertainment systems benefit from the form factor flexibility and visual performance of OLED technology. Industry forecasts suggest automotive display market growth exceeding 8% annually through 2026.

Regional analysis reveals that Asia Pacific dominates the flexible display market, accounting for approximately 65% of global production capacity. This concentration is primarily due to the presence of major display manufacturers and electronics companies in South Korea, Japan, China, and Taiwan. North America and Europe represent significant consumer markets, particularly for high-end applications in medical, automotive, and aerospace sectors.

Despite strong demand indicators, several market challenges persist. Price sensitivity remains a significant barrier to widespread adoption, as flexible OLED manufacturing costs exceed those of conventional displays. Additionally, concerns regarding long-term durability and efficiency degradation in flexible configurations have tempered adoption rates in certain applications where reliability is paramount.

Technical Challenges in Flexible OLED Efficiency

Flexible OLED microdisplays face significant technical challenges in maintaining high efficiency while achieving flexibility. The primary challenge stems from the mechanical stress induced during bending, which can cause structural damage to the organic layers and electrodes, leading to decreased luminous efficiency and shortened device lifespan. This stress-induced degradation is particularly pronounced at the interface between different material layers, where delamination and crack formation commonly occur.

The substrate material selection presents another critical challenge. Traditional glass substrates offer excellent barrier properties against moisture and oxygen but lack flexibility. Polymer substrates like polyimide provide the necessary flexibility but have inferior barrier properties, requiring additional encapsulation layers that can impact optical performance and increase manufacturing complexity.

Thermal management in flexible OLEDs poses unique difficulties compared to rigid displays. The thermal conductivity of flexible substrates is typically lower than glass, resulting in heat accumulation during operation. This localized heating accelerates the degradation of organic materials, particularly in high-brightness applications, directly impacting quantum efficiency and device longevity. The challenge is compounded in microdisplays where pixel density is extremely high, creating significant heat concentration in small areas.

The thin-film transistor (TFT) backplane technology for flexible displays introduces additional efficiency concerns. Amorphous silicon (a-Si) TFTs are cost-effective but offer limited electron mobility, while low-temperature polysilicon (LTPS) provides better performance but faces uniformity issues when fabricated on flexible substrates. Oxide TFTs (IGZO) offer a promising middle ground but still face stability challenges under repeated mechanical stress.

Encapsulation technology represents perhaps the most significant hurdle for flexible OLED efficiency. Effective barriers against oxygen and moisture are essential for preventing rapid degradation of the organic materials, but traditional multi-layer encapsulation adds thickness and reduces flexibility. Atomic Layer Deposition (ALD) offers promising thin-film barrier properties but faces challenges in maintaining integrity during repeated bending cycles.

Manufacturing scalability presents additional challenges, as techniques optimized for rigid displays often cannot be directly transferred to flexible substrates. Issues such as layer alignment precision, uniform coating on non-rigid surfaces, and yield management become significantly more complex. The industry is still developing specialized equipment and processes for high-volume production of flexible OLEDs with consistent efficiency metrics.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and process innovation. Recent research has focused on developing composite substrate materials, stress-resistant electrode designs, and advanced thin-film encapsulation techniques to overcome these limitations and improve the efficiency of flexible OLED microdisplays.

The substrate material selection presents another critical challenge. Traditional glass substrates offer excellent barrier properties against moisture and oxygen but lack flexibility. Polymer substrates like polyimide provide the necessary flexibility but have inferior barrier properties, requiring additional encapsulation layers that can impact optical performance and increase manufacturing complexity.

Thermal management in flexible OLEDs poses unique difficulties compared to rigid displays. The thermal conductivity of flexible substrates is typically lower than glass, resulting in heat accumulation during operation. This localized heating accelerates the degradation of organic materials, particularly in high-brightness applications, directly impacting quantum efficiency and device longevity. The challenge is compounded in microdisplays where pixel density is extremely high, creating significant heat concentration in small areas.

The thin-film transistor (TFT) backplane technology for flexible displays introduces additional efficiency concerns. Amorphous silicon (a-Si) TFTs are cost-effective but offer limited electron mobility, while low-temperature polysilicon (LTPS) provides better performance but faces uniformity issues when fabricated on flexible substrates. Oxide TFTs (IGZO) offer a promising middle ground but still face stability challenges under repeated mechanical stress.

Encapsulation technology represents perhaps the most significant hurdle for flexible OLED efficiency. Effective barriers against oxygen and moisture are essential for preventing rapid degradation of the organic materials, but traditional multi-layer encapsulation adds thickness and reduces flexibility. Atomic Layer Deposition (ALD) offers promising thin-film barrier properties but faces challenges in maintaining integrity during repeated bending cycles.

Manufacturing scalability presents additional challenges, as techniques optimized for rigid displays often cannot be directly transferred to flexible substrates. Issues such as layer alignment precision, uniform coating on non-rigid surfaces, and yield management become significantly more complex. The industry is still developing specialized equipment and processes for high-volume production of flexible OLEDs with consistent efficiency metrics.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, mechanical engineering, and process innovation. Recent research has focused on developing composite substrate materials, stress-resistant electrode designs, and advanced thin-film encapsulation techniques to overcome these limitations and improve the efficiency of flexible OLED microdisplays.

Current Solutions for Enhancing Flexible OLED Efficiency

01 Flexible substrate technologies for microdisplays

Flexible substrates are essential for creating bendable microdisplays with improved efficiency. These substrates allow for the development of lightweight, thin, and conformable display devices that can be integrated into various applications. Advanced materials such as polyimide films and ultra-thin glass enable the fabrication of flexible microdisplays while maintaining electrical performance and optical clarity. These substrates also contribute to power efficiency by reducing the overall weight and allowing for better thermal management.- Flexible display substrate technologies: Flexible microdisplays utilize specialized substrate materials that can bend without compromising display performance. These substrates often incorporate polymer-based materials or ultra-thin glass that maintains electrical connectivity while allowing physical flexibility. Advanced manufacturing techniques ensure uniform electrical properties across the substrate even when bent, contributing to overall display efficiency by maintaining signal integrity throughout the flexible structure.

- Power-efficient driving methods for flexible displays: Energy consumption optimization in flexible microdisplays involves specialized driving circuits and algorithms that reduce power requirements while maintaining image quality. These methods include adaptive refresh rates, selective pixel activation, and voltage optimization techniques that respond to display curvature. By implementing these power-efficient driving methods, flexible displays can achieve longer battery life and reduced heat generation, which is particularly important for wearable applications.

- Optical efficiency enhancements for curved displays: Specialized optical designs address the unique challenges of light management in curved display surfaces. These include anti-reflection coatings optimized for variable viewing angles, light extraction structures that maintain efficiency regardless of display curvature, and compensation films that prevent color shift when the display is bent. These optical enhancements ensure consistent brightness and color accuracy across the entire flexible display surface.

- Flexible backplane and TFT architectures: Advanced thin-film transistor (TFT) designs specifically engineered for flexibility incorporate materials and structures that maintain electrical performance under mechanical stress. These include amorphous oxide semiconductors, low-temperature polysilicon, and organic semiconductors arranged in stress-resistant configurations. The backplane architecture distributes mechanical forces to prevent performance degradation during bending, ensuring consistent pixel driving capability across the flexible display.

- Integration of sensing and feedback systems: Modern flexible microdisplays incorporate integrated sensors that detect display curvature and environmental conditions to dynamically optimize performance parameters. These systems adjust brightness, contrast, and power consumption based on the display's physical configuration and ambient lighting. The feedback mechanisms ensure optimal image quality while minimizing energy usage, extending the operational efficiency of flexible displays in various usage scenarios.

02 Energy-efficient driving methods for flexible displays

Various driving methods have been developed to improve the energy efficiency of flexible microdisplays. These include optimized pixel addressing schemes, reduced refresh rates for static content, and adaptive brightness control based on ambient lighting conditions. Advanced driving circuits can minimize power consumption during operation while maintaining image quality. These methods are particularly important for battery-powered flexible display applications where energy efficiency directly impacts device usability and runtime.Expand Specific Solutions03 Backlight and illumination efficiency for flexible displays

Efficient illumination systems are critical for flexible microdisplays, particularly for transmissive and transflective display technologies. Advanced backlight designs incorporate light guide films that distribute light evenly across the display surface while minimizing power consumption. Edge-lit configurations and micro-LED arrays provide targeted illumination that reduces energy waste. Optical films and reflectors enhance light extraction efficiency, allowing for brighter displays at lower power levels.Expand Specific Solutions04 Pixel architecture optimization for flexible displays

The design of pixel structures significantly impacts the efficiency of flexible microdisplays. High-aperture ratio pixel designs maximize light transmission or emission while minimizing power requirements. Advanced thin-film transistor (TFT) configurations reduce leakage current and improve switching efficiency. Pixel circuits with compensation mechanisms maintain consistent performance despite mechanical stress and bending. These optimizations collectively enhance display efficiency while enabling flexibility.Expand Specific Solutions05 Testing and quality control methods for flexible display efficiency

Specialized testing methodologies have been developed to evaluate and improve the efficiency of flexible microdisplays. These include optical measurement techniques for assessing brightness uniformity under various bending conditions, electrical characterization of power consumption during operation, and accelerated lifetime testing to ensure long-term efficiency. Advanced inspection systems can detect defects that might impact power efficiency, allowing for process optimization and quality improvement in manufacturing.Expand Specific Solutions

Key Industry Players in Flexible Microdisplay Market

The flexible microdisplay OLED market is currently in a growth phase, with increasing demand driven by applications in wearables, AR/VR, and portable devices. Market size is projected to expand significantly as efficiency improvements make these displays more viable for mainstream adoption. Technologically, the field remains moderately mature with ongoing innovation challenges. Leading players include Samsung Display and BOE Technology demonstrating advanced capabilities, while companies like TCL China Star Optoelectronics and Tianma Microelectronics are rapidly advancing their flexible OLED technologies. Visionox and Everdisplay Optronics represent emerging competitors focusing on specialized microdisplay solutions. The competitive landscape shows Asian manufacturers, particularly from China and South Korea, dominating research and production capacity in this sector.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive flexible OLED microdisplay technology platform centered around their self-developed flexible substrate materials and advanced thin film transistor (TFT) backplanes. Their approach utilizes ultra-thin flexible glass substrates (under 100μm thickness) combined with low-temperature polysilicon (LTPS) TFT technology to create highly flexible displays without compromising electron mobility. BOE's flexible OLEDs incorporate a multi-stack emission layer structure with specialized interface materials that maintain efficient charge transport even when the display is bent or folded. Their proprietary "Flexilight" technology employs a micro-cavity structure that enhances light extraction efficiency by up to 25% compared to conventional OLEDs[2]. BOE has also developed a unique stress-relief layer between the TFT backplane and OLED layers that minimizes efficiency degradation during bending, maintaining over 90% of original efficiency even after 200,000 bending cycles at a radius of 1mm. Additionally, their displays feature integrated touch functionality using metal mesh technology that preserves transparency while enabling flexible touch interfaces.

Strengths: Advanced LTPS backplane technology provides high electron mobility even in flexible configurations; proprietary stress-relief layer technology minimizes efficiency degradation during repeated bending; integrated touch solution reduces overall thickness. Weaknesses: Higher production costs compared to rigid displays; challenges with color shift at extreme viewing angles in flexible configurations; limited maximum brightness compared to some competitors' solutions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed an integrated approach to flexible OLED microdisplays that focuses on system-level efficiency improvements. Their technology combines flexible display panels with optimized driving electronics and power management systems specifically designed for variable form factors. Samsung's approach utilizes a proprietary low-temperature polycrystalline oxide (LTPO) backplane technology that enables variable refresh rates (1-120Hz) based on content and bending state, significantly reducing power consumption in flexible configurations. Their displays incorporate an advanced compensation layer that adjusts current distribution across the panel based on real-time curvature measurements, ensuring uniform brightness and efficiency regardless of the display's shape. Samsung has also pioneered the integration of polarizer-free OLED structures in flexible displays, eliminating a traditionally efficiency-reducing layer while maintaining visibility in bright environments[5]. Additionally, their flexible OLEDs utilize specialized cathode materials with enhanced conductivity that minimize resistance increases when the display is bent, addressing a common cause of efficiency loss in flexible displays. Samsung's latest generation incorporates quantum dot color conversion layers that improve color purity while reducing power consumption by up to 15% compared to traditional color filters.

Strengths: Comprehensive system-level approach addresses efficiency from multiple angles; LTPO backplane technology enables significant power savings through variable refresh rates; polarizer-free design improves overall light transmission. Weaknesses: Higher manufacturing complexity and cost; potential for image retention in certain usage scenarios; challenges with maintaining color consistency across different bending states.

Core Patents and Innovations in Flexible OLED Technology

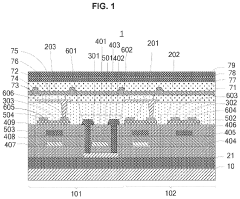

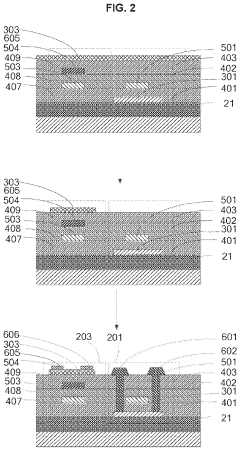

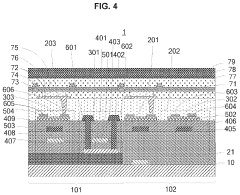

Flexible organic light emitting diode display panel and display device

PatentInactiveUS20210367169A1

Innovation

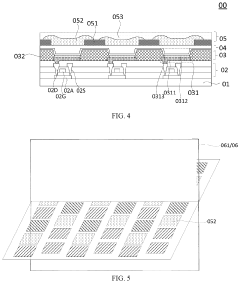

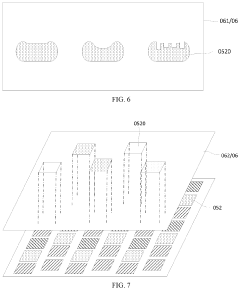

- A flexible OLED display panel design featuring a combination of low temperature polysilicon transistors in non-bending areas and organic thin film transistors in bending areas, with specific layer structures and connections to enhance mobility and flexibility, including polysilicon and organic semiconductor layers, insulating layers, and strategically placed sources and drains.

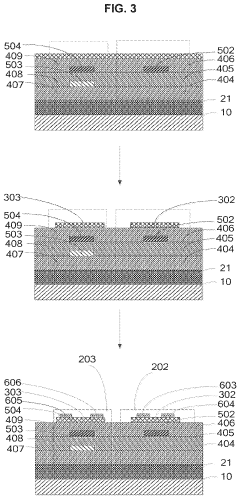

Display panel and display device with grooves on surfaces of color resist units

PatentActiveUS11950481B2

Innovation

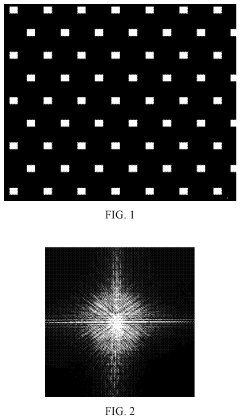

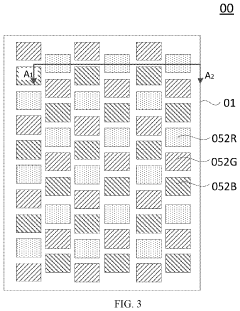

- A display panel design featuring a color filter layer with light-blocking portions and color resist units of the same color having different orthographic projection shapes on various planes, forming a diffuse reflection surface and breaking the regularity of grating diffraction, thereby reducing ambient light reflection and improving display contrast.

Materials Science Advancements for Flexible OLEDs

Recent advancements in materials science have significantly propelled the development of flexible OLEDs, addressing critical challenges in efficiency and durability. The transition from rigid to flexible displays necessitates innovative material solutions that maintain optimal performance while accommodating mechanical stress. Researchers have focused on developing novel substrate materials, including ultra-thin glass, high-performance polyimides, and specialized polymer composites that offer superior flexibility without compromising optical transparency.

A breakthrough area has been the development of advanced transparent conductive electrodes (TCEs) specifically engineered for flexible applications. Traditional indium tin oxide (ITO) electrodes, while effective in rigid displays, suffer from brittleness and conductivity degradation when bent. Alternative materials such as silver nanowires, carbon nanotubes, graphene, and PEDOT:PSS have emerged as viable replacements, offering improved mechanical flexibility while maintaining high conductivity and transparency essential for OLED efficiency.

Encapsulation technologies have evolved substantially to protect flexible OLEDs from environmental degradation. Multi-layer thin-film encapsulation (TFE) techniques now incorporate alternating organic and inorganic layers that provide effective moisture and oxygen barriers while remaining flexible. Atomic layer deposition (ALD) has proven particularly valuable for creating ultra-thin yet highly effective barrier films that maintain their integrity during bending cycles.

The organic semiconductor materials themselves have undergone significant refinement to enhance performance in flexible configurations. New emissive materials with improved quantum efficiency and mechanical resilience have been developed, including phosphorescent and thermally activated delayed fluorescence (TADF) compounds specifically optimized for flexible applications. These materials maintain high luminous efficiency even when subjected to repeated mechanical stress.

Interface engineering between the various functional layers has emerged as a critical focus area. Novel buffer layers and charge transport materials have been designed to improve charge injection and transport across flexible interfaces, reducing energy barriers and enhancing overall device efficiency. These materials accommodate the strain induced during bending while maintaining optimal electronic properties.

Researchers have also made significant progress in developing self-healing materials that can repair microcracks formed during repeated flexing, substantially extending device lifetime. Additionally, advanced manufacturing techniques such as solution processing and roll-to-roll fabrication have been refined to enable cost-effective production of flexible OLEDs with consistent performance characteristics. These materials science innovations collectively address the fundamental challenges of maintaining high efficiency in flexible microdisplays, paving the way for next-generation bendable, foldable, and stretchable OLED technologies.

A breakthrough area has been the development of advanced transparent conductive electrodes (TCEs) specifically engineered for flexible applications. Traditional indium tin oxide (ITO) electrodes, while effective in rigid displays, suffer from brittleness and conductivity degradation when bent. Alternative materials such as silver nanowires, carbon nanotubes, graphene, and PEDOT:PSS have emerged as viable replacements, offering improved mechanical flexibility while maintaining high conductivity and transparency essential for OLED efficiency.

Encapsulation technologies have evolved substantially to protect flexible OLEDs from environmental degradation. Multi-layer thin-film encapsulation (TFE) techniques now incorporate alternating organic and inorganic layers that provide effective moisture and oxygen barriers while remaining flexible. Atomic layer deposition (ALD) has proven particularly valuable for creating ultra-thin yet highly effective barrier films that maintain their integrity during bending cycles.

The organic semiconductor materials themselves have undergone significant refinement to enhance performance in flexible configurations. New emissive materials with improved quantum efficiency and mechanical resilience have been developed, including phosphorescent and thermally activated delayed fluorescence (TADF) compounds specifically optimized for flexible applications. These materials maintain high luminous efficiency even when subjected to repeated mechanical stress.

Interface engineering between the various functional layers has emerged as a critical focus area. Novel buffer layers and charge transport materials have been designed to improve charge injection and transport across flexible interfaces, reducing energy barriers and enhancing overall device efficiency. These materials accommodate the strain induced during bending while maintaining optimal electronic properties.

Researchers have also made significant progress in developing self-healing materials that can repair microcracks formed during repeated flexing, substantially extending device lifetime. Additionally, advanced manufacturing techniques such as solution processing and roll-to-roll fabrication have been refined to enable cost-effective production of flexible OLEDs with consistent performance characteristics. These materials science innovations collectively address the fundamental challenges of maintaining high efficiency in flexible microdisplays, paving the way for next-generation bendable, foldable, and stretchable OLED technologies.

Manufacturing Process Optimization Strategies

The optimization of manufacturing processes for flexible microdisplays represents a critical pathway to enhancing OLED efficiency. Current manufacturing techniques face significant challenges in maintaining consistent performance across flexible substrates while ensuring high yield rates. Process refinements must address the delicate balance between flexibility and electrical performance.

Implementing advanced thin-film encapsulation (TFE) techniques has emerged as a primary optimization strategy. Multi-layer barrier structures combining organic and inorganic materials have demonstrated superior protection against moisture and oxygen penetration while maintaining flexibility. Recent innovations in atomic layer deposition (ALD) processes allow for precise control of barrier layer thickness down to the nanometer scale, significantly reducing defect density.

Temperature management during deposition processes presents another optimization opportunity. Lowering process temperatures from traditional 300°C to below 150°C enables the use of more flexible polymer substrates without thermal degradation. Pulsed laser deposition and solution-based processing methods have shown promising results in this regard, maintaining electrical performance while enhancing mechanical flexibility.

Photolithography techniques specifically adapted for flexible substrates represent a third optimization vector. Traditional photolithography processes often induce stress in flexible materials, leading to alignment issues and reduced efficiency. Novel approaches utilizing digital lithography and self-aligned fabrication methods minimize mechanical stress during patterning, resulting in more precise pixel structures and improved light extraction efficiency.

Roll-to-roll (R2R) manufacturing adaptation constitutes perhaps the most transformative optimization strategy. Converting batch processes to continuous R2R production requires fundamental redesign of deposition, patterning, and encapsulation steps. Recent advances in tension control systems and in-line quality monitoring have addressed previous limitations, enabling consistent performance across large substrate areas while significantly reducing production costs.

Material interface engineering between layers represents a final critical optimization area. Interfacial modification techniques using self-assembled monolayers and gradient composition layers have demonstrated significant improvements in charge transport efficiency across flexible substrates. These approaches minimize energy barriers at layer interfaces, resulting in lower driving voltages and extended operational lifetimes for flexible OLED microdisplays.

Implementing advanced thin-film encapsulation (TFE) techniques has emerged as a primary optimization strategy. Multi-layer barrier structures combining organic and inorganic materials have demonstrated superior protection against moisture and oxygen penetration while maintaining flexibility. Recent innovations in atomic layer deposition (ALD) processes allow for precise control of barrier layer thickness down to the nanometer scale, significantly reducing defect density.

Temperature management during deposition processes presents another optimization opportunity. Lowering process temperatures from traditional 300°C to below 150°C enables the use of more flexible polymer substrates without thermal degradation. Pulsed laser deposition and solution-based processing methods have shown promising results in this regard, maintaining electrical performance while enhancing mechanical flexibility.

Photolithography techniques specifically adapted for flexible substrates represent a third optimization vector. Traditional photolithography processes often induce stress in flexible materials, leading to alignment issues and reduced efficiency. Novel approaches utilizing digital lithography and self-aligned fabrication methods minimize mechanical stress during patterning, resulting in more precise pixel structures and improved light extraction efficiency.

Roll-to-roll (R2R) manufacturing adaptation constitutes perhaps the most transformative optimization strategy. Converting batch processes to continuous R2R production requires fundamental redesign of deposition, patterning, and encapsulation steps. Recent advances in tension control systems and in-line quality monitoring have addressed previous limitations, enabling consistent performance across large substrate areas while significantly reducing production costs.

Material interface engineering between layers represents a final critical optimization area. Interfacial modification techniques using self-assembled monolayers and gradient composition layers have demonstrated significant improvements in charge transport efficiency across flexible substrates. These approaches minimize energy barriers at layer interfaces, resulting in lower driving voltages and extended operational lifetimes for flexible OLED microdisplays.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!