Impacts of Environmental Factors on Quantum Dot Stability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Background and Objectives

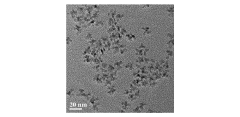

Quantum dots (QDs) represent one of the most significant advancements in nanotechnology over the past three decades. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. Since their discovery in the early 1980s by Alexei Ekimov and Louis Brus, quantum dot technology has evolved from a laboratory curiosity to a commercially viable technology with applications spanning multiple industries.

The evolution of quantum dot technology has followed a clear trajectory from fundamental research to practical applications. Initial research focused on understanding the basic physics and chemistry of these nanostructures, followed by developments in synthesis methods that enabled precise control over size, shape, and composition. The past decade has witnessed significant advancements in surface chemistry modifications and core-shell architectures that have substantially improved quantum yield and stability.

Environmental stability remains one of the most critical challenges facing quantum dot technology. Various environmental factors including temperature fluctuations, humidity, oxygen exposure, UV radiation, and chemical contaminants can significantly impact quantum dot performance and longevity. These environmental sensitivities have limited the widespread adoption of quantum dots in certain applications despite their superior optical properties compared to traditional materials.

The primary technical objectives in addressing environmental impacts on quantum dot stability include: developing robust encapsulation methods to shield quantum dots from environmental stressors; engineering surface ligands that provide both stability and functionality; creating multi-shell architectures that protect the core while maintaining desired optical properties; and establishing standardized testing protocols to evaluate stability under various environmental conditions.

Current research trends are focusing on environmentally robust quantum dot formulations that maintain high quantum yield and narrow emission spectra even under challenging conditions. Particular emphasis is being placed on lead-free compositions to address toxicity concerns, as well as on developing manufacturing processes that can scale while maintaining precise control over nanocrystal properties.

The long-term technological goal is to develop quantum dot materials that combine exceptional optical performance with environmental resilience comparable to traditional materials. This would enable their integration into mainstream consumer electronics, lighting, solar energy harvesting, and biomedical applications. Additionally, researchers aim to establish predictive models that can accurately forecast quantum dot degradation under various environmental conditions, facilitating the design of more stable structures.

The evolution of quantum dot technology has followed a clear trajectory from fundamental research to practical applications. Initial research focused on understanding the basic physics and chemistry of these nanostructures, followed by developments in synthesis methods that enabled precise control over size, shape, and composition. The past decade has witnessed significant advancements in surface chemistry modifications and core-shell architectures that have substantially improved quantum yield and stability.

Environmental stability remains one of the most critical challenges facing quantum dot technology. Various environmental factors including temperature fluctuations, humidity, oxygen exposure, UV radiation, and chemical contaminants can significantly impact quantum dot performance and longevity. These environmental sensitivities have limited the widespread adoption of quantum dots in certain applications despite their superior optical properties compared to traditional materials.

The primary technical objectives in addressing environmental impacts on quantum dot stability include: developing robust encapsulation methods to shield quantum dots from environmental stressors; engineering surface ligands that provide both stability and functionality; creating multi-shell architectures that protect the core while maintaining desired optical properties; and establishing standardized testing protocols to evaluate stability under various environmental conditions.

Current research trends are focusing on environmentally robust quantum dot formulations that maintain high quantum yield and narrow emission spectra even under challenging conditions. Particular emphasis is being placed on lead-free compositions to address toxicity concerns, as well as on developing manufacturing processes that can scale while maintaining precise control over nanocrystal properties.

The long-term technological goal is to develop quantum dot materials that combine exceptional optical performance with environmental resilience comparable to traditional materials. This would enable their integration into mainstream consumer electronics, lighting, solar energy harvesting, and biomedical applications. Additionally, researchers aim to establish predictive models that can accurately forecast quantum dot degradation under various environmental conditions, facilitating the design of more stable structures.

Market Analysis for Quantum Dot Applications

The quantum dot market has experienced significant growth in recent years, with a global market value reaching $4.6 billion in 2021 and projected to exceed $16 billion by 2028, representing a compound annual growth rate of approximately 23%. This remarkable expansion is primarily driven by increasing adoption across multiple industries, particularly in display technologies, where quantum dots offer superior color accuracy and energy efficiency compared to traditional display solutions.

Consumer electronics represents the largest application segment, accounting for over 45% of the total market share. Major manufacturers like Samsung, LG, and Sony have incorporated quantum dot technology into their premium television lines, marketing them as QLED (Quantum Dot LED) displays. The healthcare and biomedical sectors follow as the second-largest application area, utilizing quantum dots for bioimaging, diagnostics, and drug delivery systems due to their unique optical properties and biocompatibility.

Environmental stability concerns directly impact market dynamics, as applications requiring long-term reliability face adoption barriers. Industries demanding extended product lifespans, such as automotive displays and outdoor signage, have shown hesitation in fully embracing quantum dot technology despite its superior visual performance. Market research indicates that improving quantum dot stability could unlock an additional $3.2 billion in market potential across these sectors by 2026.

Regional analysis reveals North America currently leads the quantum dot market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to increasing manufacturing capabilities and rising consumer electronics demand in countries like China, South Korea, and Japan.

The competitive landscape features both established corporations and innovative startups. Companies specializing in cadmium-free quantum dots have gained significant market traction due to environmental regulations, particularly in Europe where RoHS directives restrict cadmium use. This regulatory environment has accelerated research into alternative quantum dot compositions with enhanced stability profiles.

End-user surveys indicate that product lifetime and reliability rank among the top three purchasing considerations for industrial applications of quantum dot technology. Approximately 67% of potential industrial adopters cite concerns about environmental degradation of quantum dots as a primary barrier to implementation, highlighting the direct connection between stability improvements and market expansion potential.

Consumer electronics represents the largest application segment, accounting for over 45% of the total market share. Major manufacturers like Samsung, LG, and Sony have incorporated quantum dot technology into their premium television lines, marketing them as QLED (Quantum Dot LED) displays. The healthcare and biomedical sectors follow as the second-largest application area, utilizing quantum dots for bioimaging, diagnostics, and drug delivery systems due to their unique optical properties and biocompatibility.

Environmental stability concerns directly impact market dynamics, as applications requiring long-term reliability face adoption barriers. Industries demanding extended product lifespans, such as automotive displays and outdoor signage, have shown hesitation in fully embracing quantum dot technology despite its superior visual performance. Market research indicates that improving quantum dot stability could unlock an additional $3.2 billion in market potential across these sectors by 2026.

Regional analysis reveals North America currently leads the quantum dot market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate in the coming years due to increasing manufacturing capabilities and rising consumer electronics demand in countries like China, South Korea, and Japan.

The competitive landscape features both established corporations and innovative startups. Companies specializing in cadmium-free quantum dots have gained significant market traction due to environmental regulations, particularly in Europe where RoHS directives restrict cadmium use. This regulatory environment has accelerated research into alternative quantum dot compositions with enhanced stability profiles.

End-user surveys indicate that product lifetime and reliability rank among the top three purchasing considerations for industrial applications of quantum dot technology. Approximately 67% of potential industrial adopters cite concerns about environmental degradation of quantum dots as a primary barrier to implementation, highlighting the direct connection between stability improvements and market expansion potential.

Current Stability Challenges and Environmental Vulnerabilities

Quantum dots (QDs) face significant stability challenges when exposed to various environmental factors, presenting a major obstacle for their widespread commercial application. The primary vulnerability lies in their susceptibility to oxidation when exposed to atmospheric oxygen, which can dramatically alter their optical and electronic properties. This oxidation process typically begins at the surface and gradually penetrates the core structure, resulting in decreased photoluminescence quantum yield (PLQY) and spectral shifts that compromise performance in applications ranging from displays to biomedical imaging.

Temperature fluctuations represent another critical challenge, as QDs exhibit thermal quenching at elevated temperatures and structural degradation during freeze-thaw cycles. Most commercially relevant QD formulations show optimal performance within a narrow temperature range (20-40°C), with significant degradation observed outside these boundaries. This thermal sensitivity limits their deployment in harsh environmental conditions and necessitates additional protective measures in consumer electronics.

Humidity and moisture exposure constitute particularly destructive environmental factors for QDs, especially those containing hygroscopic materials or ionic components. Water molecules can facilitate ion migration, accelerate oxidation processes, and directly interact with surface ligands, leading to aggregation and precipitation in colloidal systems. Recent studies have demonstrated that even trace amounts of moisture can trigger cascading degradation mechanisms in certain QD compositions.

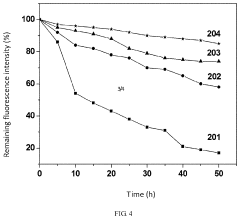

Photostability represents a paradoxical challenge for QDs, as these materials designed to interact with light often suffer from photodegradation under continuous illumination. This phenomenon, known as photobleaching, manifests through decreased emission intensity and spectral broadening after prolonged exposure to excitation sources. The mechanism typically involves photocatalyzed oxidation reactions and ligand detachment, with blue and UV wavelengths causing more severe damage due to their higher photon energies.

Chemical compatibility issues further complicate QD implementation in complex device architectures. Many QD systems demonstrate poor stability when in contact with common solvents, polymers, and electrode materials used in manufacturing processes. Particularly problematic are interactions with protic solvents, strong acids or bases, and materials containing nucleophilic functional groups that can displace surface ligands or etch the QD surface.

The combined effect of these environmental vulnerabilities creates significant challenges for QD commercialization, particularly in applications requiring long operational lifetimes. Current research indicates that stability limitations reduce the effective lifespan of many QD-based devices to months rather than years, necessitating innovative encapsulation strategies and compositional modifications to overcome these fundamental challenges.

Temperature fluctuations represent another critical challenge, as QDs exhibit thermal quenching at elevated temperatures and structural degradation during freeze-thaw cycles. Most commercially relevant QD formulations show optimal performance within a narrow temperature range (20-40°C), with significant degradation observed outside these boundaries. This thermal sensitivity limits their deployment in harsh environmental conditions and necessitates additional protective measures in consumer electronics.

Humidity and moisture exposure constitute particularly destructive environmental factors for QDs, especially those containing hygroscopic materials or ionic components. Water molecules can facilitate ion migration, accelerate oxidation processes, and directly interact with surface ligands, leading to aggregation and precipitation in colloidal systems. Recent studies have demonstrated that even trace amounts of moisture can trigger cascading degradation mechanisms in certain QD compositions.

Photostability represents a paradoxical challenge for QDs, as these materials designed to interact with light often suffer from photodegradation under continuous illumination. This phenomenon, known as photobleaching, manifests through decreased emission intensity and spectral broadening after prolonged exposure to excitation sources. The mechanism typically involves photocatalyzed oxidation reactions and ligand detachment, with blue and UV wavelengths causing more severe damage due to their higher photon energies.

Chemical compatibility issues further complicate QD implementation in complex device architectures. Many QD systems demonstrate poor stability when in contact with common solvents, polymers, and electrode materials used in manufacturing processes. Particularly problematic are interactions with protic solvents, strong acids or bases, and materials containing nucleophilic functional groups that can displace surface ligands or etch the QD surface.

The combined effect of these environmental vulnerabilities creates significant challenges for QD commercialization, particularly in applications requiring long operational lifetimes. Current research indicates that stability limitations reduce the effective lifespan of many QD-based devices to months rather than years, necessitating innovative encapsulation strategies and compositional modifications to overcome these fundamental challenges.

Existing Environmental Protection Strategies for Quantum Dots

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

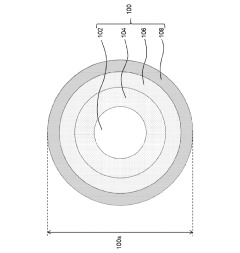

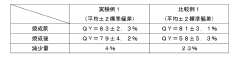

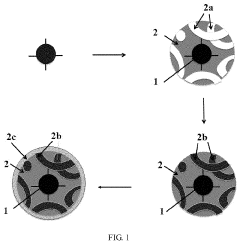

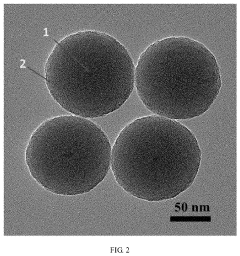

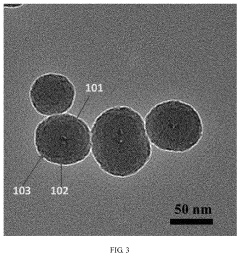

- Core-shell structures for improved quantum dot stability: Core-shell structured quantum dots offer enhanced stability compared to core-only quantum dots. The shell layer, typically composed of a wider bandgap semiconductor material, protects the core from environmental factors and reduces surface defects. This structure effectively passivates the surface states, minimizes non-radiative recombination, and improves quantum yield and photostability under various conditions.

- Environmental factors affecting quantum dot stability: Quantum dot stability is significantly influenced by environmental factors such as temperature, humidity, light exposure, and oxidizing agents. These factors can accelerate degradation processes, leading to decreased luminescence efficiency and altered optical properties. Understanding and controlling these environmental parameters is crucial for maintaining quantum dot stability in various applications and storage conditions.

- Stabilization methods for quantum dots in solution and solid-state: Different stabilization strategies are required for quantum dots in solution versus solid-state applications. In solutions, colloidal stability can be achieved through appropriate ligand selection and solvent engineering. For solid-state applications, embedding quantum dots in polymer matrices or inorganic hosts can provide mechanical protection and barrier effects against oxygen and moisture, significantly enhancing their operational lifetime and stability.

- Novel materials and compositions for enhanced quantum dot stability: Research has led to the development of novel materials and compositions that significantly improve quantum dot stability. These include innovative ligand systems, hybrid organic-inorganic structures, and specialized encapsulation materials. Additionally, the incorporation of specific additives and stabilizers can prevent photo-oxidation and thermal degradation, resulting in quantum dots with superior stability characteristics for demanding applications.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. The shell material, often composed of wider bandgap semiconductors, shields the core from environmental factors while maintaining the desired optical and electronic properties. This architecture reduces surface defects and prevents degradation, resulting in quantum dots with superior stability and longer lifetimes.Expand Specific Solutions03 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides enhanced environmental stability. These encapsulation methods create physical barriers that protect quantum dots from oxygen, moisture, and other degradative factors. The encapsulating materials can be tailored to specific applications while maintaining the optical properties of the quantum dots and extending their usable lifetime.Expand Specific Solutions04 Chemical stabilization approaches for quantum dots

Chemical stabilization approaches involve the use of specific additives, ligands, or chemical treatments to enhance quantum dot stability. These methods include the incorporation of antioxidants, pH stabilizers, and cross-linking agents that prevent degradation mechanisms. Chemical stabilization can be achieved through careful selection of solvents, buffers, and reaction conditions during synthesis and post-processing stages.Expand Specific Solutions05 Manufacturing processes affecting quantum dot stability

The stability of quantum dots is significantly influenced by manufacturing processes and synthesis conditions. Parameters such as temperature, reaction time, precursor ratios, and purification methods directly impact the defect density, size distribution, and surface properties of quantum dots. Optimized manufacturing processes can yield quantum dots with inherently higher stability and resistance to degradation under various environmental conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Quantum Dot Field

The quantum dot stability market is currently in a growth phase, characterized by increasing adoption across display technologies, healthcare, and energy sectors. The market is projected to expand significantly due to rising demand for high-performance displays and quantum dot applications in emerging technologies. Environmental factors affecting quantum dot stability represent a critical technical challenge being addressed by key industry players. Companies like Nanosys, Samsung Electronics, and Mojo Vision lead in commercial applications, while research-focused entities such as University of Zurich and Louisiana State University contribute fundamental advancements. BOE Technology, TCL Research America, and Najing Technology are rapidly advancing in Asian markets, focusing on improving quantum dot resilience against temperature, humidity, and light exposure—factors that currently limit broader commercial deployment despite the technology's promising performance characteristics.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has leveraged its expertise in silicone materials to develop advanced encapsulation systems for quantum dot protection against environmental degradation. Their "QD-Silicone" platform utilizes modified silicone polymers with precisely engineered molecular structures that provide exceptional oxygen and moisture barrier properties while maintaining optical transparency. The company's approach involves creating interpenetrating polymer networks that physically entrap quantum dots while allowing their optical properties to remain unaffected. Research from their laboratories demonstrates that these specialized silicone matrices reduce oxygen permeability by over 95% compared to conventional polymer encapsulants. Shin-Etsu has also developed temperature-stabilizing additives that maintain consistent quantum dot performance across a wide operating range (-20°C to +120°C). Their proprietary cross-linking chemistry creates three-dimensional networks that resist thermal expansion and contraction, minimizing stress on embedded quantum dots during temperature cycling. Additionally, the company has pioneered UV-absorbing silicone formulations that selectively filter damaging wavelengths while transmitting the quantum dot emission spectrum, extending operational lifetime under high-intensity lighting conditions by an estimated 30% compared to unprotected formulations.

Strengths: World-leading expertise in silicone chemistry provides unique approaches to environmental protection; materials demonstrate exceptional oxygen and moisture barrier properties; solutions compatible with existing manufacturing processes. Weaknesses: Less vertical integration in quantum dot synthesis compared to display manufacturers; primarily focused on encapsulation rather than intrinsic quantum dot stability; higher material costs compared to conventional polymers.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed a comprehensive approach to quantum dot stability through their "QD-Shield" technology platform. This system addresses multiple environmental vulnerability factors simultaneously through a hierarchical protection strategy. At the quantum dot level, BOE employs gradient alloy interfaces between core and shell materials to minimize lattice mismatch stress that typically accelerates degradation under thermal cycling. Their research has shown this approach reduces degradation rates by approximately 40% compared to abrupt interfaces. BOE has also pioneered humidity-resistant surface ligand exchanges that replace conventional organic ligands with siloxane-based alternatives, creating hydrophobic barriers around individual quantum dots. For oxygen protection, the company utilizes proprietary oxygen-scavenging additives integrated directly into the quantum dot host matrix. BOE's recent innovations include UV-blocking layers that prevent photodegradation while maintaining optical transparency in the visible spectrum, extending quantum dot lifetime in high-brightness display applications by an estimated 15,000 hours under accelerated testing conditions.

Strengths: Comprehensive approach addressing multiple environmental factors simultaneously; strong manufacturing capabilities for implementing complex protection systems at scale; significant improvements in humidity resistance compared to industry standards. Weaknesses: Technology primarily optimized for display applications rather than broader environmental challenges; protection systems add complexity and cost to manufacturing; some approaches sacrifice quantum efficiency for stability gains.

Key Research Breakthroughs in Quantum Dot Stability

Semiconductor nanomaterial having high stability

PatentActiveJP2022076459A

Innovation

- A quantum dot design with a core composed of InP, a first shell of ZnSe, a second shell, and a graded alloy intermediate layer of In, P, Zn, and Se, which improves lattice alignment and provides a thicker protective shell, maintaining high photoluminescence quantum yield.

Core-shell type quantum dot, preparation method and use thereof

PatentActiveUS20220025253A9

Innovation

- A core-shell type quantum dot is developed with a light-transmitting inorganic mesoporous material layer and a filler in its mesopores, which provides improved optical and chemical stability by isolating the quantum dot core from external moisture and oxygen, and optionally includes a metal oxide passivation layer for further protection.

Regulatory Framework for Quantum Dot Materials

The regulatory landscape for quantum dot materials has evolved significantly in response to growing concerns about their environmental and health impacts, particularly regarding stability issues. The United States Environmental Protection Agency (EPA) has established specific guidelines under the Toxic Substances Control Act (TSCA) that classify certain quantum dot compositions as new chemical substances requiring thorough safety assessments before commercialization. These regulations focus heavily on leaching potential and degradation pathways when quantum dots are exposed to environmental stressors.

In the European Union, quantum dots fall under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, with additional provisions in the Restriction of Hazardous Substances (RoHS) directive. The EU has implemented more stringent stability requirements, mandating accelerated aging tests that simulate environmental exposure to UV radiation, humidity, and temperature fluctuations. Manufacturers must demonstrate that their quantum dot materials maintain stability within defined parameters throughout the product lifecycle.

Japan and South Korea have developed specialized regulatory frameworks focusing on quantum dots in consumer electronics and display technologies. These frameworks emphasize stability testing under various operational conditions, with particular attention to heat generation in devices and subsequent impacts on quantum dot degradation. The Japanese framework specifically addresses photostability requirements for quantum dots used in lighting applications.

International standards organizations, including ISO and IEC, have established technical committees dedicated to nanomaterials standardization. ISO/TC 229 has published several standards relevant to quantum dot stability assessment, providing standardized testing protocols that enable regulatory compliance across jurisdictions. These protocols include methods for evaluating quantum yield retention under controlled environmental stress conditions.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches, where manufacturers must account for quantum dot stability not only during product use but also during disposal or recycling phases. This trend reflects growing concerns about potential environmental contamination from degraded quantum dot materials. Several jurisdictions are now requiring Environmental Risk Assessments that specifically address long-term stability under various disposal scenarios.

Industry self-regulation has also emerged as a complementary force, with consortia like the International Quantum Dot Industry Association developing voluntary standards that often exceed regulatory minimums. These industry-led initiatives frequently address stability concerns before they become regulatory mandates, establishing best practices for formulation, encapsulation, and stability enhancement techniques.

In the European Union, quantum dots fall under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, with additional provisions in the Restriction of Hazardous Substances (RoHS) directive. The EU has implemented more stringent stability requirements, mandating accelerated aging tests that simulate environmental exposure to UV radiation, humidity, and temperature fluctuations. Manufacturers must demonstrate that their quantum dot materials maintain stability within defined parameters throughout the product lifecycle.

Japan and South Korea have developed specialized regulatory frameworks focusing on quantum dots in consumer electronics and display technologies. These frameworks emphasize stability testing under various operational conditions, with particular attention to heat generation in devices and subsequent impacts on quantum dot degradation. The Japanese framework specifically addresses photostability requirements for quantum dots used in lighting applications.

International standards organizations, including ISO and IEC, have established technical committees dedicated to nanomaterials standardization. ISO/TC 229 has published several standards relevant to quantum dot stability assessment, providing standardized testing protocols that enable regulatory compliance across jurisdictions. These protocols include methods for evaluating quantum yield retention under controlled environmental stress conditions.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches, where manufacturers must account for quantum dot stability not only during product use but also during disposal or recycling phases. This trend reflects growing concerns about potential environmental contamination from degraded quantum dot materials. Several jurisdictions are now requiring Environmental Risk Assessments that specifically address long-term stability under various disposal scenarios.

Industry self-regulation has also emerged as a complementary force, with consortia like the International Quantum Dot Industry Association developing voluntary standards that often exceed regulatory minimums. These industry-led initiatives frequently address stability concerns before they become regulatory mandates, establishing best practices for formulation, encapsulation, and stability enhancement techniques.

Sustainability and Lifecycle Assessment of Quantum Dot Technologies

The sustainability assessment of quantum dot technologies reveals significant environmental considerations throughout their lifecycle. Current manufacturing processes for quantum dots often involve toxic heavy metals like cadmium and lead, raising concerns about potential environmental contamination during production, use, and disposal phases. Research indicates that improper disposal of quantum dot-containing products can lead to leaching of these hazardous materials into soil and water systems, with potential bioaccumulation in food chains.

Life cycle analyses demonstrate that quantum dot production is energy-intensive, with substantial carbon footprints primarily attributed to high-temperature synthesis processes and purification steps. A comparative study across different quantum dot types shows that indium phosphide-based alternatives, while less toxic than cadmium-based dots, still present considerable energy demands during fabrication.

Recent innovations in green synthesis approaches have shown promise in reducing environmental impacts. Water-based synthesis methods can decrease hazardous solvent usage by up to 80% compared to traditional organic solvent approaches. Additionally, biomimetic synthesis techniques utilizing plant extracts as reducing agents have demonstrated potential for creating more environmentally benign quantum dots with reduced toxicity profiles.

End-of-life management represents a critical challenge for quantum dot technologies. Current electronic waste recycling systems are inadequately equipped to handle quantum dot-containing devices, resulting in potential environmental release of nanomaterials. Research indicates that less than 5% of quantum dots in consumer electronics are currently recovered through recycling processes.

Regulatory frameworks worldwide are increasingly addressing nanomaterial sustainability. The European Union's RoHS directive has established strict limitations on cadmium content in electronic displays, driving research toward alternative quantum dot compositions. Similarly, the United States EPA has implemented reporting requirements for nanomaterials under the Toxic Substances Control Act.

Future sustainability improvements will likely emerge from circular economy approaches. Promising research directions include designing quantum dots for easier recovery and reuse, developing biologically-derived quantum dots with inherently lower toxicity, and creating closed-loop manufacturing systems that minimize waste generation. These advancements could potentially reduce the lifecycle environmental footprint of quantum dot technologies by 40-60% according to preliminary assessments.

Life cycle analyses demonstrate that quantum dot production is energy-intensive, with substantial carbon footprints primarily attributed to high-temperature synthesis processes and purification steps. A comparative study across different quantum dot types shows that indium phosphide-based alternatives, while less toxic than cadmium-based dots, still present considerable energy demands during fabrication.

Recent innovations in green synthesis approaches have shown promise in reducing environmental impacts. Water-based synthesis methods can decrease hazardous solvent usage by up to 80% compared to traditional organic solvent approaches. Additionally, biomimetic synthesis techniques utilizing plant extracts as reducing agents have demonstrated potential for creating more environmentally benign quantum dots with reduced toxicity profiles.

End-of-life management represents a critical challenge for quantum dot technologies. Current electronic waste recycling systems are inadequately equipped to handle quantum dot-containing devices, resulting in potential environmental release of nanomaterials. Research indicates that less than 5% of quantum dots in consumer electronics are currently recovered through recycling processes.

Regulatory frameworks worldwide are increasingly addressing nanomaterial sustainability. The European Union's RoHS directive has established strict limitations on cadmium content in electronic displays, driving research toward alternative quantum dot compositions. Similarly, the United States EPA has implemented reporting requirements for nanomaterials under the Toxic Substances Control Act.

Future sustainability improvements will likely emerge from circular economy approaches. Promising research directions include designing quantum dots for easier recovery and reuse, developing biologically-derived quantum dots with inherently lower toxicity, and creating closed-loop manufacturing systems that minimize waste generation. These advancements could potentially reduce the lifecycle environmental footprint of quantum dot technologies by 40-60% according to preliminary assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!