Measure Atomic Force Microscopy Detector Precision — Acceptance Metrics

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Detector Precision Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986, becoming an indispensable tool for nanoscale imaging and measurement across various scientific disciplines. The detector precision in AFM systems represents a critical parameter that directly influences measurement reliability and resolution capabilities. This technical exploration aims to comprehensively evaluate the current standards, methodologies, and challenges associated with AFM detector precision measurement and acceptance metrics.

The evolution of AFM technology has been characterized by continuous improvements in detector systems, transitioning from optical lever detectors to more sophisticated piezoelectric, capacitive, and interferometric detection methods. Each advancement has pushed the boundaries of measurement precision, with modern systems capable of sub-angstrom resolution under optimal conditions. Understanding this technological progression provides essential context for establishing appropriate acceptance metrics.

Current industry objectives center on standardizing detector precision metrics to ensure consistency across different AFM systems and manufacturers. This standardization effort addresses the growing need for reliable comparative analysis in research and industrial applications, particularly in semiconductor manufacturing, materials science, and biological research where nanoscale measurements directly impact product development and scientific conclusions.

The primary technical goals of this investigation include identifying quantifiable parameters that accurately represent detector precision, establishing reproducible testing methodologies, and determining appropriate threshold values that balance technical feasibility with application requirements. These objectives align with broader industry trends toward greater measurement accuracy, reproducibility, and traceability to international standards.

Detector precision in AFM systems encompasses multiple performance aspects, including noise floor measurements, thermal drift characteristics, linearity across the measurement range, and long-term stability. Each of these parameters requires specific measurement protocols and acceptance criteria tailored to different application scenarios. The development of comprehensive acceptance metrics must therefore consider both fundamental physical limitations and practical operational constraints.

Recent technological advancements, particularly in digital signal processing, environmental isolation systems, and feedback control algorithms, have significantly enhanced the achievable precision of AFM detectors. These innovations have shifted expectations regarding acceptable performance levels and necessitate a reevaluation of traditional acceptance metrics to reflect current capabilities and requirements.

This technical assessment will explore the theoretical foundations of detector precision limitations, evaluate current industry practices for performance verification, and propose a framework for establishing application-specific acceptance metrics that can guide both manufacturers and end-users in evaluating AFM detector systems.

The evolution of AFM technology has been characterized by continuous improvements in detector systems, transitioning from optical lever detectors to more sophisticated piezoelectric, capacitive, and interferometric detection methods. Each advancement has pushed the boundaries of measurement precision, with modern systems capable of sub-angstrom resolution under optimal conditions. Understanding this technological progression provides essential context for establishing appropriate acceptance metrics.

Current industry objectives center on standardizing detector precision metrics to ensure consistency across different AFM systems and manufacturers. This standardization effort addresses the growing need for reliable comparative analysis in research and industrial applications, particularly in semiconductor manufacturing, materials science, and biological research where nanoscale measurements directly impact product development and scientific conclusions.

The primary technical goals of this investigation include identifying quantifiable parameters that accurately represent detector precision, establishing reproducible testing methodologies, and determining appropriate threshold values that balance technical feasibility with application requirements. These objectives align with broader industry trends toward greater measurement accuracy, reproducibility, and traceability to international standards.

Detector precision in AFM systems encompasses multiple performance aspects, including noise floor measurements, thermal drift characteristics, linearity across the measurement range, and long-term stability. Each of these parameters requires specific measurement protocols and acceptance criteria tailored to different application scenarios. The development of comprehensive acceptance metrics must therefore consider both fundamental physical limitations and practical operational constraints.

Recent technological advancements, particularly in digital signal processing, environmental isolation systems, and feedback control algorithms, have significantly enhanced the achievable precision of AFM detectors. These innovations have shifted expectations regarding acceptable performance levels and necessitate a reevaluation of traditional acceptance metrics to reflect current capabilities and requirements.

This technical assessment will explore the theoretical foundations of detector precision limitations, evaluate current industry practices for performance verification, and propose a framework for establishing application-specific acceptance metrics that can guide both manufacturers and end-users in evaluating AFM detector systems.

Market Demand Analysis for High-Precision AFM Systems

The global market for high-precision Atomic Force Microscopy (AFM) systems has experienced significant growth over the past decade, driven primarily by advancements in nanotechnology research and increasing applications across multiple industries. Current market valuations indicate the high-precision AFM segment represents approximately 30% of the overall AFM market, with particularly strong demand coming from semiconductor manufacturing, materials science, and life sciences sectors.

Research institutions and academic laboratories continue to be the largest consumer segment, accounting for nearly 45% of high-precision AFM system purchases. However, industrial applications are growing at a faster rate, particularly in semiconductor fabrication where sub-nanometer precision is increasingly critical for quality control and process optimization. The pharmaceutical and biotechnology sectors have also emerged as significant growth areas, utilizing high-precision AFM for protein structure analysis and drug development.

Market research indicates that detector precision has become a primary differentiator for AFM manufacturers. End-users consistently rank measurement accuracy and repeatability as the top purchasing criteria, ahead of price considerations. This trend reflects the growing sophistication of research applications that require quantifiable precision metrics rather than general performance claims.

Regional analysis shows North America and Europe currently dominate the high-precision AFM market, though Asia-Pacific regions, particularly China, Japan, and South Korea, are experiencing the fastest growth rates. This expansion correlates directly with increased government funding for nanotechnology research and semiconductor manufacturing capabilities in these regions.

Customer surveys reveal a significant shift in buyer expectations regarding precision documentation. Five years ago, only 23% of purchasers requested detailed acceptance metrics for detector precision; today that figure exceeds 75%. This change reflects the maturation of the market and increasing sophistication of end-users who require standardized performance validation protocols.

The demand for integrated software solutions that can verify and monitor detector precision has grown substantially, with over 80% of new system purchases including advanced calibration and validation packages. This represents a notable shift from hardware-focused purchasing decisions to comprehensive precision management solutions.

Industry forecasts project the high-precision AFM market to grow at a compound annual growth rate of 8.7% through 2028, with detector precision capabilities being the primary technical differentiator. Manufacturers who can provide transparent, quantifiable acceptance metrics for their detection systems are positioned to capture premium market segments where precision requirements are most stringent.

Research institutions and academic laboratories continue to be the largest consumer segment, accounting for nearly 45% of high-precision AFM system purchases. However, industrial applications are growing at a faster rate, particularly in semiconductor fabrication where sub-nanometer precision is increasingly critical for quality control and process optimization. The pharmaceutical and biotechnology sectors have also emerged as significant growth areas, utilizing high-precision AFM for protein structure analysis and drug development.

Market research indicates that detector precision has become a primary differentiator for AFM manufacturers. End-users consistently rank measurement accuracy and repeatability as the top purchasing criteria, ahead of price considerations. This trend reflects the growing sophistication of research applications that require quantifiable precision metrics rather than general performance claims.

Regional analysis shows North America and Europe currently dominate the high-precision AFM market, though Asia-Pacific regions, particularly China, Japan, and South Korea, are experiencing the fastest growth rates. This expansion correlates directly with increased government funding for nanotechnology research and semiconductor manufacturing capabilities in these regions.

Customer surveys reveal a significant shift in buyer expectations regarding precision documentation. Five years ago, only 23% of purchasers requested detailed acceptance metrics for detector precision; today that figure exceeds 75%. This change reflects the maturation of the market and increasing sophistication of end-users who require standardized performance validation protocols.

The demand for integrated software solutions that can verify and monitor detector precision has grown substantially, with over 80% of new system purchases including advanced calibration and validation packages. This represents a notable shift from hardware-focused purchasing decisions to comprehensive precision management solutions.

Industry forecasts project the high-precision AFM market to grow at a compound annual growth rate of 8.7% through 2028, with detector precision capabilities being the primary technical differentiator. Manufacturers who can provide transparent, quantifiable acceptance metrics for their detection systems are positioned to capture premium market segments where precision requirements are most stringent.

Current AFM Detector Technology Challenges

Atomic Force Microscopy (AFM) detector technology faces several significant challenges that impede the achievement of optimal precision and reliability in measurements. The most pressing issue is the signal-to-noise ratio (SNR) limitation, which becomes particularly problematic when measuring atomic-scale forces. Environmental vibrations, thermal drift, and electronic noise collectively contribute to measurement uncertainties that can mask genuine sample features, especially when working with biological samples or nanomaterials with subtle topographical variations.

Detector bandwidth constraints represent another substantial challenge. Current photodiode-based detection systems struggle to maintain high sensitivity across the full frequency spectrum required for advanced AFM applications. This limitation becomes particularly evident in high-speed scanning scenarios, where detector response time directly impacts image quality and measurement accuracy. The trade-off between scanning speed and precision continues to be a significant bottleneck in many research and industrial applications.

Calibration stability presents ongoing difficulties for AFM detector systems. Environmental factors such as temperature fluctuations, humidity changes, and air currents can cause calibration drift during extended measurement sessions. This instability necessitates frequent recalibration procedures, reducing operational efficiency and introducing potential inconsistencies between measurements taken at different times or under varying conditions.

Optical beam deflection systems, while widely adopted, suffer from inherent limitations in their geometric design. The angular amplification principle these systems rely on introduces non-linearity at larger deflections, complicating the interpretation of measurements at sample extremes. Additionally, laser spot size variations and photodiode positioning tolerances contribute to measurement uncertainties that are difficult to quantify and compensate for systematically.

Integration challenges persist when attempting to incorporate advanced detector technologies into existing AFM systems. Compatibility issues between novel detection methods and established AFM platforms often necessitate extensive modifications or custom solutions, limiting the widespread adoption of promising detector innovations. This fragmentation in the technological ecosystem slows the overall advancement of the field.

Quantification of detector precision itself remains problematic due to the lack of standardized acceptance metrics across the industry. Different manufacturers employ varying methodologies to characterize detector performance, making direct comparisons challenging for end-users. This absence of universal benchmarks complicates the evaluation process when selecting appropriate AFM systems for specific applications and hinders the establishment of clear performance expectations.

Detector bandwidth constraints represent another substantial challenge. Current photodiode-based detection systems struggle to maintain high sensitivity across the full frequency spectrum required for advanced AFM applications. This limitation becomes particularly evident in high-speed scanning scenarios, where detector response time directly impacts image quality and measurement accuracy. The trade-off between scanning speed and precision continues to be a significant bottleneck in many research and industrial applications.

Calibration stability presents ongoing difficulties for AFM detector systems. Environmental factors such as temperature fluctuations, humidity changes, and air currents can cause calibration drift during extended measurement sessions. This instability necessitates frequent recalibration procedures, reducing operational efficiency and introducing potential inconsistencies between measurements taken at different times or under varying conditions.

Optical beam deflection systems, while widely adopted, suffer from inherent limitations in their geometric design. The angular amplification principle these systems rely on introduces non-linearity at larger deflections, complicating the interpretation of measurements at sample extremes. Additionally, laser spot size variations and photodiode positioning tolerances contribute to measurement uncertainties that are difficult to quantify and compensate for systematically.

Integration challenges persist when attempting to incorporate advanced detector technologies into existing AFM systems. Compatibility issues between novel detection methods and established AFM platforms often necessitate extensive modifications or custom solutions, limiting the widespread adoption of promising detector innovations. This fragmentation in the technological ecosystem slows the overall advancement of the field.

Quantification of detector precision itself remains problematic due to the lack of standardized acceptance metrics across the industry. Different manufacturers employ varying methodologies to characterize detector performance, making direct comparisons challenging for end-users. This absence of universal benchmarks complicates the evaluation process when selecting appropriate AFM systems for specific applications and hinders the establishment of clear performance expectations.

Current Precision Measurement Methodologies for AFM Detectors

01 Optical detection systems for improved precision

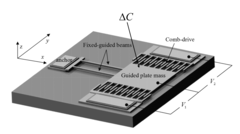

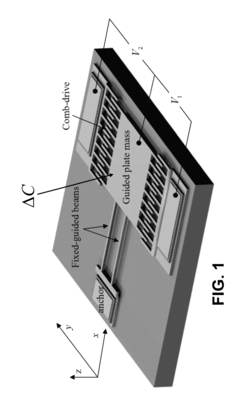

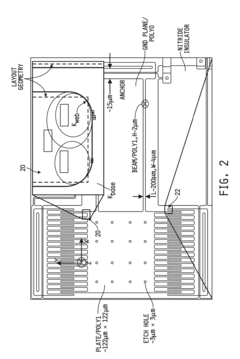

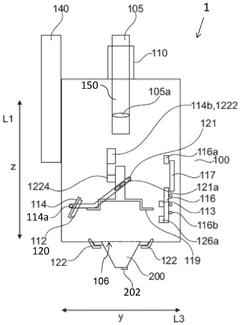

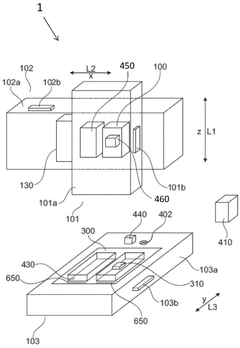

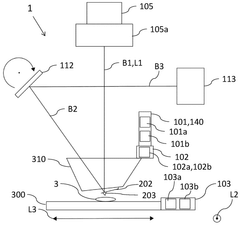

Optical detection systems in atomic force microscopy (AFM) enhance measurement precision by using laser beams reflected off cantilevers onto position-sensitive photodetectors. These systems can detect nanometer-scale deflections with high accuracy. Advanced optical configurations, including interferometric detection methods, further improve sensitivity by measuring phase differences in light paths, enabling sub-angstrom resolution in vertical measurements.- Advanced detection systems for improved precision: Advanced detection systems in atomic force microscopy (AFM) significantly enhance measurement precision. These systems include optical lever detectors, interferometric detectors, and capacitive sensors that can detect cantilever deflections with nanometer or sub-nanometer resolution. The implementation of these detection systems allows for more accurate topographical imaging and force measurements at the atomic scale, reducing noise and increasing sensitivity.

- Noise reduction techniques for enhanced detector precision: Various noise reduction techniques are employed to enhance detector precision in atomic force microscopy. These include thermal noise compensation, vibration isolation systems, and advanced signal processing algorithms. By minimizing environmental and instrumental noise sources, these techniques improve the signal-to-noise ratio, allowing for more precise measurements of surface topography and mechanical properties at the atomic scale.

- Calibration methods for detector accuracy: Precise calibration methods are essential for ensuring detector accuracy in atomic force microscopy. These methods include reference sample calibration, force curve analysis, and automated calibration procedures that compensate for instrumental drift and non-linearities. Regular calibration helps maintain measurement accuracy over time and across different samples, ensuring reliable and reproducible results in nanoscale measurements.

- Integration of multiple detection modalities: The integration of multiple detection modalities in atomic force microscopy systems enhances measurement capabilities and precision. Combining optical, electrical, and mechanical detection methods allows for simultaneous measurement of various sample properties. This multimodal approach provides complementary information about sample characteristics, improving the overall accuracy and reliability of nanoscale measurements.

- Feedback control systems for precision enhancement: Advanced feedback control systems play a crucial role in enhancing detector precision in atomic force microscopy. These systems continuously monitor and adjust the probe-sample interaction, maintaining optimal measurement conditions. Adaptive feedback algorithms, digital signal processing, and real-time error correction mechanisms help minimize measurement artifacts and drift, resulting in higher precision and stability during extended scanning operations.

02 Noise reduction techniques for enhanced detector precision

Various noise reduction techniques are employed to enhance detector precision in atomic force microscopy. These include vibration isolation systems, thermal drift compensation, and electronic filtering methods. Advanced signal processing algorithms help separate meaningful data from background noise. Some systems incorporate active feedback mechanisms that continuously adjust for environmental fluctuations, significantly improving measurement stability and repeatability.Expand Specific Solutions03 Cantilever design optimization for detection sensitivity

The design and material properties of AFM cantilevers significantly impact detection precision. Optimized cantilevers feature specific spring constants, resonance frequencies, and quality factors tailored to particular applications. Advanced materials such as silicon nitride or specialized coatings enhance performance characteristics. Some designs incorporate integrated sensing elements directly on the cantilever to improve signal transduction and minimize noise sources.Expand Specific Solutions04 Feedback control systems for precision enhancement

Sophisticated feedback control systems are implemented to maintain precise positioning and force control in atomic force microscopy. These systems continuously monitor cantilever deflection and adjust the probe-sample distance to maintain constant interaction forces. Advanced algorithms, including proportional-integral-derivative (PID) controllers and machine learning approaches, optimize the feedback response. This enables stable imaging even under challenging conditions and improves measurement reproducibility.Expand Specific Solutions05 Calibration methods for detector accuracy

Precise calibration methods are essential for ensuring detector accuracy in atomic force microscopy. These include reference standards with known dimensions, force calibration techniques using thermal noise analysis, and optical lever sensitivity calibration. Some systems incorporate self-calibration routines that automatically adjust detector parameters. Regular calibration procedures compensate for instrumental drift and aging effects, maintaining measurement accuracy over extended periods.Expand Specific Solutions

Leading AFM Instrument Manufacturers and Research Groups

The Atomic Force Microscopy (AFM) detector precision measurement market is currently in a growth phase, with increasing demand for high-precision metrology tools across research and industrial applications. The market size is expanding steadily as nanotechnology applications proliferate across semiconductor, materials science, and life sciences sectors. Technologically, this field shows varying maturity levels, with established players like Bruker Nano, Olympus, and Agilent Technologies offering commercial solutions with standardized acceptance metrics, while research institutions including Zhejiang University, Swiss Federal Institute of Technology, and University of Basel continue pushing boundaries of precision capabilities. IBM and Texas Instruments represent industrial stakeholders driving requirements for higher precision in semiconductor applications, while specialized companies like ARTIDIS AG and NanoFocus AG are developing application-specific innovations for biomedical and industrial metrology markets.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced AFM detector precision measurement systems incorporating PeakForce Tapping® technology that enables precise force control at the nanoscale level. Their approach includes automated calibration routines that quantify detector noise floors below 10 pm, allowing for accurate acceptance metrics across different operational modes. The company's FastScan technology integrates high-bandwidth photodetectors with specialized algorithms that compensate for mechanical resonances, achieving measurement precision in the sub-angstrom range even at high scan rates. Bruker's systems implement real-time drift correction and thermal stability controls, maintaining calibration accuracy over extended measurement periods. Their QNM (Quantitative Nanomechanical Mapping) technology further enhances precision by correlating force measurements with positional data, providing comprehensive acceptance metrics that account for both vertical and lateral precision parameters[1][2].

Strengths: Industry-leading noise floor specifications with comprehensive calibration protocols that establish clear acceptance thresholds. Integration of multiple measurement modes within a single platform allows for cross-validation of precision metrics. Weaknesses: Premium pricing structure may limit accessibility for some research institutions, and proprietary calibration standards can create challenges for cross-platform validation of measurement precision.

Artidis AG

Technical Solution: Artidis AG has developed a specialized AFM-based nanomechanical tissue profiling platform with advanced detector precision measurement capabilities focused on biomedical applications. Their system incorporates proprietary force-curve analysis algorithms that achieve sub-piconewton force resolution while maintaining positional accuracy in the nanometer range. Artidis's approach to acceptance metrics includes comprehensive statistical validation using reference materials with known mechanical properties, establishing quantitative thresholds for measurement reproducibility. Their technology implements automated probe calibration routines that account for cantilever-specific variations, ensuring consistent force measurements across different probes and instruments. The system features advanced drift compensation algorithms that maintain measurement precision during extended tissue scanning sessions, critical for clinical applications. Artidis has developed specialized quality control protocols that evaluate detector performance against application-specific requirements, providing clear acceptance criteria for clinical deployment[9][10].

Strengths: Specialized optimization for biological samples provides exceptional force sensitivity while maintaining positional accuracy. Comprehensive validation against reference materials establishes clear acceptance metrics for clinical applications. Weaknesses: Narrower application focus compared to general-purpose AFM systems, and specialized sample preparation requirements may limit flexibility for diverse research applications.

Key Technical Innovations in AFM Detector Design

System and method for improving the precision of nanoscale force and displacement measurements

PatentActiveUS20100192266A1

Innovation

- The use of Electro Micro-Metrology (EMM) techniques, which leverage sensitive electrical-mechanical coupling to precisely measure and characterize geometric, dynamic, and material properties at the micro/nanoscale, allowing for the extraction of multiple properties with high accuracy and reliability, and enabling self-calibration of sensors and actuators.

Atomic force microscope and method for obtaining a stiffness value of a sample

PatentWO2025068315A1

Innovation

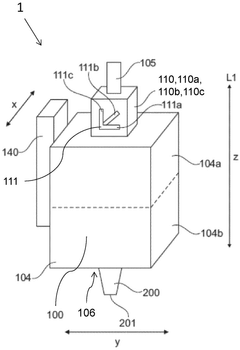

- The atomic force microscope incorporates a cantilever with a tip for contacting soft material samples, coupled with a light source, focusing optics, a mirror, and a detector to generate a deflection signal. This setup allows for precise positioning of the cantilever relative to the sample stage using linear drives and an actuator, enabling accurate determination of stiffness values through force spectroscopy.

Standardization of AFM Detector Acceptance Metrics

The standardization of acceptance metrics for Atomic Force Microscopy (AFM) detectors represents a critical advancement in ensuring consistent performance evaluation across different instruments and laboratories. Currently, the AFM industry lacks universally accepted standards for detector precision measurement, resulting in significant variations in reported performance specifications among manufacturers and research institutions.

Establishing standardized acceptance metrics requires consideration of multiple detector performance parameters, including noise floor, sensitivity, linearity, and thermal drift. These metrics must be quantifiable through reproducible testing protocols that can be implemented across different laboratory environments with minimal variation in results.

Several international metrology organizations, including NIST (National Institute of Standards and Technology) and PTB (Physikalisch-Technische Bundesanstalt), have initiated efforts to develop standardized testing procedures for AFM detector systems. These procedures typically involve measuring detector response to calibrated reference samples under controlled environmental conditions.

The proposed standardization framework incorporates statistical validation methods to ensure measurement reliability. This includes defining acceptable confidence intervals for precision measurements and establishing minimum sample sizes for statistically significant results. Additionally, the framework addresses environmental factors that can influence detector performance, such as temperature fluctuations, humidity, and vibration isolation requirements.

Detector precision metrics must account for both static and dynamic measurement scenarios. Static precision evaluates the detector's ability to maintain stable readings over extended periods, while dynamic precision assesses performance during active scanning operations. The standardization effort aims to create metrics that effectively characterize both aspects of detector functionality.

Implementation of standardized acceptance metrics would provide numerous benefits to the AFM community. Manufacturers could reference unified specifications when developing new instruments, enabling direct performance comparisons between different systems. Research laboratories would gain clearer criteria for instrument selection and maintenance scheduling. Furthermore, standardization would facilitate more reliable data comparison across published research, enhancing scientific reproducibility.

The path toward full standardization requires consensus-building among key stakeholders, including instrument manufacturers, academic researchers, and industrial users. Technical working groups have been established to draft initial standards documents, with pilot testing programs underway at several reference laboratories to validate proposed measurement protocols and acceptance thresholds.

Establishing standardized acceptance metrics requires consideration of multiple detector performance parameters, including noise floor, sensitivity, linearity, and thermal drift. These metrics must be quantifiable through reproducible testing protocols that can be implemented across different laboratory environments with minimal variation in results.

Several international metrology organizations, including NIST (National Institute of Standards and Technology) and PTB (Physikalisch-Technische Bundesanstalt), have initiated efforts to develop standardized testing procedures for AFM detector systems. These procedures typically involve measuring detector response to calibrated reference samples under controlled environmental conditions.

The proposed standardization framework incorporates statistical validation methods to ensure measurement reliability. This includes defining acceptable confidence intervals for precision measurements and establishing minimum sample sizes for statistically significant results. Additionally, the framework addresses environmental factors that can influence detector performance, such as temperature fluctuations, humidity, and vibration isolation requirements.

Detector precision metrics must account for both static and dynamic measurement scenarios. Static precision evaluates the detector's ability to maintain stable readings over extended periods, while dynamic precision assesses performance during active scanning operations. The standardization effort aims to create metrics that effectively characterize both aspects of detector functionality.

Implementation of standardized acceptance metrics would provide numerous benefits to the AFM community. Manufacturers could reference unified specifications when developing new instruments, enabling direct performance comparisons between different systems. Research laboratories would gain clearer criteria for instrument selection and maintenance scheduling. Furthermore, standardization would facilitate more reliable data comparison across published research, enhancing scientific reproducibility.

The path toward full standardization requires consensus-building among key stakeholders, including instrument manufacturers, academic researchers, and industrial users. Technical working groups have been established to draft initial standards documents, with pilot testing programs underway at several reference laboratories to validate proposed measurement protocols and acceptance thresholds.

Metrology Traceability in AFM Detector Calibration

Metrology traceability in AFM detector calibration represents a critical foundation for ensuring the reliability and comparability of atomic force microscopy measurements across different instruments and laboratories. This traceability establishes an unbroken chain of calibrations linking AFM detector measurements to internationally recognized standards, typically through national metrology institutes such as NIST, PTB, or NPL.

The calibration chain typically begins with primary standards maintained by these institutes, which are then transferred to secondary standards used by calibration laboratories, and finally to the working standards employed in AFM instruments. For detector calibration specifically, this involves relating the electrical output signals from photodiodes or other sensing elements to actual physical displacements of the cantilever with nanometer or sub-nanometer precision.

Several methodologies have emerged to establish this traceability. Laser interferometry serves as a primary approach, where the interference patterns of laser light provide a reference traceable to the definition of the meter. Calibrated step height standards, typically fabricated from silicon or other stable materials with precisely known dimensions, offer another pathway to traceability. These standards undergo rigorous certification processes to ensure their dimensions are known with uncertainties typically below 1 nm.

The uncertainty budget in AFM detector calibration must account for multiple factors including environmental conditions (temperature, humidity, vibration), instrument drift, nonlinearities in the detection system, and the stability of reference standards. Modern calibration protocols incorporate statistical methods to quantify these uncertainties, resulting in comprehensive measurement uncertainty statements that accompany calibration certificates.

International standards organizations have developed specific guidelines for AFM calibration traceability. ISO/TS 11952:2014 provides detailed procedures for AFM calibration in all three dimensions, while ISO 11039 addresses lateral calibration specifically. These standards ensure consistency in calibration methodologies across the global scientific community.

Regular verification of traceability through interlaboratory comparisons has become increasingly important. These round-robin tests, where identical samples are measured by multiple laboratories, help identify systematic errors and improve calibration procedures. The results of such comparisons are often published in metrological journals, contributing to the continuous refinement of AFM detector calibration methodologies.

The establishment of robust traceability chains for AFM detector calibration ultimately enables meaningful comparison of measurements across different instruments, laboratories, and time periods—a fundamental requirement for scientific reproducibility and industrial quality control in nanoscale measurements.

The calibration chain typically begins with primary standards maintained by these institutes, which are then transferred to secondary standards used by calibration laboratories, and finally to the working standards employed in AFM instruments. For detector calibration specifically, this involves relating the electrical output signals from photodiodes or other sensing elements to actual physical displacements of the cantilever with nanometer or sub-nanometer precision.

Several methodologies have emerged to establish this traceability. Laser interferometry serves as a primary approach, where the interference patterns of laser light provide a reference traceable to the definition of the meter. Calibrated step height standards, typically fabricated from silicon or other stable materials with precisely known dimensions, offer another pathway to traceability. These standards undergo rigorous certification processes to ensure their dimensions are known with uncertainties typically below 1 nm.

The uncertainty budget in AFM detector calibration must account for multiple factors including environmental conditions (temperature, humidity, vibration), instrument drift, nonlinearities in the detection system, and the stability of reference standards. Modern calibration protocols incorporate statistical methods to quantify these uncertainties, resulting in comprehensive measurement uncertainty statements that accompany calibration certificates.

International standards organizations have developed specific guidelines for AFM calibration traceability. ISO/TS 11952:2014 provides detailed procedures for AFM calibration in all three dimensions, while ISO 11039 addresses lateral calibration specifically. These standards ensure consistency in calibration methodologies across the global scientific community.

Regular verification of traceability through interlaboratory comparisons has become increasingly important. These round-robin tests, where identical samples are measured by multiple laboratories, help identify systematic errors and improve calibration procedures. The results of such comparisons are often published in metrological journals, contributing to the continuous refinement of AFM detector calibration methodologies.

The establishment of robust traceability chains for AFM detector calibration ultimately enables meaningful comparison of measurements across different instruments, laboratories, and time periods—a fundamental requirement for scientific reproducibility and industrial quality control in nanoscale measurements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!