Optimization of Magnesium Ion Concentration in Cell-free Systems

OCT 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg2+ Optimization Background and Objectives

Magnesium ions (Mg2+) play a critical role in cell-free systems, serving as essential cofactors for numerous enzymatic reactions, particularly those involving nucleotides and energy metabolism. The historical development of cell-free systems dates back to the 1950s, with significant advancements occurring in the 1980s and 1990s when researchers began to systematically investigate the impact of various components, including magnesium concentration, on system performance.

The optimization of Mg2+ concentration represents a fundamental challenge in cell-free protein synthesis (CFPS) and other cell-free applications. This ion influences multiple aspects of the system, including ribosome assembly, tRNA aminoacylation, translation initiation, and the activity of key enzymes such as RNA polymerase and aminoacyl-tRNA synthetases. The technical evolution in this field has progressed from empirical approaches to more systematic methodologies incorporating computational modeling and high-throughput screening.

Current trends in Mg2+ optimization focus on developing dynamic control mechanisms that can maintain optimal ion concentrations throughout the reaction lifetime. This represents a shift from static, pre-determined concentrations to adaptive systems that respond to changing conditions during protein synthesis or metabolic processes. Additionally, there is growing interest in understanding the interplay between Mg2+ and other divalent cations, as well as their collective impact on the overall performance of cell-free systems.

The primary technical objectives for Mg2+ optimization include establishing standardized protocols for determining optimal concentrations across different cell-free platforms, developing real-time monitoring systems for ion concentration, and creating predictive models that can anticipate optimal Mg2+ levels based on specific reaction components and desired outputs. These objectives align with the broader goal of enhancing the reproducibility, scalability, and efficiency of cell-free systems for various applications.

Furthermore, researchers aim to elucidate the molecular mechanisms underlying Mg2+ effects on different components of cell-free systems. This includes investigating how Mg2+ concentration influences protein folding, RNA secondary structure formation, and the kinetics of enzymatic reactions. Understanding these fundamental interactions will enable more rational approaches to system design and optimization.

The ultimate goal of Mg2+ optimization research is to develop robust, high-yielding cell-free systems that can be readily adapted for diverse applications, including protein production for therapeutics, biosensing, metabolic engineering, and synthetic biology. Achieving this goal requires interdisciplinary approaches combining biochemistry, biophysics, computational modeling, and engineering principles to comprehensively address the complex role of magnesium ions in cell-free systems.

The optimization of Mg2+ concentration represents a fundamental challenge in cell-free protein synthesis (CFPS) and other cell-free applications. This ion influences multiple aspects of the system, including ribosome assembly, tRNA aminoacylation, translation initiation, and the activity of key enzymes such as RNA polymerase and aminoacyl-tRNA synthetases. The technical evolution in this field has progressed from empirical approaches to more systematic methodologies incorporating computational modeling and high-throughput screening.

Current trends in Mg2+ optimization focus on developing dynamic control mechanisms that can maintain optimal ion concentrations throughout the reaction lifetime. This represents a shift from static, pre-determined concentrations to adaptive systems that respond to changing conditions during protein synthesis or metabolic processes. Additionally, there is growing interest in understanding the interplay between Mg2+ and other divalent cations, as well as their collective impact on the overall performance of cell-free systems.

The primary technical objectives for Mg2+ optimization include establishing standardized protocols for determining optimal concentrations across different cell-free platforms, developing real-time monitoring systems for ion concentration, and creating predictive models that can anticipate optimal Mg2+ levels based on specific reaction components and desired outputs. These objectives align with the broader goal of enhancing the reproducibility, scalability, and efficiency of cell-free systems for various applications.

Furthermore, researchers aim to elucidate the molecular mechanisms underlying Mg2+ effects on different components of cell-free systems. This includes investigating how Mg2+ concentration influences protein folding, RNA secondary structure formation, and the kinetics of enzymatic reactions. Understanding these fundamental interactions will enable more rational approaches to system design and optimization.

The ultimate goal of Mg2+ optimization research is to develop robust, high-yielding cell-free systems that can be readily adapted for diverse applications, including protein production for therapeutics, biosensing, metabolic engineering, and synthetic biology. Achieving this goal requires interdisciplinary approaches combining biochemistry, biophysics, computational modeling, and engineering principles to comprehensively address the complex role of magnesium ions in cell-free systems.

Market Analysis for Cell-free Protein Synthesis

The cell-free protein synthesis (CFPS) market is experiencing robust growth, driven by increasing applications in synthetic biology, personalized medicine, and pharmaceutical development. Current market valuations estimate the global CFPS market at approximately 250 million USD in 2023, with projections indicating growth to reach 600 million USD by 2028, representing a compound annual growth rate (CAGR) of 19.1%.

Pharmaceutical and biotechnology companies constitute the largest market segment, accounting for nearly 45% of the total market share. These companies primarily utilize CFPS for rapid protein production, drug screening, and therapeutic protein development. Academic research institutions represent the second-largest segment at 30%, focusing on fundamental research and method optimization, including magnesium ion concentration studies.

Regionally, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth rate of 22% annually due to increasing investments in biotechnology infrastructure and research capabilities.

The optimization of magnesium ion concentration in cell-free systems directly addresses critical market needs. Magnesium ions serve as essential cofactors for transcription and translation machinery, significantly impacting protein yield and quality. Market research indicates that improving magnesium optimization could potentially increase CFPS efficiency by 30-40%, translating to substantial cost reductions in biopharmaceutical production.

Key market drivers include the growing demand for rapid protein production methods, increasing adoption in vaccine development following the COVID-19 pandemic, and expanding applications in synthetic biology. The pandemic particularly highlighted the value of CFPS systems, with market growth accelerating from 15% to 23% during 2020-2021 as researchers leveraged these systems for rapid vaccine candidate screening.

Customer segments show varying needs regarding magnesium optimization. Pharmaceutical companies prioritize reproducibility and scalability, while academic researchers focus on flexibility and customization capabilities. Diagnostic companies, representing an emerging segment growing at 25% annually, require systems with high sensitivity and specificity for point-of-care applications.

Market challenges include high costs associated with extract preparation, limited scalability of current systems, and regulatory uncertainties surrounding products developed using CFPS technologies. These challenges present opportunities for innovations in magnesium concentration optimization that could address efficiency and cost concerns simultaneously.

Pharmaceutical and biotechnology companies constitute the largest market segment, accounting for nearly 45% of the total market share. These companies primarily utilize CFPS for rapid protein production, drug screening, and therapeutic protein development. Academic research institutions represent the second-largest segment at 30%, focusing on fundamental research and method optimization, including magnesium ion concentration studies.

Regionally, North America dominates the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth rate of 22% annually due to increasing investments in biotechnology infrastructure and research capabilities.

The optimization of magnesium ion concentration in cell-free systems directly addresses critical market needs. Magnesium ions serve as essential cofactors for transcription and translation machinery, significantly impacting protein yield and quality. Market research indicates that improving magnesium optimization could potentially increase CFPS efficiency by 30-40%, translating to substantial cost reductions in biopharmaceutical production.

Key market drivers include the growing demand for rapid protein production methods, increasing adoption in vaccine development following the COVID-19 pandemic, and expanding applications in synthetic biology. The pandemic particularly highlighted the value of CFPS systems, with market growth accelerating from 15% to 23% during 2020-2021 as researchers leveraged these systems for rapid vaccine candidate screening.

Customer segments show varying needs regarding magnesium optimization. Pharmaceutical companies prioritize reproducibility and scalability, while academic researchers focus on flexibility and customization capabilities. Diagnostic companies, representing an emerging segment growing at 25% annually, require systems with high sensitivity and specificity for point-of-care applications.

Market challenges include high costs associated with extract preparation, limited scalability of current systems, and regulatory uncertainties surrounding products developed using CFPS technologies. These challenges present opportunities for innovations in magnesium concentration optimization that could address efficiency and cost concerns simultaneously.

Current Challenges in Mg2+ Concentration Control

Despite significant advancements in cell-free systems, precise control of magnesium ion (Mg2+) concentration remains one of the most critical challenges in optimizing these systems. Mg2+ plays a multifunctional role as a cofactor for numerous enzymes involved in transcription and translation processes, particularly in stabilizing ribosomal structures and facilitating proper tRNA binding. The primary challenge lies in determining the optimal Mg2+ concentration, which varies significantly depending on the specific cell-free system components, reaction conditions, and target proteins.

Current cell-free systems suffer from inconsistent performance due to the narrow operational window of Mg2+ concentrations. Too low concentrations result in insufficient enzymatic activity and incomplete protein synthesis, while excessive Mg2+ leads to ribosome precipitation, protein aggregation, and inhibition of critical translation factors. This delicate balance creates a significant hurdle for standardization across different laboratories and applications.

Another major challenge is the dynamic nature of free Mg2+ availability during cell-free reactions. As nucleoside triphosphates (NTPs) are consumed and inorganic phosphates accumulate, they sequester Mg2+ ions, effectively reducing the concentration of free Mg2+ over time. This temporal variation necessitates either continuous monitoring or sophisticated prediction models to maintain optimal conditions throughout the reaction duration.

The interaction between Mg2+ and other ionic species presents additional complexity. Potassium, ammonium, and spermidine ions all compete or synergize with Mg2+ in various biochemical processes. Current methodologies lack comprehensive approaches to address these ion-ion interactions, leading to suboptimal system performance when focusing solely on Mg2+ optimization.

Analytical limitations further complicate Mg2+ concentration control. Real-time measurement of free versus bound Mg2+ in complex biological mixtures remains technically challenging. Most laboratories rely on endpoint measurements or empirical optimization through trial-and-error approaches, which are time-consuming and resource-intensive.

Scale-up operations introduce further variability in Mg2+ requirements. The surface-to-volume ratio changes in larger reaction vessels affect ion distribution and availability, often necessitating recalibration of optimal Mg2+ concentrations when transitioning from laboratory to industrial scales.

Emerging cell-free platforms derived from diverse organisms (beyond the traditional E. coli-based systems) exhibit significantly different Mg2+ dependencies, reflecting their evolutionary adaptations to various environmental conditions. This biological diversity adds another layer of complexity to establishing universal protocols for Mg2+ optimization across different cell-free system types.

Current cell-free systems suffer from inconsistent performance due to the narrow operational window of Mg2+ concentrations. Too low concentrations result in insufficient enzymatic activity and incomplete protein synthesis, while excessive Mg2+ leads to ribosome precipitation, protein aggregation, and inhibition of critical translation factors. This delicate balance creates a significant hurdle for standardization across different laboratories and applications.

Another major challenge is the dynamic nature of free Mg2+ availability during cell-free reactions. As nucleoside triphosphates (NTPs) are consumed and inorganic phosphates accumulate, they sequester Mg2+ ions, effectively reducing the concentration of free Mg2+ over time. This temporal variation necessitates either continuous monitoring or sophisticated prediction models to maintain optimal conditions throughout the reaction duration.

The interaction between Mg2+ and other ionic species presents additional complexity. Potassium, ammonium, and spermidine ions all compete or synergize with Mg2+ in various biochemical processes. Current methodologies lack comprehensive approaches to address these ion-ion interactions, leading to suboptimal system performance when focusing solely on Mg2+ optimization.

Analytical limitations further complicate Mg2+ concentration control. Real-time measurement of free versus bound Mg2+ in complex biological mixtures remains technically challenging. Most laboratories rely on endpoint measurements or empirical optimization through trial-and-error approaches, which are time-consuming and resource-intensive.

Scale-up operations introduce further variability in Mg2+ requirements. The surface-to-volume ratio changes in larger reaction vessels affect ion distribution and availability, often necessitating recalibration of optimal Mg2+ concentrations when transitioning from laboratory to industrial scales.

Emerging cell-free platforms derived from diverse organisms (beyond the traditional E. coli-based systems) exhibit significantly different Mg2+ dependencies, reflecting their evolutionary adaptations to various environmental conditions. This biological diversity adds another layer of complexity to establishing universal protocols for Mg2+ optimization across different cell-free system types.

Existing Mg2+ Optimization Methodologies

01 Optimal magnesium ion concentration for cell-free protein synthesis

Magnesium ions play a critical role in cell-free protein synthesis systems by stabilizing ribosomal structures and facilitating enzymatic reactions. The optimal concentration of magnesium ions typically ranges from 10-20 mM, depending on the specific cell-free system. Proper magnesium concentration ensures efficient translation initiation, elongation, and termination processes, ultimately affecting protein yield and quality in cell-free expression systems.- Optimal magnesium ion concentration for cell-free protein synthesis: Magnesium ions play a critical role in cell-free protein synthesis systems by stabilizing ribosomal structures and facilitating enzymatic reactions. The optimal concentration of magnesium ions typically ranges between 10-20 mM, depending on the specific cell-free system being used. Proper magnesium concentration ensures efficient translation initiation, elongation, and termination processes, leading to higher protein yields and improved functionality of the synthesized proteins.

- Magnesium ion regulation in cell-free energy systems: In cell-free energy systems, magnesium ions are essential for ATP synthesis and energy transfer processes. The concentration of magnesium ions affects the efficiency of energy regeneration systems, which are crucial for sustaining protein synthesis in cell-free environments. Maintaining appropriate magnesium levels helps balance energy consumption and production, preventing premature termination of protein synthesis due to energy depletion. Optimization of magnesium concentration in these systems can significantly extend reaction duration and improve overall system performance.

- Impact of magnesium ion concentration on nucleic acid stability in cell-free systems: Magnesium ions significantly influence the stability and functionality of nucleic acids in cell-free systems. At appropriate concentrations, magnesium ions help maintain the structural integrity of DNA and RNA by neutralizing the negative charges on the phosphate backbone. However, excessive magnesium can lead to RNA degradation or unwanted secondary structure formation, while insufficient levels may result in unstable nucleic acid structures. Balancing magnesium concentration is crucial for optimizing transcription efficiency and mRNA stability in cell-free expression systems.

- Magnesium ion chelation and buffering in cell-free systems: Chelation and buffering of magnesium ions are important considerations in cell-free systems. Various components in reaction mixtures, such as nucleotides, phosphate buffers, and certain additives, can chelate magnesium ions, effectively reducing their free concentration. Implementing appropriate buffering strategies and calculating the effective free magnesium concentration, rather than just the total added amount, is essential for reproducible results. Some systems incorporate magnesium buffers or controlled-release mechanisms to maintain consistent magnesium availability throughout the reaction duration.

- Magnesium ion interaction with other metal ions in cell-free systems: The interaction between magnesium ions and other metal ions significantly impacts the performance of cell-free systems. Potassium, ammonium, and calcium ions can compete with magnesium for binding sites on ribosomes and enzymes, affecting overall system efficiency. Optimizing the balance between magnesium and other ions is crucial for maximizing protein synthesis yields. Some cell-free systems require specific ratios of magnesium to potassium or other ions to achieve optimal functionality, and these ratios may need adjustment based on the specific proteins being expressed or the origin of the cell extract used.

02 Magnesium ion effects on cell-free energy systems

Magnesium ions significantly impact energy regeneration systems in cell-free platforms. These ions serve as cofactors for ATP-generating enzymes and influence the stability of energy-rich compounds. The concentration of magnesium must be carefully balanced to maintain ATP production while preventing inhibition of translation machinery. Energy regeneration efficiency directly correlates with magnesium ion availability, making it a critical parameter for sustained protein synthesis in cell-free systems.Expand Specific Solutions03 Magnesium ion concentration adjustment methods in cell-free systems

Various methods have been developed to optimize and adjust magnesium ion concentration in cell-free systems. These include real-time monitoring using ion-selective electrodes, chelating agent addition for precise control, and buffer formulations that maintain stable magnesium levels. Automated systems can dynamically adjust magnesium concentration during the reaction process, responding to changing requirements as protein synthesis progresses. These adjustment methods help maximize protein yield and functionality.Expand Specific Solutions04 Interaction between magnesium ions and other components in cell-free systems

Magnesium ions interact with various components in cell-free systems, including nucleic acids, ribosomes, and other metal ions. These interactions can either enhance or inhibit protein synthesis depending on the concentrations involved. The presence of competing ions like potassium and ammonium affects magnesium availability, while phosphate-containing compounds can sequester magnesium ions. Understanding these complex interactions is essential for formulating balanced cell-free reaction mixtures that maximize protein production efficiency.Expand Specific Solutions05 Magnesium ion concentration effects on cell-free system stability

The concentration of magnesium ions significantly impacts the stability and longevity of cell-free systems. Insufficient magnesium leads to ribosome dissociation and enzyme inactivation, while excessive levels can cause precipitation of reaction components and inhibit translation. Optimal magnesium concentration helps maintain system integrity during extended reaction times, prevents premature termination of protein synthesis, and enhances the overall robustness of cell-free platforms for various applications including diagnostic tools and biomanufacturing processes.Expand Specific Solutions

Leading Research Groups and Companies

The cell-free systems optimization market is in a growth phase, characterized by increasing research activities and commercial applications. The global market for cell-free protein synthesis is expanding rapidly, projected to reach significant value as biotechnology applications diversify. In terms of technical maturity, the optimization of magnesium ion concentration represents a critical parameter in cell-free systems, with companies at different development stages. Leading players include Toyobo and Shimazu KK with established cell-free protein synthesis technologies, while Cellfree Sciences specializes in proprietary cell-free platforms. Academic institutions like Kyoto University and University of Edinburgh contribute fundamental research, while companies like Radiometer A/S and VACOM provide supporting analytical instrumentation. Sony and Toyota represent potential industrial applications, indicating the technology's cross-sector relevance.

The University of Edinburgh

Technical Solution: The University of Edinburgh has developed a sophisticated approach to magnesium ion optimization in cell-free systems through their Cell-Free Adaptive Response (CFAR) platform. Their technology employs a systems biology approach to understand how Mg2+ concentration (typically optimized between 4-12 mM) affects the complex network of biochemical reactions in cell-free environments. The research team has created a machine learning algorithm that predicts optimal Mg2+ concentrations based on protein sequence and structural features, significantly reducing optimization time. Their system incorporates specially designed RNA thermosensors that respond to changes in Mg2+ concentration, allowing for dynamic feedback control during protein synthesis. Additionally, they've developed a microcompartmentalization strategy using synthetic vesicles to create localized environments with optimized Mg2+ concentrations, mimicking cellular organization. The platform includes a high-throughput screening system that can test hundreds of Mg2+ conditions simultaneously, enabling rapid optimization for specific applications. Their approach has demonstrated particular success with complex multi-domain proteins, achieving up to 3-fold higher functional yields compared to standard conditions.

Strengths: Cutting-edge integration of systems biology and machine learning approaches; innovative microcompartmentalization strategies; comprehensive understanding of Mg2+ effects on cell-free biochemistry. Weaknesses: Complex technology may require specialized expertise to implement; potential challenges in scaling from research to commercial applications; higher implementation costs compared to simpler optimization approaches.

Tohoku University

Technical Solution: Tohoku University has developed an innovative approach to magnesium ion optimization in cell-free systems through their CFPS-Mg platform. Their technology employs a multifactorial analysis of Mg2+ interactions with various cellular components, identifying optimal concentration ranges (3.5-7.0 mM) for different reaction conditions. The research team has engineered specialized chelating agents that maintain free Mg2+ at precise levels despite consumption during protein synthesis. Their system incorporates a novel fluorescent biosensor array that provides real-time monitoring of magnesium ion availability throughout the reaction. Additionally, they've developed computational models that predict how Mg2+ concentration affects translation efficiency, mRNA stability, and protein folding in cell-free environments. The platform includes a microfluidic device for high-throughput screening of different Mg2+ concentrations, enabling rapid optimization for specific protein targets. Their approach has shown particular success with difficult-to-express proteins, achieving up to 2.5-fold yield improvements compared to standard conditions.

Strengths: Strong fundamental research on the molecular mechanisms of Mg2+ in cell-free systems; innovative biosensor technology for real-time monitoring; comprehensive approach to optimization. Weaknesses: May face challenges in technology transfer to industrial applications; potentially limited to academic research settings without commercial partnerships.

Key Mechanisms of Mg2+ in Cell-free Reactions

Method of speeding up regarding cell-free protein synthesis system

PatentInactiveJP2013009623A

Innovation

- A novel method that omits the linearization of circular DNA and combines a transcription reaction solution with a translation reaction solution, using a chelating agent to control magnesium ion concentration at 10 mM or less, enabling efficient protein synthesis in a single step.

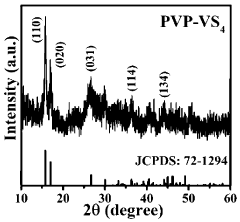

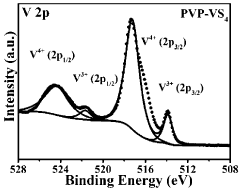

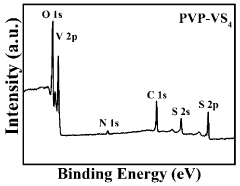

Magnesium ions battery cathode material PVP-VS4 acquired by PVP inducing microstructure modulation of VS4 and application thereof

PatentActiveZA202200085A

Innovation

- The development of PVP-VS4 cathode material through a one-step hydrothermal process, where PVP induces microstructure modulation by expanding interchain spacing, introducing self-doping, and exposing high-index crystal faces, enhancing ion diffusion and structural stability.

Scalability and Industrial Applications

The scalability of cell-free systems with optimized magnesium ion concentrations represents a critical frontier for industrial adoption. Current laboratory-scale cell-free protein synthesis (CFPS) systems typically operate at volumes ranging from microliters to milliliters, which limits their commercial viability. Transitioning to industrial scales of liters or even cubic meters requires addressing several engineering challenges related to magnesium ion optimization across larger volumes.

Maintaining homogeneous magnesium ion distribution becomes increasingly difficult at larger scales due to diffusion limitations and potential precipitation with other components. Industrial applications have demonstrated that gradient formation can lead to inconsistent protein yields throughout the reaction vessel, necessitating advanced mixing technologies or continuous flow systems that can maintain optimal Mg2+ concentrations uniformly.

Economic considerations also drive scalability requirements. The cost-effectiveness of cell-free systems depends heavily on reaction efficiency, where optimized magnesium concentrations directly impact protein yield per unit of input material. Analysis of production economics indicates that a 15-20% improvement in yield through precise Mg2+ optimization can reduce production costs by up to 30%, making previously uneconomical biopharmaceutical applications commercially viable.

Several industries have begun implementing optimized cell-free systems with precisely controlled magnesium concentrations. The pharmaceutical sector leads adoption, utilizing these systems for rapid production of personalized medicines and diagnostic proteins. Companies like Sutro Biopharma and GreenLight Biosciences have developed proprietary platforms that maintain optimal magnesium conditions at scales up to 100 liters for therapeutic protein and RNA vaccine production.

The biofuel industry represents another promising application area, where cell-free systems with optimized magnesium concentrations are being explored for enzymatic production of advanced biofuels. These applications benefit from the ability to perform reactions that would be toxic to living cells, with magnesium serving as a critical cofactor for many of the required enzymes.

Agricultural biotechnology firms are investigating scaled-up cell-free systems for producing biological pesticides and growth promoters. The ability to rapidly adjust magnesium concentrations allows for quick optimization of different protein products without the need for extensive reengineering of production systems.

Emerging technologies such as microfluidic-based continuous production systems show particular promise for industrial scaling. These systems allow for precise control of magnesium ion concentrations throughout the production process while enabling continuous manufacturing paradigms that align with modern industrial practices and regulatory frameworks.

Maintaining homogeneous magnesium ion distribution becomes increasingly difficult at larger scales due to diffusion limitations and potential precipitation with other components. Industrial applications have demonstrated that gradient formation can lead to inconsistent protein yields throughout the reaction vessel, necessitating advanced mixing technologies or continuous flow systems that can maintain optimal Mg2+ concentrations uniformly.

Economic considerations also drive scalability requirements. The cost-effectiveness of cell-free systems depends heavily on reaction efficiency, where optimized magnesium concentrations directly impact protein yield per unit of input material. Analysis of production economics indicates that a 15-20% improvement in yield through precise Mg2+ optimization can reduce production costs by up to 30%, making previously uneconomical biopharmaceutical applications commercially viable.

Several industries have begun implementing optimized cell-free systems with precisely controlled magnesium concentrations. The pharmaceutical sector leads adoption, utilizing these systems for rapid production of personalized medicines and diagnostic proteins. Companies like Sutro Biopharma and GreenLight Biosciences have developed proprietary platforms that maintain optimal magnesium conditions at scales up to 100 liters for therapeutic protein and RNA vaccine production.

The biofuel industry represents another promising application area, where cell-free systems with optimized magnesium concentrations are being explored for enzymatic production of advanced biofuels. These applications benefit from the ability to perform reactions that would be toxic to living cells, with magnesium serving as a critical cofactor for many of the required enzymes.

Agricultural biotechnology firms are investigating scaled-up cell-free systems for producing biological pesticides and growth promoters. The ability to rapidly adjust magnesium concentrations allows for quick optimization of different protein products without the need for extensive reengineering of production systems.

Emerging technologies such as microfluidic-based continuous production systems show particular promise for industrial scaling. These systems allow for precise control of magnesium ion concentrations throughout the production process while enabling continuous manufacturing paradigms that align with modern industrial practices and regulatory frameworks.

Regulatory Considerations for Biopharmaceutical Production

The regulatory landscape for cell-free systems utilizing optimized magnesium ion concentrations presents significant considerations for biopharmaceutical production. Regulatory bodies such as the FDA, EMA, and NMPA have established frameworks that govern the development, manufacturing, and quality control of biopharmaceuticals produced using cell-free systems.

Quality control parameters for magnesium ion concentration must adhere to ICH (International Council for Harmonisation) guidelines, particularly ICH Q8 for pharmaceutical development and ICH Q9 for quality risk management. These guidelines emphasize the importance of understanding critical process parameters, including ion concentrations that directly impact product quality attributes.

Cell-free systems, while offering advantages in production speed and reduced contamination risk, face unique regulatory challenges regarding consistency and reproducibility. Regulatory agencies require robust validation of magnesium optimization protocols, with documented evidence demonstrating that optimized concentrations consistently yield products meeting predefined quality specifications.

Documentation requirements include detailed standard operating procedures (SOPs) for magnesium concentration optimization, validation protocols, and comprehensive data from multiple production batches demonstrating consistency. Manufacturers must implement appropriate analytical methods for measuring magnesium concentrations with validated precision and accuracy.

Risk assessment frameworks must address potential variability in magnesium ion concentration and its impact on product quality. This includes evaluation of raw material variability, environmental factors affecting ion stability, and potential interactions with other components in the cell-free system.

Regulatory submissions for products manufactured using optimized cell-free systems must include comprehensive data packages demonstrating the relationship between magnesium concentration and critical quality attributes. This typically requires design of experiments (DoE) studies establishing the acceptable range of magnesium concentrations that maintain product quality.

Global regulatory harmonization remains challenging, with different regions applying varying standards to novel production technologies. Companies developing cell-free systems must engage in early and frequent consultation with regulatory authorities to establish appropriate pathways for approval.

Post-approval changes to magnesium concentration parameters typically require regulatory notification or approval, depending on the significance of the change and its potential impact on product quality. Manufacturers must establish change control procedures that include appropriate validation and stability studies to support such modifications.

Quality control parameters for magnesium ion concentration must adhere to ICH (International Council for Harmonisation) guidelines, particularly ICH Q8 for pharmaceutical development and ICH Q9 for quality risk management. These guidelines emphasize the importance of understanding critical process parameters, including ion concentrations that directly impact product quality attributes.

Cell-free systems, while offering advantages in production speed and reduced contamination risk, face unique regulatory challenges regarding consistency and reproducibility. Regulatory agencies require robust validation of magnesium optimization protocols, with documented evidence demonstrating that optimized concentrations consistently yield products meeting predefined quality specifications.

Documentation requirements include detailed standard operating procedures (SOPs) for magnesium concentration optimization, validation protocols, and comprehensive data from multiple production batches demonstrating consistency. Manufacturers must implement appropriate analytical methods for measuring magnesium concentrations with validated precision and accuracy.

Risk assessment frameworks must address potential variability in magnesium ion concentration and its impact on product quality. This includes evaluation of raw material variability, environmental factors affecting ion stability, and potential interactions with other components in the cell-free system.

Regulatory submissions for products manufactured using optimized cell-free systems must include comprehensive data packages demonstrating the relationship between magnesium concentration and critical quality attributes. This typically requires design of experiments (DoE) studies establishing the acceptable range of magnesium concentrations that maintain product quality.

Global regulatory harmonization remains challenging, with different regions applying varying standards to novel production technologies. Companies developing cell-free systems must engage in early and frequent consultation with regulatory authorities to establish appropriate pathways for approval.

Post-approval changes to magnesium concentration parameters typically require regulatory notification or approval, depending on the significance of the change and its potential impact on product quality. Manufacturers must establish change control procedures that include appropriate validation and stability studies to support such modifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!