Patents Influencing Quantum Dot Stability in Displays

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Display Technology Evolution and Objectives

Quantum dot display technology has evolved significantly since the discovery of quantum dots (QDs) in the early 1980s. Initially, these semiconductor nanocrystals were primarily studied for their unique optical properties, including size-dependent emission wavelengths and high quantum yields. The journey from laboratory curiosity to commercial display technology spans several decades, with key milestones marking the transition from theoretical understanding to practical implementation.

The first major breakthrough came in the 1990s when researchers demonstrated controlled synthesis methods for producing uniform QDs with predictable optical characteristics. This period established the fundamental relationship between QD size and emission color, laying the groundwork for their application in display technologies. By the early 2000s, the focus shifted toward enhancing quantum yield and developing surface passivation techniques to improve stability—a critical challenge that continues to influence patent activity today.

The mid-2000s witnessed the emergence of the first QD-enhanced LCD prototypes, where QDs were incorporated into display backlighting systems to improve color gamut. This period marked the transition from purely academic research to commercial development, with companies like QD Vision and Nanosys pioneering early implementations. By 2013, the first commercial QD-enhanced televisions reached the market, signaling the technology's commercial viability despite ongoing stability challenges.

Recent technological evolution has focused intensively on addressing quantum dot stability issues, which represent the primary barrier to widespread adoption and longevity of QD displays. Patent activity in this area has accelerated dramatically since 2015, with innovations targeting environmental sensitivity, photo-oxidation resistance, and thermal degradation prevention. These patents reflect the industry's recognition that stability is paramount for commercial success.

The current technological objectives center on developing quantum dots that maintain performance under the harsh operating conditions of displays, including prolonged exposure to blue light, elevated temperatures, and environmental factors like oxygen and moisture. Specifically, the industry aims to achieve QD formulations with operational lifetimes exceeding 30,000 hours without significant degradation in color purity or brightness—a benchmark necessary to compete with established display technologies.

Looking forward, the evolution trajectory points toward fully integrated quantum dot displays, potentially including electroluminescent quantum dot (ELQD) technologies that eliminate the need for backlighting systems altogether. This represents the ultimate goal of QD display technology: self-emissive quantum dot pixels that offer perfect black levels, wide color gamut, and energy efficiency while maintaining long-term stability under real-world operating conditions.

The first major breakthrough came in the 1990s when researchers demonstrated controlled synthesis methods for producing uniform QDs with predictable optical characteristics. This period established the fundamental relationship between QD size and emission color, laying the groundwork for their application in display technologies. By the early 2000s, the focus shifted toward enhancing quantum yield and developing surface passivation techniques to improve stability—a critical challenge that continues to influence patent activity today.

The mid-2000s witnessed the emergence of the first QD-enhanced LCD prototypes, where QDs were incorporated into display backlighting systems to improve color gamut. This period marked the transition from purely academic research to commercial development, with companies like QD Vision and Nanosys pioneering early implementations. By 2013, the first commercial QD-enhanced televisions reached the market, signaling the technology's commercial viability despite ongoing stability challenges.

Recent technological evolution has focused intensively on addressing quantum dot stability issues, which represent the primary barrier to widespread adoption and longevity of QD displays. Patent activity in this area has accelerated dramatically since 2015, with innovations targeting environmental sensitivity, photo-oxidation resistance, and thermal degradation prevention. These patents reflect the industry's recognition that stability is paramount for commercial success.

The current technological objectives center on developing quantum dots that maintain performance under the harsh operating conditions of displays, including prolonged exposure to blue light, elevated temperatures, and environmental factors like oxygen and moisture. Specifically, the industry aims to achieve QD formulations with operational lifetimes exceeding 30,000 hours without significant degradation in color purity or brightness—a benchmark necessary to compete with established display technologies.

Looking forward, the evolution trajectory points toward fully integrated quantum dot displays, potentially including electroluminescent quantum dot (ELQD) technologies that eliminate the need for backlighting systems altogether. This represents the ultimate goal of QD display technology: self-emissive quantum dot pixels that offer perfect black levels, wide color gamut, and energy efficiency while maintaining long-term stability under real-world operating conditions.

Market Analysis of Quantum Dot Display Applications

The quantum dot display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for superior display technologies with enhanced color performance and energy efficiency. The global quantum dot display market was valued at approximately $4.2 billion in 2022 and is projected to reach $18.6 billion by 2028, representing a compound annual growth rate (CAGR) of 28.3% during the forecast period.

Television remains the dominant application segment, accounting for over 65% of the quantum dot display market. Major manufacturers including Samsung, LG, TCL, and Sony have incorporated quantum dot technology into their premium television lineups, with Samsung's QLED series being particularly successful in commercial markets. The enhanced color gamut and brightness capabilities of quantum dot displays have positioned them as a compelling alternative to OLED technology in the high-end television segment.

The monitor and laptop segment represents the fastest-growing application area, with a CAGR exceeding 32%. This growth is primarily driven by increasing demand for high-performance displays in gaming, content creation, and professional applications. Companies like ASUS, Acer, and Dell have launched quantum dot monitors targeting professional designers and gamers who require exceptional color accuracy and visual performance.

Smartphone and tablet applications are emerging as significant growth opportunities, particularly in the premium device segment. While currently representing less than 10% of the quantum dot display market, this segment is expected to expand substantially as manufacturers seek differentiation through enhanced visual experiences in mobile devices.

Automotive displays represent another promising application area, with luxury vehicle manufacturers incorporating quantum dot technology into dashboard displays and entertainment systems. The automotive segment is projected to grow at a CAGR of 26% through 2028, driven by increasing consumer expectations for in-vehicle technology experiences.

Geographically, North America and Asia-Pacific dominate the quantum dot display market, collectively accounting for approximately 75% of global market share. China, South Korea, Japan, and the United States represent the largest individual markets, reflecting the concentration of display manufacturing capabilities and consumer electronics demand in these regions.

The market dynamics are significantly influenced by patent portfolios related to quantum dot stability. Companies with strong intellectual property positions in encapsulation technologies, heavy metal-free quantum dot formulations, and manufacturing processes have established competitive advantages in commercialization efforts. This patent landscape has shaped market entry strategies and partnership formations throughout the industry.

Television remains the dominant application segment, accounting for over 65% of the quantum dot display market. Major manufacturers including Samsung, LG, TCL, and Sony have incorporated quantum dot technology into their premium television lineups, with Samsung's QLED series being particularly successful in commercial markets. The enhanced color gamut and brightness capabilities of quantum dot displays have positioned them as a compelling alternative to OLED technology in the high-end television segment.

The monitor and laptop segment represents the fastest-growing application area, with a CAGR exceeding 32%. This growth is primarily driven by increasing demand for high-performance displays in gaming, content creation, and professional applications. Companies like ASUS, Acer, and Dell have launched quantum dot monitors targeting professional designers and gamers who require exceptional color accuracy and visual performance.

Smartphone and tablet applications are emerging as significant growth opportunities, particularly in the premium device segment. While currently representing less than 10% of the quantum dot display market, this segment is expected to expand substantially as manufacturers seek differentiation through enhanced visual experiences in mobile devices.

Automotive displays represent another promising application area, with luxury vehicle manufacturers incorporating quantum dot technology into dashboard displays and entertainment systems. The automotive segment is projected to grow at a CAGR of 26% through 2028, driven by increasing consumer expectations for in-vehicle technology experiences.

Geographically, North America and Asia-Pacific dominate the quantum dot display market, collectively accounting for approximately 75% of global market share. China, South Korea, Japan, and the United States represent the largest individual markets, reflecting the concentration of display manufacturing capabilities and consumer electronics demand in these regions.

The market dynamics are significantly influenced by patent portfolios related to quantum dot stability. Companies with strong intellectual property positions in encapsulation technologies, heavy metal-free quantum dot formulations, and manufacturing processes have established competitive advantages in commercialization efforts. This patent landscape has shaped market entry strategies and partnership formations throughout the industry.

Current Stability Challenges in Quantum Dot Technology

Quantum dot (QD) technology has revolutionized display applications with its superior color performance and energy efficiency. However, stability remains a critical challenge that impedes widespread commercial adoption. The primary stability issues stem from the inherent chemical and physical properties of quantum dots, particularly their susceptibility to oxidation, photobleaching, and thermal degradation when exposed to operational conditions.

Oxidation represents one of the most significant challenges, as quantum dots typically contain materials like cadmium selenide (CdSe) or indium phosphide (InP) that readily react with oxygen. This oxidation process leads to the formation of surface defects that act as non-radiative recombination centers, dramatically reducing quantum yield and shifting emission wavelengths over time.

Photobleaching occurs when quantum dots are exposed to continuous illumination, causing photochemical reactions that permanently damage their structure. This is particularly problematic in display applications where QDs must withstand thousands of hours of operation while maintaining consistent optical properties. Patent literature reveals that photobleaching rates accelerate significantly at higher brightness levels, creating a fundamental trade-off between display luminance and longevity.

Thermal stability presents another major hurdle, as quantum dots exhibit decreased efficiency at elevated temperatures. During display operation, temperatures can reach 80-100°C, causing structural changes in the QD core-shell architecture. Patents from leading manufacturers indicate that thermal degradation manifests as broadened emission spectra, decreased quantum yield, and color shift—all detrimental to display quality.

The encapsulation of quantum dots within display components introduces additional stability challenges. Current manufacturing processes struggle to create hermetic barriers that completely isolate QDs from environmental factors while maintaining optical transparency and flexibility. Patent analysis shows that moisture ingress through encapsulation layers remains a persistent problem, with water molecules catalyzing degradation reactions at the quantum dot surface.

Blue light stability represents a particular challenge for red and green quantum dots in LCD backlighting applications. These QDs must absorb high-energy blue light and downconvert it to longer wavelengths, but this process accelerates degradation. Recent patents focus on core-shell structures with thicker shells and gradient composition to mitigate this effect, though complete resolution remains elusive.

The stability challenges are further complicated by the industry's shift toward cadmium-free quantum dots in response to environmental regulations like RoHS. Alternative materials such as InP typically demonstrate lower initial performance and even greater stability issues, creating a significant technical barrier that numerous patents attempt to address through novel surface chemistry and passivation techniques.

Oxidation represents one of the most significant challenges, as quantum dots typically contain materials like cadmium selenide (CdSe) or indium phosphide (InP) that readily react with oxygen. This oxidation process leads to the formation of surface defects that act as non-radiative recombination centers, dramatically reducing quantum yield and shifting emission wavelengths over time.

Photobleaching occurs when quantum dots are exposed to continuous illumination, causing photochemical reactions that permanently damage their structure. This is particularly problematic in display applications where QDs must withstand thousands of hours of operation while maintaining consistent optical properties. Patent literature reveals that photobleaching rates accelerate significantly at higher brightness levels, creating a fundamental trade-off between display luminance and longevity.

Thermal stability presents another major hurdle, as quantum dots exhibit decreased efficiency at elevated temperatures. During display operation, temperatures can reach 80-100°C, causing structural changes in the QD core-shell architecture. Patents from leading manufacturers indicate that thermal degradation manifests as broadened emission spectra, decreased quantum yield, and color shift—all detrimental to display quality.

The encapsulation of quantum dots within display components introduces additional stability challenges. Current manufacturing processes struggle to create hermetic barriers that completely isolate QDs from environmental factors while maintaining optical transparency and flexibility. Patent analysis shows that moisture ingress through encapsulation layers remains a persistent problem, with water molecules catalyzing degradation reactions at the quantum dot surface.

Blue light stability represents a particular challenge for red and green quantum dots in LCD backlighting applications. These QDs must absorb high-energy blue light and downconvert it to longer wavelengths, but this process accelerates degradation. Recent patents focus on core-shell structures with thicker shells and gradient composition to mitigate this effect, though complete resolution remains elusive.

The stability challenges are further complicated by the industry's shift toward cadmium-free quantum dots in response to environmental regulations like RoHS. Alternative materials such as InP typically demonstrate lower initial performance and even greater stability issues, creating a significant technical barrier that numerous patents attempt to address through novel surface chemistry and passivation techniques.

Current Approaches to Quantum Dot Stability Improvement

01 Surface modification for quantum dot stability

Surface modification techniques can significantly enhance the stability of quantum dots. These methods include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. Such modifications can prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification for enhanced stability: Surface modification techniques are employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. Such modifications protect the quantum dots from oxidation, aggregation, and environmental degradation, thereby improving their long-term stability and performance in various applications.

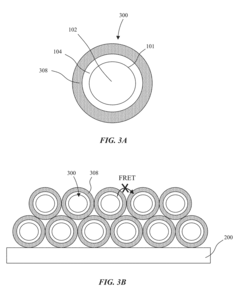

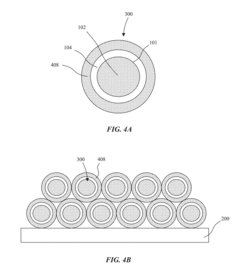

- Core-shell structures for improved stability: Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. The shell material, often a semiconductor with a wider bandgap than the core, prevents oxidation and surface defects while maintaining the optical and electronic properties of the quantum dots. This architecture improves photostability, thermal stability, and chemical resistance in various environmental conditions.

- Polymer encapsulation methods: Polymer encapsulation provides a robust approach to stabilizing quantum dots by embedding them within polymer matrices or coating them with polymer layers. This technique shields quantum dots from oxygen, moisture, and other environmental factors that can cause degradation. The polymer encapsulation also enables better dispersion in various solvents and integration into different material systems while maintaining the optical and electronic properties of the quantum dots.

- Stabilization in solution and colloidal systems: Stabilization of quantum dots in solution and colloidal systems involves controlling the surface chemistry and environmental conditions to prevent aggregation and precipitation. This includes pH adjustment, ionic strength control, and addition of stabilizing agents. Proper solvent selection and surface ligand engineering are crucial for maintaining colloidal stability, which is essential for applications requiring well-dispersed quantum dots such as biological imaging, sensing, and solution-processed electronics.

- Environmental and thermal stability enhancement: Techniques to improve the environmental and thermal stability of quantum dots focus on making them resistant to degradation under varying conditions such as high temperature, humidity, and light exposure. These include specialized annealing processes, incorporation of stabilizing additives, and development of robust encapsulation materials. Enhanced environmental stability is critical for quantum dot applications in displays, lighting, and photovoltaics where long-term performance under challenging conditions is required.

02 Core-shell structures for enhanced stability

Core-shell quantum dot structures provide enhanced stability by protecting the core material from environmental factors. The shell material, often composed of wider bandgap semiconductors, creates a physical barrier that prevents oxidation and degradation of the core. These structures can be engineered with multiple shell layers or gradient compositions to further improve stability while maintaining desired optical and electronic properties.Expand Specific Solutions03 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides protection from environmental factors that cause degradation. These encapsulation methods create a barrier against oxygen, moisture, and other reactive species while preserving the optical and electronic properties of the quantum dots. Various encapsulation techniques can be tailored for specific applications, from displays to biomedical imaging.Expand Specific Solutions04 Chemical composition optimization for stability

Optimizing the chemical composition of quantum dots can inherently improve their stability. This includes adjusting the ratio of constituent elements, doping with specific atoms, and controlling the synthesis parameters to create more robust quantum dot structures. Certain compositions demonstrate superior resistance to photobleaching, thermal degradation, and chemical attack, resulting in quantum dots with extended lifespans and consistent performance.Expand Specific Solutions05 Environmental control systems for quantum dot preservation

Environmental control systems can be implemented to maintain quantum dot stability during storage, processing, and application. These systems include oxygen-free environments, controlled humidity conditions, temperature regulation, and protection from UV radiation. By controlling these environmental factors, the degradation mechanisms that affect quantum dots can be minimized, extending their useful lifetime and preserving their unique optical and electronic properties.Expand Specific Solutions

Leading Companies in Quantum Dot Display Industry

The quantum dot stability in displays market is currently in a growth phase, with increasing adoption across the industry. The market size is expanding rapidly as quantum dot technology offers superior color performance and energy efficiency compared to traditional display technologies. Technologically, the field is maturing but still faces challenges in long-term stability and manufacturing scalability. Leading players include Samsung Display and Samsung Electronics, who have established strong patent portfolios, while BOE Technology Group and TCL China Star Optoelectronics are rapidly advancing their capabilities. Japanese firms like Sharp and Japan Display maintain significant intellectual property positions. Western companies including 3M Innovative Properties, Apple, and Corning contribute specialized innovations, while emerging players like Avantama and Najing Technology focus on quantum dot materials development, creating a competitive landscape with diverse technological approaches.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has pioneered quantum dot stability enhancement through their patented core-shell structure optimization techniques. Their technology focuses on creating gradient alloy interfaces between the core and shell materials to minimize lattice mismatch stress, which is a primary cause of QD degradation over time. BOE's patents describe specialized surface ligand exchange processes that replace conventional organic ligands with more robust hybrid organic-inorganic compounds, significantly improving thermal stability up to 150°C. The company has developed proprietary encapsulation methods using atomic layer deposition to create hermetic barrier films that protect QDs from oxygen and moisture. Their recent innovations include integration of quantum dots into specialized polymer matrices with reactive functional groups that chemically bond to the QD surface, preventing aggregation while maintaining high quantum yield even after prolonged high-temperature and high-humidity testing.

Strengths: Exceptional environmental stability allowing integration into various display manufacturing processes; superior resistance to photo-oxidation extending display lifetime; compatibility with existing manufacturing equipment reducing implementation costs. Weaknesses: Some solutions require additional processing steps increasing production time; certain stabilization additives may slightly reduce initial quantum efficiency; technology optimization still needed for flexible display applications.

3M Innovative Properties Co.

Technical Solution: 3M has developed specialized quantum dot stabilization technologies focused on polymer encapsulation and barrier film approaches. Their patents describe innovative methods for dispersing quantum dots within carefully engineered polymer matrices that provide both mechanical protection and chemical isolation. 3M's technology employs proprietary cross-linkable polymers with functional groups designed to interact with quantum dot surfaces, creating stable chemical bonds that prevent migration and aggregation. Their barrier film technology incorporates multiple alternating inorganic and organic layers with precisely controlled thickness to create an effective oxygen and moisture barrier while maintaining optical transparency. 3M has also patented unique surface modification techniques using fluorinated ligands that significantly enhance QD resistance to environmental degradation. Their quantum dot films incorporate specialized UV absorbers and antioxidants strategically positioned to intercept degradation triggers before they reach the quantum dots, extending stability under high-intensity display operating conditions.

Strengths: Excellent scalability for mass production; superior barrier properties against environmental contaminants; compatibility with various display architectures including LCD and OLED. Weaknesses: Some solutions add complexity to the optical stack potentially affecting display thickness; certain polymer encapsulants may yellow slightly over extended time periods; optimization still needed for highest-brightness applications.

Key Patents Analysis for Quantum Dot Stability Solutions

Crosslinked emissive layer containing quantum dots for light-emitting device and method for making same

PatentActiveUS20200144527A1

Innovation

- A light-emitting device is developed with a crosslinked emissive layer containing quantum dots dispersed in a matrix formed from crosslinkable charge transport materials, which are crosslinked using UV activation, enhancing stability and performance by protecting the quantum dots from environmental factors and improving their packing density.

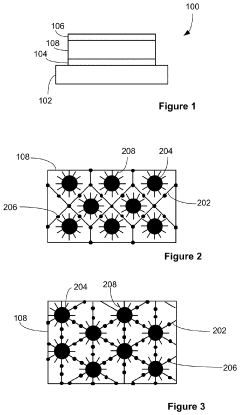

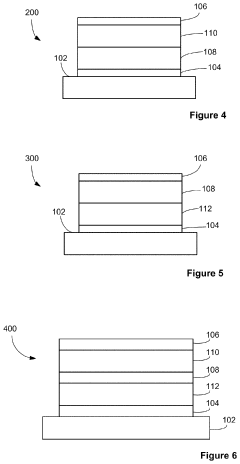

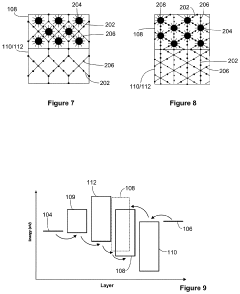

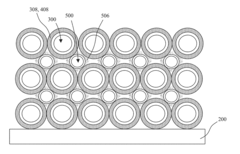

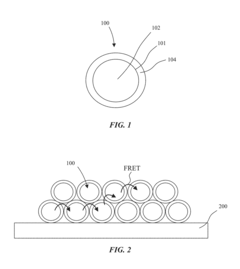

Quantum dot spacing for high efficiency quantum dot LED displays

PatentActiveUS20180019371A1

Innovation

- Engineering QD films with quantum dots separated by a distance of 0.5-10 nm, using metal oxide coatings or core-material coatings to reduce FRET, thereby increasing the efficiency and stability of QD-LED devices.

Environmental and Regulatory Considerations for Quantum Dot Materials

The quantum dot display industry faces significant environmental and regulatory challenges that directly impact technology development and market adoption. Cadmium-based quantum dots, despite their superior performance characteristics, have been increasingly restricted under regulations such as the European Union's Restriction of Hazardous Substances (RoHS) Directive, which limits cadmium content to 100 ppm in electronic devices. This regulatory landscape has driven substantial patent activity focused on developing cadmium-free alternatives and encapsulation technologies that prevent toxic material leakage.

Environmental considerations have become paramount as quantum dot manufacturers navigate complex global regulatory frameworks. Patents from leading companies like Samsung, Nanosys, and QD Vision reveal strategic approaches to addressing these challenges through material innovation. These patents frequently focus on heavy metal reduction or elimination while maintaining display performance, with particular emphasis on substituting indium phosphide, zinc selenide, or other less toxic materials for traditional cadmium selenide quantum dots.

Encapsulation technologies represent another significant area of patent activity, with innovations centered on preventing quantum dot degradation from environmental exposure while simultaneously containing potentially harmful materials. Multi-layer barrier technologies that combine organic and inorganic materials have emerged as a dominant approach, with patents describing sophisticated structures that balance environmental protection with optical performance.

Waste management and end-of-life considerations have also influenced patent development, particularly regarding the recyclability of quantum dot components. Several patents address manufacturing processes designed to facilitate the recovery of valuable materials while preventing environmental contamination. These innovations reflect growing regulatory pressure for extended producer responsibility and circular economy principles in electronics manufacturing.

Water and energy consumption during quantum dot production represents another environmental concern addressed in recent patents. Innovations in synthesis methods that reduce solvent use, lower reaction temperatures, and minimize energy requirements demonstrate the industry's response to sustainability demands. Patents describing continuous flow synthesis methods and aqueous-based production techniques highlight efforts to develop more environmentally benign manufacturing processes.

The global regulatory landscape continues to evolve, with different regions implementing varying standards for quantum dot materials. This regulatory fragmentation has spurred patents for adaptable quantum dot formulations that can be modified to meet diverse requirements across international markets. Such flexibility has become a competitive advantage for companies operating in multiple jurisdictions, as evidenced by patents describing modular quantum dot systems with interchangeable components based on regional regulations.

Environmental considerations have become paramount as quantum dot manufacturers navigate complex global regulatory frameworks. Patents from leading companies like Samsung, Nanosys, and QD Vision reveal strategic approaches to addressing these challenges through material innovation. These patents frequently focus on heavy metal reduction or elimination while maintaining display performance, with particular emphasis on substituting indium phosphide, zinc selenide, or other less toxic materials for traditional cadmium selenide quantum dots.

Encapsulation technologies represent another significant area of patent activity, with innovations centered on preventing quantum dot degradation from environmental exposure while simultaneously containing potentially harmful materials. Multi-layer barrier technologies that combine organic and inorganic materials have emerged as a dominant approach, with patents describing sophisticated structures that balance environmental protection with optical performance.

Waste management and end-of-life considerations have also influenced patent development, particularly regarding the recyclability of quantum dot components. Several patents address manufacturing processes designed to facilitate the recovery of valuable materials while preventing environmental contamination. These innovations reflect growing regulatory pressure for extended producer responsibility and circular economy principles in electronics manufacturing.

Water and energy consumption during quantum dot production represents another environmental concern addressed in recent patents. Innovations in synthesis methods that reduce solvent use, lower reaction temperatures, and minimize energy requirements demonstrate the industry's response to sustainability demands. Patents describing continuous flow synthesis methods and aqueous-based production techniques highlight efforts to develop more environmentally benign manufacturing processes.

The global regulatory landscape continues to evolve, with different regions implementing varying standards for quantum dot materials. This regulatory fragmentation has spurred patents for adaptable quantum dot formulations that can be modified to meet diverse requirements across international markets. Such flexibility has become a competitive advantage for companies operating in multiple jurisdictions, as evidenced by patents describing modular quantum dot systems with interchangeable components based on regional regulations.

Manufacturing Process Innovations for Stable Quantum Dot Displays

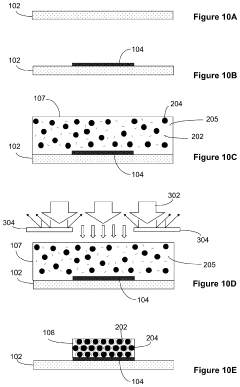

Manufacturing process innovations have been pivotal in addressing quantum dot stability challenges in display technologies. Recent patent filings reveal significant advancements in encapsulation techniques, with major display manufacturers developing multi-layer barrier structures that effectively shield quantum dots from oxygen and moisture. These innovations typically employ alternating organic and inorganic layers, creating tortuous paths that dramatically reduce permeation rates while maintaining optical clarity.

A notable manufacturing breakthrough comes from solution-processing methods that enable quantum dot integration directly into existing display production lines. Patents from Samsung and Nanosys describe proprietary processes for incorporating quantum dots into photoresist materials, allowing for direct patterning through conventional photolithography. This approach eliminates several manufacturing steps while enhancing dot uniformity and reducing exposure to environmental degradants.

Temperature management during manufacturing has emerged as another critical innovation area. Several patents detail precise thermal control systems that maintain optimal conditions throughout the quantum dot deposition and curing processes. These systems prevent thermal degradation while ensuring complete solvent removal, addressing a significant cause of long-term stability issues in earlier generation displays.

Surface treatment technologies represent another significant advancement, with patents describing novel ligand exchange processes that enhance quantum dot-polymer compatibility. These treatments create stronger bonds between dots and host matrices, reducing migration and aggregation that typically lead to efficiency losses and color shifts over time. Companies like Quantum Materials Corp have developed automated ligand exchange systems that maintain inert environments throughout the process.

Cross-linking innovations have also contributed substantially to stability improvements. Recent patents describe photo-initiated and thermal cross-linking methods that create three-dimensional networks around quantum dots, effectively immobilizing them within display films. These techniques have demonstrated remarkable resistance to temperature cycling and prolonged high-brightness operation in reliability testing.

Roll-to-roll manufacturing adaptations for quantum dot films represent perhaps the most commercially significant innovation, enabling high-volume production while maintaining strict environmental controls. Patents from 3M and Dow describe specialized coating stations with controlled atmosphere chambers and in-line quality monitoring systems that ensure consistent quantum dot film properties at industrial scales.

A notable manufacturing breakthrough comes from solution-processing methods that enable quantum dot integration directly into existing display production lines. Patents from Samsung and Nanosys describe proprietary processes for incorporating quantum dots into photoresist materials, allowing for direct patterning through conventional photolithography. This approach eliminates several manufacturing steps while enhancing dot uniformity and reducing exposure to environmental degradants.

Temperature management during manufacturing has emerged as another critical innovation area. Several patents detail precise thermal control systems that maintain optimal conditions throughout the quantum dot deposition and curing processes. These systems prevent thermal degradation while ensuring complete solvent removal, addressing a significant cause of long-term stability issues in earlier generation displays.

Surface treatment technologies represent another significant advancement, with patents describing novel ligand exchange processes that enhance quantum dot-polymer compatibility. These treatments create stronger bonds between dots and host matrices, reducing migration and aggregation that typically lead to efficiency losses and color shifts over time. Companies like Quantum Materials Corp have developed automated ligand exchange systems that maintain inert environments throughout the process.

Cross-linking innovations have also contributed substantially to stability improvements. Recent patents describe photo-initiated and thermal cross-linking methods that create three-dimensional networks around quantum dots, effectively immobilizing them within display films. These techniques have demonstrated remarkable resistance to temperature cycling and prolonged high-brightness operation in reliability testing.

Roll-to-roll manufacturing adaptations for quantum dot films represent perhaps the most commercially significant innovation, enabling high-volume production while maintaining strict environmental controls. Patents from 3M and Dow describe specialized coating stations with controlled atmosphere chambers and in-line quality monitoring systems that ensure consistent quantum dot film properties at industrial scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!