Projecting PTFE stability enhancement through cross‑linked filler networks

PTFE Stability Enhancement Background and Objectives

Polytetrafluoroethylene (PTFE), commonly known as Teflon, has been a cornerstone in various industries since its accidental discovery in 1938. This fluoropolymer's unique properties, including exceptional chemical resistance, low friction coefficient, and high thermal stability, have made it indispensable in applications ranging from cookware to aerospace. However, despite its remarkable characteristics, PTFE faces challenges in maintaining stability under extreme conditions, particularly at elevated temperatures and in harsh chemical environments.

The evolution of PTFE technology has been driven by the continuous demand for materials that can withstand increasingly severe operating conditions. As industries push the boundaries of performance, the limitations of traditional PTFE have become more apparent. This has led to a growing focus on enhancing PTFE's stability, with particular emphasis on improving its mechanical properties and thermal resistance without compromising its inherent chemical inertness.

Recent advancements in materials science have opened new avenues for PTFE enhancement, with cross-linked filler networks emerging as a promising approach. This technique involves incorporating specially designed fillers into the PTFE matrix and creating cross-links between these fillers and the polymer chains. The objective is to reinforce the material's structure at the molecular level, thereby improving its overall stability and performance characteristics.

The primary goals of this technological advancement are multifaceted. Firstly, there is a drive to extend PTFE's operational temperature range, allowing it to maintain its properties under more extreme heat conditions. Secondly, researchers aim to enhance the material's resistance to deformation and wear, particularly in high-stress applications. Additionally, there is a focus on improving PTFE's barrier properties, making it even more effective in containing aggressive chemicals and preventing permeation.

Another critical objective is to address the environmental concerns associated with traditional PTFE production and disposal. By enhancing the material's stability and longevity, there is potential to reduce the frequency of replacement and minimize waste. Furthermore, the development of more durable PTFE composites could lead to thinner, more efficient components, contributing to material conservation and improved sustainability in various industrial processes.

The pursuit of PTFE stability enhancement through cross-linked filler networks represents a convergence of fundamental polymer science and practical industrial needs. It exemplifies the ongoing trend in materials engineering towards creating "smart" composites that can adapt to and withstand challenging environments. As research in this area progresses, it holds the promise of unlocking new applications for PTFE and revolutionizing existing ones, potentially transforming industries that rely on high-performance fluoropolymers.

Market Analysis for Enhanced PTFE Applications

The market for enhanced PTFE applications has been experiencing significant growth in recent years, driven by the increasing demand for high-performance materials in various industries. PTFE, known for its exceptional chemical resistance, low friction, and thermal stability, has long been a staple in industries such as automotive, aerospace, and chemical processing. However, the development of cross-linked filler networks to enhance PTFE stability has opened up new opportunities and expanded the potential market for this material.

The automotive sector represents a substantial portion of the enhanced PTFE market. With the growing emphasis on fuel efficiency and emission reduction, manufacturers are seeking lightweight materials that can withstand harsh operating conditions. Enhanced PTFE components, such as seals, gaskets, and bearings, offer improved durability and performance under high temperatures and pressures, making them ideal for use in engines, transmissions, and fuel systems.

In the aerospace industry, the demand for enhanced PTFE is driven by the need for materials that can maintain their properties in extreme environments. The improved stability of PTFE through cross-linked filler networks allows for its use in critical applications such as hydraulic systems, electrical insulation, and fuel line components. As the aerospace sector continues to grow, particularly in emerging markets, the demand for enhanced PTFE is expected to rise correspondingly.

The chemical processing industry is another key market for enhanced PTFE applications. The material's exceptional chemical resistance makes it invaluable in the production of corrosion-resistant linings, seals, and gaskets for chemical reactors and storage tanks. The enhanced stability provided by cross-linked filler networks extends the lifespan of these components, reducing maintenance costs and improving overall process efficiency.

The electronics sector is emerging as a promising market for enhanced PTFE. With the miniaturization of electronic devices and the increasing demand for high-frequency applications, enhanced PTFE's low dielectric constant and improved thermal stability make it an attractive option for printed circuit boards, cable insulation, and semiconductor manufacturing equipment.

Market analysts project steady growth for the enhanced PTFE market over the next decade. The global market size is expected to expand as industries continue to adopt these advanced materials for their critical applications. Factors such as increasing industrialization in developing countries, stringent regulations on emissions and safety, and the ongoing push for energy-efficient solutions are likely to drive this growth.

However, challenges remain in the widespread adoption of enhanced PTFE. The higher cost compared to traditional PTFE and other competing materials may limit its use in price-sensitive applications. Additionally, the development of alternative materials with similar properties could pose a threat to market growth. Despite these challenges, the unique combination of properties offered by enhanced PTFE, particularly its improved stability through cross-linked filler networks, positions it favorably in the high-performance materials market.

Current Challenges in PTFE Stability

Polytetrafluoroethylene (PTFE) has long been valued for its exceptional chemical resistance, low friction coefficient, and thermal stability. However, as industrial applications demand ever-increasing performance, several challenges in PTFE stability have come to the forefront, necessitating innovative solutions.

One of the primary challenges facing PTFE stability is its susceptibility to deformation under high loads and elevated temperatures. While PTFE exhibits excellent thermal resistance, prolonged exposure to extreme temperatures can lead to creep and dimensional changes, compromising the integrity of seals and other critical components. This issue is particularly pronounced in aerospace and automotive applications where components are subjected to severe thermal cycling.

Another significant challenge is the material's tendency to undergo cold flow or plastic deformation even at room temperature when subjected to constant stress. This characteristic can result in the loss of sealing properties in gaskets and other static applications, potentially leading to leaks and system failures. The cold flow phenomenon is exacerbated in dynamic applications where PTFE components are subjected to continuous movement or vibration.

PTFE's poor wear resistance presents a further stability challenge, especially in tribological applications. Despite its low friction coefficient, PTFE exhibits high wear rates under sliding conditions, which can lead to premature failure of bearings, seals, and other moving parts. This limitation has restricted PTFE's use in certain high-wear environments and necessitated frequent component replacements in others.

The material's inherent porosity is another factor affecting its stability. PTFE's porous structure can absorb liquids and gases, leading to swelling and potential degradation of mechanical properties. This permeability not only affects the dimensional stability of PTFE components but also limits its effectiveness as a barrier material in certain chemical processing and storage applications.

Furthermore, PTFE's resistance to chemical bonding, while advantageous in many scenarios, poses challenges in creating stable composites and in adhering PTFE to other materials. This limitation hampers the development of advanced PTFE-based materials with enhanced properties and restricts design flexibility in multi-material systems.

Addressing these stability challenges is crucial for expanding PTFE's application range and improving its long-term performance. The concept of enhancing PTFE stability through cross-linked filler networks offers a promising avenue for overcoming these limitations. By introducing a network of cross-linked fillers within the PTFE matrix, researchers aim to improve the material's resistance to deformation, enhance its wear resistance, and mitigate issues related to cold flow and porosity.

Existing Cross-linked Filler Network Solutions

01 Thermal stability enhancement of PTFE

Various methods are employed to improve the thermal stability of PTFE, including the addition of stabilizers, modification of the polymer structure, and optimization of processing conditions. These techniques aim to enhance PTFE's resistance to degradation at high temperatures, extending its usability in demanding applications.- Thermal stability enhancement of PTFE: Various methods are employed to improve the thermal stability of PTFE, including the addition of stabilizers, modification of the polymer structure, and optimization of processing conditions. These techniques aim to increase the temperature resistance of PTFE, making it suitable for high-temperature applications.

- Chemical resistance improvement of PTFE: Researchers have developed strategies to enhance the chemical resistance of PTFE, such as incorporating additives, surface treatments, and creating composite materials. These approaches help to maintain PTFE's stability when exposed to aggressive chemical environments.

- Mechanical stability enhancement of PTFE: Techniques for improving the mechanical stability of PTFE include reinforcement with fillers, crosslinking, and the development of PTFE-based composites. These methods aim to increase the material's strength, wear resistance, and dimensional stability under various stress conditions.

- UV and weathering resistance of PTFE: Efforts to enhance PTFE's stability against UV radiation and weathering include the incorporation of UV stabilizers, surface treatments, and the development of specialized PTFE grades. These improvements help maintain the material's properties in outdoor and harsh environmental conditions.

- Processing stability of PTFE: Researchers have focused on improving the processing stability of PTFE through the optimization of polymerization techniques, the use of processing aids, and the development of modified PTFE grades. These advancements aim to enhance the material's stability during manufacturing and fabrication processes.

02 Chemical resistance improvement of PTFE

Researchers have developed strategies to enhance PTFE's already excellent chemical resistance. This includes surface treatments, incorporation of additives, and development of composite materials. These improvements allow PTFE to withstand even more aggressive chemical environments, broadening its application range.Expand Specific Solutions03 Mechanical properties enhancement of PTFE

Efforts to improve PTFE's mechanical properties focus on increasing its wear resistance, tensile strength, and creep resistance. Techniques such as reinforcement with fillers, crosslinking, and nanocomposite formation are utilized to achieve these enhancements, making PTFE more suitable for high-stress applications.Expand Specific Solutions04 UV and weathering resistance of PTFE

Improving PTFE's resistance to UV radiation and weathering is crucial for outdoor applications. Methods include the incorporation of UV stabilizers, surface treatments, and the development of protective coatings. These enhancements help maintain PTFE's properties under prolonged exposure to environmental factors.Expand Specific Solutions05 Processing and fabrication stability of PTFE

Innovations in PTFE processing and fabrication focus on maintaining its stability during manufacturing processes. This includes optimizing sintering conditions, developing new molding techniques, and creating specialized additives that improve processability without compromising the final product's stability and performance.Expand Specific Solutions

Key Players in PTFE Industry

The market for PTFE stability enhancement through cross-linked filler networks is in a growth phase, with increasing demand for high-performance materials in various industries. The global PTFE market size is projected to reach several billion dollars by 2025, driven by applications in automotive, electronics, and industrial sectors. Technologically, the field is advancing rapidly, with companies like DuPont, W. L. Gore & Associates, and The Chemours Co. leading innovation. These firms are developing proprietary cross-linking techniques and filler materials to improve PTFE's thermal and mechanical properties. Other players such as DAIKIN INDUSTRIES and AGC, Inc. are also contributing to the technological maturity of this field through research and development efforts.

DAIKIN INDUSTRIES Ltd.

DuPont de Nemours, Inc.

Core Innovations in PTFE Stability Enhancement

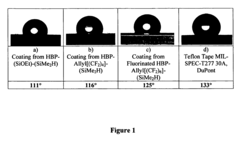

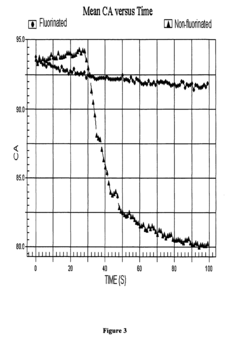

- Development of hyperbranched copolymer networks combining perfluorocarbon and organosilicon entities, which are soluble, thermally stable, and exhibit high hydrophobicity/oleophobicity, allowing for crosslinking and improved adhesion to substrates without the need for polar groups, enabling diverse applications like coatings and sealants.

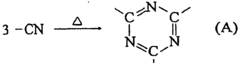

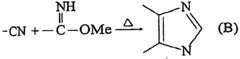

- A method involving the use of crosslinkable polytetrafluoroethylene with a reactive cyano group (-CN) that can be compression molded and baked without flowing, allowing for crosslinking at temperatures below the melting point, enabling the production of PTFE molded bodies with improved strength, crystallinity, and surface characteristics without anisotropy or heterogeneity, using conventional molding methods and avoiding hazardous substances.

Environmental Impact of PTFE Production

The production of polytetrafluoroethylene (PTFE) has significant environmental implications that warrant careful consideration. The manufacturing process involves the use of fluoropolymers, which can lead to the release of perfluorooctanoic acid (PFOA) and other perfluorinated compounds into the environment. These substances are known for their persistence and potential adverse effects on ecosystems and human health.

One of the primary environmental concerns associated with PTFE production is the emission of greenhouse gases. The synthesis of PTFE requires the use of fluorinated gases, such as tetrafluoroethylene (TFE), which have high global warming potentials. These emissions contribute to climate change and necessitate stringent control measures to minimize their release into the atmosphere.

Water pollution is another critical issue in PTFE manufacturing. The production process generates wastewater containing fluorinated compounds, which can contaminate local water sources if not properly treated. These pollutants are challenging to remove through conventional water treatment methods, potentially leading to long-term environmental contamination.

The disposal of PTFE waste presents additional environmental challenges. While PTFE itself is non-biodegradable, the incineration of PTFE-containing products can release harmful substances, including hydrogen fluoride and other toxic compounds. This necessitates specialized disposal methods to prevent air and soil pollution.

Energy consumption in PTFE production is substantial, contributing to indirect environmental impacts through increased carbon emissions from power generation. The high temperatures required for polymerization and the energy-intensive nature of fluoropolymer synthesis result in a significant carbon footprint for PTFE manufacturing facilities.

To address these environmental concerns, the industry has been developing more sustainable production methods. These include the implementation of closed-loop systems to reduce emissions and water usage, the adoption of alternative polymerization techniques that minimize the use of harmful chemicals, and the exploration of bio-based precursors for PTFE production.

Regulatory bodies worldwide have imposed stricter environmental standards on PTFE manufacturers, driving innovations in pollution control technologies. Advanced air filtration systems, improved wastewater treatment processes, and more efficient production techniques are being developed and implemented to mitigate the environmental impact of PTFE production.

The pursuit of cross-linked filler networks for PTFE stability enhancement may offer opportunities to reduce the environmental footprint of PTFE products. By improving the durability and performance of PTFE materials, this approach could potentially decrease the frequency of replacement and disposal, thereby reducing overall waste generation and resource consumption in the long term.

Regulatory Framework for PTFE in Various Industries

The regulatory framework for PTFE in various industries is complex and multifaceted, reflecting the diverse applications of this versatile material. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating PTFE use in food contact applications and medical devices. The FDA has approved PTFE for use in food processing equipment and packaging, subject to specific limitations and conditions outlined in 21 CFR 177.1550.

For medical applications, PTFE is classified as a Class II medical device under FDA regulations, requiring manufacturers to submit a 510(k) premarket notification before introducing new PTFE-based products. The European Union's regulatory approach is governed by the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which mandates the registration of PTFE and its precursors with the European Chemicals Agency (ECHA).

In the automotive and aerospace industries, PTFE must comply with stringent safety and performance standards set by organizations such as the Society of Automotive Engineers (SAE) and the Federal Aviation Administration (FAA). These standards often focus on the material's thermal stability, chemical resistance, and mechanical properties under extreme conditions.

Environmental regulations also play a significant role in PTFE production and use. The U.S. Environmental Protection Agency (EPA) has implemented restrictions on the use of perfluorooctanoic acid (PFOA), a chemical historically used in PTFE manufacturing, under the Toxic Substances Control Act (TSCA). Similar measures have been adopted by regulatory bodies worldwide, including the European Union's ban on PFOA and related substances under the Stockholm Convention on Persistent Organic Pollutants.

In the electronics industry, PTFE must adhere to the Restriction of Hazardous Substances (RoHS) directive in the European Union, which limits the use of certain hazardous substances in electrical and electronic equipment. While PTFE itself is not restricted under RoHS, manufacturers must ensure that any additives or processing aids used in PTFE production comply with these regulations.

As research into cross-linked filler networks for enhancing PTFE stability progresses, regulatory frameworks may need to evolve to address potential new applications and manufacturing processes. Regulatory bodies will likely focus on assessing the safety and environmental impact of these novel PTFE formulations, potentially requiring additional testing and documentation before approval for use in sensitive applications such as medical devices or food contact materials.