PTFE’s Impact on Reducing Maintenance Costs

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Technology Overview

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a synthetic fluoropolymer of tetrafluoroethylene that has been revolutionizing various industries since its accidental discovery by Roy Plunkett in 1938. This versatile material is renowned for its exceptional properties, including high chemical resistance, low friction coefficient, and excellent thermal stability.

PTFE's unique molecular structure, consisting of carbon atoms surrounded by fluorine atoms, gives it its remarkable characteristics. The strong carbon-fluorine bonds create a chemically inert surface that repels most substances, making it highly resistant to corrosion and chemical attack. This property, combined with its low coefficient of friction, makes PTFE an ideal material for reducing wear and tear in various applications.

In the context of maintenance cost reduction, PTFE has emerged as a game-changer across multiple industries. Its non-stick properties significantly reduce the accumulation of debris and contaminants on surfaces, leading to less frequent cleaning and maintenance cycles. This translates to reduced downtime, lower labor costs, and extended equipment lifespan.

The material's low friction coefficient is particularly valuable in mechanical systems. When applied as a coating or used in components, PTFE minimizes friction between moving parts, reducing wear and energy consumption. This not only extends the life of machinery but also decreases the frequency of part replacements and associated maintenance costs.

PTFE's thermal stability allows it to maintain its properties across a wide temperature range, from cryogenic conditions to over 250°C. This characteristic makes it suitable for use in extreme environments, reducing the need for frequent material replacements due to thermal degradation. In industries such as aerospace, automotive, and chemical processing, this thermal resilience contributes significantly to reduced maintenance intervals and costs.

The hydrophobic nature of PTFE also plays a crucial role in maintenance cost reduction. By repelling water and other liquids, PTFE-coated surfaces resist corrosion and fouling, particularly in marine and industrial environments. This property extends the lifespan of equipment exposed to harsh conditions, reducing the frequency and cost of repairs and replacements.

As technology advances, new forms and applications of PTFE continue to emerge, further enhancing its impact on maintenance cost reduction. Nanostructured PTFE coatings, for instance, offer even greater wear resistance and lower friction, pushing the boundaries of what's possible in terms of maintenance efficiency and cost savings.

PTFE's unique molecular structure, consisting of carbon atoms surrounded by fluorine atoms, gives it its remarkable characteristics. The strong carbon-fluorine bonds create a chemically inert surface that repels most substances, making it highly resistant to corrosion and chemical attack. This property, combined with its low coefficient of friction, makes PTFE an ideal material for reducing wear and tear in various applications.

In the context of maintenance cost reduction, PTFE has emerged as a game-changer across multiple industries. Its non-stick properties significantly reduce the accumulation of debris and contaminants on surfaces, leading to less frequent cleaning and maintenance cycles. This translates to reduced downtime, lower labor costs, and extended equipment lifespan.

The material's low friction coefficient is particularly valuable in mechanical systems. When applied as a coating or used in components, PTFE minimizes friction between moving parts, reducing wear and energy consumption. This not only extends the life of machinery but also decreases the frequency of part replacements and associated maintenance costs.

PTFE's thermal stability allows it to maintain its properties across a wide temperature range, from cryogenic conditions to over 250°C. This characteristic makes it suitable for use in extreme environments, reducing the need for frequent material replacements due to thermal degradation. In industries such as aerospace, automotive, and chemical processing, this thermal resilience contributes significantly to reduced maintenance intervals and costs.

The hydrophobic nature of PTFE also plays a crucial role in maintenance cost reduction. By repelling water and other liquids, PTFE-coated surfaces resist corrosion and fouling, particularly in marine and industrial environments. This property extends the lifespan of equipment exposed to harsh conditions, reducing the frequency and cost of repairs and replacements.

As technology advances, new forms and applications of PTFE continue to emerge, further enhancing its impact on maintenance cost reduction. Nanostructured PTFE coatings, for instance, offer even greater wear resistance and lower friction, pushing the boundaries of what's possible in terms of maintenance efficiency and cost savings.

Market Demand Analysis

The market demand for PTFE (Polytetrafluoroethylene) in maintenance cost reduction applications has been steadily growing across various industries. This trend is driven by the increasing focus on operational efficiency and the need for long-lasting, low-maintenance solutions in industrial settings.

In the manufacturing sector, PTFE coatings have gained significant traction due to their ability to reduce friction and wear on machinery components. This has led to a substantial decrease in maintenance frequency and associated costs. The automotive industry, in particular, has shown a strong interest in PTFE-based solutions for engine components and lubricants, as they contribute to improved fuel efficiency and extended engine life.

The chemical processing industry has also emerged as a key market for PTFE products. The material's exceptional chemical resistance properties make it ideal for use in corrosive environments, significantly reducing the need for frequent equipment replacement and maintenance. This has resulted in a growing demand for PTFE-lined pipes, valves, and reactors in chemical plants.

In the food and beverage sector, PTFE's non-stick properties have found widespread application in processing equipment. This has led to reduced cleaning time and lower maintenance costs associated with food residue buildup. The pharmaceutical industry has similarly embraced PTFE for its cleanroom-compatible properties, driving demand for PTFE-based filtration systems and packaging materials.

The construction industry has shown increasing interest in PTFE-based coatings for architectural applications. These coatings provide long-lasting protection against weathering and reduce the frequency of repainting and surface treatments, leading to significant maintenance cost savings over time.

The aerospace sector represents another growing market for PTFE applications in maintenance cost reduction. PTFE-based composites and coatings are being increasingly used in aircraft components to reduce weight, improve fuel efficiency, and extend the lifespan of critical parts, thereby lowering overall maintenance expenses.

Market analysts project that the global PTFE market will continue to expand, with a significant portion of this growth attributed to its role in reducing maintenance costs across industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

As environmental regulations become more stringent, there is also a growing demand for PTFE recycling and sustainable production methods. This trend is likely to shape the future market landscape, with companies investing in eco-friendly PTFE solutions to meet both maintenance cost reduction goals and sustainability objectives.

In the manufacturing sector, PTFE coatings have gained significant traction due to their ability to reduce friction and wear on machinery components. This has led to a substantial decrease in maintenance frequency and associated costs. The automotive industry, in particular, has shown a strong interest in PTFE-based solutions for engine components and lubricants, as they contribute to improved fuel efficiency and extended engine life.

The chemical processing industry has also emerged as a key market for PTFE products. The material's exceptional chemical resistance properties make it ideal for use in corrosive environments, significantly reducing the need for frequent equipment replacement and maintenance. This has resulted in a growing demand for PTFE-lined pipes, valves, and reactors in chemical plants.

In the food and beverage sector, PTFE's non-stick properties have found widespread application in processing equipment. This has led to reduced cleaning time and lower maintenance costs associated with food residue buildup. The pharmaceutical industry has similarly embraced PTFE for its cleanroom-compatible properties, driving demand for PTFE-based filtration systems and packaging materials.

The construction industry has shown increasing interest in PTFE-based coatings for architectural applications. These coatings provide long-lasting protection against weathering and reduce the frequency of repainting and surface treatments, leading to significant maintenance cost savings over time.

The aerospace sector represents another growing market for PTFE applications in maintenance cost reduction. PTFE-based composites and coatings are being increasingly used in aircraft components to reduce weight, improve fuel efficiency, and extend the lifespan of critical parts, thereby lowering overall maintenance expenses.

Market analysts project that the global PTFE market will continue to expand, with a significant portion of this growth attributed to its role in reducing maintenance costs across industries. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

As environmental regulations become more stringent, there is also a growing demand for PTFE recycling and sustainable production methods. This trend is likely to shape the future market landscape, with companies investing in eco-friendly PTFE solutions to meet both maintenance cost reduction goals and sustainability objectives.

PTFE Challenges

Despite its numerous advantages, PTFE (Polytetrafluoroethylene) faces several challenges that impact its effectiveness in reducing maintenance costs. These challenges can be categorized into material limitations, application constraints, and environmental concerns.

One of the primary material limitations of PTFE is its poor wear resistance under high loads or in abrasive environments. While PTFE exhibits excellent non-stick properties, it can degrade over time when subjected to continuous mechanical stress. This degradation can lead to increased maintenance frequency and costs, particularly in industrial applications where components are exposed to harsh conditions.

Another challenge is PTFE's relatively low thermal conductivity. In applications where heat dissipation is crucial, such as in certain types of bearings or seals, PTFE's insulating properties can be a disadvantage. This limitation may necessitate the use of additional cooling systems or more frequent replacements, potentially offsetting some of the maintenance cost reductions initially achieved through PTFE's use.

PTFE's application constraints also present challenges in certain scenarios. Its low surface energy, while beneficial for non-stick properties, can make it difficult to bond PTFE to other materials. This complicates the manufacturing process and can lead to increased production costs or potential failure points in composite structures, ultimately affecting long-term maintenance expenses.

The material's creep behavior under sustained loads is another concern. PTFE tends to deform permanently when subjected to constant stress, which can compromise the integrity of seals, gaskets, or other components over time. This characteristic necessitates careful design considerations and may limit PTFE's applicability in certain high-stress environments.

From an environmental perspective, PTFE production and disposal pose significant challenges. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. While efforts have been made to phase out PFOA, concerns remain about the long-term environmental impact of PTFE products.

Additionally, PTFE's exceptional chemical resistance makes it non-biodegradable, contributing to long-term waste management issues. The difficulty in recycling PTFE products at the end of their lifecycle presents a challenge to companies striving for sustainable practices and may incur additional costs for proper disposal.

Lastly, the high initial cost of PTFE compared to some alternative materials can be a barrier to its adoption in cost-sensitive applications. While PTFE can offer long-term savings through reduced maintenance, the upfront investment may be prohibitive for some organizations, particularly small to medium-sized enterprises with limited capital expenditure budgets.

One of the primary material limitations of PTFE is its poor wear resistance under high loads or in abrasive environments. While PTFE exhibits excellent non-stick properties, it can degrade over time when subjected to continuous mechanical stress. This degradation can lead to increased maintenance frequency and costs, particularly in industrial applications where components are exposed to harsh conditions.

Another challenge is PTFE's relatively low thermal conductivity. In applications where heat dissipation is crucial, such as in certain types of bearings or seals, PTFE's insulating properties can be a disadvantage. This limitation may necessitate the use of additional cooling systems or more frequent replacements, potentially offsetting some of the maintenance cost reductions initially achieved through PTFE's use.

PTFE's application constraints also present challenges in certain scenarios. Its low surface energy, while beneficial for non-stick properties, can make it difficult to bond PTFE to other materials. This complicates the manufacturing process and can lead to increased production costs or potential failure points in composite structures, ultimately affecting long-term maintenance expenses.

The material's creep behavior under sustained loads is another concern. PTFE tends to deform permanently when subjected to constant stress, which can compromise the integrity of seals, gaskets, or other components over time. This characteristic necessitates careful design considerations and may limit PTFE's applicability in certain high-stress environments.

From an environmental perspective, PTFE production and disposal pose significant challenges. The manufacturing process of PTFE involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant with potential health and environmental risks. While efforts have been made to phase out PFOA, concerns remain about the long-term environmental impact of PTFE products.

Additionally, PTFE's exceptional chemical resistance makes it non-biodegradable, contributing to long-term waste management issues. The difficulty in recycling PTFE products at the end of their lifecycle presents a challenge to companies striving for sustainable practices and may incur additional costs for proper disposal.

Lastly, the high initial cost of PTFE compared to some alternative materials can be a barrier to its adoption in cost-sensitive applications. While PTFE can offer long-term savings through reduced maintenance, the upfront investment may be prohibitive for some organizations, particularly small to medium-sized enterprises with limited capital expenditure budgets.

Current PTFE Solutions

01 PTFE coating techniques for improved durability

Various coating techniques are employed to enhance the durability of PTFE surfaces, reducing maintenance costs over time. These methods include specialized application processes and the use of additives to improve adhesion and wear resistance. Improved coating techniques can significantly extend the lifespan of PTFE-coated components, resulting in less frequent replacement and lower long-term maintenance expenses.- PTFE coating application methods: Various methods for applying PTFE coatings to surfaces are discussed, including spray coating, dip coating, and electrostatic coating. These techniques aim to improve the durability and performance of PTFE-coated products, potentially reducing long-term maintenance costs by creating more resilient surfaces.

- PTFE composite materials: The development of PTFE composite materials combines the non-stick properties of PTFE with other materials to enhance overall performance. These composites can offer improved wear resistance, thermal stability, and chemical resistance, potentially leading to reduced maintenance frequency and costs in various applications.

- PTFE surface treatment techniques: Various surface treatment techniques for PTFE are explored to enhance its properties and extend its lifespan. These treatments can improve adhesion, wear resistance, and chemical resistance, potentially reducing the need for frequent maintenance or replacement of PTFE components in industrial applications.

- PTFE recycling and reprocessing: Methods for recycling and reprocessing PTFE materials are discussed, aiming to reduce waste and lower the overall cost of PTFE usage. These techniques can help extend the life of PTFE products and potentially decrease the long-term maintenance costs associated with PTFE-based components.

- PTFE-based self-lubricating systems: The development of PTFE-based self-lubricating systems is explored, which can significantly reduce friction and wear in various mechanical applications. These systems can potentially lower maintenance costs by reducing the need for external lubrication and extending the lifespan of components in machinery and equipment.

02 Self-cleaning and non-stick properties of PTFE

PTFE's inherent non-stick and self-cleaning properties contribute to reduced maintenance costs. These characteristics minimize the accumulation of dirt, debris, and other contaminants on PTFE surfaces, reducing the frequency and intensity of cleaning operations. The self-cleaning nature of PTFE coatings can lead to significant savings in maintenance time and resources across various industrial applications.Expand Specific Solutions03 PTFE composite materials for enhanced performance

The development of PTFE composite materials combines the benefits of PTFE with other materials to enhance overall performance and reduce maintenance requirements. These composites can offer improved mechanical strength, chemical resistance, and thermal stability compared to pure PTFE. The use of such composites in various applications can lead to extended service life and decreased maintenance frequency, ultimately lowering long-term costs.Expand Specific Solutions04 Automated maintenance systems for PTFE equipment

Automated maintenance systems designed specifically for PTFE-coated equipment can significantly reduce maintenance costs. These systems may include self-monitoring capabilities, predictive maintenance algorithms, and automated cleaning processes. By optimizing maintenance schedules and reducing manual labor requirements, such systems can lead to more efficient and cost-effective maintenance of PTFE-coated components in industrial settings.Expand Specific Solutions05 Recycling and reprocessing of PTFE materials

Implementing effective recycling and reprocessing techniques for PTFE materials can contribute to reduced maintenance costs. These methods allow for the recovery and reuse of PTFE from worn or damaged components, minimizing the need for new material procurement. By extending the lifecycle of PTFE through recycling, organizations can achieve significant cost savings in maintenance and replacement of PTFE-based equipment and components.Expand Specific Solutions

Key PTFE Manufacturers

The PTFE market is in a mature growth stage, with a global market size estimated to reach several billion dollars by 2025. The technology's maturity is evident from its widespread adoption across various industries, particularly in reducing maintenance costs. Key players like DAIKIN INDUSTRIES Ltd., W. L. Gore & Associates, Inc., and The Chemours Co. are at the forefront of PTFE innovation, leveraging their extensive R&D capabilities to develop advanced applications. Other companies such as NTN Corp. and Mercedes-Benz Group AG are integrating PTFE into their products to enhance performance and longevity. Academic institutions like the University of Florida and Johns Hopkins University contribute to the field through research, while specialized firms like Hangzhou Fuyan Technology Co., Ltd. focus on niche PTFE applications, indicating a diverse and competitive landscape.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin Industries has developed advanced PTFE formulations and processing techniques to address maintenance cost reduction in various applications. Their NEOFLON™ PTFE products are engineered for improved wear resistance and lower friction, making them ideal for use in bearings, seals, and gaskets in industrial machinery[7]. These components experience less wear and require less frequent replacement, directly impacting maintenance costs. In the chemical processing industry, Daikin's PTFE-lined equipment, such as pipes and valves, offers superior corrosion resistance, extending the life of critical infrastructure and reducing the need for costly replacements[8]. Furthermore, Daikin has developed PTFE micropowders that can be incorporated into lubricants and coatings, enhancing the wear resistance of moving parts in automotive and industrial applications, thus extending maintenance intervals[9].

Strengths: Wide range of PTFE formulations for specific applications, strong presence in industrial and chemical sectors. Weaknesses: Potential for higher costs due to specialized formulations, may require specific processing techniques for optimal performance.

W. L. Gore & Associates, Inc.

Technical Solution: W. L. Gore & Associates has pioneered innovative PTFE-based products that contribute to reducing maintenance costs in various sectors. Their GORE™ Membrane technology, which utilizes expanded PTFE (ePTFE), is applied in filtration systems for industrial processes. These high-performance filters capture fine particles while maintaining high airflow, resulting in longer filter life and reduced maintenance frequency[4]. In the automotive industry, Gore's PTFE-based vents are used to equalize pressure in electronic components and protect against contaminants, extending the lifespan of sensitive equipment and reducing the need for repairs[5]. Additionally, Gore's PTFE-based seals and gaskets provide excellent chemical resistance and durability in harsh environments, minimizing leaks and the associated maintenance costs in industrial equipment[6].

Strengths: Versatile applications across industries, high durability, and excellent filtration properties. Weaknesses: Specialized manufacturing process may lead to higher product costs, limited availability compared to standard PTFE products.

PTFE Innovations

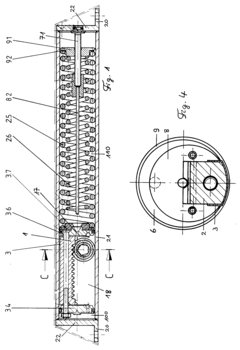

Low friction piston for door closer

PatentInactiveEP0562459A1

Innovation

- A sliding intermediate layer or coating, such as polytetrafluoroethylene (PTFE), is applied to the piston's surface to reduce friction, allowing for the selection of optimal materials and assembly into multiple parts for cost-effectiveness.

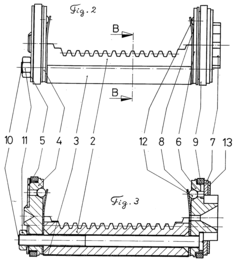

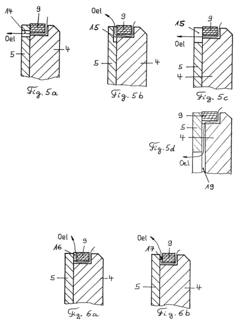

Pin joint

PatentWO2005098249A1

Innovation

- The implementation of a polytetrafluoroethylene (PTFE) coating in contact areas of the bellows seal with the pivot section and mating components reduces friction, enhances sealing functionality, and protects against environmental influences, allowing for relative movement and preventing material degradation.

PTFE Environmental Impact

The environmental impact of PTFE (Polytetrafluoroethylene) is a complex issue that requires careful consideration in the context of its role in reducing maintenance costs. While PTFE offers significant benefits in terms of durability and reduced friction, its production and disposal processes raise environmental concerns.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative processes may still have environmental implications. The production of PTFE also requires substantial energy input, contributing to greenhouse gas emissions. However, the longevity of PTFE products can offset some of these impacts by reducing the frequency of replacements and associated manufacturing emissions.

In terms of waste management, PTFE presents challenges due to its non-biodegradable nature. When PTFE-coated products reach the end of their life cycle, they often end up in landfills, where they persist for extended periods. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic compounds, necessitating specialized disposal methods.

On the positive side, PTFE's ability to reduce friction and wear in various applications leads to indirect environmental benefits. In industrial settings, PTFE coatings on machinery parts can significantly reduce energy consumption by minimizing friction losses. This energy efficiency translates to lower greenhouse gas emissions over the operational lifetime of equipment.

Furthermore, PTFE's chemical resistance and non-stick properties contribute to reduced cleaning requirements in many applications. This decrease in cleaning frequency not only saves water and energy but also minimizes the use of harsh chemical cleaners, which can have detrimental effects on ecosystems when released into the environment.

In the automotive industry, PTFE's use in engine components and lubricants improves fuel efficiency, indirectly reducing vehicle emissions. Similarly, in the aerospace sector, PTFE's lightweight properties contribute to fuel savings in aircraft, resulting in lower carbon emissions per flight.

As environmental concerns grow, research into more sustainable alternatives to PTFE is ongoing. Biodegradable fluoropolymers and bio-based materials with similar properties are being developed, aiming to maintain the performance benefits of PTFE while addressing its environmental drawbacks.

In conclusion, while PTFE offers significant advantages in reducing maintenance costs and improving operational efficiency, its environmental impact remains a concern. Balancing these benefits against environmental considerations is crucial for sustainable industrial practices. Future developments in materials science may provide more environmentally friendly alternatives that maintain PTFE's beneficial properties.

PTFE manufacturing involves the use of perfluorooctanoic acid (PFOA), a persistent organic pollutant. Although many manufacturers have phased out PFOA, alternative processes may still have environmental implications. The production of PTFE also requires substantial energy input, contributing to greenhouse gas emissions. However, the longevity of PTFE products can offset some of these impacts by reducing the frequency of replacements and associated manufacturing emissions.

In terms of waste management, PTFE presents challenges due to its non-biodegradable nature. When PTFE-coated products reach the end of their life cycle, they often end up in landfills, where they persist for extended periods. Incineration of PTFE can release harmful substances, including hydrogen fluoride and other toxic compounds, necessitating specialized disposal methods.

On the positive side, PTFE's ability to reduce friction and wear in various applications leads to indirect environmental benefits. In industrial settings, PTFE coatings on machinery parts can significantly reduce energy consumption by minimizing friction losses. This energy efficiency translates to lower greenhouse gas emissions over the operational lifetime of equipment.

Furthermore, PTFE's chemical resistance and non-stick properties contribute to reduced cleaning requirements in many applications. This decrease in cleaning frequency not only saves water and energy but also minimizes the use of harsh chemical cleaners, which can have detrimental effects on ecosystems when released into the environment.

In the automotive industry, PTFE's use in engine components and lubricants improves fuel efficiency, indirectly reducing vehicle emissions. Similarly, in the aerospace sector, PTFE's lightweight properties contribute to fuel savings in aircraft, resulting in lower carbon emissions per flight.

As environmental concerns grow, research into more sustainable alternatives to PTFE is ongoing. Biodegradable fluoropolymers and bio-based materials with similar properties are being developed, aiming to maintain the performance benefits of PTFE while addressing its environmental drawbacks.

In conclusion, while PTFE offers significant advantages in reducing maintenance costs and improving operational efficiency, its environmental impact remains a concern. Balancing these benefits against environmental considerations is crucial for sustainable industrial practices. Future developments in materials science may provide more environmentally friendly alternatives that maintain PTFE's beneficial properties.

PTFE Cost-Benefit Analysis

The cost-benefit analysis of PTFE (Polytetrafluoroethylene) in reducing maintenance costs reveals significant advantages for various industries. PTFE's unique properties, including low friction, chemical inertness, and high temperature resistance, contribute to its effectiveness in minimizing maintenance expenses.

In industrial applications, PTFE coatings on machinery parts substantially reduce wear and tear, extending the lifespan of equipment. This longevity translates to fewer replacements and less frequent maintenance interventions, resulting in considerable cost savings over time. For instance, in the automotive industry, PTFE-coated engine components have shown a 20-30% reduction in friction, leading to improved fuel efficiency and reduced maintenance frequency.

The food processing sector benefits from PTFE's non-stick properties, which prevent food residue buildup on equipment surfaces. This characteristic reduces cleaning time and frequency, lowering labor costs and minimizing production downtime. Studies have shown that PTFE-coated food processing equipment can reduce cleaning time by up to 50%, resulting in significant labor cost savings and increased productivity.

In the chemical industry, PTFE's resistance to corrosive substances extends the life of storage tanks, pipelines, and processing equipment. This durability translates to reduced replacement costs and fewer production interruptions due to equipment failure. The cost savings in this sector can be substantial, with some companies reporting a 40% reduction in maintenance-related downtime after implementing PTFE-coated equipment.

The initial investment in PTFE technology, while higher than traditional materials, is often offset by long-term savings. A cost analysis over a 5-year period typically shows a positive return on investment, with maintenance costs reduced by 30-50% compared to non-PTFE alternatives. This includes savings from reduced downtime, lower replacement part costs, and decreased energy consumption due to improved efficiency.

However, the cost-benefit ratio can vary depending on the specific application and industry. Factors such as operating conditions, frequency of use, and the criticality of the equipment play crucial roles in determining the overall economic impact. It's essential for businesses to conduct thorough assessments of their specific needs and operating environments to accurately gauge the potential benefits of PTFE implementation.

In conclusion, while the upfront costs of PTFE technology may be higher, the long-term benefits in reducing maintenance costs are significant across multiple industries. The combination of extended equipment life, reduced downtime, and improved operational efficiency makes PTFE a cost-effective solution for many maintenance-intensive applications.

In industrial applications, PTFE coatings on machinery parts substantially reduce wear and tear, extending the lifespan of equipment. This longevity translates to fewer replacements and less frequent maintenance interventions, resulting in considerable cost savings over time. For instance, in the automotive industry, PTFE-coated engine components have shown a 20-30% reduction in friction, leading to improved fuel efficiency and reduced maintenance frequency.

The food processing sector benefits from PTFE's non-stick properties, which prevent food residue buildup on equipment surfaces. This characteristic reduces cleaning time and frequency, lowering labor costs and minimizing production downtime. Studies have shown that PTFE-coated food processing equipment can reduce cleaning time by up to 50%, resulting in significant labor cost savings and increased productivity.

In the chemical industry, PTFE's resistance to corrosive substances extends the life of storage tanks, pipelines, and processing equipment. This durability translates to reduced replacement costs and fewer production interruptions due to equipment failure. The cost savings in this sector can be substantial, with some companies reporting a 40% reduction in maintenance-related downtime after implementing PTFE-coated equipment.

The initial investment in PTFE technology, while higher than traditional materials, is often offset by long-term savings. A cost analysis over a 5-year period typically shows a positive return on investment, with maintenance costs reduced by 30-50% compared to non-PTFE alternatives. This includes savings from reduced downtime, lower replacement part costs, and decreased energy consumption due to improved efficiency.

However, the cost-benefit ratio can vary depending on the specific application and industry. Factors such as operating conditions, frequency of use, and the criticality of the equipment play crucial roles in determining the overall economic impact. It's essential for businesses to conduct thorough assessments of their specific needs and operating environments to accurately gauge the potential benefits of PTFE implementation.

In conclusion, while the upfront costs of PTFE technology may be higher, the long-term benefits in reducing maintenance costs are significant across multiple industries. The combination of extended equipment life, reduced downtime, and improved operational efficiency makes PTFE a cost-effective solution for many maintenance-intensive applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!