PTFE’s Role in Lightweight Composite Materials

JUN 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PTFE Composite Evolution

PTFE composites have undergone significant evolution since their inception, driven by the increasing demand for lightweight materials with superior performance characteristics. The journey of PTFE composites began in the mid-20th century when the unique properties of PTFE were first recognized and exploited in various industrial applications.

In the early stages, PTFE composites were primarily used in simple forms, such as filled PTFE materials where the polymer matrix was combined with various fillers to enhance specific properties. These early composites found applications in seals, gaskets, and bearings due to their low friction and chemical resistance.

As manufacturing techniques advanced, the 1970s and 1980s saw the development of more sophisticated PTFE composite structures. This period marked the introduction of PTFE-based laminates and fabric-reinforced composites, which significantly expanded the application range of these materials. The aerospace industry, in particular, began to adopt PTFE composites for their excellent thermal stability and low weight.

The 1990s brought about a revolution in PTFE composite technology with the advent of expanded PTFE (ePTFE) membranes. These microporous structures offered unprecedented combinations of breathability, water resistance, and durability, leading to their widespread use in high-performance textiles and filtration systems.

Entering the 21st century, nanotechnology began to play a crucial role in PTFE composite evolution. The incorporation of nanoparticles and nanofibers into PTFE matrices resulted in composites with enhanced mechanical strength, thermal conductivity, and electrical properties. This nano-enhanced generation of PTFE composites opened up new possibilities in electronics, energy storage, and biomedical applications.

Recent years have seen a focus on sustainability and eco-friendly manufacturing processes in PTFE composite development. Researchers are exploring bio-based fillers and environmentally benign processing methods to reduce the environmental footprint of these materials while maintaining their high-performance characteristics.

The latest frontier in PTFE composite evolution involves the integration of smart materials and functionalities. Self-healing PTFE composites, shape-memory PTFE-based materials, and composites with embedded sensors are emerging areas of research, promising a new generation of adaptive and responsive lightweight materials.

Throughout this evolution, the role of PTFE in lightweight composite materials has been transformative. Its unique combination of low density, chemical inertness, and excellent tribological properties has consistently pushed the boundaries of material science, enabling innovations across multiple industries and applications.

In the early stages, PTFE composites were primarily used in simple forms, such as filled PTFE materials where the polymer matrix was combined with various fillers to enhance specific properties. These early composites found applications in seals, gaskets, and bearings due to their low friction and chemical resistance.

As manufacturing techniques advanced, the 1970s and 1980s saw the development of more sophisticated PTFE composite structures. This period marked the introduction of PTFE-based laminates and fabric-reinforced composites, which significantly expanded the application range of these materials. The aerospace industry, in particular, began to adopt PTFE composites for their excellent thermal stability and low weight.

The 1990s brought about a revolution in PTFE composite technology with the advent of expanded PTFE (ePTFE) membranes. These microporous structures offered unprecedented combinations of breathability, water resistance, and durability, leading to their widespread use in high-performance textiles and filtration systems.

Entering the 21st century, nanotechnology began to play a crucial role in PTFE composite evolution. The incorporation of nanoparticles and nanofibers into PTFE matrices resulted in composites with enhanced mechanical strength, thermal conductivity, and electrical properties. This nano-enhanced generation of PTFE composites opened up new possibilities in electronics, energy storage, and biomedical applications.

Recent years have seen a focus on sustainability and eco-friendly manufacturing processes in PTFE composite development. Researchers are exploring bio-based fillers and environmentally benign processing methods to reduce the environmental footprint of these materials while maintaining their high-performance characteristics.

The latest frontier in PTFE composite evolution involves the integration of smart materials and functionalities. Self-healing PTFE composites, shape-memory PTFE-based materials, and composites with embedded sensors are emerging areas of research, promising a new generation of adaptive and responsive lightweight materials.

Throughout this evolution, the role of PTFE in lightweight composite materials has been transformative. Its unique combination of low density, chemical inertness, and excellent tribological properties has consistently pushed the boundaries of material science, enabling innovations across multiple industries and applications.

Lightweight Market Demand

The demand for lightweight composite materials has been steadily increasing across various industries, driven by the need for improved fuel efficiency, enhanced performance, and reduced environmental impact. In the automotive sector, stringent emissions regulations and the push for electric vehicles have accelerated the adoption of lightweight materials. The aerospace industry continues to seek weight reduction solutions to improve aircraft fuel efficiency and payload capacity. The construction industry is also embracing lightweight composites for their strength-to-weight ratio and durability.

PTFE (Polytetrafluoroethylene) plays a crucial role in this growing market for lightweight composite materials. Its unique properties, including low friction, high temperature resistance, and chemical inertness, make it an ideal component in many composite formulations. The integration of PTFE in lightweight composites has opened new possibilities for material engineers to create products with enhanced performance characteristics.

The global market for lightweight composite materials is projected to experience significant growth in the coming years. This expansion is fueled by increasing applications in automotive, aerospace, wind energy, and sports equipment industries. The automotive lightweight materials market alone is expected to grow substantially, driven by the shift towards electric vehicles and the need for improved fuel economy in conventional vehicles.

In the aerospace sector, the demand for lightweight composites incorporating PTFE is particularly strong. Aircraft manufacturers are constantly seeking ways to reduce weight without compromising safety or performance. PTFE-enhanced composites offer solutions for various aircraft components, from interior panels to critical structural elements, contributing to overall weight reduction and improved fuel efficiency.

The sports and leisure industry has also recognized the benefits of PTFE in lightweight composites. High-performance sporting goods, such as tennis rackets, golf clubs, and bicycle frames, are increasingly utilizing these advanced materials to provide athletes with equipment that is both lighter and more durable.

The construction industry is another sector showing growing interest in lightweight composites featuring PTFE. These materials offer architects and engineers new possibilities in designing structures that are not only lighter but also more resistant to environmental factors. The use of PTFE-enhanced composites in building facades, roofing materials, and structural components is expected to increase, driven by the need for sustainable and energy-efficient construction solutions.

As environmental concerns continue to shape market demands, the role of PTFE in lightweight composites becomes even more significant. Its contribution to creating materials that enable reduced energy consumption and lower carbon emissions aligns well with global sustainability goals. This alignment is likely to further drive demand across industries committed to reducing their environmental footprint.

PTFE (Polytetrafluoroethylene) plays a crucial role in this growing market for lightweight composite materials. Its unique properties, including low friction, high temperature resistance, and chemical inertness, make it an ideal component in many composite formulations. The integration of PTFE in lightweight composites has opened new possibilities for material engineers to create products with enhanced performance characteristics.

The global market for lightweight composite materials is projected to experience significant growth in the coming years. This expansion is fueled by increasing applications in automotive, aerospace, wind energy, and sports equipment industries. The automotive lightweight materials market alone is expected to grow substantially, driven by the shift towards electric vehicles and the need for improved fuel economy in conventional vehicles.

In the aerospace sector, the demand for lightweight composites incorporating PTFE is particularly strong. Aircraft manufacturers are constantly seeking ways to reduce weight without compromising safety or performance. PTFE-enhanced composites offer solutions for various aircraft components, from interior panels to critical structural elements, contributing to overall weight reduction and improved fuel efficiency.

The sports and leisure industry has also recognized the benefits of PTFE in lightweight composites. High-performance sporting goods, such as tennis rackets, golf clubs, and bicycle frames, are increasingly utilizing these advanced materials to provide athletes with equipment that is both lighter and more durable.

The construction industry is another sector showing growing interest in lightweight composites featuring PTFE. These materials offer architects and engineers new possibilities in designing structures that are not only lighter but also more resistant to environmental factors. The use of PTFE-enhanced composites in building facades, roofing materials, and structural components is expected to increase, driven by the need for sustainable and energy-efficient construction solutions.

As environmental concerns continue to shape market demands, the role of PTFE in lightweight composites becomes even more significant. Its contribution to creating materials that enable reduced energy consumption and lower carbon emissions aligns well with global sustainability goals. This alignment is likely to further drive demand across industries committed to reducing their environmental footprint.

PTFE Composite Challenges

Despite the numerous advantages of PTFE in lightweight composite materials, several challenges persist in its application and integration. One of the primary obstacles is the inherent non-stick property of PTFE, which makes it difficult to bond with other materials in the composite matrix. This poor adhesion can lead to delamination and reduced overall strength of the composite structure.

Another significant challenge is the high processing temperature required for PTFE, typically around 370°C. This elevated temperature can cause thermal degradation of other components in the composite, limiting the range of materials that can be effectively combined with PTFE. Additionally, the high processing temperature increases energy consumption and production costs.

The relatively high cost of PTFE compared to other polymer materials poses an economic challenge, especially for large-scale applications. This cost factor often necessitates a careful balance between performance benefits and economic feasibility in composite design.

PTFE's low surface energy, while beneficial in many applications, can hinder its wettability and compatibility with certain resins and matrices. This characteristic complicates the uniform dispersion of PTFE particles or fibers within the composite, potentially leading to inconsistent material properties and performance.

The thermal expansion coefficient of PTFE is significantly higher than that of many other materials used in composites. This mismatch can cause internal stresses and potential structural issues in composite materials subjected to temperature fluctuations, particularly in aerospace and automotive applications where thermal cycling is common.

Furthermore, achieving a uniform distribution of PTFE in composite materials remains a technical challenge. Agglomeration of PTFE particles or uneven fiber distribution can result in inconsistent material properties, affecting the overall performance and reliability of the composite.

The chemical inertness of PTFE, while advantageous in many scenarios, can be a drawback when chemical bonding or reactivity with the matrix is desired for enhanced interfacial strength. This limitation restricts certain composite design strategies and can necessitate the use of surface treatments or coupling agents, adding complexity to the manufacturing process.

Lastly, the recyclability and end-of-life management of PTFE-containing composites present environmental challenges. The high chemical stability of PTFE makes it resistant to conventional recycling methods, potentially limiting the sustainability profile of these advanced materials in an increasingly eco-conscious industrial landscape.

Another significant challenge is the high processing temperature required for PTFE, typically around 370°C. This elevated temperature can cause thermal degradation of other components in the composite, limiting the range of materials that can be effectively combined with PTFE. Additionally, the high processing temperature increases energy consumption and production costs.

The relatively high cost of PTFE compared to other polymer materials poses an economic challenge, especially for large-scale applications. This cost factor often necessitates a careful balance between performance benefits and economic feasibility in composite design.

PTFE's low surface energy, while beneficial in many applications, can hinder its wettability and compatibility with certain resins and matrices. This characteristic complicates the uniform dispersion of PTFE particles or fibers within the composite, potentially leading to inconsistent material properties and performance.

The thermal expansion coefficient of PTFE is significantly higher than that of many other materials used in composites. This mismatch can cause internal stresses and potential structural issues in composite materials subjected to temperature fluctuations, particularly in aerospace and automotive applications where thermal cycling is common.

Furthermore, achieving a uniform distribution of PTFE in composite materials remains a technical challenge. Agglomeration of PTFE particles or uneven fiber distribution can result in inconsistent material properties, affecting the overall performance and reliability of the composite.

The chemical inertness of PTFE, while advantageous in many scenarios, can be a drawback when chemical bonding or reactivity with the matrix is desired for enhanced interfacial strength. This limitation restricts certain composite design strategies and can necessitate the use of surface treatments or coupling agents, adding complexity to the manufacturing process.

Lastly, the recyclability and end-of-life management of PTFE-containing composites present environmental challenges. The high chemical stability of PTFE makes it resistant to conventional recycling methods, potentially limiting the sustainability profile of these advanced materials in an increasingly eco-conscious industrial landscape.

Current PTFE Solutions

01 PTFE weight reduction techniques

Various methods are employed to reduce the weight of PTFE materials while maintaining their desirable properties. These techniques include creating microporous structures, incorporating lightweight fillers, and developing advanced manufacturing processes to produce thinner PTFE films or sheets.- PTFE weight reduction in composites: Various methods are employed to reduce the weight of PTFE in composite materials while maintaining desired properties. These techniques include using PTFE micropowders, creating porous PTFE structures, and combining PTFE with lightweight fillers. The goal is to achieve a balance between weight reduction and performance characteristics in applications such as aerospace and automotive industries.

- PTFE fiber production for lightweight textiles: Innovations in PTFE fiber production focus on creating ultra-lightweight textiles. These advancements involve spinning techniques, fiber drawing processes, and surface treatments to produce PTFE fibers with reduced weight while maintaining strength and chemical resistance. The resulting lightweight PTFE textiles find applications in protective clothing and industrial filtration.

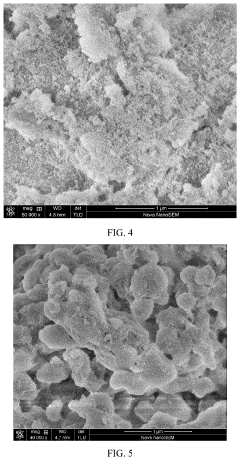

- Nanocomposites with PTFE for weight optimization: Nanocomposites incorporating PTFE are developed to optimize weight-to-performance ratios. These materials combine PTFE with nanofillers such as carbon nanotubes or nanoclays, resulting in lightweight composites with enhanced mechanical and thermal properties. The nanocomposite approach allows for significant weight reduction while improving overall material performance.

- Expanded PTFE (ePTFE) for lightweight applications: Expanded PTFE (ePTFE) is utilized to create lightweight structures with high porosity. The expansion process creates a microporous structure that significantly reduces the material's weight while maintaining its chemical resistance and thermal properties. ePTFE finds applications in lightweight membranes, filters, and insulation materials where weight reduction is crucial.

- PTFE weight reduction in coatings and films: Techniques are developed to reduce the weight of PTFE in coatings and films without compromising their non-stick and protective properties. These methods include creating ultra-thin PTFE layers, incorporating lightweight additives, and developing novel application processes. The resulting lightweight PTFE coatings and films are used in various industries to reduce overall product weight.

02 PTFE composites for weight optimization

PTFE is combined with other materials to create lightweight composites. These composites often incorporate materials such as carbon fibers, glass fibers, or hollow microspheres to reduce overall weight while enhancing specific properties like strength or thermal conductivity.Expand Specific Solutions03 Expanded PTFE (ePTFE) for weight reduction

Expanded PTFE, created through a stretching process, offers significantly reduced weight compared to standard PTFE. This material maintains excellent chemical resistance and low friction properties while providing a porous structure that contributes to its lightweight nature.Expand Specific Solutions04 PTFE nanoparticles and ultrafine powders

The development of PTFE nanoparticles and ultrafine powders allows for the creation of lightweight coatings and additives. These small particles can be dispersed in various matrices, providing PTFE properties with minimal weight addition.Expand Specific Solutions05 Weight-optimized PTFE applications

Specific applications leverage the lightweight properties of PTFE and its composites. These include aerospace components, high-performance textiles, and medical devices where weight reduction is crucial without compromising on the unique properties of PTFE.Expand Specific Solutions

Composite Industry Players

The PTFE composite materials market is in a growth phase, driven by increasing demand for lightweight, high-performance materials across various industries. The market size is expanding, with a projected CAGR of around 6% over the next five years. Technologically, PTFE composites are mature but continue to evolve, with companies like DuPont, Chemours, and Daikin leading innovation. These industry giants, along with specialized firms like Porex Corp. and academic institutions such as the University of Florida, are pushing the boundaries of PTFE composite applications. The competitive landscape is characterized by a mix of established chemical companies and niche players, with ongoing research focused on enhancing PTFE's properties and expanding its use in advanced composite structures.

DAIKIN INDUSTRIES Ltd.

Technical Solution: Daikin Industries has made significant advancements in PTFE-based lightweight composite materials through its NEOFLON™ product line. The company has developed high-performance PTFE grades that can be incorporated into various polymer matrices to create lightweight composites with enhanced chemical resistance, low friction, and high temperature stability[1]. Daikin's approach includes the engineering of PTFE micropowders and modified PTFE resins that can be easily dispersed in thermoplastic and thermoset systems, resulting in improved mechanical properties and weight reduction[2]. Their PTFE-enhanced composites find applications in aerospace, automotive, and industrial sectors where lightweight solutions are crucial. Daikin has also introduced innovative processing techniques for PTFE composites, such as melt-processable PTFE grades, which allow for easier integration into complex composite structures[3]. The company's research efforts have focused on developing eco-friendly PTFE solutions, including low-PFOA (perfluorooctanoic acid) PTFE grades, to address environmental concerns while maintaining the lightweight properties of PTFE composites[4].

Strengths: Extensive experience in fluoropolymer technology; global presence in multiple industries; strong focus on environmental sustainability. Weaknesses: High production costs for advanced PTFE grades; potential regulatory challenges related to fluoropolymers in some regions.

The Chemours Co.

Technical Solution: The Chemours Company has developed advanced PTFE-based composite materials for lightweight applications. Their Teflon™ PTFE fluoropolymer resins are incorporated into composite structures to enhance properties such as chemical resistance, low friction, and high temperature stability[1]. Chemours has engineered PTFE micropowders that can be dispersed in various polymer matrices to create lightweight composites with improved wear resistance and lubricity[2]. These PTFE-enhanced composites find applications in aerospace, automotive, and industrial sectors where weight reduction is critical. The company has also introduced expanded PTFE (ePTFE) membranes that can be laminated with other materials to form ultra-lightweight, breathable composites for protective clothing and filtration applications[3].

Strengths: Extensive expertise in fluoropolymer technology; wide range of PTFE grades for different composite applications; global manufacturing and distribution network. Weaknesses: PTFE's high cost compared to some alternative materials; challenges in recycling PTFE-containing composites.

PTFE Composite Innovations

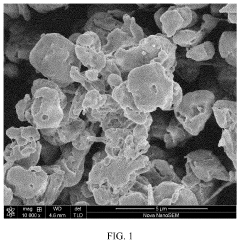

PTFE composite powder, preparation method thereof, and composite material containing the same

PatentInactiveUS20240174820A1

Innovation

- A PTFE composite powder is developed by coating an inorganic powder layer on the PTFE powder, followed by a surface treatment agent, which improves compatibility with various polymers and enhances interface bonding, using a method that avoids sodium-naphthalene treatment and requires simpler, more environmentally friendly processes.

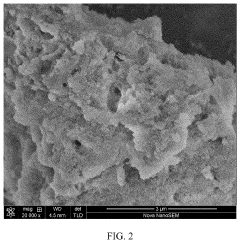

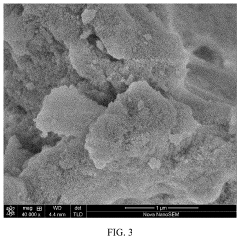

Inert Wear Resistant PTFE-Based Solid Lubricant Nanocomposite

PatentActiveUS20130172219A1

Innovation

- A PTFE-based composite material filled with irregularly shaped metal oxide nanoparticles, such as aluminum oxide, at lower weight percentages (1-10%) provides enhanced wear resistance, achieved through blending and heating processes like compression molding, which improves mechanical interaction and reduces wear rates significantly.

Environmental Impact

The environmental impact of PTFE in lightweight composite materials is a critical consideration in the development and application of these advanced materials. PTFE, or polytetrafluoroethylene, is known for its exceptional chemical resistance and low friction properties, making it a valuable component in composite structures. However, its environmental footprint requires careful examination.

PTFE production involves the use of fluoropolymers, which can have significant environmental implications. The manufacturing process often releases perfluorooctanoic acid (PFOA) and other perfluorinated compounds, which are persistent environmental pollutants. These substances have been linked to various ecological and health concerns, including potential carcinogenic effects and bioaccumulation in wildlife.

Despite these challenges, the incorporation of PTFE in lightweight composites offers some environmental benefits. The durability and longevity of PTFE-enhanced composites can lead to reduced material consumption over time, as products require less frequent replacement. Additionally, the lightweight nature of these composites contributes to improved fuel efficiency in transportation applications, potentially lowering overall carbon emissions.

Recycling and end-of-life management of PTFE-containing composites present both opportunities and challenges. While PTFE itself is recyclable, its integration into complex composite structures can complicate the recycling process. Advanced separation techniques are being developed to address this issue, aiming to recover and reuse PTFE from composite waste streams.

The aerospace and automotive industries, major users of PTFE-enhanced lightweight composites, are increasingly focusing on sustainable practices. This has led to research into bio-based alternatives and environmentally friendly production methods for PTFE and similar materials. Such innovations could significantly reduce the environmental impact of these composites in the future.

Life cycle assessments (LCAs) of PTFE in lightweight composites reveal a complex environmental profile. While the production phase may have higher environmental costs, the use phase often shows benefits in terms of energy efficiency and reduced emissions. Balancing these factors is crucial for determining the overall environmental sustainability of PTFE-enhanced composites.

As environmental regulations become more stringent, particularly regarding fluoropolymers, the industry is adapting. Manufacturers are exploring alternative production methods and seeking substitutes for PFOA and other harmful compounds. These efforts aim to maintain the performance benefits of PTFE while minimizing its environmental footprint.

PTFE production involves the use of fluoropolymers, which can have significant environmental implications. The manufacturing process often releases perfluorooctanoic acid (PFOA) and other perfluorinated compounds, which are persistent environmental pollutants. These substances have been linked to various ecological and health concerns, including potential carcinogenic effects and bioaccumulation in wildlife.

Despite these challenges, the incorporation of PTFE in lightweight composites offers some environmental benefits. The durability and longevity of PTFE-enhanced composites can lead to reduced material consumption over time, as products require less frequent replacement. Additionally, the lightweight nature of these composites contributes to improved fuel efficiency in transportation applications, potentially lowering overall carbon emissions.

Recycling and end-of-life management of PTFE-containing composites present both opportunities and challenges. While PTFE itself is recyclable, its integration into complex composite structures can complicate the recycling process. Advanced separation techniques are being developed to address this issue, aiming to recover and reuse PTFE from composite waste streams.

The aerospace and automotive industries, major users of PTFE-enhanced lightweight composites, are increasingly focusing on sustainable practices. This has led to research into bio-based alternatives and environmentally friendly production methods for PTFE and similar materials. Such innovations could significantly reduce the environmental impact of these composites in the future.

Life cycle assessments (LCAs) of PTFE in lightweight composites reveal a complex environmental profile. While the production phase may have higher environmental costs, the use phase often shows benefits in terms of energy efficiency and reduced emissions. Balancing these factors is crucial for determining the overall environmental sustainability of PTFE-enhanced composites.

As environmental regulations become more stringent, particularly regarding fluoropolymers, the industry is adapting. Manufacturers are exploring alternative production methods and seeking substitutes for PFOA and other harmful compounds. These efforts aim to maintain the performance benefits of PTFE while minimizing its environmental footprint.

PTFE Recycling Strategies

Recycling strategies for PTFE (polytetrafluoroethylene) in lightweight composite materials are becoming increasingly important as environmental concerns and resource conservation gain prominence. The recycling of PTFE presents unique challenges due to its chemical stability and resistance to thermal degradation, which are the same properties that make it valuable in composite applications.

One of the primary recycling strategies for PTFE in composites involves mechanical recycling. This process begins with the separation of PTFE from other composite components through grinding or shredding. The recovered PTFE particles can then be reprocessed into new products, although often with some loss in performance compared to virgin material. This method is particularly effective for clean, single-source PTFE waste streams.

Chemical recycling offers another avenue for PTFE recovery. This approach involves breaking down the PTFE polymer into its constituent monomers or other valuable chemical compounds. Pyrolysis, a process of thermal decomposition in the absence of oxygen, has shown promise in converting PTFE into tetrafluoroethylene (TFE) and other fluorinated compounds. These recovered chemicals can serve as raw materials for new PTFE production or other industrial applications.

A more recent development in PTFE recycling is the use of supercritical fluid technology. This method employs supercritical carbon dioxide or water to dissolve and extract PTFE from composite materials. The advantage of this approach is its ability to recover PTFE without significant degradation, potentially allowing for higher-quality recycled material.

Upcycling strategies are also being explored, where recycled PTFE is incorporated into new, higher-value applications. For instance, recovered PTFE particles can be used as additives in high-performance coatings or as fillers in specialized polymer blends, leveraging the material's unique properties even in its recycled form.

The development of design-for-recycling principles is crucial for improving PTFE recyclability in composite materials. This involves creating composite structures that facilitate easier separation of PTFE from other components at the end of the product's life cycle. Such design considerations may include the use of compatible adhesives or matrix materials that allow for more efficient recycling processes.

As research in this field progresses, novel recycling technologies are emerging. These include advanced solvent-based extraction methods and the use of engineered enzymes to break down PTFE. While still in early stages, these approaches hold promise for more efficient and environmentally friendly PTFE recycling in the future.

One of the primary recycling strategies for PTFE in composites involves mechanical recycling. This process begins with the separation of PTFE from other composite components through grinding or shredding. The recovered PTFE particles can then be reprocessed into new products, although often with some loss in performance compared to virgin material. This method is particularly effective for clean, single-source PTFE waste streams.

Chemical recycling offers another avenue for PTFE recovery. This approach involves breaking down the PTFE polymer into its constituent monomers or other valuable chemical compounds. Pyrolysis, a process of thermal decomposition in the absence of oxygen, has shown promise in converting PTFE into tetrafluoroethylene (TFE) and other fluorinated compounds. These recovered chemicals can serve as raw materials for new PTFE production or other industrial applications.

A more recent development in PTFE recycling is the use of supercritical fluid technology. This method employs supercritical carbon dioxide or water to dissolve and extract PTFE from composite materials. The advantage of this approach is its ability to recover PTFE without significant degradation, potentially allowing for higher-quality recycled material.

Upcycling strategies are also being explored, where recycled PTFE is incorporated into new, higher-value applications. For instance, recovered PTFE particles can be used as additives in high-performance coatings or as fillers in specialized polymer blends, leveraging the material's unique properties even in its recycled form.

The development of design-for-recycling principles is crucial for improving PTFE recyclability in composite materials. This involves creating composite structures that facilitate easier separation of PTFE from other components at the end of the product's life cycle. Such design considerations may include the use of compatible adhesives or matrix materials that allow for more efficient recycling processes.

As research in this field progresses, novel recycling technologies are emerging. These include advanced solvent-based extraction methods and the use of engineered enzymes to break down PTFE. While still in early stages, these approaches hold promise for more efficient and environmentally friendly PTFE recycling in the future.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!