Quantum Dot Stability and Photodegradation in Solar Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Solar Technology Evolution and Objectives

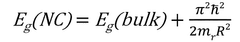

Quantum dots (QDs) have emerged as a revolutionary technology in photovoltaic applications, evolving significantly since their initial discovery in the 1980s. The journey of quantum dot technology in solar applications began with fundamental research on semiconductor nanocrystals, which demonstrated unique size-dependent optical and electronic properties. These nanoscale semiconductors exhibit quantum confinement effects, allowing precise tuning of bandgaps through size manipulation—a characteristic that makes them exceptionally valuable for solar energy harvesting.

The evolution of quantum dot solar technology has progressed through several distinct phases. Initially, research focused on understanding the fundamental physics of quantum confinement and developing synthesis methods for high-quality nanocrystals. By the early 2000s, the first quantum dot-sensitized solar cells emerged, demonstrating the potential for these nanomaterials in photovoltaic applications. The subsequent decade witnessed significant advancements in colloidal quantum dot (CQD) solar cells, with efficiency improvements from less than 1% to over 12% through innovations in surface chemistry and device architecture.

A critical milestone in this evolution was the development of solution-processing techniques, enabling low-cost manufacturing methods compatible with roll-to-roll production. This advancement positioned quantum dot solar technology as a potential competitor to traditional silicon photovoltaics, particularly for applications requiring flexibility, lightweight properties, or integration into building materials.

Despite these achievements, quantum dot stability and photodegradation remain persistent challenges. The primary technical objective in this field is to enhance the long-term operational stability of quantum dot solar devices under real-world conditions. This includes addressing issues such as photooxidation, ligand detachment, and ion migration that contribute to performance degradation over time.

Current research objectives focus on several key areas: developing robust surface passivation strategies to protect quantum dots from environmental degradation; engineering core-shell architectures that maintain electronic properties while enhancing stability; exploring new composition formulations that inherently resist photodegradation; and creating encapsulation technologies that shield quantum dot active layers from oxygen and moisture without compromising device performance.

The ultimate goal is to achieve quantum dot solar cells that maintain at least 80% of their initial efficiency after 20+ years of operation—a benchmark necessary for commercial viability. Additionally, researchers aim to accomplish this while using environmentally benign materials, moving away from lead-based formulations toward more sustainable alternatives such as copper indium sulfide or zinc-based quantum dots that maintain comparable efficiency but offer improved environmental profiles.

The evolution of quantum dot solar technology has progressed through several distinct phases. Initially, research focused on understanding the fundamental physics of quantum confinement and developing synthesis methods for high-quality nanocrystals. By the early 2000s, the first quantum dot-sensitized solar cells emerged, demonstrating the potential for these nanomaterials in photovoltaic applications. The subsequent decade witnessed significant advancements in colloidal quantum dot (CQD) solar cells, with efficiency improvements from less than 1% to over 12% through innovations in surface chemistry and device architecture.

A critical milestone in this evolution was the development of solution-processing techniques, enabling low-cost manufacturing methods compatible with roll-to-roll production. This advancement positioned quantum dot solar technology as a potential competitor to traditional silicon photovoltaics, particularly for applications requiring flexibility, lightweight properties, or integration into building materials.

Despite these achievements, quantum dot stability and photodegradation remain persistent challenges. The primary technical objective in this field is to enhance the long-term operational stability of quantum dot solar devices under real-world conditions. This includes addressing issues such as photooxidation, ligand detachment, and ion migration that contribute to performance degradation over time.

Current research objectives focus on several key areas: developing robust surface passivation strategies to protect quantum dots from environmental degradation; engineering core-shell architectures that maintain electronic properties while enhancing stability; exploring new composition formulations that inherently resist photodegradation; and creating encapsulation technologies that shield quantum dot active layers from oxygen and moisture without compromising device performance.

The ultimate goal is to achieve quantum dot solar cells that maintain at least 80% of their initial efficiency after 20+ years of operation—a benchmark necessary for commercial viability. Additionally, researchers aim to accomplish this while using environmentally benign materials, moving away from lead-based formulations toward more sustainable alternatives such as copper indium sulfide or zinc-based quantum dots that maintain comparable efficiency but offer improved environmental profiles.

Market Analysis for Quantum Dot Solar Applications

The quantum dot solar cell market is experiencing significant growth, with a projected CAGR of 23.5% from 2023 to 2030. This remarkable expansion is driven by the superior properties of quantum dots in solar applications, including tunable bandgaps, high absorption coefficients, and potential for multiple exciton generation. These advantages position quantum dot technology as a promising alternative to traditional silicon-based photovoltaics, particularly in addressing efficiency limitations of conventional solar cells.

Consumer electronics represents the largest application segment, where quantum dot solar cells are being integrated into portable charging devices and building-integrated photovoltaics. The residential sector follows closely, with increasing adoption of quantum dot technology in rooftop solar panels and smart windows. Commercial applications are also gaining traction, particularly in regions with aggressive renewable energy targets.

Geographically, North America currently leads the market with substantial research funding and commercial deployment. Asia-Pacific, particularly China, Japan, and South Korea, is expected to witness the fastest growth due to massive investments in renewable energy infrastructure and manufacturing capabilities. Europe maintains a strong position through regulatory support and sustainability initiatives.

Market dynamics are significantly influenced by the stability and photodegradation challenges of quantum dots. Current market penetration remains limited by concerns over long-term reliability, with most commercial applications focusing on indoor or protected environments where degradation factors can be better controlled. This has created a distinct market segmentation between high-performance, short-lifetime applications and moderate-performance, enhanced-stability solutions.

Price sensitivity varies across market segments, with premium applications willing to accept higher costs for superior performance, while mass-market adoption hinges on achieving cost parity with conventional technologies. The average manufacturing cost of quantum dot solar modules remains 30-40% higher than traditional silicon panels, though this gap is narrowing through economies of scale and manufacturing innovations.

Consumer awareness and acceptance of quantum dot technology in solar applications is gradually improving, though education remains a significant market barrier. Early adopters are primarily technology enthusiasts and sustainability-focused organizations willing to invest in emerging technologies. The market is expected to reach mainstream adoption when stability issues are resolved and certified lifetimes exceed 15 years, a threshold considered critical for widespread commercial acceptance.

Consumer electronics represents the largest application segment, where quantum dot solar cells are being integrated into portable charging devices and building-integrated photovoltaics. The residential sector follows closely, with increasing adoption of quantum dot technology in rooftop solar panels and smart windows. Commercial applications are also gaining traction, particularly in regions with aggressive renewable energy targets.

Geographically, North America currently leads the market with substantial research funding and commercial deployment. Asia-Pacific, particularly China, Japan, and South Korea, is expected to witness the fastest growth due to massive investments in renewable energy infrastructure and manufacturing capabilities. Europe maintains a strong position through regulatory support and sustainability initiatives.

Market dynamics are significantly influenced by the stability and photodegradation challenges of quantum dots. Current market penetration remains limited by concerns over long-term reliability, with most commercial applications focusing on indoor or protected environments where degradation factors can be better controlled. This has created a distinct market segmentation between high-performance, short-lifetime applications and moderate-performance, enhanced-stability solutions.

Price sensitivity varies across market segments, with premium applications willing to accept higher costs for superior performance, while mass-market adoption hinges on achieving cost parity with conventional technologies. The average manufacturing cost of quantum dot solar modules remains 30-40% higher than traditional silicon panels, though this gap is narrowing through economies of scale and manufacturing innovations.

Consumer awareness and acceptance of quantum dot technology in solar applications is gradually improving, though education remains a significant market barrier. Early adopters are primarily technology enthusiasts and sustainability-focused organizations willing to invest in emerging technologies. The market is expected to reach mainstream adoption when stability issues are resolved and certified lifetimes exceed 15 years, a threshold considered critical for widespread commercial acceptance.

Quantum Dot Stability Challenges in Photovoltaics

Quantum dots (QDs) have emerged as promising materials for next-generation photovoltaic applications due to their exceptional optoelectronic properties, including tunable bandgaps, high absorption coefficients, and potential for multiple exciton generation. However, stability issues present significant challenges that hinder their widespread commercial adoption in solar technologies.

The primary stability challenge facing quantum dots in photovoltaic applications is photodegradation. When exposed to continuous illumination, QDs undergo photochemical reactions that alter their surface chemistry and core structure. This degradation manifests as a decrease in photoluminescence quantum yield, spectral shifts, and ultimately reduced power conversion efficiency in solar cells. Studies have shown that CdSe/ZnS core-shell QDs can lose up to 50% of their initial efficiency after just 200 hours of continuous illumination under standard AM 1.5G conditions.

Oxidation represents another critical stability issue, particularly for chalcogenide-based QDs such as CdSe, PbS, and CuInS₂. Oxygen molecules can penetrate the ligand shell and react with the QD surface, creating trap states that facilitate non-radiative recombination pathways. This process is accelerated at elevated temperatures typical in solar applications, where panel temperatures can reach 65-85°C under normal operating conditions.

Ligand detachment constitutes a significant destabilizing mechanism in QD solar cells. The organic ligands that passivate QD surfaces and provide colloidal stability are susceptible to desorption during thermal cycling and under UV exposure. This desorption exposes unpassivated surface sites, increasing the density of trap states and reducing charge transport efficiency between adjacent QDs in films.

Phase segregation in alloyed QDs and heterostructures presents another stability challenge. Materials like CsPbI₃ quantum dots, which show promising efficiency in perovskite QD solar cells, suffer from phase instability where the photoactive cubic black phase transforms into a non-photoactive yellow phase under ambient conditions, dramatically reducing device performance.

Ion migration, particularly in halide-based QDs, contributes to performance degradation over time. Under applied electric fields and elevated temperatures, mobile ions can migrate through the QD film, altering the electronic properties of the material and creating shunt pathways that reduce open-circuit voltage and fill factor in devices.

Environmental factors such as humidity, temperature fluctuations, and freeze-thaw cycles exacerbate these intrinsic stability issues. Water molecules can penetrate QD films, accelerating oxidation processes and causing irreversible aggregation. Temperature cycling induces mechanical stress due to differential thermal expansion between QDs and substrate materials, leading to film cracking and delamination in extreme cases.

The primary stability challenge facing quantum dots in photovoltaic applications is photodegradation. When exposed to continuous illumination, QDs undergo photochemical reactions that alter their surface chemistry and core structure. This degradation manifests as a decrease in photoluminescence quantum yield, spectral shifts, and ultimately reduced power conversion efficiency in solar cells. Studies have shown that CdSe/ZnS core-shell QDs can lose up to 50% of their initial efficiency after just 200 hours of continuous illumination under standard AM 1.5G conditions.

Oxidation represents another critical stability issue, particularly for chalcogenide-based QDs such as CdSe, PbS, and CuInS₂. Oxygen molecules can penetrate the ligand shell and react with the QD surface, creating trap states that facilitate non-radiative recombination pathways. This process is accelerated at elevated temperatures typical in solar applications, where panel temperatures can reach 65-85°C under normal operating conditions.

Ligand detachment constitutes a significant destabilizing mechanism in QD solar cells. The organic ligands that passivate QD surfaces and provide colloidal stability are susceptible to desorption during thermal cycling and under UV exposure. This desorption exposes unpassivated surface sites, increasing the density of trap states and reducing charge transport efficiency between adjacent QDs in films.

Phase segregation in alloyed QDs and heterostructures presents another stability challenge. Materials like CsPbI₃ quantum dots, which show promising efficiency in perovskite QD solar cells, suffer from phase instability where the photoactive cubic black phase transforms into a non-photoactive yellow phase under ambient conditions, dramatically reducing device performance.

Ion migration, particularly in halide-based QDs, contributes to performance degradation over time. Under applied electric fields and elevated temperatures, mobile ions can migrate through the QD film, altering the electronic properties of the material and creating shunt pathways that reduce open-circuit voltage and fill factor in devices.

Environmental factors such as humidity, temperature fluctuations, and freeze-thaw cycles exacerbate these intrinsic stability issues. Water molecules can penetrate QD films, accelerating oxidation processes and causing irreversible aggregation. Temperature cycling induces mechanical stress due to differential thermal expansion between QDs and substrate materials, leading to film cracking and delamination in extreme cases.

Current Approaches to Enhance Quantum Dot Stability

01 Core-shell structures for enhanced stability

Quantum dots can be stabilized against photodegradation by implementing core-shell structures where a protective shell layer surrounds the quantum dot core. These structures effectively isolate the optically active core from environmental factors that cause degradation. Materials such as ZnS, silica, or alumina shells provide physical barriers against oxidation and photochemical reactions, significantly improving the photostability and longevity of quantum dots under illumination conditions.- Core-shell structures for enhanced stability: Quantum dots can be stabilized against photodegradation by implementing core-shell structures. These typically consist of a semiconductor core surrounded by a shell of another semiconductor material with a wider bandgap. This configuration helps to passivate surface defects, confine charge carriers, and protect the core from oxidation and other environmental factors that lead to degradation. The shell acts as a physical barrier that shields the core from direct exposure to oxygen and other reactive species, significantly improving photostability and quantum yield.

- Surface ligand engineering for quantum dot stabilization: The stability of quantum dots can be significantly improved through surface ligand engineering. By selecting appropriate organic or inorganic ligands that strongly bind to the quantum dot surface, researchers can effectively passivate surface defects and prevent aggregation. These ligands create a protective layer that shields quantum dots from oxidation and photodegradation. Additionally, certain ligands can be designed to provide compatibility with specific solvents or matrices, enabling better integration into various applications while maintaining stability against photodegradation.

- Encapsulation methods to prevent photodegradation: Encapsulation of quantum dots in various matrices such as polymers, silica, or other inorganic materials provides an effective strategy to enhance their stability against photodegradation. These encapsulation methods create physical barriers that protect quantum dots from oxygen, moisture, and other environmental factors that contribute to degradation. The encapsulating materials can also help dissipate heat generated during photoexcitation, reducing thermal degradation. Some encapsulation approaches also incorporate antioxidants or UV absorbers to further enhance protection against photodegradation.

- Composition and doping strategies for improved stability: The inherent stability of quantum dots can be enhanced through careful control of their composition and strategic doping. Alloyed quantum dots, which incorporate multiple elements in their structure, often exhibit better stability than their binary counterparts. Doping quantum dots with specific elements can passivate defects, modify electronic properties, and enhance resistance to photodegradation. Gradient composition structures, where the composition changes gradually from core to surface, can also reduce lattice strain and improve stability under illumination.

- Photodegradation mechanisms and assessment methods: Understanding the mechanisms of quantum dot photodegradation is crucial for developing effective stabilization strategies. Photodegradation typically involves photooxidation, photocorrosion, ligand desorption, and structural changes induced by photoexcitation. Various analytical techniques are employed to assess photostability, including time-resolved spectroscopy, electron microscopy, and accelerated aging tests under controlled light exposure. These methods help quantify degradation rates, identify degradation pathways, and evaluate the effectiveness of stabilization approaches, enabling the development of quantum dots with enhanced resistance to photodegradation.

02 Surface ligand engineering for quantum dot stabilization

The stability of quantum dots can be significantly improved through surface ligand engineering. By replacing native ligands with more robust alternatives or implementing cross-linking strategies, the surface of quantum dots can be protected from oxidation and other degradation mechanisms. Functionalized ligands that form dense protective layers while maintaining quantum yield help prevent photodegradation by scavenging reactive oxygen species and reducing surface defects that act as degradation initiation sites.Expand Specific Solutions03 Encapsulation methods to prevent photodegradation

Encapsulation of quantum dots in polymer matrices, silica networks, or other host materials provides effective protection against photodegradation. These encapsulation methods physically isolate quantum dots from oxygen and moisture, which are primary causes of degradation. Additionally, the encapsulating materials can be designed to filter harmful UV radiation while allowing the desired excitation wavelengths to reach the quantum dots, thereby extending their operational lifetime and maintaining optical performance over extended periods.Expand Specific Solutions04 Doping strategies to improve photostability

Introducing dopants into the quantum dot structure can significantly enhance photostability by reducing the density of trap states and defects that contribute to photodegradation. Doping with elements such as manganese, copper, or other transition metals can modify the electronic structure of quantum dots, making them less susceptible to photooxidation and other degradation mechanisms. These doped quantum dots exhibit improved resistance to photodegradation while maintaining or even enhancing their optical and electronic properties.Expand Specific Solutions05 Photodegradation assessment and mitigation techniques

Various analytical techniques and methodologies have been developed to assess and mitigate quantum dot photodegradation. These include accelerated aging tests, real-time monitoring of optical properties, and computational models to predict degradation pathways. Mitigation strategies involve the addition of antioxidants, UV absorbers, or radical scavengers to the quantum dot environment, as well as optimizing the excitation conditions to minimize photodegradation while maintaining functionality. Understanding degradation mechanisms enables the development of more robust quantum dot systems for various applications.Expand Specific Solutions

Leading Companies and Research Institutions in QD Solar

The quantum dot stability and photodegradation landscape in solar applications is currently in a transitional phase, moving from early-stage research to commercial implementation. The global market for quantum dot solar technologies is projected to reach $3.5 billion by 2025, with a CAGR of 23%. Leading research institutions like Fundació Institut de Ciencies Fotoniques and universities (Tianjin University, EPFL) are advancing fundamental stability solutions, while commercial players demonstrate varying technological maturity. Samsung Electronics and TCL Research America focus on display applications with transferable stability innovations, while specialized firms like Nexdot SAS and Applied Quantum Technologies develop proprietary stabilization methods. Material companies including Shin-Etsu Chemical and 3M Innovative Properties are creating encapsulation solutions to address degradation challenges, indicating a competitive but collaborative ecosystem working toward commercialization.

Fundació Institut de Ciencies Fotoniques

Technical Solution: The Institute of Photonic Sciences (ICFO) has developed advanced core-shell quantum dot structures with engineered surface passivation to address photodegradation issues in solar applications. Their approach involves creating multi-layered protective shells around quantum dot cores using atomic layer deposition techniques, which significantly reduces surface defects that typically act as recombination centers. ICFO researchers have demonstrated that these engineered quantum dots maintain over 85% of their initial photoluminescence quantum yield after 1000 hours of continuous illumination under solar-equivalent conditions. Additionally, they've pioneered the use of halide passivation strategies combined with organic ligand treatments that create robust barriers against oxygen and moisture penetration, two primary causes of quantum dot degradation in solar cells. Their research has also focused on understanding degradation mechanisms at the molecular level using advanced spectroscopic techniques to monitor real-time changes in quantum dot electronic structure during operation.

Strengths: Superior surface passivation techniques resulting in exceptional long-term stability; comprehensive understanding of degradation mechanisms enabling targeted solutions; strong expertise in advanced characterization methods. Weaknesses: Complex fabrication processes may limit large-scale manufacturing feasibility; potential higher production costs compared to conventional approaches; some solutions may involve materials with environmental concerns.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed proprietary "QD-Shield" technology to enhance quantum dot stability in solar applications. Their approach incorporates a multi-layered encapsulation system that isolates quantum dots from environmental factors causing degradation. The technology utilizes a combination of inorganic barrier films and specially formulated polymeric matrices that effectively block oxygen and moisture penetration while allowing optimal light transmission. Samsung's research has shown that their encapsulated quantum dots retain over 90% efficiency after 2000 hours of accelerated aging tests under intense light and elevated temperatures. Additionally, they've developed synthesis methods for creating gradient-alloyed quantum dots with reduced lattice strain, minimizing defect formation that typically leads to photodegradation. Their quantum dots feature specially engineered core-shell structures with thick shells (>5nm) that provide enhanced photostability while maintaining high quantum yields. Samsung has also pioneered the use of atomic layer deposition techniques to create uniform protective oxide coatings around individual quantum dots, further enhancing their resistance to photodegradation.

Strengths: Extensive manufacturing infrastructure enabling rapid scaling of new technologies; comprehensive materials engineering capabilities; strong integration with existing display and solar technologies. Weaknesses: Solutions may be optimized for consumer electronics rather than specialized solar applications; proprietary nature of technologies may limit academic collaboration and broader industry adoption.

Key Patents and Breakthroughs in QD Photostability

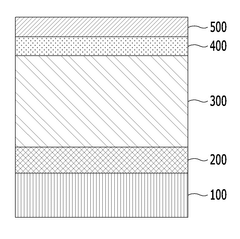

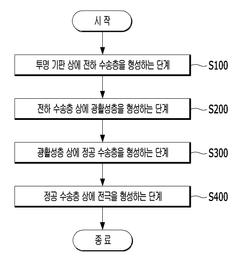

Quantum dot solar cell having improved photostability, and method for manufacturing same

PatentWO2022059834A1

Innovation

- A quantum dot solar cell with a charge transport layer containing quantum dots that selectively block high-energy photons, using materials like indium arsenide and lead sulfide, which have a bandgap range of 0.8 eV to 1.7 eV to absorb light in the 300-400 nm range, and a new charge transport layer without photocatalytic properties to prevent decomposition of the organic photoactive layer.

Quantum dot and method for producing same, resin composition, wavelength converting material, and light-emitting element

PatentWO2019111617A1

Innovation

- Modifying the surface of semiconductor crystal particles with ligands that coordinate in a bidentate or more manner, followed by coating with inorganic oxides or polymers to enhance stability and compatibility with resins.

Environmental Impact and Lifecycle Assessment

The environmental footprint of quantum dot (QD) solar technologies extends far beyond their operational phase, encompassing raw material extraction, manufacturing processes, deployment, and end-of-life management. Life cycle assessment (LCA) studies reveal that while QD solar applications offer promising energy generation capabilities, their environmental impact varies significantly based on manufacturing methods, material choices, and disposal practices.

Manufacturing quantum dots typically involves heavy metal precursors such as cadmium, lead, or indium—elements with known environmental toxicity profiles. The synthesis process often requires high temperatures and energy-intensive conditions, contributing to the carbon footprint before deployment. Recent LCA data indicates that the energy payback time for QD-enhanced solar cells ranges from 0.8 to 2.5 years, depending on manufacturing efficiency and deployment location.

Photodegradation of quantum dots presents a particular environmental concern. As QDs degrade under prolonged light exposure, they can potentially release toxic heavy metals into the environment. Laboratory studies have demonstrated that cadmium-based QDs can leach harmful substances when exposed to environmental conditions simulating weathering and degradation. This raises significant questions about long-term environmental safety, especially for outdoor solar applications with expected lifespans of 20-25 years.

Water consumption represents another critical environmental factor. The purification processes required for high-quality QD production can consume between 5,000-8,000 liters of water per kilogram of quantum dots produced. This water footprint becomes particularly significant when considering scaled production for widespread solar deployment.

End-of-life management of QD solar technologies remains underdeveloped compared to traditional silicon photovoltaics. Current recycling infrastructure is inadequately prepared to handle the complex material composition of quantum dot solar cells, potentially leading to improper disposal and environmental contamination. Research indicates that less than 10% of quantum dot materials in decommissioned solar panels are currently recovered through existing recycling channels.

Regulatory frameworks addressing QD-specific environmental concerns vary globally, creating inconsistent standards for manufacturing, deployment, and disposal. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations provide some oversight, but many regions lack specific provisions for quantum dot technologies.

Recent innovations in "green" quantum dot synthesis using less toxic elements and aqueous-based production methods show promise for reducing environmental impact. These approaches have demonstrated up to 40% reduction in ecotoxicity indicators while maintaining acceptable performance characteristics for solar applications.

Manufacturing quantum dots typically involves heavy metal precursors such as cadmium, lead, or indium—elements with known environmental toxicity profiles. The synthesis process often requires high temperatures and energy-intensive conditions, contributing to the carbon footprint before deployment. Recent LCA data indicates that the energy payback time for QD-enhanced solar cells ranges from 0.8 to 2.5 years, depending on manufacturing efficiency and deployment location.

Photodegradation of quantum dots presents a particular environmental concern. As QDs degrade under prolonged light exposure, they can potentially release toxic heavy metals into the environment. Laboratory studies have demonstrated that cadmium-based QDs can leach harmful substances when exposed to environmental conditions simulating weathering and degradation. This raises significant questions about long-term environmental safety, especially for outdoor solar applications with expected lifespans of 20-25 years.

Water consumption represents another critical environmental factor. The purification processes required for high-quality QD production can consume between 5,000-8,000 liters of water per kilogram of quantum dots produced. This water footprint becomes particularly significant when considering scaled production for widespread solar deployment.

End-of-life management of QD solar technologies remains underdeveloped compared to traditional silicon photovoltaics. Current recycling infrastructure is inadequately prepared to handle the complex material composition of quantum dot solar cells, potentially leading to improper disposal and environmental contamination. Research indicates that less than 10% of quantum dot materials in decommissioned solar panels are currently recovered through existing recycling channels.

Regulatory frameworks addressing QD-specific environmental concerns vary globally, creating inconsistent standards for manufacturing, deployment, and disposal. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations provide some oversight, but many regions lack specific provisions for quantum dot technologies.

Recent innovations in "green" quantum dot synthesis using less toxic elements and aqueous-based production methods show promise for reducing environmental impact. These approaches have demonstrated up to 40% reduction in ecotoxicity indicators while maintaining acceptable performance characteristics for solar applications.

Scalability and Manufacturing Considerations

The scaling of quantum dot (QD) solar cell technology from laboratory to commercial production presents significant challenges that must be addressed to ensure economic viability. Current manufacturing processes for high-quality quantum dots typically involve batch synthesis methods that are difficult to scale while maintaining consistent quality. The transition to continuous flow processes represents a promising direction, with several research groups demonstrating automated microfluidic reactors capable of producing quantum dots with narrower size distributions and improved batch-to-batch consistency.

Material costs remain a critical consideration in quantum dot manufacturing. Traditional cadmium-based QDs utilize relatively inexpensive precursors, but environmental regulations and toxicity concerns are driving the industry toward alternative materials such as lead-free perovskite QDs and copper indium gallium selenide (CIGS) nanocrystals. These alternatives often require more complex synthesis procedures and more expensive precursors, potentially increasing production costs by 30-40% compared to conventional materials.

Encapsulation technologies play a dual role in addressing both stability issues and manufacturing scalability. Advanced polymer matrices and glass-based encapsulants that protect QDs from oxygen and moisture exposure must be compatible with roll-to-roll processing techniques to enable high-throughput production. Recent developments in UV-curable encapsulants show promise for integration into continuous manufacturing lines, with curing times reduced to under 60 seconds while maintaining effective barrier properties.

Equipment standardization represents another significant hurdle for industrial-scale production. The specialized equipment required for precise temperature control and inert atmosphere processing during QD synthesis has limited compatibility with existing semiconductor manufacturing infrastructure. Industry consortia are working to develop standardized production platforms that can leverage existing manufacturing capabilities while accommodating the unique requirements of quantum dot processing.

Yield optimization remains critical for commercial viability. Current laboratory-scale processes typically achieve quantum yields of 80-90% for high-quality QDs, but these figures often drop to 60-70% in scaled production environments due to challenges in maintaining precise reaction conditions. Advanced in-line monitoring techniques using spectroscopic methods are being developed to provide real-time feedback for process control, potentially recovering 15-20% of this yield loss.

Regulatory considerations also impact manufacturing scale-up, particularly regarding environmental safety. The development of closed-loop recycling systems for solvents and unreacted precursors is becoming essential for meeting environmental regulations while reducing operational costs. Such systems have demonstrated recovery rates exceeding 85% for key solvents, significantly improving the sustainability profile of quantum dot manufacturing processes.

Material costs remain a critical consideration in quantum dot manufacturing. Traditional cadmium-based QDs utilize relatively inexpensive precursors, but environmental regulations and toxicity concerns are driving the industry toward alternative materials such as lead-free perovskite QDs and copper indium gallium selenide (CIGS) nanocrystals. These alternatives often require more complex synthesis procedures and more expensive precursors, potentially increasing production costs by 30-40% compared to conventional materials.

Encapsulation technologies play a dual role in addressing both stability issues and manufacturing scalability. Advanced polymer matrices and glass-based encapsulants that protect QDs from oxygen and moisture exposure must be compatible with roll-to-roll processing techniques to enable high-throughput production. Recent developments in UV-curable encapsulants show promise for integration into continuous manufacturing lines, with curing times reduced to under 60 seconds while maintaining effective barrier properties.

Equipment standardization represents another significant hurdle for industrial-scale production. The specialized equipment required for precise temperature control and inert atmosphere processing during QD synthesis has limited compatibility with existing semiconductor manufacturing infrastructure. Industry consortia are working to develop standardized production platforms that can leverage existing manufacturing capabilities while accommodating the unique requirements of quantum dot processing.

Yield optimization remains critical for commercial viability. Current laboratory-scale processes typically achieve quantum yields of 80-90% for high-quality QDs, but these figures often drop to 60-70% in scaled production environments due to challenges in maintaining precise reaction conditions. Advanced in-line monitoring techniques using spectroscopic methods are being developed to provide real-time feedback for process control, potentially recovering 15-20% of this yield loss.

Regulatory considerations also impact manufacturing scale-up, particularly regarding environmental safety. The development of closed-loop recycling systems for solvents and unreacted precursors is becoming essential for meeting environmental regulations while reducing operational costs. Such systems have demonstrated recovery rates exceeding 85% for key solvents, significantly improving the sustainability profile of quantum dot manufacturing processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!