Quantum Dot Stability in High-Performance Liquid Chromatography

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot HPLC Technology Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials with exceptional optical and electronic properties since their discovery in the early 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit size-dependent luminescence characteristics and high quantum yields, making them invaluable for numerous applications across biomedical imaging, sensing, and analytical chemistry. The integration of quantum dots with High-Performance Liquid Chromatography (HPLC) represents a significant technological convergence with tremendous potential for enhancing analytical capabilities.

The evolution of quantum dot technology has progressed through several distinct phases, beginning with their initial synthesis and characterization, followed by surface modification strategies to enhance their stability and functionality, and more recently, their incorporation into analytical separation techniques. The marriage of quantum dots with HPLC systems has been driven by the need for more sensitive, selective, and versatile detection methods in complex sample analysis.

A critical challenge in this technological integration has been maintaining quantum dot stability under the harsh conditions typical of HPLC separations. The high pressures, varied mobile phase compositions, and potential interactions with stationary phases can significantly compromise quantum dot integrity, leading to diminished optical performance, aggregation, or surface degradation. These stability issues have limited the widespread adoption of quantum dot-enhanced HPLC methodologies despite their theoretical advantages.

The technical objectives of current research in this field are multifaceted. Primary goals include developing quantum dot formulations with enhanced chemical stability in diverse mobile phase environments, particularly in the presence of organic solvents and varying pH conditions. Additionally, researchers aim to engineer surface coatings that preserve quantum dot luminescence properties while minimizing non-specific interactions with HPLC components.

Another significant objective is the standardization of quantum dot-HPLC methodologies to ensure reproducibility and reliability across different analytical platforms. This includes establishing protocols for quantum dot incorporation either as detection agents or as analytes themselves, optimizing separation parameters, and developing calibration standards.

Looking forward, the field is trending toward the development of "smart" quantum dots specifically designed for HPLC applications, featuring responsive surface chemistries that adapt to separation conditions while maintaining structural integrity. Parallel advances in microfluidic HPLC systems offer promising synergies with quantum dot technology, potentially enabling more efficient separations with minimal sample volumes and reduced quantum dot consumption.

The ultimate technological goal remains the seamless integration of quantum dots into routine HPLC workflows, leveraging their unique optical properties to achieve unprecedented detection limits and analytical capabilities across pharmaceutical, environmental, and biomedical applications.

The evolution of quantum dot technology has progressed through several distinct phases, beginning with their initial synthesis and characterization, followed by surface modification strategies to enhance their stability and functionality, and more recently, their incorporation into analytical separation techniques. The marriage of quantum dots with HPLC systems has been driven by the need for more sensitive, selective, and versatile detection methods in complex sample analysis.

A critical challenge in this technological integration has been maintaining quantum dot stability under the harsh conditions typical of HPLC separations. The high pressures, varied mobile phase compositions, and potential interactions with stationary phases can significantly compromise quantum dot integrity, leading to diminished optical performance, aggregation, or surface degradation. These stability issues have limited the widespread adoption of quantum dot-enhanced HPLC methodologies despite their theoretical advantages.

The technical objectives of current research in this field are multifaceted. Primary goals include developing quantum dot formulations with enhanced chemical stability in diverse mobile phase environments, particularly in the presence of organic solvents and varying pH conditions. Additionally, researchers aim to engineer surface coatings that preserve quantum dot luminescence properties while minimizing non-specific interactions with HPLC components.

Another significant objective is the standardization of quantum dot-HPLC methodologies to ensure reproducibility and reliability across different analytical platforms. This includes establishing protocols for quantum dot incorporation either as detection agents or as analytes themselves, optimizing separation parameters, and developing calibration standards.

Looking forward, the field is trending toward the development of "smart" quantum dots specifically designed for HPLC applications, featuring responsive surface chemistries that adapt to separation conditions while maintaining structural integrity. Parallel advances in microfluidic HPLC systems offer promising synergies with quantum dot technology, potentially enabling more efficient separations with minimal sample volumes and reduced quantum dot consumption.

The ultimate technological goal remains the seamless integration of quantum dots into routine HPLC workflows, leveraging their unique optical properties to achieve unprecedented detection limits and analytical capabilities across pharmaceutical, environmental, and biomedical applications.

Market Analysis for QD-Enhanced Chromatography Applications

The quantum dot (QD) enhanced chromatography market is experiencing significant growth, driven by increasing demand for advanced analytical techniques in pharmaceutical research, biotechnology, and environmental monitoring. The global market for high-performance liquid chromatography (HPLC) was valued at approximately $4.5 billion in 2022 and is projected to reach $6.8 billion by 2028, with a compound annual growth rate of 7.2%. Within this broader market, QD-enhanced chromatography applications represent an emerging segment with substantial growth potential.

Pharmaceutical and biotechnology sectors currently dominate the demand for QD-enhanced chromatography, accounting for nearly 45% of market applications. These industries require increasingly sensitive detection methods for complex biological samples, drug development, and quality control processes. The enhanced fluorescence properties of quantum dots offer significant advantages over traditional chromatography detection methods, particularly for trace analysis of biomolecules and pharmaceuticals.

Academic and research institutions constitute the second-largest market segment, representing approximately 30% of current applications. This sector is driving innovation in QD-chromatography techniques through fundamental research and method development. The remaining market share is distributed across environmental testing, food safety, and clinical diagnostics sectors, each experiencing growing adoption rates as QD stability and integration challenges are gradually overcome.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China, South Korea, and India, is expected to demonstrate the highest growth rate over the next five years due to expanding pharmaceutical manufacturing capabilities and increasing R&D investments in analytical technologies.

Market analysis indicates that end-users are primarily concerned with three factors when considering QD-enhanced chromatography: detection sensitivity, reproducibility, and cost-effectiveness. Current QD stability limitations represent a significant barrier to wider market adoption, with 67% of potential users citing concerns about long-term reliability and batch-to-batch consistency as major obstacles to implementation.

The competitive landscape features established analytical instrument manufacturers partnering with nanomaterial specialists to develop integrated QD-chromatography solutions. Companies offering proprietary surface modification technologies that enhance QD stability in chromatographic environments are gaining competitive advantage. Market forecasts suggest that successful resolution of stability challenges could expand the QD-chromatography market by 200-300% within five years, particularly in applications requiring ultrasensitive detection of biological and environmental analytes.

Pharmaceutical and biotechnology sectors currently dominate the demand for QD-enhanced chromatography, accounting for nearly 45% of market applications. These industries require increasingly sensitive detection methods for complex biological samples, drug development, and quality control processes. The enhanced fluorescence properties of quantum dots offer significant advantages over traditional chromatography detection methods, particularly for trace analysis of biomolecules and pharmaceuticals.

Academic and research institutions constitute the second-largest market segment, representing approximately 30% of current applications. This sector is driving innovation in QD-chromatography techniques through fundamental research and method development. The remaining market share is distributed across environmental testing, food safety, and clinical diagnostics sectors, each experiencing growing adoption rates as QD stability and integration challenges are gradually overcome.

Geographically, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). The Asia-Pacific region, particularly China, South Korea, and India, is expected to demonstrate the highest growth rate over the next five years due to expanding pharmaceutical manufacturing capabilities and increasing R&D investments in analytical technologies.

Market analysis indicates that end-users are primarily concerned with three factors when considering QD-enhanced chromatography: detection sensitivity, reproducibility, and cost-effectiveness. Current QD stability limitations represent a significant barrier to wider market adoption, with 67% of potential users citing concerns about long-term reliability and batch-to-batch consistency as major obstacles to implementation.

The competitive landscape features established analytical instrument manufacturers partnering with nanomaterial specialists to develop integrated QD-chromatography solutions. Companies offering proprietary surface modification technologies that enhance QD stability in chromatographic environments are gaining competitive advantage. Market forecasts suggest that successful resolution of stability challenges could expand the QD-chromatography market by 200-300% within five years, particularly in applications requiring ultrasensitive detection of biological and environmental analytes.

Current Challenges in QD Stability for HPLC Systems

Despite significant advancements in quantum dot (QD) technology, their application in high-performance liquid chromatography (HPLC) systems faces several persistent challenges related to stability. The primary concern is the inherent chemical instability of QDs when exposed to the diverse range of solvents, pH conditions, and temperatures commonly encountered in HPLC environments. Many QDs exhibit degradation through surface oxidation when in contact with aqueous mobile phases, particularly those containing dissolved oxygen or at extreme pH values.

Physical stability represents another critical challenge, as QDs tend to aggregate in certain mobile phase compositions, especially those with high ionic strength or when transitioning between different solvent gradients. This aggregation not only reduces detection sensitivity but can also lead to column clogging and increased backpressure in HPLC systems, compromising analytical reliability and reproducibility.

The surface chemistry of QDs presents a complex stability issue. Most QDs require surface ligands or coatings to maintain colloidal stability, but these coatings can be stripped or modified during HPLC separations, particularly when using organic solvents or surfactants. The loss of these protective layers exposes the QD core to degradation and alters their optical properties, resulting in diminished fluorescence quantum yield and detection sensitivity.

Photostability during analysis poses another significant challenge. QDs can undergo photobleaching when exposed to the excitation sources used in fluorescence detection systems, especially during extended analysis times. This photodegradation leads to signal drift and compromises quantitative accuracy, particularly problematic for trace analysis applications where consistent signal response is crucial.

Temperature fluctuations within HPLC systems further exacerbate stability issues. Many QDs exhibit temperature-dependent optical properties, with fluorescence intensity decreasing at elevated temperatures commonly reached during certain separation protocols. Additionally, temperature cycling can accelerate surface degradation and ligand detachment, further compromising QD stability.

Batch-to-batch reproducibility of QD materials represents a significant obstacle for routine analytical applications. Variations in synthesis conditions lead to inconsistent stability profiles between different QD batches, making method validation and standardization challenging for regulatory compliance in pharmaceutical and clinical applications.

The interaction between QDs and stationary phases introduces additional complexity. Surface adsorption of QDs onto column packing materials can occur, particularly with silica-based columns containing residual silanol groups. This non-specific adsorption reduces recovery rates and introduces peak tailing, severely impacting chromatographic performance and quantitative accuracy.

Physical stability represents another critical challenge, as QDs tend to aggregate in certain mobile phase compositions, especially those with high ionic strength or when transitioning between different solvent gradients. This aggregation not only reduces detection sensitivity but can also lead to column clogging and increased backpressure in HPLC systems, compromising analytical reliability and reproducibility.

The surface chemistry of QDs presents a complex stability issue. Most QDs require surface ligands or coatings to maintain colloidal stability, but these coatings can be stripped or modified during HPLC separations, particularly when using organic solvents or surfactants. The loss of these protective layers exposes the QD core to degradation and alters their optical properties, resulting in diminished fluorescence quantum yield and detection sensitivity.

Photostability during analysis poses another significant challenge. QDs can undergo photobleaching when exposed to the excitation sources used in fluorescence detection systems, especially during extended analysis times. This photodegradation leads to signal drift and compromises quantitative accuracy, particularly problematic for trace analysis applications where consistent signal response is crucial.

Temperature fluctuations within HPLC systems further exacerbate stability issues. Many QDs exhibit temperature-dependent optical properties, with fluorescence intensity decreasing at elevated temperatures commonly reached during certain separation protocols. Additionally, temperature cycling can accelerate surface degradation and ligand detachment, further compromising QD stability.

Batch-to-batch reproducibility of QD materials represents a significant obstacle for routine analytical applications. Variations in synthesis conditions lead to inconsistent stability profiles between different QD batches, making method validation and standardization challenging for regulatory compliance in pharmaceutical and clinical applications.

The interaction between QDs and stationary phases introduces additional complexity. Surface adsorption of QDs onto column packing materials can occur, particularly with silica-based columns containing residual silanol groups. This non-specific adsorption reduces recovery rates and introduces peak tailing, severely impacting chromatographic performance and quantitative accuracy.

Current Stabilization Techniques for QDs in HPLC Environments

01 Surface modification for quantum dot stability

Surface modification techniques can significantly enhance the stability of quantum dots. These methods include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. Such modifications can prevent oxidation, reduce aggregation, and improve the overall durability of quantum dots in various environmental conditions, thereby extending their functional lifetime and maintaining their optical properties.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. This architecture also reduces surface defects and improves quantum yield while maintaining optical properties over extended periods under various environmental conditions.

- Environmental factors affecting quantum dot stability: Quantum dots are sensitive to various environmental factors that can compromise their stability. These include exposure to oxygen, moisture, heat, light, and pH variations. Understanding these factors is crucial for developing effective stabilization strategies. Research focuses on creating quantum dots that maintain their optical and electronic properties under challenging environmental conditions through innovative formulation and encapsulation methods.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to oxidation and photobleaching is significantly enhanced. This approach also improves compatibility with various solvents and matrices, facilitating integration into devices and biological systems while maintaining optical properties over extended periods.

- Stabilization methods for specific applications: Different applications of quantum dots require tailored stabilization approaches. For biological applications, biocompatible coatings that maintain stability in physiological environments are essential. For optoelectronic devices, stabilization against heat and electrical stress is crucial. For display technologies, quantum dots must remain stable under continuous illumination. These application-specific stabilization methods involve customized surface chemistry and encapsulation techniques to ensure optimal performance.

02 Core-shell structures for enhanced stability

Core-shell quantum dot architectures provide improved stability by protecting the core material from environmental degradation. The shell material, often composed of wider bandgap semiconductors, creates a physical barrier that prevents oxidation and leaching of the core. These structures can be engineered with gradient compositions or multiple shell layers to reduce lattice mismatch stress and further enhance stability while maintaining desired optical and electronic properties.Expand Specific Solutions03 Stabilization in various media and environments

Quantum dots can be stabilized in different media and environments through specific formulation strategies. This includes incorporation into polymer matrices, dispersion in specialized solvents, or integration with stabilizing additives. These approaches prevent aggregation and maintain colloidal stability in aqueous solutions, organic solvents, or solid-state materials, enabling quantum dots to function reliably in diverse applications from biological imaging to optoelectronic devices.Expand Specific Solutions04 Thermal and photo-stability enhancement

Improving the thermal and photo-stability of quantum dots involves specialized synthesis methods and post-processing techniques. These include annealing processes, doping with specific elements, and development of robust encapsulation materials. Such enhancements prevent degradation under high temperatures or intense light exposure, maintaining quantum yield and emission characteristics even in demanding operational conditions such as LED applications or solar concentrators.Expand Specific Solutions05 Manufacturing processes for stability control

Advanced manufacturing processes can be designed specifically to enhance quantum dot stability. These include precise temperature control during synthesis, controlled atmosphere processing, and specialized purification techniques. Continuous flow reactors, microfluidic systems, and automated synthesis platforms enable reproducible production of stable quantum dots with consistent properties. These manufacturing innovations are critical for scaling up production while maintaining the stability required for commercial applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in QD-HPLC Field

The quantum dot stability in high-performance liquid chromatography market is currently in its growth phase, with increasing adoption across analytical chemistry and biomedical applications. The global market size is estimated to reach approximately $350 million by 2025, driven by expanding applications in pharmaceutical analysis and biotechnology. Technologically, the field shows moderate maturity with significant ongoing innovation. Leading companies like Samsung Electronics and Samsung Display are advancing display applications, while Shin-Etsu Chemical and Applied Materials focus on semiconductor integration. Academic institutions including Wuhan University and Xiamen University are contributing fundamental research, while specialized firms like Najing Technology and Suzhou Xingshuo Nanotechnology are developing proprietary stabilization techniques for quantum dots in chromatographic environments.

Wuhan University

Technical Solution: Wuhan University has developed innovative surface modification techniques for quantum dots to enhance their stability during high-performance liquid chromatography (HPLC) analysis. Their approach involves creating core-shell structures with silica or polymer coatings that protect the quantum dot core from degradation in various mobile phases used in HPLC. The research team has successfully demonstrated that these modified quantum dots maintain their fluorescence properties and structural integrity even after multiple HPLC separation cycles. They've also pioneered ligand exchange protocols specifically designed to improve quantum dot compatibility with common HPLC solvents while preventing aggregation during the separation process. Their technology enables reliable quantitative analysis of complex biological samples using quantum dot-based fluorescence detection coupled with HPLC.

Strengths: Superior surface modification techniques that significantly enhance quantum dot stability in various HPLC conditions; excellent retention of optical properties during separation. Weaknesses: The complex modification processes may increase production costs and limit scalability for commercial applications; some modifications may alter the quantum dots' original photophysical properties.

Xiamen University

Technical Solution: Xiamen University has developed a groundbreaking approach to quantum dot stability in HPLC environments through their proprietary "gradient shell" technology. This involves synthesizing quantum dots with gradually changing composition from core to surface, creating a buffer zone that protects against chemical degradation during chromatographic separation. Their research team has engineered quantum dots with specialized ligand systems that maintain colloidal stability in a wide range of mobile phase compositions, from highly aqueous to organic solvent-rich conditions. Additionally, they've developed novel post-column derivatization techniques that allow for enhanced detection sensitivity of quantum dots after HPLC separation. Their technology enables multiplexed detection capabilities by using quantum dots with different emission wavelengths that remain stable throughout the HPLC process, allowing simultaneous analysis of multiple analytes.

Strengths: Exceptional stability across diverse mobile phase compositions; innovative gradient shell technology provides superior protection against degradation; enables multiplexed detection capabilities. Weaknesses: The complex synthesis procedures require precise control of reaction conditions; the technology may have limitations in extremely acidic HPLC conditions.

Key Patents and Breakthroughs in QD Surface Chemistry

High-performance liquid chromatography with a controllable transverse flow inducer

PatentActiveEP3322978A1

Innovation

- The use of a controllable transverse flow inducer, which generates micro-scale vortices through alternating current electrokinetics, allowing for orthogonal flow induction independent of axial velocity, reducing dispersion by combining pressure and electro-osmotic flow, and enabling retention modulation without permanent surface charges.

Methods for detecting estradiol by mass spectrometry

PatentInactiveUS20090134325A1

Innovation

- The method involves purifying estradiol through liquid chromatography, ionizing it, and detecting the ions using mass spectrometry without derivatization, with specific mass/charge ratios for precursor and fragment ions, and using agents like ammonium sulfate to free estradiol from proteins, achieving a limit of quantitation of less than 80 pg/mL.

Environmental Impact and Safety Considerations of QD-HPLC Systems

The integration of quantum dots (QDs) with high-performance liquid chromatography (HPLC) systems presents significant environmental and safety considerations that must be addressed for sustainable implementation. QDs, particularly those containing heavy metals such as cadmium, lead, or mercury, pose potential ecological risks if improperly handled or disposed of. When these nanoparticles enter aquatic ecosystems, they can bioaccumulate in organisms and potentially transfer through food chains, leading to widespread environmental contamination.

Laboratory safety protocols for QD-HPLC systems require specialized handling procedures due to the nanoscale properties of quantum dots. Researchers must implement proper personal protective equipment (PPE) including respiratory protection, as aerosolized QDs present inhalation hazards. Additionally, the potential for dermal absorption necessitates comprehensive skin protection measures during both preparation and analytical procedures.

Waste management represents a critical challenge in QD-HPLC applications. The combination of organic solvents used in mobile phases with potentially toxic QD materials creates complex waste streams requiring specialized treatment. Current best practices include segregation of QD-containing waste, chemical stabilization procedures, and partnership with specialized hazardous waste management services equipped to handle nanomaterials.

Regulatory frameworks governing QD-HPLC systems vary globally, creating compliance challenges for international research collaborations and commercial applications. The European Union's REACH regulations and the United States EPA guidelines provide some governance, but many jurisdictions lack specific protocols for nanomaterial-enhanced analytical techniques. This regulatory gap necessitates proactive industry self-regulation and the development of standardized safety protocols.

Recent advances in green chemistry approaches offer promising solutions to mitigate environmental concerns. The development of heavy metal-free QDs using elements like carbon, silicon, or indium phosphide represents a significant step toward more environmentally benign alternatives. Additionally, research into biodegradable surface coatings and ligands may reduce the environmental persistence of QDs released during system maintenance or disposal.

Life cycle assessment (LCA) studies of QD-HPLC systems remain limited but indicate that the environmental footprint extends beyond direct toxicity concerns to include energy consumption during synthesis and operation. Comprehensive sustainability evaluations must consider these broader impacts alongside acute toxicity profiles to fully characterize the environmental implications of this emerging analytical technology.

Laboratory safety protocols for QD-HPLC systems require specialized handling procedures due to the nanoscale properties of quantum dots. Researchers must implement proper personal protective equipment (PPE) including respiratory protection, as aerosolized QDs present inhalation hazards. Additionally, the potential for dermal absorption necessitates comprehensive skin protection measures during both preparation and analytical procedures.

Waste management represents a critical challenge in QD-HPLC applications. The combination of organic solvents used in mobile phases with potentially toxic QD materials creates complex waste streams requiring specialized treatment. Current best practices include segregation of QD-containing waste, chemical stabilization procedures, and partnership with specialized hazardous waste management services equipped to handle nanomaterials.

Regulatory frameworks governing QD-HPLC systems vary globally, creating compliance challenges for international research collaborations and commercial applications. The European Union's REACH regulations and the United States EPA guidelines provide some governance, but many jurisdictions lack specific protocols for nanomaterial-enhanced analytical techniques. This regulatory gap necessitates proactive industry self-regulation and the development of standardized safety protocols.

Recent advances in green chemistry approaches offer promising solutions to mitigate environmental concerns. The development of heavy metal-free QDs using elements like carbon, silicon, or indium phosphide represents a significant step toward more environmentally benign alternatives. Additionally, research into biodegradable surface coatings and ligands may reduce the environmental persistence of QDs released during system maintenance or disposal.

Life cycle assessment (LCA) studies of QD-HPLC systems remain limited but indicate that the environmental footprint extends beyond direct toxicity concerns to include energy consumption during synthesis and operation. Comprehensive sustainability evaluations must consider these broader impacts alongside acute toxicity profiles to fully characterize the environmental implications of this emerging analytical technology.

Validation Methods and Performance Metrics for QD-HPLC Technology

Validation of Quantum Dot-based High-Performance Liquid Chromatography (QD-HPLC) technology requires rigorous methodological approaches to ensure reliability, reproducibility, and accuracy. The validation process typically begins with system suitability tests that evaluate parameters such as retention time stability, peak symmetry, and column efficiency under QD-specific conditions. These tests must account for the unique optical and chemical properties of quantum dots that distinguish them from traditional HPLC analytes.

Performance metrics for QD-HPLC systems are multifaceted, encompassing both chromatographic and quantum dot-specific parameters. Key chromatographic metrics include resolution (Rs), which should exceed 1.5 for adequate peak separation; theoretical plate count (N), typically requiring >2000 plates/column for QD applications; and tailing factor (Tf), which should remain between 0.9-1.2 to ensure peak symmetry. QD-specific metrics focus on fluorescence stability throughout the separation process, with acceptable fluorescence intensity variation typically below 5% RSD.

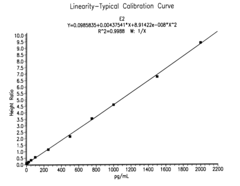

Method validation protocols for QD-HPLC follow modified ICH guidelines, with particular emphasis on robustness testing due to the sensitivity of quantum dots to environmental factors. Specificity validation requires demonstration that the method can distinguish between QDs of different compositions, sizes, and surface modifications, often utilizing spectral fingerprinting alongside retention characteristics. Linearity assessment typically covers 5-6 concentration points, with r² values exceeding 0.995 considered acceptable.

Precision validation for QD-HPLC demands more stringent criteria than conventional HPLC, with intra-day precision (repeatability) typically requiring RSD values below 2% and inter-day precision (intermediate precision) below 3%. These tighter tolerances reflect the higher sensitivity requirements for quantum dot applications, particularly in biomedical and diagnostic contexts.

Accuracy determination presents unique challenges in QD-HPLC validation due to the limited availability of certified reference materials. Recovery studies using spiked samples across three concentration levels (80%, 100%, and 120% of target concentration) are commonly employed, with acceptable recovery ranges of 97-103% for high-concentration applications and 95-105% for trace analysis.

Limit of detection (LOD) and limit of quantification (LOQ) determinations for QD-HPLC typically employ signal-to-noise ratio approaches, with LOD defined at S/N ≥ 3 and LOQ at S/N ≥ 10. For fluorescence-based detection, these limits are often in the nanomolar or even picomolar range, significantly lower than conventional HPLC methods.

Stability-indicating capabilities represent a critical performance metric unique to QD-HPLC validation. Methods must demonstrate ability to detect and quantify degradation products resulting from QD core oxidation, ligand detachment, or aggregation phenomena. Forced degradation studies under various stress conditions (thermal, photolytic, pH extremes) are essential components of this validation aspect.

Performance metrics for QD-HPLC systems are multifaceted, encompassing both chromatographic and quantum dot-specific parameters. Key chromatographic metrics include resolution (Rs), which should exceed 1.5 for adequate peak separation; theoretical plate count (N), typically requiring >2000 plates/column for QD applications; and tailing factor (Tf), which should remain between 0.9-1.2 to ensure peak symmetry. QD-specific metrics focus on fluorescence stability throughout the separation process, with acceptable fluorescence intensity variation typically below 5% RSD.

Method validation protocols for QD-HPLC follow modified ICH guidelines, with particular emphasis on robustness testing due to the sensitivity of quantum dots to environmental factors. Specificity validation requires demonstration that the method can distinguish between QDs of different compositions, sizes, and surface modifications, often utilizing spectral fingerprinting alongside retention characteristics. Linearity assessment typically covers 5-6 concentration points, with r² values exceeding 0.995 considered acceptable.

Precision validation for QD-HPLC demands more stringent criteria than conventional HPLC, with intra-day precision (repeatability) typically requiring RSD values below 2% and inter-day precision (intermediate precision) below 3%. These tighter tolerances reflect the higher sensitivity requirements for quantum dot applications, particularly in biomedical and diagnostic contexts.

Accuracy determination presents unique challenges in QD-HPLC validation due to the limited availability of certified reference materials. Recovery studies using spiked samples across three concentration levels (80%, 100%, and 120% of target concentration) are commonly employed, with acceptable recovery ranges of 97-103% for high-concentration applications and 95-105% for trace analysis.

Limit of detection (LOD) and limit of quantification (LOQ) determinations for QD-HPLC typically employ signal-to-noise ratio approaches, with LOD defined at S/N ≥ 3 and LOQ at S/N ≥ 10. For fluorescence-based detection, these limits are often in the nanomolar or even picomolar range, significantly lower than conventional HPLC methods.

Stability-indicating capabilities represent a critical performance metric unique to QD-HPLC validation. Methods must demonstrate ability to detect and quantify degradation products resulting from QD core oxidation, ligand detachment, or aggregation phenomena. Forced degradation studies under various stress conditions (thermal, photolytic, pH extremes) are essential components of this validation aspect.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!