Quantum Dot Stability in High-Temperature Electronics Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Background and Objectives

Quantum dots (QDs) represent a revolutionary class of semiconductor nanocrystals that have emerged as transformative materials in electronics and optoelectronics over the past three decades. These nanoscale particles, typically ranging from 2 to 10 nanometers in diameter, exhibit unique quantum confinement effects that allow precise tuning of their optical and electronic properties through size manipulation. The evolution of quantum dot technology began in the early 1980s with theoretical predictions, followed by successful synthesis methods developed in the 1990s that enabled practical applications.

The fundamental appeal of quantum dots lies in their exceptional photoluminescence efficiency, size-dependent emission wavelengths, broad absorption spectra, and narrow emission bands. These characteristics have positioned quantum dots as superior alternatives to traditional phosphors and organic dyes in numerous applications. However, their implementation in high-temperature electronic environments presents significant challenges that have limited their broader adoption in industrial and automotive electronics.

The stability of quantum dots at elevated temperatures represents a critical technological barrier. When exposed to high temperatures (typically above 150°C), quantum dots often experience degradation mechanisms including surface oxidation, ligand detachment, core-shell interface diffusion, and structural deformation. These processes lead to decreased quantum yield, emission wavelength shifts, and ultimately, complete luminescence quenching. This instability has restricted quantum dot applications primarily to consumer electronics operating at moderate temperatures.

Recent technological advancements have focused on enhancing quantum dot thermal stability through various approaches, including robust inorganic shell structures, surface passivation techniques, and matrix encapsulation methods. Research has demonstrated promising results with certain core-shell architectures (such as CdSe/ZnS and InP/ZnS) showing improved stability at temperatures up to 200°C for limited durations. However, sustained performance at higher temperatures remains elusive.

The primary objective of quantum dot stability research for high-temperature electronics is to develop nanocrystal structures capable of maintaining their optical and electronic properties at temperatures exceeding 250°C for extended periods (>10,000 hours). This would enable their integration into automotive engine control systems, industrial process monitoring equipment, aerospace electronics, and deep-well drilling sensors. Secondary objectives include developing cost-effective synthesis methods for thermally stable quantum dots and establishing standardized testing protocols for high-temperature performance evaluation.

Achieving these objectives would unlock significant market opportunities in harsh-environment electronics, estimated to reach $4.5 billion by 2028. The technological evolution pathway suggests that incremental improvements in thermal stability will continue through materials engineering approaches, with potential breakthrough innovations emerging from novel core-shell architectures and hybrid organic-inorganic passivation strategies.

The fundamental appeal of quantum dots lies in their exceptional photoluminescence efficiency, size-dependent emission wavelengths, broad absorption spectra, and narrow emission bands. These characteristics have positioned quantum dots as superior alternatives to traditional phosphors and organic dyes in numerous applications. However, their implementation in high-temperature electronic environments presents significant challenges that have limited their broader adoption in industrial and automotive electronics.

The stability of quantum dots at elevated temperatures represents a critical technological barrier. When exposed to high temperatures (typically above 150°C), quantum dots often experience degradation mechanisms including surface oxidation, ligand detachment, core-shell interface diffusion, and structural deformation. These processes lead to decreased quantum yield, emission wavelength shifts, and ultimately, complete luminescence quenching. This instability has restricted quantum dot applications primarily to consumer electronics operating at moderate temperatures.

Recent technological advancements have focused on enhancing quantum dot thermal stability through various approaches, including robust inorganic shell structures, surface passivation techniques, and matrix encapsulation methods. Research has demonstrated promising results with certain core-shell architectures (such as CdSe/ZnS and InP/ZnS) showing improved stability at temperatures up to 200°C for limited durations. However, sustained performance at higher temperatures remains elusive.

The primary objective of quantum dot stability research for high-temperature electronics is to develop nanocrystal structures capable of maintaining their optical and electronic properties at temperatures exceeding 250°C for extended periods (>10,000 hours). This would enable their integration into automotive engine control systems, industrial process monitoring equipment, aerospace electronics, and deep-well drilling sensors. Secondary objectives include developing cost-effective synthesis methods for thermally stable quantum dots and establishing standardized testing protocols for high-temperature performance evaluation.

Achieving these objectives would unlock significant market opportunities in harsh-environment electronics, estimated to reach $4.5 billion by 2028. The technological evolution pathway suggests that incremental improvements in thermal stability will continue through materials engineering approaches, with potential breakthrough innovations emerging from novel core-shell architectures and hybrid organic-inorganic passivation strategies.

Market Analysis for High-Temperature Electronics

The high-temperature electronics market has been experiencing significant growth, driven by increasing demands from industries such as automotive, aerospace, defense, oil and gas exploration, and industrial manufacturing. These sectors require electronic components capable of functioning reliably in extreme temperature environments, typically ranging from 150°C to 300°C and beyond. The global high-temperature electronics market was valued at approximately $3.2 billion in 2022 and is projected to reach $5.8 billion by 2028, representing a compound annual growth rate (CAGR) of 10.4%.

The automotive industry constitutes the largest market segment, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the growing adoption of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), which require high-temperature resistant components for power management and control systems. The increasing electrification of vehicles has created substantial demand for semiconductor devices that can operate efficiently under the hood, where temperatures frequently exceed 150°C.

Aerospace and defense sectors collectively represent the second-largest market segment at 28%. These industries demand electronics capable of withstanding extreme conditions, including high temperatures, radiation, and mechanical stress. Military applications, satellite systems, and aircraft engine control units are key drivers within this segment.

The oil and gas industry, while smaller in market share at approximately 15%, presents some of the most challenging operating environments, with downhole drilling operations requiring electronics that can function at temperatures up to 300°C. This sector has been investing heavily in digitalization and automation, further driving demand for high-temperature electronic solutions.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% during the forecast period, primarily due to rapid industrialization in China and India, and increasing investments in automotive and electronics manufacturing.

The market for quantum dot applications specifically within high-temperature electronics remains nascent but promising. Current estimates suggest this specialized segment represents approximately $180 million, with projections indicating growth to $450 million by 2028. This growth trajectory is contingent upon overcoming stability challenges that currently limit quantum dot implementation in high-temperature environments.

The automotive industry constitutes the largest market segment, accounting for nearly 35% of the total market share. This dominance is primarily attributed to the growing adoption of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), which require high-temperature resistant components for power management and control systems. The increasing electrification of vehicles has created substantial demand for semiconductor devices that can operate efficiently under the hood, where temperatures frequently exceed 150°C.

Aerospace and defense sectors collectively represent the second-largest market segment at 28%. These industries demand electronics capable of withstanding extreme conditions, including high temperatures, radiation, and mechanical stress. Military applications, satellite systems, and aircraft engine control units are key drivers within this segment.

The oil and gas industry, while smaller in market share at approximately 15%, presents some of the most challenging operating environments, with downhole drilling operations requiring electronics that can function at temperatures up to 300°C. This sector has been investing heavily in digitalization and automation, further driving demand for high-temperature electronic solutions.

Geographically, North America leads the market with a 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 12.3% during the forecast period, primarily due to rapid industrialization in China and India, and increasing investments in automotive and electronics manufacturing.

The market for quantum dot applications specifically within high-temperature electronics remains nascent but promising. Current estimates suggest this specialized segment represents approximately $180 million, with projections indicating growth to $450 million by 2028. This growth trajectory is contingent upon overcoming stability challenges that currently limit quantum dot implementation in high-temperature environments.

Current Challenges in QD Thermal Stability

Despite significant advancements in quantum dot (QD) technology, thermal stability remains one of the most critical challenges limiting their widespread adoption in high-temperature electronics applications. When exposed to elevated temperatures (typically above 150°C), quantum dots exhibit several degradation mechanisms that compromise their optoelectronic properties. The primary issue is the thermally-induced oxidation of the QD surface, which creates trap states that quench luminescence and reduce quantum yield. This oxidation process accelerates exponentially with temperature increases, making it particularly problematic for automotive, aerospace, and industrial electronics applications.

Surface ligand instability presents another major challenge. The organic ligands that passivate QD surfaces and provide colloidal stability begin to detach at elevated temperatures, leading to QD aggregation and loss of their unique size-dependent properties. Current ligand systems typically show significant degradation beginning at 100-120°C, well below the operating temperatures required for many high-reliability electronics (which can reach 200°C or higher).

Interdiffusion between the core and shell materials in core-shell QDs is exacerbated at high temperatures. This phenomenon blurs the sharp interfaces that are essential for maintaining quantum confinement effects and spectral purity. Studies have shown that even brief exposure to temperatures above 180°C can cause significant interdiffusion in common CdSe/ZnS and InP/ZnS core-shell systems, resulting in broadened emission spectra and reduced photoluminescence quantum yield.

Sintering and Ostwald ripening processes accelerate dramatically at elevated temperatures, causing smaller QDs to dissolve while larger ones grow. This size redistribution leads to broadened size distributions and consequently broadened emission spectra, undermining the narrow emission profiles that make QDs valuable for display and lighting applications.

The encapsulation materials used to integrate QDs into devices also present compatibility issues at high temperatures. Silicones, epoxies, and other polymeric matrices commonly used for QD encapsulation often undergo thermal degradation, yellowing, or mechanical stress that can damage the embedded QDs or alter their optical properties.

Current research approaches to address these challenges include developing inorganic surface passivation strategies, exploring high-temperature-resistant ligand systems based on silanes or phosphonates, and investigating all-inorganic perovskite QDs that demonstrate improved thermal stability. However, solutions that maintain QD performance at temperatures above 200°C for extended periods (thousands of hours) remain elusive, representing a significant barrier to their implementation in high-reliability electronics applications.

Surface ligand instability presents another major challenge. The organic ligands that passivate QD surfaces and provide colloidal stability begin to detach at elevated temperatures, leading to QD aggregation and loss of their unique size-dependent properties. Current ligand systems typically show significant degradation beginning at 100-120°C, well below the operating temperatures required for many high-reliability electronics (which can reach 200°C or higher).

Interdiffusion between the core and shell materials in core-shell QDs is exacerbated at high temperatures. This phenomenon blurs the sharp interfaces that are essential for maintaining quantum confinement effects and spectral purity. Studies have shown that even brief exposure to temperatures above 180°C can cause significant interdiffusion in common CdSe/ZnS and InP/ZnS core-shell systems, resulting in broadened emission spectra and reduced photoluminescence quantum yield.

Sintering and Ostwald ripening processes accelerate dramatically at elevated temperatures, causing smaller QDs to dissolve while larger ones grow. This size redistribution leads to broadened size distributions and consequently broadened emission spectra, undermining the narrow emission profiles that make QDs valuable for display and lighting applications.

The encapsulation materials used to integrate QDs into devices also present compatibility issues at high temperatures. Silicones, epoxies, and other polymeric matrices commonly used for QD encapsulation often undergo thermal degradation, yellowing, or mechanical stress that can damage the embedded QDs or alter their optical properties.

Current research approaches to address these challenges include developing inorganic surface passivation strategies, exploring high-temperature-resistant ligand systems based on silanes or phosphonates, and investigating all-inorganic perovskite QDs that demonstrate improved thermal stability. However, solutions that maintain QD performance at temperatures above 200°C for extended periods (thousands of hours) remain elusive, representing a significant barrier to their implementation in high-reliability electronics applications.

Current Thermal Stabilization Solutions

01 Surface modification for enhanced stability

Surface modification techniques are employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

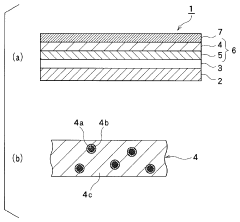

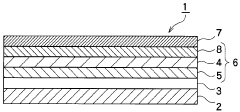

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. This architecture also reduces surface defects and passivates dangling bonds, resulting in improved photoluminescence quantum yield and enhanced stability under various operating conditions.

- Environmental stability enhancement methods: Methods to improve quantum dot stability against environmental factors include encapsulation in polymers or inorganic matrices, incorporation into host materials, and development of specialized packaging techniques. These approaches protect quantum dots from oxygen, moisture, heat, and light exposure, which are common causes of degradation. Enhanced environmental stability is crucial for applications in displays, lighting, and sensing technologies where long-term performance is required.

- Thermal and photo-stability improvement strategies: Strategies to enhance thermal and photo-stability of quantum dots include doping with specific elements, engineering of energy transfer pathways, and development of heat-resistant compositions. These approaches minimize degradation under high-temperature conditions and prolonged light exposure, which are critical for applications in displays, solar cells, and high-power lighting. Improved thermal and photo-stability extends device lifetime and maintains consistent performance under operating conditions.

- Colloidal stability and dispersion techniques: Techniques to improve colloidal stability and dispersion of quantum dots in various media include surface ligand engineering, pH control, and development of specialized dispersants. These methods prevent aggregation and precipitation of quantum dots in solution, which is essential for processing and integration into devices. Stable colloidal dispersions enable uniform film formation, consistent optical properties, and improved manufacturing processes for quantum dot-based technologies.

02 Core-shell structures for improved stability

Core-shell quantum dot structures significantly improve stability by providing physical barriers against environmental factors. The shell material, typically a semiconductor with a wider bandgap than the core, protects the core from oxidation and other degradation mechanisms. Multi-shell structures can further enhance stability while maintaining or improving optical properties, making quantum dots more suitable for commercial applications.Expand Specific Solutions03 Encapsulation methods for quantum dot protection

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides protection from environmental factors. These encapsulation methods create physical barriers against oxygen, moisture, and heat, which are primary causes of quantum dot degradation. The encapsulating materials can be designed to be compatible with specific applications while maintaining the optical properties of the quantum dots.Expand Specific Solutions04 Chemical composition optimization for stability

The chemical composition of quantum dots significantly affects their stability. By optimizing the elemental composition, stoichiometry, and doping of quantum dots, researchers can create more stable structures. Heavy metal-free quantum dots and those with specific dopants have shown enhanced resistance to photobleaching and chemical degradation, making them more suitable for long-term applications in various fields.Expand Specific Solutions05 Stability enhancement through manufacturing processes

Manufacturing processes significantly impact quantum dot stability. Advanced synthesis methods, precise temperature control, and post-synthesis treatments can lead to quantum dots with fewer defects and greater structural integrity. Techniques such as annealing, purification protocols, and controlled reaction environments help create quantum dots with improved stability characteristics for various applications.Expand Specific Solutions

Leading Companies in Quantum Dot Electronics

Quantum dot stability in high-temperature electronics applications is currently in an early growth phase, with the market expanding rapidly due to increasing demand for advanced display technologies and energy-efficient devices. The global market is projected to reach significant scale as quantum dots transition from research to commercial applications. Technologically, the field shows varying maturity levels across companies. Samsung Electronics, Samsung Display, and LG Energy Solution lead with established manufacturing capabilities, while specialized players like Mojo Vision and Qustomdot focus on innovative applications. Research institutions including Xiamen University and KIST are advancing fundamental stability solutions. The primary challenge remains developing quantum dots that maintain optical and electronic properties at elevated temperatures required for industrial electronics applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed proprietary quantum dot stabilization technology for high-temperature electronics applications, focusing on encapsulation methods that protect QDs from thermal degradation. Their approach involves core-shell structures with multiple protective layers, where the inner shell prevents core oxidation while the outer shell provides thermal insulation. Samsung's research has demonstrated quantum dots maintaining over 90% luminescence efficiency at temperatures up to 150°C for extended periods [1]. Their patented ligand exchange process replaces conventional organic ligands with thermally-resistant inorganic compounds, significantly improving stability in high-temperature environments. Additionally, Samsung has pioneered matrix embedding techniques where QDs are dispersed within ceramic or glass-based matrices that act as thermal buffers, allowing their quantum dots to function reliably in automotive displays and outdoor signage operating in extreme temperature conditions [3].

Strengths: Superior encapsulation technology providing exceptional thermal stability; extensive manufacturing infrastructure allowing rapid commercialization; comprehensive IP portfolio in QD stabilization. Weaknesses: Higher production costs compared to conventional materials; some solutions require specialized manufacturing processes that limit scalability; potential environmental concerns with certain stabilizing compounds used in their formulations.

SAMSUNG DISPLAY CO LTD

Technical Solution:

Key Patents in Heat-Resistant Quantum Dots

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

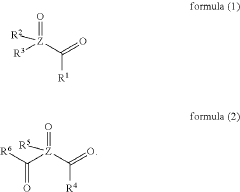

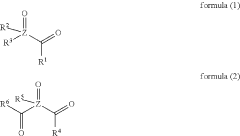

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Electroluminescence element

PatentWO2009041594A1

Innovation

- Using a protective material with a glass transition temperature and melting point of 90°C or higher for the quantum dots, such as hydrophilic and hydrophobic group-containing compounds like 4,4',4''-tris[2-naphthyl(phenyl)amino]triphenylamine, to prevent aggregation and maintain light-emitting properties under high-temperature conditions.

Material Science Advancements for QD Applications

Recent advancements in material science have significantly contributed to enhancing quantum dot (QD) stability for high-temperature electronics applications. Core-shell structures represent one of the most promising developments, where a protective layer of wider bandgap material encapsulates the QD core, effectively reducing surface defects and preventing oxidation. These structures have demonstrated remarkable thermal stability improvements, with some zinc-based core-shell QDs maintaining luminescence efficiency at temperatures exceeding 200°C.

Surface ligand engineering has emerged as another critical approach to QD stabilization. Traditional organic ligands often degrade at elevated temperatures, leading to QD aggregation and performance deterioration. Research has focused on developing thermally robust inorganic ligands and hybrid organic-inorganic systems that maintain structural integrity under extreme conditions. Notably, metal chalcogenide complexes and silica-based encapsulation methods have shown exceptional promise in preserving QD properties at temperatures up to 250°C.

Doping strategies have revolutionized QD thermal stability by introducing specific impurity atoms into the crystal lattice. Manganese and copper dopants, for instance, have been found to enhance both photoluminescence quantum yield and thermal stability. These dopants create additional energy states that can compensate for thermally-induced carrier losses, maintaining electronic performance at elevated temperatures. Recent studies have demonstrated that optimally doped QDs can retain over 80% of their room temperature efficiency when operating at 150°C.

Matrix embedding techniques represent another significant advancement, wherein QDs are dispersed within thermally resistant host materials such as silica, alumina, or specialized polymers. This approach physically constrains QD movement, preventing aggregation while providing thermal insulation. Ceramic-based matrices have shown particular promise for high-temperature electronics, with some composite materials maintaining QD functionality at temperatures approaching 300°C.

Atomic layer deposition (ALD) has emerged as a precision technique for creating ultrathin, conformal protective layers around QDs. This method allows for atomic-level control over shell thickness and composition, resulting in enhanced thermal stability without significantly altering the QD's optical and electronic properties. ALD-protected QDs have demonstrated remarkable resistance to thermal degradation, with some variants maintaining stable performance through hundreds of thermal cycling events between room temperature and 200°C.

Surface ligand engineering has emerged as another critical approach to QD stabilization. Traditional organic ligands often degrade at elevated temperatures, leading to QD aggregation and performance deterioration. Research has focused on developing thermally robust inorganic ligands and hybrid organic-inorganic systems that maintain structural integrity under extreme conditions. Notably, metal chalcogenide complexes and silica-based encapsulation methods have shown exceptional promise in preserving QD properties at temperatures up to 250°C.

Doping strategies have revolutionized QD thermal stability by introducing specific impurity atoms into the crystal lattice. Manganese and copper dopants, for instance, have been found to enhance both photoluminescence quantum yield and thermal stability. These dopants create additional energy states that can compensate for thermally-induced carrier losses, maintaining electronic performance at elevated temperatures. Recent studies have demonstrated that optimally doped QDs can retain over 80% of their room temperature efficiency when operating at 150°C.

Matrix embedding techniques represent another significant advancement, wherein QDs are dispersed within thermally resistant host materials such as silica, alumina, or specialized polymers. This approach physically constrains QD movement, preventing aggregation while providing thermal insulation. Ceramic-based matrices have shown particular promise for high-temperature electronics, with some composite materials maintaining QD functionality at temperatures approaching 300°C.

Atomic layer deposition (ALD) has emerged as a precision technique for creating ultrathin, conformal protective layers around QDs. This method allows for atomic-level control over shell thickness and composition, resulting in enhanced thermal stability without significantly altering the QD's optical and electronic properties. ALD-protected QDs have demonstrated remarkable resistance to thermal degradation, with some variants maintaining stable performance through hundreds of thermal cycling events between room temperature and 200°C.

Environmental Impact of QD Manufacturing Processes

The manufacturing processes of quantum dots (QDs) present significant environmental challenges that warrant careful consideration, especially as their application in high-temperature electronics expands. Traditional QD synthesis methods often involve toxic heavy metals such as cadmium, lead, and mercury, which pose substantial environmental and health risks if released during production or disposal phases. These heavy metals can contaminate soil and water systems, leading to bioaccumulation in food chains and potential long-term ecological damage.

The solvent-based synthesis routes commonly employed in QD manufacturing utilize hazardous organic compounds like trioctylphosphine oxide (TOPO) and hexadecylamine. These chemicals require careful handling and disposal protocols to prevent environmental contamination. Additionally, the high-temperature conditions necessary for certain QD synthesis methods result in considerable energy consumption, contributing to the carbon footprint of production facilities.

Waste management represents another critical environmental concern in QD manufacturing. The production process generates chemical byproducts and unreacted precursors that require specialized treatment before disposal. Without proper management, these waste streams can lead to environmental pollution and regulatory compliance issues for manufacturers.

Water usage in QD production processes also presents sustainability challenges. Purification steps often demand significant quantities of water, and the resulting wastewater may contain trace amounts of heavy metals and organic compounds that require treatment before discharge into municipal systems or natural water bodies.

Recent advancements in green chemistry approaches offer promising alternatives to conventional QD manufacturing methods. These include aqueous-based synthesis routes, the use of less toxic precursors, and the development of more environmentally benign capping agents. For instance, researchers have made progress in developing cadmium-free QDs using elements like indium, zinc, and copper, which present reduced environmental hazards while maintaining suitable electronic properties for high-temperature applications.

Life cycle assessment (LCA) studies of QD manufacturing processes indicate that the environmental impact varies significantly depending on synthesis methods, precursor selection, and waste management practices. Comprehensive LCA frameworks can help manufacturers identify hotspots in their production processes and implement targeted improvements to reduce environmental footprints.

Regulatory frameworks governing QD manufacturing continue to evolve globally, with increasing emphasis on restricting hazardous substances and promoting sustainable production practices. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is becoming essential for QD manufacturers targeting international markets, particularly in high-temperature electronics applications where product reliability and environmental compliance are equally valued.

The solvent-based synthesis routes commonly employed in QD manufacturing utilize hazardous organic compounds like trioctylphosphine oxide (TOPO) and hexadecylamine. These chemicals require careful handling and disposal protocols to prevent environmental contamination. Additionally, the high-temperature conditions necessary for certain QD synthesis methods result in considerable energy consumption, contributing to the carbon footprint of production facilities.

Waste management represents another critical environmental concern in QD manufacturing. The production process generates chemical byproducts and unreacted precursors that require specialized treatment before disposal. Without proper management, these waste streams can lead to environmental pollution and regulatory compliance issues for manufacturers.

Water usage in QD production processes also presents sustainability challenges. Purification steps often demand significant quantities of water, and the resulting wastewater may contain trace amounts of heavy metals and organic compounds that require treatment before discharge into municipal systems or natural water bodies.

Recent advancements in green chemistry approaches offer promising alternatives to conventional QD manufacturing methods. These include aqueous-based synthesis routes, the use of less toxic precursors, and the development of more environmentally benign capping agents. For instance, researchers have made progress in developing cadmium-free QDs using elements like indium, zinc, and copper, which present reduced environmental hazards while maintaining suitable electronic properties for high-temperature applications.

Life cycle assessment (LCA) studies of QD manufacturing processes indicate that the environmental impact varies significantly depending on synthesis methods, precursor selection, and waste management practices. Comprehensive LCA frameworks can help manufacturers identify hotspots in their production processes and implement targeted improvements to reduce environmental footprints.

Regulatory frameworks governing QD manufacturing continue to evolve globally, with increasing emphasis on restricting hazardous substances and promoting sustainable production practices. Compliance with regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) is becoming essential for QD manufacturers targeting international markets, particularly in high-temperature electronics applications where product reliability and environmental compliance are equally valued.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!