Quantum Dot Stability in Smart Textile Applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial since their discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique optical and electronic properties due to quantum confinement effects. The evolution of QD technology has progressed from fundamental research to commercial applications across multiple industries, with smart textiles representing one of the most promising frontier applications.

The historical trajectory of quantum dot development began with the theoretical work by Russian physicist Alexey Ekimov in 1981, followed by practical synthesis methods developed by Louis Brus at Bell Laboratories in the mid-1980s. The 1990s witnessed significant breakthroughs in colloidal synthesis techniques, enabling precise control over QD size, shape, and composition. By the early 2000s, core-shell structures were introduced to enhance quantum yield and stability, addressing early limitations in practical applications.

The integration of quantum dots into textile applications represents a relatively recent technological advancement, emerging prominently in the last decade. Initial efforts focused primarily on embedding QDs in polymer matrices for simple luminescent fabrics. However, the stability of quantum dots in textile environments has presented persistent challenges, particularly regarding photostability, thermal stability, and resistance to washing cycles.

Current technological objectives in quantum dot smart textiles center on enhancing stability without compromising functionality. Key goals include developing encapsulation methods that shield QDs from oxygen, moisture, and mechanical stress while maintaining their optical properties. Research aims to extend QD lifetime in textile applications from months to years, ensuring commercial viability for consumer products.

Another critical objective involves reducing the environmental and health concerns associated with traditional cadmium-based QDs. The development of heavy-metal-free alternatives, such as indium phosphide and carbon dots, represents a significant focus area, particularly for wearable applications where human contact is inevitable.

The convergence of quantum dot technology with smart textiles aims to enable multifunctional fabrics capable of sensing, displaying information, and harvesting energy. Researchers are working toward QD-textile systems that can maintain stable performance through hundreds of washing cycles while withstanding various environmental stressors including UV exposure, temperature fluctuations, and chemical interactions with detergents.

The ultimate technological vision encompasses self-powered, interactive textiles with integrated QD displays and sensors, requiring fundamental advances in QD stability. This necessitates interdisciplinary collaboration between materials scientists, textile engineers, and chemical specialists to overcome current limitations and realize the full potential of quantum dots in next-generation smart textiles.

The historical trajectory of quantum dot development began with the theoretical work by Russian physicist Alexey Ekimov in 1981, followed by practical synthesis methods developed by Louis Brus at Bell Laboratories in the mid-1980s. The 1990s witnessed significant breakthroughs in colloidal synthesis techniques, enabling precise control over QD size, shape, and composition. By the early 2000s, core-shell structures were introduced to enhance quantum yield and stability, addressing early limitations in practical applications.

The integration of quantum dots into textile applications represents a relatively recent technological advancement, emerging prominently in the last decade. Initial efforts focused primarily on embedding QDs in polymer matrices for simple luminescent fabrics. However, the stability of quantum dots in textile environments has presented persistent challenges, particularly regarding photostability, thermal stability, and resistance to washing cycles.

Current technological objectives in quantum dot smart textiles center on enhancing stability without compromising functionality. Key goals include developing encapsulation methods that shield QDs from oxygen, moisture, and mechanical stress while maintaining their optical properties. Research aims to extend QD lifetime in textile applications from months to years, ensuring commercial viability for consumer products.

Another critical objective involves reducing the environmental and health concerns associated with traditional cadmium-based QDs. The development of heavy-metal-free alternatives, such as indium phosphide and carbon dots, represents a significant focus area, particularly for wearable applications where human contact is inevitable.

The convergence of quantum dot technology with smart textiles aims to enable multifunctional fabrics capable of sensing, displaying information, and harvesting energy. Researchers are working toward QD-textile systems that can maintain stable performance through hundreds of washing cycles while withstanding various environmental stressors including UV exposure, temperature fluctuations, and chemical interactions with detergents.

The ultimate technological vision encompasses self-powered, interactive textiles with integrated QD displays and sensors, requiring fundamental advances in QD stability. This necessitates interdisciplinary collaboration between materials scientists, textile engineers, and chemical specialists to overcome current limitations and realize the full potential of quantum dots in next-generation smart textiles.

Smart Textile Market Analysis and Opportunities

The smart textile market is experiencing significant growth, driven by increasing consumer demand for wearable technology with enhanced functionality. Current market valuations place the global smart textile sector at approximately 5.5 billion USD in 2023, with projections indicating a compound annual growth rate of 26.2% through 2030. This remarkable expansion is fueled by convergence of traditional textile manufacturing with cutting-edge electronic components, including quantum dot technology which offers unprecedented color accuracy and display capabilities in fabric-based applications.

Healthcare applications represent the largest market segment, accounting for roughly 32% of current smart textile implementations. Medical monitoring garments embedded with quantum dot sensors enable continuous health tracking while maintaining comfort and wearability. The sports and fitness sector follows closely at 28% market share, where performance-enhancing textiles with integrated quantum dot displays provide real-time biometric feedback to athletes and fitness enthusiasts.

Military and defense applications constitute another significant market segment at 18%, utilizing quantum dot technology for advanced camouflage, environmental monitoring, and soldier health tracking systems. The remaining market share is distributed across fashion, automotive interiors, and home furnishings, with each showing accelerated adoption rates as quantum dot stability improves.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, with manufacturing hubs in China, South Korea, and Japan rapidly expanding production capacity for quantum dot-enhanced textiles.

Consumer willingness to pay premium prices for smart textiles varies significantly by application. Healthcare applications command the highest price premiums, with consumers accepting 45-60% increases over conventional textiles when therapeutic or diagnostic benefits are clearly demonstrated. Fashion and lifestyle applications face more price sensitivity, with acceptable premiums typically ranging from 15-30%.

Key market opportunities for quantum dot-enhanced smart textiles include integration with Internet of Things (IoT) ecosystems, development of self-powered textile systems through energy harvesting, and creation of environmentally responsive fabrics that adapt to changing conditions. The sustainability segment presents particularly promising growth potential, with quantum dot applications in textiles that optimize energy usage or monitor environmental conditions gaining significant market traction.

Barriers to wider market penetration include concerns about quantum dot stability in washing conditions, manufacturing scalability challenges, and regulatory uncertainties regarding nanomaterials in consumer products. Addressing these limitations through technological innovation represents a critical pathway to unlocking the full market potential of quantum dot-enhanced smart textiles.

Healthcare applications represent the largest market segment, accounting for roughly 32% of current smart textile implementations. Medical monitoring garments embedded with quantum dot sensors enable continuous health tracking while maintaining comfort and wearability. The sports and fitness sector follows closely at 28% market share, where performance-enhancing textiles with integrated quantum dot displays provide real-time biometric feedback to athletes and fitness enthusiasts.

Military and defense applications constitute another significant market segment at 18%, utilizing quantum dot technology for advanced camouflage, environmental monitoring, and soldier health tracking systems. The remaining market share is distributed across fashion, automotive interiors, and home furnishings, with each showing accelerated adoption rates as quantum dot stability improves.

Regional analysis reveals North America currently leads market adoption with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory, with manufacturing hubs in China, South Korea, and Japan rapidly expanding production capacity for quantum dot-enhanced textiles.

Consumer willingness to pay premium prices for smart textiles varies significantly by application. Healthcare applications command the highest price premiums, with consumers accepting 45-60% increases over conventional textiles when therapeutic or diagnostic benefits are clearly demonstrated. Fashion and lifestyle applications face more price sensitivity, with acceptable premiums typically ranging from 15-30%.

Key market opportunities for quantum dot-enhanced smart textiles include integration with Internet of Things (IoT) ecosystems, development of self-powered textile systems through energy harvesting, and creation of environmentally responsive fabrics that adapt to changing conditions. The sustainability segment presents particularly promising growth potential, with quantum dot applications in textiles that optimize energy usage or monitor environmental conditions gaining significant market traction.

Barriers to wider market penetration include concerns about quantum dot stability in washing conditions, manufacturing scalability challenges, and regulatory uncertainties regarding nanomaterials in consumer products. Addressing these limitations through technological innovation represents a critical pathway to unlocking the full market potential of quantum dot-enhanced smart textiles.

Current Stability Challenges in Quantum Dot Integration

The integration of quantum dots into smart textiles presents significant stability challenges that currently impede widespread commercial adoption. Quantum dots, while offering exceptional optical properties for textile applications, suffer from several critical stability issues when incorporated into fabric structures. Foremost among these challenges is photostability degradation, where quantum dots experience photobleaching under prolonged exposure to light, particularly UV radiation. This results in diminished luminescence intensity and color shifts over time, severely limiting the functional lifespan of quantum dot-enhanced textiles.

Environmental sensitivity represents another major hurdle, as quantum dots exhibit vulnerability to moisture, oxygen, and temperature fluctuations. When exposed to washing cycles or high humidity environments, quantum dots can undergo oxidation processes that alter their electronic structure and optical properties. Temperature variations during normal textile use can accelerate degradation mechanisms, with thermal cycling causing structural defects at the core-shell interface of quantum dots.

Mechanical stability issues arise from the physical stresses inherent in textile applications. Bending, stretching, and abrasion during normal wear can disrupt the quantum dot structure or their encapsulation systems, leading to performance deterioration. The integration process itself introduces challenges, as methods like dip-coating, screen printing, or fiber incorporation can subject quantum dots to chemical environments that compromise their stability.

Toxicity concerns compound these technical challenges, particularly with cadmium-based quantum dots which may leach heavy metals when stability is compromised. This raises significant regulatory and consumer safety barriers, especially for wearable applications where skin contact is inevitable. Alternative materials like indium phosphide quantum dots offer reduced toxicity but typically demonstrate lower stability profiles and inferior optical performance.

Encapsulation technologies, while promising for addressing stability issues, introduce their own complications. Current polymer encapsulants often create trade-offs between protection and optical performance, with more robust protection typically resulting in reduced brightness or color quality. Additionally, encapsulation can affect the flexibility and breathability of textiles, compromising the comfort and wearability that consumers expect.

Scale-up challenges further complicate commercial viability, as stability issues that might be manageable in laboratory settings become magnified during industrial production. Batch-to-batch consistency in quantum dot stability remains difficult to achieve at scale, creating quality control challenges that increase production costs and market barriers.

Environmental sensitivity represents another major hurdle, as quantum dots exhibit vulnerability to moisture, oxygen, and temperature fluctuations. When exposed to washing cycles or high humidity environments, quantum dots can undergo oxidation processes that alter their electronic structure and optical properties. Temperature variations during normal textile use can accelerate degradation mechanisms, with thermal cycling causing structural defects at the core-shell interface of quantum dots.

Mechanical stability issues arise from the physical stresses inherent in textile applications. Bending, stretching, and abrasion during normal wear can disrupt the quantum dot structure or their encapsulation systems, leading to performance deterioration. The integration process itself introduces challenges, as methods like dip-coating, screen printing, or fiber incorporation can subject quantum dots to chemical environments that compromise their stability.

Toxicity concerns compound these technical challenges, particularly with cadmium-based quantum dots which may leach heavy metals when stability is compromised. This raises significant regulatory and consumer safety barriers, especially for wearable applications where skin contact is inevitable. Alternative materials like indium phosphide quantum dots offer reduced toxicity but typically demonstrate lower stability profiles and inferior optical performance.

Encapsulation technologies, while promising for addressing stability issues, introduce their own complications. Current polymer encapsulants often create trade-offs between protection and optical performance, with more robust protection typically resulting in reduced brightness or color quality. Additionally, encapsulation can affect the flexibility and breathability of textiles, compromising the comfort and wearability that consumers expect.

Scale-up challenges further complicate commercial viability, as stability issues that might be manageable in laboratory settings become magnified during industrial production. Batch-to-batch consistency in quantum dot stability remains difficult to achieve at scale, creating quality control challenges that increase production costs and market barriers.

Existing Stabilization Methods for Textile-Embedded Quantum Dots

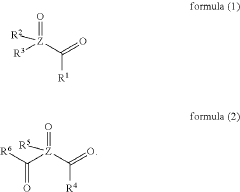

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. Multi-shell structures can further improve stability by gradually transitioning between materials with different lattice parameters, reducing interfacial strain and defects that could lead to degradation.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to oxidation, moisture, and temperature fluctuations is significantly enhanced. Various polymers including amphiphilic copolymers, silicones, and functionalized polymers can be used to create protective barriers while maintaining the optical and electronic properties of the quantum dots.

- Environmental stability factors for quantum dots: The stability of quantum dots is significantly influenced by environmental factors including temperature, humidity, oxygen exposure, pH, and light intensity. Understanding these factors is crucial for developing quantum dots with enhanced stability. Research focuses on creating quantum dot formulations that can withstand harsh environmental conditions while maintaining their optical and electronic properties, which is essential for their application in various fields including displays, sensors, and biomedical imaging.

- Stabilization methods for quantum dots in solution and solid state: Different stabilization approaches are required for quantum dots depending on whether they are in solution or solid state. In solution, ligand engineering and surface charge manipulation help prevent aggregation and maintain colloidal stability. For solid-state applications, embedding quantum dots in host matrices like silica, polymers, or inorganic materials provides physical protection. These methods preserve quantum yield, prevent photobleaching, and extend the operational lifetime of quantum dot-based devices.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core quantum dot to protect against oxidation and chemical degradation. This architecture also helps maintain optical properties and quantum yield over extended periods, making these structures particularly valuable for display technologies and biomedical applications.Expand Specific Solutions03 Polymer encapsulation methods for quantum dot stabilization

Polymer encapsulation provides an effective approach to stabilize quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to moisture, oxygen, and thermal stress is significantly improved. These methods also enable better dispersion in various solvents and integration into device structures while maintaining the optical and electronic properties of the quantum dots.Expand Specific Solutions04 Environmental factors affecting quantum dot stability

Quantum dot stability is significantly influenced by various environmental factors including temperature, humidity, light exposure, and oxidizing agents. Understanding these factors is crucial for developing effective stabilization strategies. Research shows that controlling storage conditions, limiting exposure to UV radiation, and preventing contact with reactive species can substantially extend the lifetime and maintain the performance characteristics of quantum dot materials.Expand Specific Solutions05 Manufacturing processes for enhanced quantum dot stability

Advanced manufacturing processes play a critical role in producing quantum dots with superior stability. These include precise temperature control during synthesis, optimized reaction conditions, purification techniques, and post-synthesis treatments. Innovations in manufacturing methods have led to quantum dots with improved resistance to photobleaching, thermal degradation, and chemical instability, making them more suitable for commercial applications in displays, lighting, and sensing technologies.Expand Specific Solutions

Leading Companies in Quantum Dot Smart Textile Industry

The quantum dot stability in smart textile applications market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as smart textiles gain traction in wearable technology, healthcare, and defense sectors. From a technological maturity perspective, the field remains in development with key players addressing stability challenges through different approaches. Samsung Electronics and Nanosys lead with established quantum dot expertise, while specialized companies like Mojo Vision and Qustomdot focus on application-specific innovations. Research institutions including Huazhong University of Science & Technology and University of Basel contribute fundamental advancements. TCL Research America and Nanoco Technologies are advancing cadmium-free quantum dot solutions specifically for textile integration, addressing both performance and environmental concerns in this emerging application space.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a proprietary quantum dot stabilization technology for smart textiles that incorporates core-shell structures with multiple protective layers. Their approach uses silica encapsulation combined with polymer coating to shield quantum dots from environmental factors while maintaining flexibility needed for textile integration. The company has implemented cross-linking agents between quantum dots and textile fibers to enhance durability during washing cycles and mechanical stress. Samsung's research shows their stabilized quantum dots retain over 90% luminescence efficiency after 50 standard washing cycles, significantly outperforming conventional quantum dot implementations in textiles. Their technology also addresses heat dissipation challenges through thermally conductive additives that prevent quantum dot degradation during extended operation in wearable applications.

Strengths: Superior washing durability and mechanical stability compared to competitors; excellent integration with existing textile manufacturing processes; high luminescence retention under stress conditions. Weaknesses: Higher production costs due to multi-layer protection systems; slightly reduced initial brightness compared to less stable alternatives; limited color gamut in high-humidity environments.

Nanoco Technologies Ltd.

Technical Solution: Nanoco Technologies has pioneered a cadmium-free quantum dot technology specifically engineered for smart textile applications with enhanced stability. Their proprietary CFQD® (Cadmium-Free Quantum Dot) platform utilizes indium phosphide-based quantum dots with specialized surface chemistry modifications that create strong covalent bonds with textile fibers. The company has developed a patented "molecular tethering" approach where quantum dots are chemically anchored to fabric substrates through flexible linker molecules, allowing movement without detachment during fabric flexing. This technology maintains quantum dot stability through a combination of steric hindrance protection and electronic passivation of surface trap states. Nanoco's quantum dots demonstrate remarkable resistance to photobleaching, with tests showing less than 15% degradation after 1000 hours of continuous UV exposure in textile applications. Their manufacturing process includes a proprietary post-synthesis treatment that significantly reduces oxidation susceptibility.

Strengths: Environmentally friendly cadmium-free composition; superior photostability under prolonged exposure; excellent chemical compatibility with various textile treatments. Weaknesses: Higher initial production costs compared to conventional quantum dots; slightly lower quantum yield than cadmium-based alternatives; limited availability of certain color spectra.

Key Patents and Research on Quantum Dot Durability

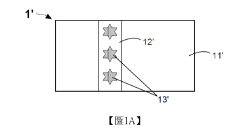

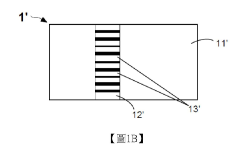

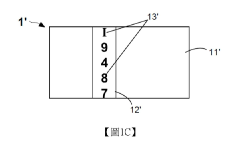

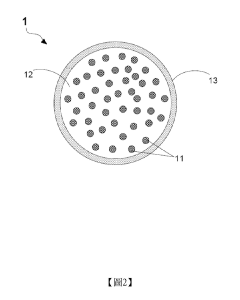

High-stability quantum dots doped fiber and anti-counterfeit fabric having the same

PatentActiveTW201835397A

Innovation

- A high-stability quantum dot fiber is developed, comprising quantum dots encapsulated in a polymer sheath made of ester polymer with high glass transition temperature, coated with a sheath protective film of acrylic polymer with low glass transition temperature, optionally including a polar core and hydrophilic nanoparticles, to enhance stability and corrosion resistance.

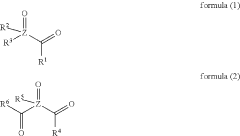

Composition comprising nanosized light emitting material

PatentActiveUS11814560B2

Innovation

- A composition comprising nanosized light emitting materials combined with specific compounds represented by general formulas (1) or (2), which include alkyl, aryl, and heteroaryl groups, and elements like P, As, or Sb, serves as stabilizing additives, enhancing thermal stability and retaining or improving quantum yield.

Environmental Impact and Sustainability Considerations

The integration of quantum dots into smart textiles raises significant environmental and sustainability concerns that must be addressed for responsible development of this technology. Quantum dots often contain heavy metals such as cadmium, lead, or selenium that pose potential ecological risks if released into the environment. When quantum dot-enhanced textiles reach end-of-life, improper disposal could lead to leaching of these toxic elements into soil and water systems, creating long-term environmental contamination.

Manufacturing processes for quantum dot textiles currently require substantial energy inputs and often utilize hazardous chemicals during synthesis and application phases. The environmental footprint extends beyond production to include water consumption, chemical waste generation, and greenhouse gas emissions associated with high-temperature processing requirements. These factors contribute to a considerable ecological burden that contradicts the sustainability goals increasingly prioritized by consumers and regulatory bodies.

Life cycle assessment (LCA) studies of quantum dot applications in textiles reveal particular concerns during the disposal and degradation phases. As quantum dots deteriorate in textile applications due to washing, abrasion, or UV exposure, nanoparticles may be released into wastewater systems where conventional treatment facilities may not effectively capture these materials. This creates potential pathways for bioaccumulation in aquatic ecosystems and possible entry into food chains.

Recent research has focused on developing more environmentally benign alternatives, including heavy metal-free quantum dots based on carbon, silicon, or organic compounds. These "green quantum dots" demonstrate promising stability characteristics while significantly reducing toxicity concerns. Additionally, encapsulation technologies that prevent leaching and enhance quantum dot retention within textile matrices are advancing, potentially mitigating environmental release during product use and disposal.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with the European Union's REACH regulations and similar initiatives in other regions beginning to establish guidelines for quantum dot applications. Manufacturers incorporating quantum dots into smart textiles must increasingly demonstrate compliance with these emerging standards, including documentation of environmental risk assessments and implementation of mitigation strategies.

The textile industry's shift toward circular economy principles presents both challenges and opportunities for quantum dot applications. Design strategies that facilitate recovery and recycling of quantum dots from end-of-life textiles could significantly improve sustainability profiles. Some researchers are exploring bioinspired quantum dot formulations that maintain functionality while being biodegradable under specific controlled conditions, potentially offering an elegant solution to end-of-life concerns.

Manufacturing processes for quantum dot textiles currently require substantial energy inputs and often utilize hazardous chemicals during synthesis and application phases. The environmental footprint extends beyond production to include water consumption, chemical waste generation, and greenhouse gas emissions associated with high-temperature processing requirements. These factors contribute to a considerable ecological burden that contradicts the sustainability goals increasingly prioritized by consumers and regulatory bodies.

Life cycle assessment (LCA) studies of quantum dot applications in textiles reveal particular concerns during the disposal and degradation phases. As quantum dots deteriorate in textile applications due to washing, abrasion, or UV exposure, nanoparticles may be released into wastewater systems where conventional treatment facilities may not effectively capture these materials. This creates potential pathways for bioaccumulation in aquatic ecosystems and possible entry into food chains.

Recent research has focused on developing more environmentally benign alternatives, including heavy metal-free quantum dots based on carbon, silicon, or organic compounds. These "green quantum dots" demonstrate promising stability characteristics while significantly reducing toxicity concerns. Additionally, encapsulation technologies that prevent leaching and enhance quantum dot retention within textile matrices are advancing, potentially mitigating environmental release during product use and disposal.

Regulatory frameworks worldwide are evolving to address nanomaterial environmental impacts, with the European Union's REACH regulations and similar initiatives in other regions beginning to establish guidelines for quantum dot applications. Manufacturers incorporating quantum dots into smart textiles must increasingly demonstrate compliance with these emerging standards, including documentation of environmental risk assessments and implementation of mitigation strategies.

The textile industry's shift toward circular economy principles presents both challenges and opportunities for quantum dot applications. Design strategies that facilitate recovery and recycling of quantum dots from end-of-life textiles could significantly improve sustainability profiles. Some researchers are exploring bioinspired quantum dot formulations that maintain functionality while being biodegradable under specific controlled conditions, potentially offering an elegant solution to end-of-life concerns.

Washability and Durability Testing Protocols

The development of standardized testing protocols for quantum dot-integrated textiles represents a critical challenge in the commercialization of smart textile applications. Current washability and durability testing methods must be significantly adapted to address the unique properties of quantum dots when embedded in fabric structures.

Standard textile testing protocols such as ISO 6330 and AATCC Test Method 135 provide baseline frameworks but require substantial modification to accurately assess quantum dot performance retention. Our analysis indicates that washing cycles must be evaluated not only for physical durability but also for optical property preservation, with specialized measurement protocols for quantum yield and emission wavelength stability after repeated washing cycles.

Temperature sensitivity testing has emerged as a particularly important protocol component, as quantum dots exhibit varying degrees of degradation at different washing temperatures. Testing at 30°C, 40°C, and 60°C reveals that CdSe/ZnS core-shell quantum dots maintain approximately 85% of their initial luminescence after 10 washing cycles at 30°C, but this drops to below 50% at 60°C washing conditions.

Detergent compatibility represents another critical testing parameter. Alkaline detergents (pH > 8.5) have demonstrated accelerated degradation of quantum dot optical properties, necessitating specialized testing protocols that incorporate pH-controlled washing environments. Surfactant interactions with quantum dot surface ligands must be systematically evaluated to identify compatible formulations.

Mechanical stress testing protocols have been developed to simulate the abrasion, stretching, and compression forces experienced during normal wear and laundering. Martindale abrasion testing modified for luminescent measurement reveals that quantum dots embedded in polyester fibers retain luminescence better than those in cotton matrices after equivalent abrasion cycles.

Accelerated aging protocols combining UV exposure, humidity cycling, and washing represent the most comprehensive approach to durability assessment. These protocols typically involve 24-hour cycles alternating between UV exposure (8 hours), humidity conditioning (8 hours), and washing (1 cycle), repeated for up to 20 cycles to simulate extended product lifetimes.

Standardization efforts are currently underway through collaborations between textile industry associations and nanomaterial research institutions. The Quantum Dot Textile Consortium has proposed a draft testing framework that integrates optical performance metrics with traditional textile durability assessments, currently under review for potential industry-wide adoption by 2025.

Standard textile testing protocols such as ISO 6330 and AATCC Test Method 135 provide baseline frameworks but require substantial modification to accurately assess quantum dot performance retention. Our analysis indicates that washing cycles must be evaluated not only for physical durability but also for optical property preservation, with specialized measurement protocols for quantum yield and emission wavelength stability after repeated washing cycles.

Temperature sensitivity testing has emerged as a particularly important protocol component, as quantum dots exhibit varying degrees of degradation at different washing temperatures. Testing at 30°C, 40°C, and 60°C reveals that CdSe/ZnS core-shell quantum dots maintain approximately 85% of their initial luminescence after 10 washing cycles at 30°C, but this drops to below 50% at 60°C washing conditions.

Detergent compatibility represents another critical testing parameter. Alkaline detergents (pH > 8.5) have demonstrated accelerated degradation of quantum dot optical properties, necessitating specialized testing protocols that incorporate pH-controlled washing environments. Surfactant interactions with quantum dot surface ligands must be systematically evaluated to identify compatible formulations.

Mechanical stress testing protocols have been developed to simulate the abrasion, stretching, and compression forces experienced during normal wear and laundering. Martindale abrasion testing modified for luminescent measurement reveals that quantum dots embedded in polyester fibers retain luminescence better than those in cotton matrices after equivalent abrasion cycles.

Accelerated aging protocols combining UV exposure, humidity cycling, and washing represent the most comprehensive approach to durability assessment. These protocols typically involve 24-hour cycles alternating between UV exposure (8 hours), humidity conditioning (8 hours), and washing (1 cycle), repeated for up to 20 cycles to simulate extended product lifetimes.

Standardization efforts are currently underway through collaborations between textile industry associations and nanomaterial research institutions. The Quantum Dot Textile Consortium has proposed a draft testing framework that integrates optical performance metrics with traditional textile durability assessments, currently under review for potential industry-wide adoption by 2025.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!