Quantum Dot Stability in Sub-Micron Thick Films for Displays

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Display Technology Evolution and Objectives

Quantum dot (QD) display technology has evolved significantly over the past two decades, transforming from a laboratory curiosity to a commercial reality that is reshaping the display industry. The journey began in the early 2000s when researchers first demonstrated the potential of quantum dots for display applications, leveraging their unique optical properties including size-tunable emission wavelengths, narrow emission spectra, and high quantum yields. These semiconductor nanocrystals, typically ranging from 2 to 10 nanometers in diameter, offered unprecedented color purity and brightness compared to traditional phosphor-based technologies.

The evolution of QD display technology can be traced through several distinct phases. The initial phase (2000-2010) focused primarily on fundamental research, establishing the synthesis methods and basic properties of various QD materials, predominantly cadmium-based compounds. During this period, researchers grappled with significant challenges related to QD stability, particularly their sensitivity to oxygen, moisture, and photo-oxidation processes that led to rapid degradation of optical properties.

The second phase (2010-2015) marked the transition from laboratory to commercial applications, with the introduction of the first QD-enhanced LCD displays. These early implementations utilized QDs in edge-lit configurations, where the nanocrystals were embedded in polymer films or glass tubes positioned at the edge of the display backlight. While this approach improved color performance compared to conventional LCDs, it utilized only a fraction of the potential benefits that quantum dots could offer.

The current phase (2015-present) has witnessed rapid technological advancement with the development of quantum dot color conversion films for direct integration into display backlights. This evolution has been driven by the pursuit of higher efficiency, improved color gamut, and enhanced display brightness. Concurrently, significant research efforts have focused on addressing the fundamental stability challenges of quantum dots, particularly when incorporated into sub-micron thick films required for advanced display architectures.

The primary objectives in quantum dot display technology development now center on several key areas. First, enhancing the long-term stability of QDs in thin film configurations, particularly under high-intensity blue light exposure and elevated temperatures typical in display operation. Second, developing cadmium-free quantum dot materials that maintain the exceptional optical properties of traditional QDs while eliminating toxic heavy metals. Third, improving manufacturing processes to enable cost-effective production of uniform, defect-free QD films at scale.

Looking forward, the industry is moving toward electroluminescent quantum dot displays (QLED), where quantum dots serve as the primary emissive elements rather than color conversion materials. This represents the ultimate evolution of the technology, promising displays with perfect black levels, wide viewing angles, and unprecedented color performance, while potentially reducing power consumption compared to current technologies.

The evolution of QD display technology can be traced through several distinct phases. The initial phase (2000-2010) focused primarily on fundamental research, establishing the synthesis methods and basic properties of various QD materials, predominantly cadmium-based compounds. During this period, researchers grappled with significant challenges related to QD stability, particularly their sensitivity to oxygen, moisture, and photo-oxidation processes that led to rapid degradation of optical properties.

The second phase (2010-2015) marked the transition from laboratory to commercial applications, with the introduction of the first QD-enhanced LCD displays. These early implementations utilized QDs in edge-lit configurations, where the nanocrystals were embedded in polymer films or glass tubes positioned at the edge of the display backlight. While this approach improved color performance compared to conventional LCDs, it utilized only a fraction of the potential benefits that quantum dots could offer.

The current phase (2015-present) has witnessed rapid technological advancement with the development of quantum dot color conversion films for direct integration into display backlights. This evolution has been driven by the pursuit of higher efficiency, improved color gamut, and enhanced display brightness. Concurrently, significant research efforts have focused on addressing the fundamental stability challenges of quantum dots, particularly when incorporated into sub-micron thick films required for advanced display architectures.

The primary objectives in quantum dot display technology development now center on several key areas. First, enhancing the long-term stability of QDs in thin film configurations, particularly under high-intensity blue light exposure and elevated temperatures typical in display operation. Second, developing cadmium-free quantum dot materials that maintain the exceptional optical properties of traditional QDs while eliminating toxic heavy metals. Third, improving manufacturing processes to enable cost-effective production of uniform, defect-free QD films at scale.

Looking forward, the industry is moving toward electroluminescent quantum dot displays (QLED), where quantum dots serve as the primary emissive elements rather than color conversion materials. This represents the ultimate evolution of the technology, promising displays with perfect black levels, wide viewing angles, and unprecedented color performance, while potentially reducing power consumption compared to current technologies.

Market Analysis for QD-Enhanced Display Applications

The quantum dot (QD) display market has witnessed remarkable growth over the past decade, evolving from a niche technology to a mainstream display enhancement solution. The global QD display market was valued at approximately $4.5 billion in 2022 and is projected to reach $18.6 billion by 2028, representing a compound annual growth rate (CAGR) of 26.7%. This substantial growth is primarily driven by increasing consumer demand for superior visual experiences, particularly in high-definition televisions, smartphones, and computer monitors.

Consumer electronics represents the largest application segment for QD-enhanced displays, accounting for over 70% of the total market share. Within this segment, television manufacturers have been the earliest and most enthusiastic adopters, with Samsung and TCL leading the commercialization efforts. The premium television market has particularly benefited from quantum dot technology, as it enables significantly improved color gamut, brightness, and energy efficiency compared to conventional LCD displays.

The smartphone and tablet display market is emerging as the fastest-growing segment for QD technology, with a projected CAGR of 32% through 2028. This acceleration is attributed to the increasing consumer preference for mobile devices with enhanced visual capabilities for gaming, video streaming, and augmented reality applications. Major smartphone manufacturers including Samsung, Apple, and Xiaomi have either implemented or are actively researching QD integration into their flagship devices.

Regional analysis reveals that Asia-Pacific dominates the QD display market, accounting for approximately 65% of global production capacity. This dominance is primarily due to the strong presence of display manufacturers in South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer purchasing power and early technology adoption trends.

The automotive display market represents a promising growth opportunity for QD technology, with projections indicating a market value of $1.2 billion by 2027. As vehicles increasingly incorporate sophisticated infotainment systems and digital dashboards, the demand for high-performance displays with superior visibility under varying lighting conditions has intensified. QD-enhanced displays offer advantages in this context due to their high brightness, wide color gamut, and potential for curved or flexible form factors.

Market challenges include price sensitivity, particularly in mid-range consumer electronics, and competition from alternative technologies such as OLED and MicroLED. However, recent advancements in QD manufacturing processes have significantly reduced production costs, making QD-enhanced displays increasingly competitive across various price segments. The stability of quantum dots in sub-micron thick films remains a critical factor influencing market adoption rates, as improved stability directly correlates with device longevity and performance consistency.

Consumer electronics represents the largest application segment for QD-enhanced displays, accounting for over 70% of the total market share. Within this segment, television manufacturers have been the earliest and most enthusiastic adopters, with Samsung and TCL leading the commercialization efforts. The premium television market has particularly benefited from quantum dot technology, as it enables significantly improved color gamut, brightness, and energy efficiency compared to conventional LCD displays.

The smartphone and tablet display market is emerging as the fastest-growing segment for QD technology, with a projected CAGR of 32% through 2028. This acceleration is attributed to the increasing consumer preference for mobile devices with enhanced visual capabilities for gaming, video streaming, and augmented reality applications. Major smartphone manufacturers including Samsung, Apple, and Xiaomi have either implemented or are actively researching QD integration into their flagship devices.

Regional analysis reveals that Asia-Pacific dominates the QD display market, accounting for approximately 65% of global production capacity. This dominance is primarily due to the strong presence of display manufacturers in South Korea, Japan, China, and Taiwan. North America and Europe follow as significant markets, driven by high consumer purchasing power and early technology adoption trends.

The automotive display market represents a promising growth opportunity for QD technology, with projections indicating a market value of $1.2 billion by 2027. As vehicles increasingly incorporate sophisticated infotainment systems and digital dashboards, the demand for high-performance displays with superior visibility under varying lighting conditions has intensified. QD-enhanced displays offer advantages in this context due to their high brightness, wide color gamut, and potential for curved or flexible form factors.

Market challenges include price sensitivity, particularly in mid-range consumer electronics, and competition from alternative technologies such as OLED and MicroLED. However, recent advancements in QD manufacturing processes have significantly reduced production costs, making QD-enhanced displays increasingly competitive across various price segments. The stability of quantum dots in sub-micron thick films remains a critical factor influencing market adoption rates, as improved stability directly correlates with device longevity and performance consistency.

Current Stability Challenges in Sub-Micron QD Films

Quantum dot (QD) films for display applications face significant stability challenges when reduced to sub-micron thicknesses. The primary concern is photostability, as quantum dots experience photobleaching under continuous light exposure, particularly blue light used for excitation in display systems. This degradation manifests as decreased quantum yield and color shift over time, severely impacting display performance and longevity. The rate of degradation accelerates dramatically in thinner films due to increased surface-to-volume ratio and reduced protective matrix material.

Oxidation presents another critical challenge, with oxygen molecules penetrating the thin film structure and reacting with the QD surface, creating trap states that diminish luminescence efficiency. In sub-micron films, the diffusion pathways for oxygen are significantly shortened, accelerating oxidative degradation. This issue becomes particularly pronounced at elevated temperatures typical in display operation environments, where both diffusion rates and reaction kinetics are enhanced.

Thermal stability represents a third major concern, as QDs in thin films experience greater thermal fluctuations with less thermal mass to buffer temperature changes. Operating temperatures in display devices frequently exceed 80°C, approaching the glass transition temperature of many polymer matrices used in QD films. This thermal stress induces ligand detachment, core/shell interface degradation, and potential Ostwald ripening effects, all of which compromise quantum yield and spectral characteristics.

The mechanical integrity of ultra-thin QD films presents unique challenges during manufacturing and operation. Sub-micron films are more susceptible to cracking, delamination, and non-uniform thickness distribution during coating processes. These mechanical defects create localized stress points that accelerate degradation and lead to non-uniform optical performance across the display area.

Moisture sensitivity compounds these issues, as water molecules can penetrate thin films more readily than thicker counterparts. Water interaction with QDs and their ligands causes hydrolysis reactions that compromise the nanocrystal structure and surface passivation. Even trace amounts of moisture can trigger cascading degradation mechanisms that significantly reduce device lifetime.

The combination of these degradation pathways creates complex failure mechanisms that are difficult to isolate and address individually. Current encapsulation technologies struggle to provide adequate protection at sub-micron thicknesses without introducing optical artifacts or processing complications. The industry standard barrier films typically require thicknesses exceeding the target dimensions for next-generation display architectures, creating a fundamental materials science challenge that requires innovative approaches to overcome.

Oxidation presents another critical challenge, with oxygen molecules penetrating the thin film structure and reacting with the QD surface, creating trap states that diminish luminescence efficiency. In sub-micron films, the diffusion pathways for oxygen are significantly shortened, accelerating oxidative degradation. This issue becomes particularly pronounced at elevated temperatures typical in display operation environments, where both diffusion rates and reaction kinetics are enhanced.

Thermal stability represents a third major concern, as QDs in thin films experience greater thermal fluctuations with less thermal mass to buffer temperature changes. Operating temperatures in display devices frequently exceed 80°C, approaching the glass transition temperature of many polymer matrices used in QD films. This thermal stress induces ligand detachment, core/shell interface degradation, and potential Ostwald ripening effects, all of which compromise quantum yield and spectral characteristics.

The mechanical integrity of ultra-thin QD films presents unique challenges during manufacturing and operation. Sub-micron films are more susceptible to cracking, delamination, and non-uniform thickness distribution during coating processes. These mechanical defects create localized stress points that accelerate degradation and lead to non-uniform optical performance across the display area.

Moisture sensitivity compounds these issues, as water molecules can penetrate thin films more readily than thicker counterparts. Water interaction with QDs and their ligands causes hydrolysis reactions that compromise the nanocrystal structure and surface passivation. Even trace amounts of moisture can trigger cascading degradation mechanisms that significantly reduce device lifetime.

The combination of these degradation pathways creates complex failure mechanisms that are difficult to isolate and address individually. Current encapsulation technologies struggle to provide adequate protection at sub-micron thicknesses without introducing optical artifacts or processing complications. The industry standard barrier films typically require thicknesses exceeding the target dimensions for next-generation display architectures, creating a fundamental materials science challenge that requires innovative approaches to overcome.

Technical Solutions for QD Stability Enhancement

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. The shell material, often composed of wider bandgap semiconductors, shields the core from environmental factors while maintaining the desired optical and electronic properties. This architecture reduces surface defects and prevents degradation, resulting in quantum dots with superior stability and longer lifetimes.

- Polymer encapsulation for quantum dot stabilization: Encapsulating quantum dots within polymer matrices provides an effective approach to enhance their stability. Polymers create a protective barrier that shields quantum dots from oxygen, moisture, and other environmental factors that can cause degradation. This encapsulation method also improves dispersibility in various solvents and compatibility with different materials, making the quantum dots more stable for practical applications.

- Environmental stability factors for quantum dots: The stability of quantum dots is significantly influenced by environmental factors such as temperature, pH, light exposure, and surrounding media. Understanding and controlling these factors is crucial for maintaining quantum dot stability. Various approaches have been developed to enhance resistance to environmental stressors, including specialized storage conditions, stabilizing additives, and engineered quantum dot compositions that exhibit improved tolerance to challenging environments.

- Manufacturing processes affecting quantum dot stability: The manufacturing and synthesis processes significantly impact the stability of quantum dots. Factors such as reaction temperature, precursor purity, reaction time, and post-synthesis processing all influence the structural integrity and long-term stability of the resulting quantum dots. Advanced synthesis methods have been developed to produce quantum dots with improved crystallinity, fewer defects, and enhanced stability characteristics for various applications.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core quantum dot to prevent oxidation and leaching of core materials. This architecture also helps maintain optical properties and quantum yield over extended periods, making these structures particularly valuable for display technologies and biological applications.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Quantum dots are sensitive to various environmental factors that can compromise their stability. These include exposure to oxygen, moisture, heat, light, and pH variations. Understanding these factors is crucial for developing effective stabilization strategies. Research focuses on creating quantum dots that maintain their properties under challenging environmental conditions, enabling their use in diverse applications from displays to biomedical imaging.Expand Specific Solutions04 Polymer encapsulation for quantum dot protection

Polymer encapsulation provides an effective method for enhancing quantum dot stability. By embedding quantum dots within polymer matrices or encapsulating them with specific polymers, they can be protected from oxidation, moisture, and mechanical stress. This approach not only improves stability but also facilitates integration into devices and systems. Various polymers with different properties can be selected based on the specific application requirements.Expand Specific Solutions05 Stabilization additives and formulation techniques

Specific additives and formulation techniques can significantly enhance quantum dot stability. These include antioxidants, UV stabilizers, and specific solvents that create favorable environments for quantum dots. Advanced formulation methods involve precise control of quantum dot concentration, dispersion techniques, and incorporation of synergistic stabilizing agents. These approaches are particularly important for commercial applications where long-term stability under various conditions is required.Expand Specific Solutions

Leading Companies in Quantum Dot Display Ecosystem

Quantum Dot Stability in Sub-Micron Thick Films for Displays is currently in a growth phase, with the market expected to reach significant expansion as display technologies evolve. The global quantum dot display market is experiencing rapid development, driven by increasing demand for enhanced color performance and energy efficiency. Technologically, the field shows varying maturity levels among key players. Companies like Nanosys and Samsung Display have established advanced stability solutions, while newer entrants such as Najing Technology and Nanoco Technologies are developing innovative approaches. TCL China Star, BOE Technology, and LG Electronics are integrating quantum dot technology into commercial display products, focusing on overcoming stability challenges in thin-film applications through proprietary encapsulation methods and material engineering.

BOE Technology Group Co., Ltd.

Technical Solution: BOE Technology has developed innovative quantum dot technology for enhanced stability in sub-micron display films. Their approach centers on a proprietary "QD-Matrix" technology that incorporates specially engineered quantum dots within a cross-linked polymer network, significantly improving thermal and photo-stability in films as thin as 0.8 microns. BOE's quantum dots feature a gradient-alloyed core/multi-shell architecture that minimizes interfacial defects and prevents core degradation under display operating conditions. The company has pioneered advanced surface modification techniques that create strong covalent bonds between quantum dots and the host polymer matrix, preventing aggregation and maintaining dispersion homogeneity even in ultra-thin films. Their manufacturing process employs precision microfluidic techniques that ensure narrow size distribution (±1.5nm) and consistent quantum yield across production batches. BOE has also developed specialized barrier film technology that provides effective protection against oxygen and moisture while maintaining overall film thinness. Their recent advancements include hybrid inorganic-organic encapsulation methods that significantly extend quantum dot lifetime in display environments without compromising optical performance or increasing film thickness.

Strengths: Strong integration with existing display manufacturing infrastructure; comprehensive approach addressing both quantum dot chemistry and film processing; significant resources dedicated to scaling production for commercial applications. Weaknesses: Relatively newer entrant to quantum dot technology compared to some specialized competitors; some solutions still show accelerated aging under high-brightness conditions; optimization still needed for films below 0.5 microns.

Nanoco Technologies Ltd.

Technical Solution: Nanoco Technologies has developed cadmium-free CFQD® (Cadmium-Free Quantum Dots) technology specifically engineered for stability in thin-film display applications. Their proprietary CFQD® quantum dots utilize an indium-based chemistry with a unique core-shell architecture that enhances stability while maintaining high quantum efficiency in sub-micron films. The company's patented "CFQD® Flex" technology incorporates these quantum dots into ultra-thin polymer matrices as thin as 0.7 microns while preserving optical performance. Nanoco has developed specialized surface ligand chemistry that creates strong bonds between the quantum dots and the host polymer matrix, preventing aggregation and maintaining dispersion homogeneity even in films below 1 micron thickness. Their manufacturing process employs continuous flow technology that ensures precise size control and batch-to-batch consistency, critical for uniform performance in thin-film applications. Additionally, Nanoco has pioneered encapsulation techniques that shield quantum dots from oxygen and moisture penetration, extending stability under display operating conditions.

Strengths: Cadmium-free composition addresses environmental and regulatory concerns; proprietary surface chemistry enables excellent dispersion in polymer matrices; continuous flow manufacturing ensures consistent quality and scalability. Weaknesses: Slightly lower quantum efficiency compared to cadmium-based alternatives; requires more complex synthesis processes; stability improvements still needed for extreme operating conditions and very thin films below 0.5 microns.

Critical Patents in Sub-Micron QD Film Technology

Stable quantum dot film for display applications

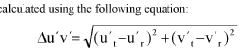

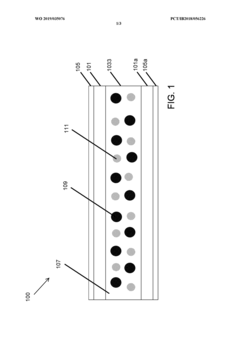

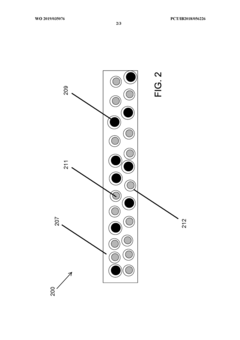

PatentWO2019035076A1

Innovation

- The use of passivated quantum dots with a metal oxide coating provides localized protection, reducing the need for barrier films and allowing for thinner, more cost-effective nanocomposite films with improved moisture and oxygen resistance, while maintaining optical properties.

Quantum dot, quantum dot composition, wavelength conversion material, wavelength conversion film, backlight unit, and image display device

PatentWO2020241112A1

Innovation

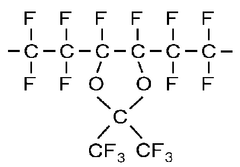

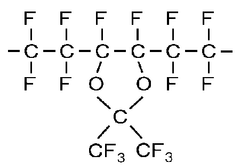

- Surface modification of quantum dots with fluorine-containing ligands, such as silane coupling agents, siloxane polymers, and perfluoropolyethers, to enhance stability and dispersibility in fluororesins, preventing aggregation and maintaining luminescent properties, and using a combination of fluorine-containing and fluorine-free resins to create a wavelength conversion film with improved adhesion and reduced thickness.

Environmental Impact and Regulatory Compliance

The environmental impact of quantum dot (QD) technology in display applications presents significant considerations for manufacturers and regulatory bodies alike. Heavy metals such as cadmium and lead, commonly used in traditional QD formulations, pose serious environmental and health risks throughout the product lifecycle. When improperly disposed of, these materials can leach into soil and water systems, potentially contaminating ecosystems and entering the food chain. This concern has prompted stringent regulations worldwide, including the European Union's Restriction of Hazardous Substances (RoHS) directive, which limits cadmium content to 100 ppm in electronic devices.

In response to these challenges, the industry has been developing cadmium-free quantum dots (CFQDs) using alternative materials such as indium phosphide, zinc selenide, and perovskite structures. While these alternatives reduce heavy metal toxicity, they often face trade-offs in performance metrics such as color gamut and efficiency. The environmental footprint of quantum dot displays must be assessed through comprehensive life cycle analyses that consider raw material extraction, manufacturing energy requirements, use-phase energy consumption, and end-of-life management.

Manufacturing processes for sub-micron QD films introduce additional environmental considerations. Solvent-based deposition methods may release volatile organic compounds (VOCs), contributing to air pollution and potential worker health hazards. Water-based alternatives are emerging but often require performance optimization. Energy-intensive processes such as high-temperature annealing also contribute to the carbon footprint of QD display production, necessitating more efficient manufacturing protocols.

Regulatory compliance frameworks continue to evolve globally, with varying requirements across different markets. Beyond RoHS, manufacturers must navigate regulations such as REACH in Europe, which requires registration and safety assessment of chemical substances, and similar frameworks in North America and Asia. These regulations increasingly emphasize extended producer responsibility, requiring manufacturers to consider the entire lifecycle environmental impact of their products.

Industry sustainability initiatives are gaining momentum, with major display manufacturers establishing take-back programs and exploring circular economy approaches. Research into biodegradable encapsulation materials and environmentally benign quantum dot compositions represents promising directions for reducing environmental impact. Additionally, improvements in QD stability directly contribute to environmental sustainability by extending device lifespans and reducing electronic waste generation.

The path toward environmentally responsible QD display technology requires balancing performance requirements with ecological considerations. As regulatory pressures increase and consumer awareness grows, manufacturers investing in environmentally sound QD technologies may gain competitive advantages through both regulatory compliance and market differentiation based on sustainability credentials.

In response to these challenges, the industry has been developing cadmium-free quantum dots (CFQDs) using alternative materials such as indium phosphide, zinc selenide, and perovskite structures. While these alternatives reduce heavy metal toxicity, they often face trade-offs in performance metrics such as color gamut and efficiency. The environmental footprint of quantum dot displays must be assessed through comprehensive life cycle analyses that consider raw material extraction, manufacturing energy requirements, use-phase energy consumption, and end-of-life management.

Manufacturing processes for sub-micron QD films introduce additional environmental considerations. Solvent-based deposition methods may release volatile organic compounds (VOCs), contributing to air pollution and potential worker health hazards. Water-based alternatives are emerging but often require performance optimization. Energy-intensive processes such as high-temperature annealing also contribute to the carbon footprint of QD display production, necessitating more efficient manufacturing protocols.

Regulatory compliance frameworks continue to evolve globally, with varying requirements across different markets. Beyond RoHS, manufacturers must navigate regulations such as REACH in Europe, which requires registration and safety assessment of chemical substances, and similar frameworks in North America and Asia. These regulations increasingly emphasize extended producer responsibility, requiring manufacturers to consider the entire lifecycle environmental impact of their products.

Industry sustainability initiatives are gaining momentum, with major display manufacturers establishing take-back programs and exploring circular economy approaches. Research into biodegradable encapsulation materials and environmentally benign quantum dot compositions represents promising directions for reducing environmental impact. Additionally, improvements in QD stability directly contribute to environmental sustainability by extending device lifespans and reducing electronic waste generation.

The path toward environmentally responsible QD display technology requires balancing performance requirements with ecological considerations. As regulatory pressures increase and consumer awareness grows, manufacturers investing in environmentally sound QD technologies may gain competitive advantages through both regulatory compliance and market differentiation based on sustainability credentials.

Manufacturing Scalability and Cost Analysis

The scalability of quantum dot (QD) manufacturing processes for sub-micron thick films represents a critical factor in their commercial viability for display applications. Current production methods vary significantly in their scalability potential, with solution-based processes showing the most promise for large-scale implementation. Spin coating, inkjet printing, and roll-to-roll processing have demonstrated capabilities for uniform QD film deposition across large areas, though each presents unique challenges when scaled to industrial production volumes.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for QD displays, with the quantum dots themselves representing the most significant component. High-purity precursors and specialized encapsulation materials contribute substantially to these costs. Production yields remain a significant concern, with current industrial processes achieving 70-85% yields for high-quality QD films, substantially impacting overall economics.

Equipment investment presents another major cost consideration. Advanced deposition systems for precise sub-micron film control require capital expenditures ranging from $2-10 million per production line, depending on throughput requirements and technological sophistication. Maintenance and calibration of these systems add recurring operational expenses estimated at 5-8% of initial equipment costs annually.

Energy consumption during manufacturing varies by process, with thermal annealing and encapsulation steps being particularly energy-intensive. Estimates suggest energy costs contribute 10-15% to overall production expenses. Labor requirements have decreased with increasing automation, now representing only 5-10% of manufacturing costs in modern facilities.

Economies of scale show promising trends, with analysis indicating potential cost reductions of 30-40% when scaling from pilot to full commercial production. However, these benefits are partially offset by the increased complexity of maintaining stability in larger batch processes. The industry is witnessing a gradual decline in production costs, with an average annual reduction of 8-12% as manufacturing technologies mature and supply chains develop.

Comparative analysis with competing display technologies reveals that while initial manufacturing costs for QD displays remain higher than conventional LCD production, the gap is narrowing. Current cost premiums of 25-35% are projected to decrease to 10-15% within three years as manufacturing processes are optimized and material utilization improves. This trajectory suggests QD display technology is approaching the economic threshold necessary for mainstream market adoption.

Cost analysis reveals that material expenses constitute approximately 40-60% of total manufacturing costs for QD displays, with the quantum dots themselves representing the most significant component. High-purity precursors and specialized encapsulation materials contribute substantially to these costs. Production yields remain a significant concern, with current industrial processes achieving 70-85% yields for high-quality QD films, substantially impacting overall economics.

Equipment investment presents another major cost consideration. Advanced deposition systems for precise sub-micron film control require capital expenditures ranging from $2-10 million per production line, depending on throughput requirements and technological sophistication. Maintenance and calibration of these systems add recurring operational expenses estimated at 5-8% of initial equipment costs annually.

Energy consumption during manufacturing varies by process, with thermal annealing and encapsulation steps being particularly energy-intensive. Estimates suggest energy costs contribute 10-15% to overall production expenses. Labor requirements have decreased with increasing automation, now representing only 5-10% of manufacturing costs in modern facilities.

Economies of scale show promising trends, with analysis indicating potential cost reductions of 30-40% when scaling from pilot to full commercial production. However, these benefits are partially offset by the increased complexity of maintaining stability in larger batch processes. The industry is witnessing a gradual decline in production costs, with an average annual reduction of 8-12% as manufacturing technologies mature and supply chains develop.

Comparative analysis with competing display technologies reveals that while initial manufacturing costs for QD displays remain higher than conventional LCD production, the gap is narrowing. Current cost premiums of 25-35% are projected to decrease to 10-15% within three years as manufacturing processes are optimized and material utilization improves. This trajectory suggests QD display technology is approaching the economic threshold necessary for mainstream market adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!