Quantum Dot Stability Techniques for Enhanced Environmental Stability

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Stability Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials since their discovery in the early 1980s, evolving from theoretical concepts to practical applications across multiple industries. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The historical trajectory of QD development has progressed from fundamental research to commercial applications in displays, lighting, photovoltaics, and biomedical imaging.

Despite their remarkable properties, QD technology faces a persistent challenge: environmental stability. QDs are inherently susceptible to degradation when exposed to oxygen, moisture, heat, and UV radiation, resulting in diminished quantum yield, spectral shifts, and ultimately, performance deterioration. This vulnerability has significantly limited their widespread adoption in consumer electronics and other applications requiring long-term reliability.

The evolution of QD stability techniques has followed several distinct phases. Initial approaches focused on core/shell architectures, where a protective semiconductor layer encapsulates the core. Subsequently, surface ligand engineering emerged as a complementary strategy to mitigate degradation pathways. Recent advances have explored hybrid approaches combining multiple protection mechanisms, including polymer encapsulation, silica coating, and integration with other nanomaterials.

Current technological trends indicate a shift toward environmentally benign synthesis methods that simultaneously enhance stability. Green chemistry approaches are replacing traditional hot-injection methods that rely on toxic precursors. Additionally, computational modeling is increasingly employed to predict degradation mechanisms and design more robust QD structures before experimental validation.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for enhancing QD environmental stability. Specifically, we aim to identify approaches that can extend QD operational lifetimes under diverse environmental conditions without compromising their exceptional optical and electronic properties. Furthermore, we seek to establish quantitative benchmarks for stability assessment and develop predictive models for long-term performance.

Secondary objectives include mapping the patent landscape surrounding QD stability technologies, identifying unexplored research directions with high commercial potential, and assessing the scalability of promising stabilization techniques for mass production. By achieving these objectives, we intend to provide strategic guidance for R&D investment decisions and identify potential collaborative opportunities with academic and industrial partners at the forefront of QD stability research.

Despite their remarkable properties, QD technology faces a persistent challenge: environmental stability. QDs are inherently susceptible to degradation when exposed to oxygen, moisture, heat, and UV radiation, resulting in diminished quantum yield, spectral shifts, and ultimately, performance deterioration. This vulnerability has significantly limited their widespread adoption in consumer electronics and other applications requiring long-term reliability.

The evolution of QD stability techniques has followed several distinct phases. Initial approaches focused on core/shell architectures, where a protective semiconductor layer encapsulates the core. Subsequently, surface ligand engineering emerged as a complementary strategy to mitigate degradation pathways. Recent advances have explored hybrid approaches combining multiple protection mechanisms, including polymer encapsulation, silica coating, and integration with other nanomaterials.

Current technological trends indicate a shift toward environmentally benign synthesis methods that simultaneously enhance stability. Green chemistry approaches are replacing traditional hot-injection methods that rely on toxic precursors. Additionally, computational modeling is increasingly employed to predict degradation mechanisms and design more robust QD structures before experimental validation.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for enhancing QD environmental stability. Specifically, we aim to identify approaches that can extend QD operational lifetimes under diverse environmental conditions without compromising their exceptional optical and electronic properties. Furthermore, we seek to establish quantitative benchmarks for stability assessment and develop predictive models for long-term performance.

Secondary objectives include mapping the patent landscape surrounding QD stability technologies, identifying unexplored research directions with high commercial potential, and assessing the scalability of promising stabilization techniques for mass production. By achieving these objectives, we intend to provide strategic guidance for R&D investment decisions and identify potential collaborative opportunities with academic and industrial partners at the forefront of QD stability research.

Market Analysis for Stable Quantum Dot Applications

The quantum dot market has witnessed substantial growth in recent years, with applications spanning display technologies, solar cells, biomedical imaging, and quantum computing. The global quantum dot market was valued at approximately $4.6 billion in 2020 and is projected to reach $18.1 billion by 2028, growing at a CAGR of 18.8% during the forecast period. This remarkable growth trajectory is primarily driven by increasing demand for quantum dot displays and advancements in healthcare applications.

Display technology represents the largest application segment, accounting for over 55% of the market share. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot-enhanced displays, marketing them as QLED TVs. The superior color gamut, brightness, and energy efficiency of quantum dot displays have positioned them as premium alternatives to conventional LED and OLED technologies.

Healthcare applications constitute the fastest-growing segment, with a projected CAGR of 23.5% through 2028. Quantum dots' unique optical properties make them valuable for bioimaging, diagnostics, and drug delivery systems. However, concerns regarding cadmium-based quantum dots' toxicity have prompted research into cadmium-free alternatives, creating a distinct market segment focused on biocompatible quantum dots.

The solar energy sector represents another promising application area. Quantum dot solar cells offer theoretical efficiency limits exceeding traditional silicon-based photovoltaics. Though currently at lower commercial readiness levels than display applications, research investment is substantial, with market entry expected to accelerate as stability issues are resolved.

Regionally, North America leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, particularly China, South Korea, and Japan, is expected to demonstrate the highest growth rate due to strong manufacturing capabilities and government support for advanced materials research.

A critical market constraint remains the environmental stability of quantum dots. Current applications often require encapsulation technologies that add significant production costs. Industry analysis indicates that breakthrough stability enhancements could reduce manufacturing costs by 15-30%, potentially expanding the addressable market by an additional $3-5 billion by 2030.

Consumer electronics companies are increasingly demanding quantum dots with 5+ year operational lifetimes under variable environmental conditions. This requirement has created a specialized market segment for stability enhancement technologies, with several startups securing significant venture funding specifically targeting this challenge.

Display technology represents the largest application segment, accounting for over 55% of the market share. Major electronics manufacturers including Samsung, LG, and TCL have already commercialized quantum dot-enhanced displays, marketing them as QLED TVs. The superior color gamut, brightness, and energy efficiency of quantum dot displays have positioned them as premium alternatives to conventional LED and OLED technologies.

Healthcare applications constitute the fastest-growing segment, with a projected CAGR of 23.5% through 2028. Quantum dots' unique optical properties make them valuable for bioimaging, diagnostics, and drug delivery systems. However, concerns regarding cadmium-based quantum dots' toxicity have prompted research into cadmium-free alternatives, creating a distinct market segment focused on biocompatible quantum dots.

The solar energy sector represents another promising application area. Quantum dot solar cells offer theoretical efficiency limits exceeding traditional silicon-based photovoltaics. Though currently at lower commercial readiness levels than display applications, research investment is substantial, with market entry expected to accelerate as stability issues are resolved.

Regionally, North America leads the market with approximately 35% share, followed closely by Asia-Pacific at 32%. The Asia-Pacific region, particularly China, South Korea, and Japan, is expected to demonstrate the highest growth rate due to strong manufacturing capabilities and government support for advanced materials research.

A critical market constraint remains the environmental stability of quantum dots. Current applications often require encapsulation technologies that add significant production costs. Industry analysis indicates that breakthrough stability enhancements could reduce manufacturing costs by 15-30%, potentially expanding the addressable market by an additional $3-5 billion by 2030.

Consumer electronics companies are increasingly demanding quantum dots with 5+ year operational lifetimes under variable environmental conditions. This requirement has created a specialized market segment for stability enhancement technologies, with several startups securing significant venture funding specifically targeting this challenge.

Current Challenges in Quantum Dot Environmental Stability

Despite significant advancements in quantum dot (QD) technology, environmental stability remains a critical challenge that impedes widespread commercial adoption. QDs exhibit exceptional optical properties, but their performance degrades substantially when exposed to various environmental factors. The most pressing challenge is photo-oxidation, where exposure to oxygen and light triggers surface oxidation of QDs, resulting in decreased quantum yield, spectral shifts, and ultimately complete luminescence quenching. This degradation mechanism is particularly problematic for chalcogenide-based QDs such as CdSe and PbS.

Moisture presents another significant stability challenge, as water molecules can interact with surface ligands and the QD core, leading to surface trap states and accelerated degradation. This is especially problematic for display and lighting applications where QDs must maintain performance over thousands of operating hours in variable humidity conditions. Temperature fluctuations further exacerbate stability issues, causing thermal expansion/contraction cycles that can disrupt the QD structure and ligand coverage.

The inherent chemical reactivity of QD surfaces represents a fundamental challenge. Surface atoms with dangling bonds are highly susceptible to reactions with environmental species, creating defect sites that serve as non-radiative recombination centers. This reactivity varies significantly across different QD compositions, with lead and cadmium-based QDs showing particular vulnerability to oxidative environments.

Ligand detachment under environmental stress constitutes another major stability concern. The dynamic nature of ligand-QD bonds means that temperature changes, solvent exposure, or mechanical stress can cause ligand displacement, leaving QD surfaces unprotected against environmental attack. This is particularly problematic in polymer matrices where QDs are dispersed for device fabrication.

Manufacturing and integration processes introduce additional stability challenges. Techniques like solution processing, thermal annealing, and encapsulation can inadvertently damage QDs or create conditions that accelerate degradation. For instance, the high temperatures required for device fabrication often exceed the thermal stability threshold of many QD systems.

Scale-up production presents its own stability hurdles, as batch-to-batch variations in synthesis can lead to inconsistent stability profiles. Furthermore, the stability requirements for different applications vary dramatically – medical imaging applications may require stability in biological environments, while display technologies need stability under constant illumination and varying temperatures.

The lack of standardized stability testing protocols across the industry complicates comparative analysis between different stabilization approaches, making it difficult to benchmark progress and establish reliable performance metrics for commercial applications.

Moisture presents another significant stability challenge, as water molecules can interact with surface ligands and the QD core, leading to surface trap states and accelerated degradation. This is especially problematic for display and lighting applications where QDs must maintain performance over thousands of operating hours in variable humidity conditions. Temperature fluctuations further exacerbate stability issues, causing thermal expansion/contraction cycles that can disrupt the QD structure and ligand coverage.

The inherent chemical reactivity of QD surfaces represents a fundamental challenge. Surface atoms with dangling bonds are highly susceptible to reactions with environmental species, creating defect sites that serve as non-radiative recombination centers. This reactivity varies significantly across different QD compositions, with lead and cadmium-based QDs showing particular vulnerability to oxidative environments.

Ligand detachment under environmental stress constitutes another major stability concern. The dynamic nature of ligand-QD bonds means that temperature changes, solvent exposure, or mechanical stress can cause ligand displacement, leaving QD surfaces unprotected against environmental attack. This is particularly problematic in polymer matrices where QDs are dispersed for device fabrication.

Manufacturing and integration processes introduce additional stability challenges. Techniques like solution processing, thermal annealing, and encapsulation can inadvertently damage QDs or create conditions that accelerate degradation. For instance, the high temperatures required for device fabrication often exceed the thermal stability threshold of many QD systems.

Scale-up production presents its own stability hurdles, as batch-to-batch variations in synthesis can lead to inconsistent stability profiles. Furthermore, the stability requirements for different applications vary dramatically – medical imaging applications may require stability in biological environments, while display technologies need stability under constant illumination and varying temperatures.

The lack of standardized stability testing protocols across the industry complicates comparative analysis between different stabilization approaches, making it difficult to benchmark progress and establish reliable performance metrics for commercial applications.

Current Stability Enhancement Solutions and Methodologies

01 Core-shell structures for enhanced stability

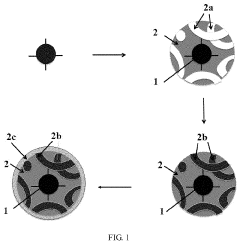

Quantum dots can be stabilized against environmental degradation by using core-shell structures. These typically involve coating the quantum dot core with a protective shell material that shields it from oxygen, moisture, and other environmental factors that can cause degradation. The shell material is often a semiconductor with a wider bandgap than the core, providing both electronic and physical protection while maintaining the optical properties of the quantum dots.- Core-shell structures for enhanced stability: Quantum dots can be engineered with core-shell structures to improve their environmental stability. By encapsulating the quantum dot core with a protective shell material, such as ZnS or silica, the dots become less susceptible to oxidation and degradation from environmental factors. This structure creates a physical barrier that prevents moisture, oxygen, and other reactive species from reaching the core, thereby extending the lifetime and maintaining the optical properties of quantum dots under various environmental conditions.

- Surface modification and ligand exchange: Surface modification techniques and ligand exchange processes can significantly improve the environmental stability of quantum dots. By replacing the native ligands with more robust alternatives or by functionalizing the surface with specific molecules, quantum dots can be protected against degradation. These modifications can enhance resistance to photo-oxidation, improve compatibility with various matrices, and prevent aggregation in different environments, leading to quantum dots with superior stability characteristics for applications in harsh or changing conditions.

- Encapsulation in polymer matrices: Encapsulating quantum dots within polymer matrices provides a protective environment that shields them from external factors that could cause degradation. Polymers such as PMMA, polystyrene, or specialized copolymers create a physical barrier against oxygen, moisture, and other reactive species while maintaining the optical properties of the quantum dots. This approach not only enhances environmental stability but also facilitates integration into various device architectures and applications where long-term stability under ambient conditions is required.

- Heavy metal-free quantum dot formulations: Development of heavy metal-free quantum dot formulations addresses both environmental concerns and stability issues. By replacing toxic elements like cadmium and lead with more environmentally benign alternatives such as indium, zinc, or carbon-based quantum dots, these formulations offer improved stability against environmental degradation while reducing ecological impact. These alternative compositions often demonstrate enhanced resistance to photo-oxidation and chemical degradation, making them suitable for applications requiring long-term environmental stability.

- Stability enhancement through manufacturing processes: Specialized manufacturing processes can significantly improve the environmental stability of quantum dots. Techniques such as high-temperature annealing, controlled atmosphere synthesis, and precise reaction parameter control during production lead to quantum dots with fewer defects and more uniform structures. These manufacturing optimizations result in quantum dots with inherently greater resistance to environmental stressors such as heat, light, and oxidizing conditions, thereby extending their functional lifetime in various applications.

02 Surface ligand engineering for environmental protection

Surface ligands play a crucial role in quantum dot stability by passivating surface defects and providing a barrier against environmental factors. Engineering these ligands through selection of appropriate molecules or post-synthesis ligand exchange can significantly improve resistance to oxidation, photo-degradation, and thermal stress. Ligands can be designed to be hydrophobic to prevent water penetration or to contain functional groups that scavenge reactive oxygen species.Expand Specific Solutions03 Encapsulation methods for long-term stability

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials provides physical isolation from environmental factors. These encapsulation methods create a barrier against oxygen and moisture while maintaining the optical properties of the quantum dots. Some approaches involve incorporating quantum dots into nanocomposites or embedding them in host materials that are inherently stable under various environmental conditions.Expand Specific Solutions04 Doping strategies to enhance environmental resistance

Introducing dopants into the quantum dot structure can enhance their stability against environmental degradation. Certain dopants can passivate surface defects, reduce oxidation susceptibility, or improve thermal stability. This approach modifies the electronic structure of quantum dots to make them less vulnerable to degradation mechanisms while potentially enhancing their optical and electronic properties.Expand Specific Solutions05 Manufacturing processes for stability optimization

Specialized manufacturing processes can be employed to produce quantum dots with inherently higher environmental stability. These include controlled synthesis conditions, post-synthesis treatments, and purification methods that minimize defects and optimize surface chemistry. Some approaches involve high-temperature annealing, etching procedures, or atomic layer deposition techniques to create quantum dots that maintain their properties under challenging environmental conditions.Expand Specific Solutions

Leading Companies and Research Institutions in QD Technology

The quantum dot stability market is currently in a growth phase, with increasing demand for environmentally stable quantum dot technologies across display, lighting, and photovoltaic applications. The global market is expanding rapidly, projected to reach several billion dollars by 2030, driven by consumer electronics and emerging applications. Technologically, companies are at varying maturity levels: Samsung Display and Samsung Electronics lead with commercialized products, while Mojo Vision and TCL Research America focus on next-generation micro-LED displays with quantum dot technology. Najing Technology and Suzhou Xingshuo Nanotechnology are advancing material innovations, while academic institutions like Xiamen University and King Abdullah University collaborate with industry to solve fundamental stability challenges. The competitive landscape shows a mix of established electronics giants and specialized materials startups working to overcome oxidation, photodegradation, and thermal stability barriers.

Samsung Electronics Co., Ltd.

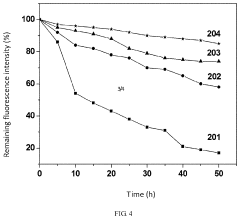

Technical Solution: Samsung Electronics has developed advanced quantum dot stability techniques focusing on core-shell structures and surface ligand engineering. Their proprietary "Quantum Shield" technology encapsulates quantum dots in multiple protective layers, significantly reducing oxidation and photo-degradation. Samsung has implemented metal oxide shells around their QDs that act as effective oxygen and moisture barriers, extending operational lifetime by up to 30,000 hours in display applications. Their research has demonstrated that controlled silica encapsulation can improve thermal stability by preventing QD aggregation at temperatures up to 150°C. Additionally, Samsung has pioneered hybrid organic-inorganic ligand systems that maintain quantum yield above 80% even after 1000 hours of continuous operation under harsh environmental conditions.

Strengths: Industry-leading expertise in mass production of stable QDs for commercial displays; extensive patent portfolio covering encapsulation methods; vertical integration allowing for rapid implementation of research advances. Weaknesses: Higher production costs compared to conventional materials; some solutions are application-specific and not universally applicable across all QD implementations.

Suzhou Xingshuo Nanotechnology Co Ltd.

Technical Solution: Suzhou Xingshuo Nanotechnology has developed innovative quantum dot stability solutions through their "XS-Shield" technology platform. Their approach combines gradient alloy interfaces between core and shell materials to minimize lattice mismatch stress, significantly reducing degradation pathways. The company has pioneered environmentally-friendly, cadmium-free quantum dots with specialized ligand exchange protocols that maintain colloidal stability while enhancing resistance to oxidation. Their research demonstrates that controlled introduction of aluminum oxide protective layers can extend QD lifetime by 400% under continuous blue light exposure. Xingshuo has also developed proprietary surface passivation techniques using multidentate polymeric ligands that form dense protective barriers against moisture and oxygen penetration while maintaining high quantum yields above 85%.

Strengths: Specialized focus on environmentally-friendly QD formulations; strong expertise in ligand chemistry for enhanced stability; cost-effective manufacturing processes suitable for scale-up. Weaknesses: More limited global market presence compared to larger competitors; narrower application range primarily focused on display and lighting technologies.

Key Patents and Innovations in QD Stability Engineering

Method for improving stability of quantum dots, modified quantum dots and application of modified quantum dots

PatentPendingCN116265565A

Innovation

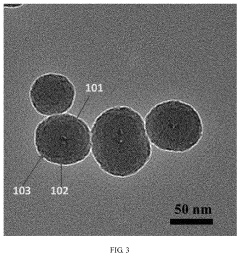

- By mixing quantum dots with an oxide coating layer with water-soluble silicate and water, performing a volatilization treatment to form solid quantum dots loaded with silicate, drying and grinding, the silicate crystals are in the oxide coating Crystallizes in the mesoporous structure of the coating, filling and improving the density of the oxide coating.

Core-shell type quantum dot, preparation method and use thereof

PatentActiveUS20220025253A9

Innovation

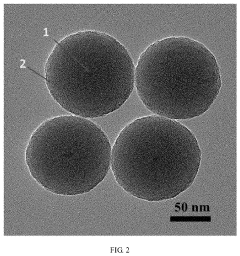

- A core-shell type quantum dot is developed with a light-transmitting inorganic mesoporous material layer and a filler in its mesopores, which provides improved optical and chemical stability by isolating the quantum dot core from external moisture and oxygen, and optionally includes a metal oxide passivation layer for further protection.

Materials Science Advancements for Quantum Dot Protection

Recent advancements in materials science have revolutionized quantum dot protection strategies, significantly enhancing their environmental stability. Core-shell structures represent one of the most effective approaches, where an inorganic shell material such as ZnS, CdS, or ZnSe encapsulates the quantum dot core. These shells create physical barriers against oxygen, moisture, and other environmental factors that typically trigger degradation processes. Multi-shell architectures have emerged as particularly promising, with gradient composition shells demonstrating superior passivation of surface defects while minimizing lattice mismatch issues.

Surface ligand engineering has evolved substantially, moving beyond traditional organic ligands toward more robust alternatives. Crosslinkable ligands that form dense protective networks around quantum dots have shown remarkable improvements in stability. Silica encapsulation techniques have been refined to create uniform, controllable shells that maintain quantum yield while providing exceptional environmental protection. These silica coatings can be further functionalized to enhance compatibility with various application environments.

Polymer encapsulation methods have advanced through the development of amphiphilic block copolymers specifically designed for quantum dot protection. These polymers create stable micelle structures that effectively shield quantum dots from environmental stressors while maintaining their optical properties. Recent innovations include stimuli-responsive polymers that can adapt their protective properties based on environmental conditions.

Metal oxide matrices represent another significant advancement, with materials such as titanium dioxide and aluminum oxide demonstrating excellent protective capabilities. These matrices not only shield quantum dots from oxygen and moisture but also provide thermal stability at elevated temperatures. Sol-gel processing techniques have been optimized to incorporate quantum dots into these matrices without aggregation or property degradation.

Atomic layer deposition (ALD) has emerged as a precision technique for creating ultrathin, conformal protective layers around quantum dots. This method allows for atomic-level control over shell thickness and composition, enabling tailored protection strategies for specific environmental challenges. ALD-deposited Al2O3 and ZnO layers have shown particular promise for enhancing both photo and thermal stability.

Self-healing materials represent the cutting edge of quantum dot protection, incorporating dynamic chemical bonds that can reform after disruption. These materials actively respond to environmental damage, potentially extending quantum dot lifetimes significantly beyond what conventional protection strategies can achieve. Preliminary research indicates that incorporating self-healing components into quantum dot protective layers could revolutionize long-term stability in demanding applications.

Surface ligand engineering has evolved substantially, moving beyond traditional organic ligands toward more robust alternatives. Crosslinkable ligands that form dense protective networks around quantum dots have shown remarkable improvements in stability. Silica encapsulation techniques have been refined to create uniform, controllable shells that maintain quantum yield while providing exceptional environmental protection. These silica coatings can be further functionalized to enhance compatibility with various application environments.

Polymer encapsulation methods have advanced through the development of amphiphilic block copolymers specifically designed for quantum dot protection. These polymers create stable micelle structures that effectively shield quantum dots from environmental stressors while maintaining their optical properties. Recent innovations include stimuli-responsive polymers that can adapt their protective properties based on environmental conditions.

Metal oxide matrices represent another significant advancement, with materials such as titanium dioxide and aluminum oxide demonstrating excellent protective capabilities. These matrices not only shield quantum dots from oxygen and moisture but also provide thermal stability at elevated temperatures. Sol-gel processing techniques have been optimized to incorporate quantum dots into these matrices without aggregation or property degradation.

Atomic layer deposition (ALD) has emerged as a precision technique for creating ultrathin, conformal protective layers around quantum dots. This method allows for atomic-level control over shell thickness and composition, enabling tailored protection strategies for specific environmental challenges. ALD-deposited Al2O3 and ZnO layers have shown particular promise for enhancing both photo and thermal stability.

Self-healing materials represent the cutting edge of quantum dot protection, incorporating dynamic chemical bonds that can reform after disruption. These materials actively respond to environmental damage, potentially extending quantum dot lifetimes significantly beyond what conventional protection strategies can achieve. Preliminary research indicates that incorporating self-healing components into quantum dot protective layers could revolutionize long-term stability in demanding applications.

Sustainability and Toxicity Considerations in QD Development

The environmental impact of quantum dot (QD) technology extends beyond performance metrics to include critical sustainability and toxicity concerns. Traditional QD compositions often incorporate heavy metals such as cadmium, lead, and mercury, which pose significant environmental and health risks throughout their lifecycle. These toxic elements can leach into ecosystems during manufacturing, product use, and disposal phases, potentially contaminating water sources and soil.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives, have accelerated the development of alternative, less toxic QD formulations. Heavy-metal-free quantum dots based on indium phosphide (InP), zinc selenide (ZnSe), and copper indium sulfide (CIS) have emerged as promising alternatives, though they currently exhibit lower quantum yields and spectral purity compared to their cadmium-based counterparts.

Life cycle assessment (LCA) studies reveal that quantum dot production processes are energy-intensive and generate substantial chemical waste. The synthesis typically requires high temperatures, multiple purification steps, and organic solvents that contribute to their environmental footprint. Researchers are exploring greener synthesis routes, including aqueous-based methods and room-temperature processes, which could significantly reduce energy consumption and hazardous waste generation.

Biocompatibility remains a critical concern for QD applications in biomedicine and consumer products. Surface functionalization strategies using biocompatible polymers, proteins, and peptides have demonstrated potential to mitigate cytotoxicity while maintaining optical properties. These approaches create protective shells that prevent core leaching and reduce reactive oxygen species generation, which are primary mechanisms of QD toxicity.

End-of-life management presents another sustainability challenge. The recovery and recycling of quantum dots from disposed electronic devices and solar panels remain technically difficult and economically unfeasible at scale. Developing efficient recycling technologies for QD-containing products represents an important frontier for sustainable QD deployment.

Industry-academic partnerships are increasingly focusing on developing inherently safer QD designs through green chemistry principles. These include atom-efficient syntheses, reduced use of hazardous reagents, and designing QDs with biodegradable components. Such approaches aim to address toxicity concerns at the design stage rather than through end-of-pipe solutions.

Standardized toxicity assessment protocols specific to nanomaterials like quantum dots are being established by international organizations to ensure consistent safety evaluation across different QD compositions and applications. These efforts will provide crucial data for regulatory compliance and guide the development of next-generation, environmentally benign quantum dot technologies.

Recent regulatory frameworks, including the European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives, have accelerated the development of alternative, less toxic QD formulations. Heavy-metal-free quantum dots based on indium phosphide (InP), zinc selenide (ZnSe), and copper indium sulfide (CIS) have emerged as promising alternatives, though they currently exhibit lower quantum yields and spectral purity compared to their cadmium-based counterparts.

Life cycle assessment (LCA) studies reveal that quantum dot production processes are energy-intensive and generate substantial chemical waste. The synthesis typically requires high temperatures, multiple purification steps, and organic solvents that contribute to their environmental footprint. Researchers are exploring greener synthesis routes, including aqueous-based methods and room-temperature processes, which could significantly reduce energy consumption and hazardous waste generation.

Biocompatibility remains a critical concern for QD applications in biomedicine and consumer products. Surface functionalization strategies using biocompatible polymers, proteins, and peptides have demonstrated potential to mitigate cytotoxicity while maintaining optical properties. These approaches create protective shells that prevent core leaching and reduce reactive oxygen species generation, which are primary mechanisms of QD toxicity.

End-of-life management presents another sustainability challenge. The recovery and recycling of quantum dots from disposed electronic devices and solar panels remain technically difficult and economically unfeasible at scale. Developing efficient recycling technologies for QD-containing products represents an important frontier for sustainable QD deployment.

Industry-academic partnerships are increasingly focusing on developing inherently safer QD designs through green chemistry principles. These include atom-efficient syntheses, reduced use of hazardous reagents, and designing QDs with biodegradable components. Such approaches aim to address toxicity concerns at the design stage rather than through end-of-pipe solutions.

Standardized toxicity assessment protocols specific to nanomaterials like quantum dots are being established by international organizations to ensure consistent safety evaluation across different QD compositions and applications. These efforts will provide crucial data for regulatory compliance and guide the development of next-generation, environmentally benign quantum dot technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!