Regulatory Implications of Quantum Dot Stability in Aviation

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Stability in Aviation: Background and Objectives

Quantum dots (QDs) have emerged as a revolutionary nanomaterial with exceptional optical and electronic properties that make them increasingly valuable across multiple industries. In aviation specifically, these semiconductor nanocrystals offer promising applications ranging from advanced display technologies in cockpit instrumentation to potential quantum computing solutions for flight systems. The historical development of quantum dots traces back to the early 1980s when they were first theoretically described, followed by successful laboratory synthesis in the 1990s. Since then, their technological maturity has accelerated significantly, particularly in the last decade.

The aviation industry has begun exploring quantum dot applications due to their unique characteristics: size-dependent emission wavelengths, high quantum yield, narrow emission spectra, and broad excitation ranges. These properties enable enhanced visual displays with superior color accuracy and brightness even in challenging lighting conditions common in aviation environments. Additionally, quantum dots show potential for integration into aircraft sensors, structural health monitoring systems, and next-generation avionics.

However, the stability of quantum dots remains a critical concern in aviation applications. Aircraft operate in extreme environments characterized by significant temperature fluctuations, vibration, radiation exposure at high altitudes, and varying humidity levels. These conditions can potentially compromise quantum dot stability, leading to performance degradation, altered optical properties, or even complete failure of quantum dot-based systems.

The primary objective of this technical research is to comprehensively evaluate the regulatory implications surrounding quantum dot stability specifically within aviation contexts. This includes identifying existing regulatory frameworks that may apply to nanomaterials in aviation, analyzing potential gaps in current regulations, and determining how stability concerns might influence certification processes for quantum dot-enabled aviation technologies.

Secondary objectives include mapping the technical challenges related to quantum dot stability under aviation-specific environmental stressors, evaluating current mitigation strategies, and forecasting technological developments that may address these stability concerns. The research also aims to establish a clear understanding of how quantum dot degradation mechanisms might impact aviation safety and reliability standards.

This investigation is particularly timely as the aviation industry increasingly explores advanced materials to enhance efficiency, reduce weight, and improve functionality. Understanding the regulatory landscape for quantum dot implementation will be crucial for manufacturers, regulatory bodies, and aviation stakeholders to ensure that innovation proceeds with appropriate safety considerations and compliance frameworks in place.

The aviation industry has begun exploring quantum dot applications due to their unique characteristics: size-dependent emission wavelengths, high quantum yield, narrow emission spectra, and broad excitation ranges. These properties enable enhanced visual displays with superior color accuracy and brightness even in challenging lighting conditions common in aviation environments. Additionally, quantum dots show potential for integration into aircraft sensors, structural health monitoring systems, and next-generation avionics.

However, the stability of quantum dots remains a critical concern in aviation applications. Aircraft operate in extreme environments characterized by significant temperature fluctuations, vibration, radiation exposure at high altitudes, and varying humidity levels. These conditions can potentially compromise quantum dot stability, leading to performance degradation, altered optical properties, or even complete failure of quantum dot-based systems.

The primary objective of this technical research is to comprehensively evaluate the regulatory implications surrounding quantum dot stability specifically within aviation contexts. This includes identifying existing regulatory frameworks that may apply to nanomaterials in aviation, analyzing potential gaps in current regulations, and determining how stability concerns might influence certification processes for quantum dot-enabled aviation technologies.

Secondary objectives include mapping the technical challenges related to quantum dot stability under aviation-specific environmental stressors, evaluating current mitigation strategies, and forecasting technological developments that may address these stability concerns. The research also aims to establish a clear understanding of how quantum dot degradation mechanisms might impact aviation safety and reliability standards.

This investigation is particularly timely as the aviation industry increasingly explores advanced materials to enhance efficiency, reduce weight, and improve functionality. Understanding the regulatory landscape for quantum dot implementation will be crucial for manufacturers, regulatory bodies, and aviation stakeholders to ensure that innovation proceeds with appropriate safety considerations and compliance frameworks in place.

Market Analysis for Quantum Dot Applications in Aerospace

The quantum dot market in aerospace applications is experiencing significant growth, driven by the unique properties these nanomaterials offer for aviation and space technologies. Current market valuations indicate the global quantum dot market reached approximately 4.5 billion USD in 2022, with aerospace applications representing about 8% of this total. Industry forecasts project a compound annual growth rate of 23.7% for quantum dot technologies in aerospace through 2030, outpacing many other advanced materials sectors.

Demand for quantum dot applications in aerospace is primarily concentrated in three key segments: display technologies for cockpit instrumentation, sensing applications for structural health monitoring, and photovoltaic solutions for spacecraft power systems. The cockpit display segment currently dominates with approximately 45% market share due to the superior color accuracy, brightness, and energy efficiency quantum dots provide in harsh lighting conditions experienced during flight.

Regional analysis reveals North America leads the aerospace quantum dot market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). This distribution correlates strongly with the concentration of major aerospace manufacturers and defense contractors in these regions. The United States, in particular, has established a commanding position through significant defense-related research funding and strong industry-academic partnerships.

Customer segmentation shows commercial aviation accounts for 38% of demand, military applications 33%, and space systems 29%. The military segment is projected to grow fastest at 27.3% annually through 2028, driven by increasing requirements for advanced sensing and display technologies in next-generation aircraft.

Key market drivers include increasing safety regulations requiring more sophisticated monitoring systems, growing demand for fuel-efficient aircraft where lightweight quantum dot sensors can contribute to weight reduction, and the push toward more autonomous flight systems requiring advanced sensing capabilities. Additionally, the space sector's expansion with commercial players has accelerated demand for radiation-resistant quantum dot technologies.

Market barriers primarily revolve around regulatory concerns regarding quantum dot stability in aviation environments, high implementation costs, and integration challenges with existing systems. The regulatory landscape remains particularly complex, with aviation authorities worldwide still developing comprehensive frameworks for nanomaterial certification in critical aerospace applications.

Pricing trends indicate a gradual decrease in quantum dot manufacturing costs, with premium pricing still maintained for aerospace-grade materials due to rigorous certification requirements. The average price per gram for aerospace-certified quantum dots has decreased by 18% over the past three years, though remains approximately 3.5 times higher than consumer electronics-grade materials.

Demand for quantum dot applications in aerospace is primarily concentrated in three key segments: display technologies for cockpit instrumentation, sensing applications for structural health monitoring, and photovoltaic solutions for spacecraft power systems. The cockpit display segment currently dominates with approximately 45% market share due to the superior color accuracy, brightness, and energy efficiency quantum dots provide in harsh lighting conditions experienced during flight.

Regional analysis reveals North America leads the aerospace quantum dot market with 42% share, followed by Europe (28%) and Asia-Pacific (23%). This distribution correlates strongly with the concentration of major aerospace manufacturers and defense contractors in these regions. The United States, in particular, has established a commanding position through significant defense-related research funding and strong industry-academic partnerships.

Customer segmentation shows commercial aviation accounts for 38% of demand, military applications 33%, and space systems 29%. The military segment is projected to grow fastest at 27.3% annually through 2028, driven by increasing requirements for advanced sensing and display technologies in next-generation aircraft.

Key market drivers include increasing safety regulations requiring more sophisticated monitoring systems, growing demand for fuel-efficient aircraft where lightweight quantum dot sensors can contribute to weight reduction, and the push toward more autonomous flight systems requiring advanced sensing capabilities. Additionally, the space sector's expansion with commercial players has accelerated demand for radiation-resistant quantum dot technologies.

Market barriers primarily revolve around regulatory concerns regarding quantum dot stability in aviation environments, high implementation costs, and integration challenges with existing systems. The regulatory landscape remains particularly complex, with aviation authorities worldwide still developing comprehensive frameworks for nanomaterial certification in critical aerospace applications.

Pricing trends indicate a gradual decrease in quantum dot manufacturing costs, with premium pricing still maintained for aerospace-grade materials due to rigorous certification requirements. The average price per gram for aerospace-certified quantum dots has decreased by 18% over the past three years, though remains approximately 3.5 times higher than consumer electronics-grade materials.

Current Challenges in Quantum Dot Stability for Aviation

Quantum dot (QD) technology in aviation faces significant stability challenges that impede its widespread implementation. The primary concern revolves around environmental degradation, as quantum dots exhibit sensitivity to oxygen, moisture, temperature fluctuations, and UV radiation—all prevalent factors in aviation environments. When exposed to these elements, QDs experience photobleaching and oxidation, leading to diminished optical properties and compromised functionality over time.

The harsh operating conditions of aircraft present particularly severe challenges. Temperature variations from -60°C at cruising altitude to potentially over 50°C on ground in certain regions create thermal stress that accelerates QD degradation. Additionally, the constant vibration and mechanical stress experienced during flight operations can disrupt QD structures and their protective encapsulation systems.

Manufacturing consistency represents another significant hurdle. Current production methods struggle to deliver uniform QD size distributions and surface chemistry across large-scale production batches. This variability directly impacts performance reliability in critical aviation applications where consistent behavior is paramount for safety and operational efficiency.

Integration challenges further complicate implementation. Incorporating QDs into existing aviation systems requires compatible interfaces with conventional electronics and optical systems. The development of stable matrices and encapsulation technologies that can withstand aviation-specific stressors while maintaining QD functionality remains an ongoing challenge for materials scientists and engineers.

Regulatory compliance adds another layer of complexity. Aviation's stringent safety standards necessitate extensive stability testing under various operational conditions. Current QD technologies often fail to demonstrate the required longevity and performance consistency under these rigorous testing protocols, creating a significant barrier to certification and deployment.

Long-term reliability verification poses methodological challenges. Accelerated aging tests may not accurately predict real-world degradation patterns in aviation environments. The industry lacks standardized testing protocols specifically designed for quantum dot applications in aircraft systems, making comparative assessment difficult.

Toxicity concerns persist regarding potential cadmium leaching from certain types of quantum dots if encapsulation fails during the product lifecycle. This presents both environmental and health risks that must be addressed before widespread adoption in enclosed aircraft environments.

Cost-effective solutions for these stability issues remain elusive. Current approaches to enhance QD stability, such as core-shell structures and advanced encapsulation techniques, significantly increase production costs, creating economic barriers to adoption in cost-sensitive aviation applications.

The harsh operating conditions of aircraft present particularly severe challenges. Temperature variations from -60°C at cruising altitude to potentially over 50°C on ground in certain regions create thermal stress that accelerates QD degradation. Additionally, the constant vibration and mechanical stress experienced during flight operations can disrupt QD structures and their protective encapsulation systems.

Manufacturing consistency represents another significant hurdle. Current production methods struggle to deliver uniform QD size distributions and surface chemistry across large-scale production batches. This variability directly impacts performance reliability in critical aviation applications where consistent behavior is paramount for safety and operational efficiency.

Integration challenges further complicate implementation. Incorporating QDs into existing aviation systems requires compatible interfaces with conventional electronics and optical systems. The development of stable matrices and encapsulation technologies that can withstand aviation-specific stressors while maintaining QD functionality remains an ongoing challenge for materials scientists and engineers.

Regulatory compliance adds another layer of complexity. Aviation's stringent safety standards necessitate extensive stability testing under various operational conditions. Current QD technologies often fail to demonstrate the required longevity and performance consistency under these rigorous testing protocols, creating a significant barrier to certification and deployment.

Long-term reliability verification poses methodological challenges. Accelerated aging tests may not accurately predict real-world degradation patterns in aviation environments. The industry lacks standardized testing protocols specifically designed for quantum dot applications in aircraft systems, making comparative assessment difficult.

Toxicity concerns persist regarding potential cadmium leaching from certain types of quantum dots if encapsulation fails during the product lifecycle. This presents both environmental and health risks that must be addressed before widespread adoption in enclosed aircraft environments.

Cost-effective solutions for these stability issues remain elusive. Current approaches to enhance QD stability, such as core-shell structures and advanced encapsulation techniques, significantly increase production costs, creating economic barriers to adoption in cost-sensitive aviation applications.

Existing Stability Solutions for Aviation-Grade Quantum Dots

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

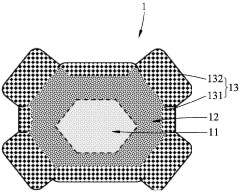

- Core-shell structures for improved quantum dot stability: Core-shell structured quantum dots offer enhanced stability compared to core-only quantum dots. By encapsulating the quantum dot core with one or more shell layers of different semiconductor materials, the electronic properties can be preserved while providing protection against environmental factors. These structures effectively reduce surface defects and prevent leaching of toxic elements, resulting in quantum dots with superior stability and optical properties.

- Polymer encapsulation for quantum dot stabilization: Encapsulating quantum dots within polymer matrices provides significant improvements in stability. Polymers create a protective barrier that shields quantum dots from oxygen, moisture, and other environmental factors that can cause degradation. Various polymers including amphiphilic block copolymers, silicones, and biocompatible polymers can be used for this purpose, enabling quantum dots to maintain their optical and electronic properties over extended periods even under harsh conditions.

- Stabilization methods for quantum dots in solution: Maintaining the stability of quantum dots in solution requires specific approaches to prevent aggregation and precipitation. These include the use of stabilizing ligands, pH control, ionic strength adjustment, and addition of surfactants. Solution-phase stability is crucial for applications such as bioimaging, sensing, and optoelectronic devices where quantum dots need to remain dispersed and maintain their optical properties in liquid environments.

- Thermal and photo-stability enhancement techniques: Improving the thermal and photo-stability of quantum dots is essential for their application in lighting, displays, and solar cells. Techniques include doping with specific elements, creating alloyed interfaces between core and shell, and incorporating stabilizing additives. These approaches help quantum dots maintain their luminescence efficiency and prevent degradation when exposed to high temperatures or continuous illumination, significantly extending their operational lifetime.

02 Core-shell structures for improved quantum dot stability

Core-shell structured quantum dots offer enhanced stability compared to core-only quantum dots. The shell material, typically a semiconductor with a wider bandgap than the core, provides physical and chemical protection to the core. This structure effectively isolates the core from the surrounding environment, reducing surface defects and preventing degradation from exposure to oxygen, moisture, and other environmental factors.Expand Specific Solutions03 Encapsulation methods for quantum dot stabilization

Encapsulation of quantum dots in matrices such as polymers, silica, or other inorganic materials significantly improves their stability. These encapsulation methods create a protective barrier around the quantum dots, shielding them from environmental factors that could cause degradation. Additionally, encapsulation can prevent leaching of toxic components from quantum dots, making them safer for various applications including biomedical uses.Expand Specific Solutions04 Stabilization through chemical composition control

The stability of quantum dots can be significantly enhanced through careful control of their chemical composition. This includes precise stoichiometry management, doping with specific elements, and alloying techniques. By optimizing the chemical composition, researchers can reduce defects, improve crystallinity, and enhance resistance to photo-oxidation and other degradation mechanisms, resulting in quantum dots with superior stability properties.Expand Specific Solutions05 Environmental factors affecting quantum dot stability

Various environmental factors significantly impact the stability of quantum dots, including temperature, pH, light exposure, and the presence of oxidizing agents. Understanding and controlling these factors is crucial for maintaining quantum dot stability during synthesis, storage, and application. Research has focused on developing quantum dots that remain stable across a wide range of environmental conditions, enabling their use in diverse applications from displays to biological imaging.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The quantum dot stability regulatory landscape in aviation is evolving rapidly, with the market currently in an early growth phase. The global market size for quantum dot applications in aviation is projected to reach significant scale as regulatory frameworks mature. From a technical maturity perspective, research institutions like Northwestern Polytechnical University and Beijing Institute of Technology are establishing fundamental research, while commercial entities demonstrate varying levels of implementation readiness. Companies like Airbus, Boeing, and COMAC are integrating quantum dot technologies into aircraft systems with careful regulatory consideration, while specialized firms such as TCL Research America and Mojo Vision are developing advanced display applications that must meet stringent aviation safety standards. The regulatory framework remains fragmented across different jurisdictions, requiring harmonized approaches to certification.

Commercial Aircraft Corp. of China Ltd.

Technical Solution: COMAC has developed a regulatory framework specifically addressing quantum dot stability in aviation applications for the Chinese market, with particular focus on alignment with CAAC regulations. Their approach incorporates quantum dot technology in cabin display systems using silicon-based encapsulation methods that enhance stability under varying pressure and humidity conditions typical in commercial flight operations. COMAC's testing protocols evaluate quantum dot degradation across 15,000 simulated flight hours, with special attention to high-altitude UV exposure effects. Their regulatory compliance strategy includes material safety documentation that addresses both Chinese standards and international frameworks like ICAO Technical Instructions for the Safe Transport of Dangerous Goods by Air, particularly for cadmium-containing quantum dot formulations. COMAC collaborates with Chinese research institutions to develop cadmium-free alternatives that meet aviation stability requirements while addressing regulatory concerns about heavy metal content.

Strengths: Strong understanding of CAAC regulatory requirements; established relationships with Chinese certification authorities; integrated approach combining materials science and regulatory compliance. Weaknesses: Limited international regulatory experience compared to Western manufacturers; developing but still maturing testing infrastructure for long-term stability assessment.

Joby Aero, Inc.

Technical Solution: Joby Aero has developed innovative approaches to quantum dot implementation in electric vertical takeoff and landing (eVTOL) aircraft, focusing on regulatory pathways for novel aviation applications. Their technology utilizes perovskite-based quantum dots in pilot display systems that maintain stability under the unique vibration profiles and rapid altitude changes characteristic of eVTOL operations. Joby's regulatory strategy addresses the emerging certification requirements for urban air mobility platforms, working closely with the FAA's Center for Emerging Concepts and Innovation to establish acceptable means of compliance for quantum dot stability in this new aviation segment. Their testing protocols evaluate quantum dot performance under combined stressors including vibration, temperature cycling, and electromagnetic interference—conditions particularly relevant to electric aircraft operations in urban environments. Joby has pioneered accelerated aging methodologies that correlate with real-world degradation patterns, providing certification authorities with data supporting the long-term stability of their quantum dot implementations.

Strengths: Leading position in emerging eVTOL regulatory frameworks; innovative testing methodologies specific to urban air mobility use cases; collaborative approach with certification authorities. Weaknesses: Limited operational history compared to established aviation manufacturers; regulatory pathways still evolving for their specific application domain.

Critical Patents and Research on Quantum Dot Stabilization

Quantum dot with excellent stability and method for making the same

PatentActiveTW202233803A

Innovation

- A quantum dot structure with a core-shell configuration, where a non-oxidized core is protected by a selectively grown inner shell, followed by etching and ligand exchange to stabilize the core, allowing for uniform particle size and improved yield.

Aviation Safety Regulations Impact on Quantum Dot Implementation

The integration of quantum dot technology in aviation systems faces significant regulatory hurdles that must be addressed before widespread implementation can occur. Current aviation safety regulations, established by bodies such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and International Civil Aviation Organization (ICAO), have not specifically addressed quantum dot technology due to its relative novelty in aviation applications.

These regulatory frameworks primarily focus on ensuring the reliability, durability, and safety of all components used in aircraft systems. For quantum dot implementation, this presents challenges particularly regarding stability verification under extreme aviation conditions. Regulations such as FAR Part 25 for transport category aircraft and DO-160 environmental testing standards would require quantum dot-based systems to demonstrate resilience to temperature fluctuations, pressure changes, vibration, and electromagnetic interference.

The certification process for new aviation technologies typically involves extensive testing protocols and documentation requirements. Quantum dot manufacturers and aviation system integrators must develop comprehensive test data demonstrating long-term stability under simulated flight conditions. This includes accelerated aging tests, environmental stress screening, and failure mode analysis specifically tailored to quantum dot characteristics.

Regulatory bodies have expressed particular concern regarding the potential for quantum dot degradation during emergency situations. Current safety regulations mandate that critical display systems maintain functionality during smoke, fire, or depressurization events. The potential for heavy metal leaching from degraded quantum dots presents a unique regulatory consideration that existing frameworks may not adequately address.

Recent regulatory guidance from the FAA's Advisory Circular AC 20-173 on display system certification provides some applicable parameters, though amendments may be necessary to specifically address quantum dot technology. Similarly, EASA's CS-25 certification specifications would require interpretation or amendment to properly evaluate quantum dot stability requirements.

Industry stakeholders have begun collaborative efforts with regulatory agencies to develop appropriate standards. The SAE International G-10 Committee on Aerospace Behavioral Engineering has established a working group focused on quantum dot display technologies, aiming to propose regulatory guidelines that balance innovation with safety requirements. This proactive approach may accelerate the regulatory pathway for quantum dot implementation in aviation systems.

These regulatory frameworks primarily focus on ensuring the reliability, durability, and safety of all components used in aircraft systems. For quantum dot implementation, this presents challenges particularly regarding stability verification under extreme aviation conditions. Regulations such as FAR Part 25 for transport category aircraft and DO-160 environmental testing standards would require quantum dot-based systems to demonstrate resilience to temperature fluctuations, pressure changes, vibration, and electromagnetic interference.

The certification process for new aviation technologies typically involves extensive testing protocols and documentation requirements. Quantum dot manufacturers and aviation system integrators must develop comprehensive test data demonstrating long-term stability under simulated flight conditions. This includes accelerated aging tests, environmental stress screening, and failure mode analysis specifically tailored to quantum dot characteristics.

Regulatory bodies have expressed particular concern regarding the potential for quantum dot degradation during emergency situations. Current safety regulations mandate that critical display systems maintain functionality during smoke, fire, or depressurization events. The potential for heavy metal leaching from degraded quantum dots presents a unique regulatory consideration that existing frameworks may not adequately address.

Recent regulatory guidance from the FAA's Advisory Circular AC 20-173 on display system certification provides some applicable parameters, though amendments may be necessary to specifically address quantum dot technology. Similarly, EASA's CS-25 certification specifications would require interpretation or amendment to properly evaluate quantum dot stability requirements.

Industry stakeholders have begun collaborative efforts with regulatory agencies to develop appropriate standards. The SAE International G-10 Committee on Aerospace Behavioral Engineering has established a working group focused on quantum dot display technologies, aiming to propose regulatory guidelines that balance innovation with safety requirements. This proactive approach may accelerate the regulatory pathway for quantum dot implementation in aviation systems.

Environmental Considerations and Sustainability Compliance

The environmental impact of quantum dot technology in aviation applications presents significant regulatory challenges that must be addressed to ensure compliance with sustainability standards. Quantum dots contain heavy metals such as cadmium, lead, and selenium that pose potential environmental hazards if improperly managed throughout their lifecycle. Current environmental regulations, including the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), impose strict limitations on these materials in electronic applications, creating compliance challenges for aviation implementations.

The stability of quantum dots directly influences their environmental footprint. Less stable quantum dots may leach toxic components during operation or disposal, particularly under the extreme temperature and pressure conditions experienced in aviation environments. This degradation pathway represents a critical environmental concern that regulatory frameworks increasingly address through lifecycle assessment requirements and end-of-life management protocols.

Aviation-specific environmental regulations add another layer of complexity. The International Civil Aviation Organization (ICAO) has established environmental protection standards that increasingly incorporate materials management considerations. These standards, coupled with regional frameworks like the EU's Aviation Environmental Report guidelines, create a complex regulatory landscape that quantum dot implementations must navigate to achieve certification and operational approval.

Sustainability compliance for quantum dot applications in aviation requires comprehensive lifecycle assessment. From raw material extraction through manufacturing, operational use, and eventual disposal, each phase must demonstrate minimal environmental impact. Recent advancements in green chemistry approaches have yielded more environmentally benign quantum dot formulations, including heavy metal-free alternatives using carbon, silicon, or indium phosphide cores that align better with sustainability objectives while maintaining performance characteristics.

Waste management considerations represent another critical regulatory dimension. End-of-life recovery and recycling protocols for quantum dot-containing components must be established to prevent environmental contamination and comply with circular economy principles increasingly embedded in aviation sustainability frameworks. The aviation industry's commitment to carbon neutrality by 2050 further emphasizes the need for quantum dot technologies to demonstrate favorable environmental profiles throughout their lifecycle.

Regulatory harmonization remains an ongoing challenge, with different jurisdictions implementing varying standards for nanomaterials in aviation applications. This regulatory fragmentation creates compliance complexities for global aviation supply chains and necessitates proactive engagement with regulatory bodies during technology development phases to ensure alignment with evolving sustainability requirements.

The stability of quantum dots directly influences their environmental footprint. Less stable quantum dots may leach toxic components during operation or disposal, particularly under the extreme temperature and pressure conditions experienced in aviation environments. This degradation pathway represents a critical environmental concern that regulatory frameworks increasingly address through lifecycle assessment requirements and end-of-life management protocols.

Aviation-specific environmental regulations add another layer of complexity. The International Civil Aviation Organization (ICAO) has established environmental protection standards that increasingly incorporate materials management considerations. These standards, coupled with regional frameworks like the EU's Aviation Environmental Report guidelines, create a complex regulatory landscape that quantum dot implementations must navigate to achieve certification and operational approval.

Sustainability compliance for quantum dot applications in aviation requires comprehensive lifecycle assessment. From raw material extraction through manufacturing, operational use, and eventual disposal, each phase must demonstrate minimal environmental impact. Recent advancements in green chemistry approaches have yielded more environmentally benign quantum dot formulations, including heavy metal-free alternatives using carbon, silicon, or indium phosphide cores that align better with sustainability objectives while maintaining performance characteristics.

Waste management considerations represent another critical regulatory dimension. End-of-life recovery and recycling protocols for quantum dot-containing components must be established to prevent environmental contamination and comply with circular economy principles increasingly embedded in aviation sustainability frameworks. The aviation industry's commitment to carbon neutrality by 2050 further emphasizes the need for quantum dot technologies to demonstrate favorable environmental profiles throughout their lifecycle.

Regulatory harmonization remains an ongoing challenge, with different jurisdictions implementing varying standards for nanomaterials in aviation applications. This regulatory fragmentation creates compliance complexities for global aviation supply chains and necessitates proactive engagement with regulatory bodies during technology development phases to ensure alignment with evolving sustainability requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!