Quantum Dot Stability in Reflective Display Technologies

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Display Evolution and Objectives

Quantum dot (QD) technology has undergone significant evolution since its initial discovery in the 1980s. The journey began with fundamental research on semiconductor nanocrystals, which demonstrated unique optical properties including size-dependent emission wavelengths and high quantum yields. By the early 2000s, quantum dots transitioned from laboratory curiosities to commercially viable materials, initially finding applications in biological imaging and sensing before entering the display technology sector.

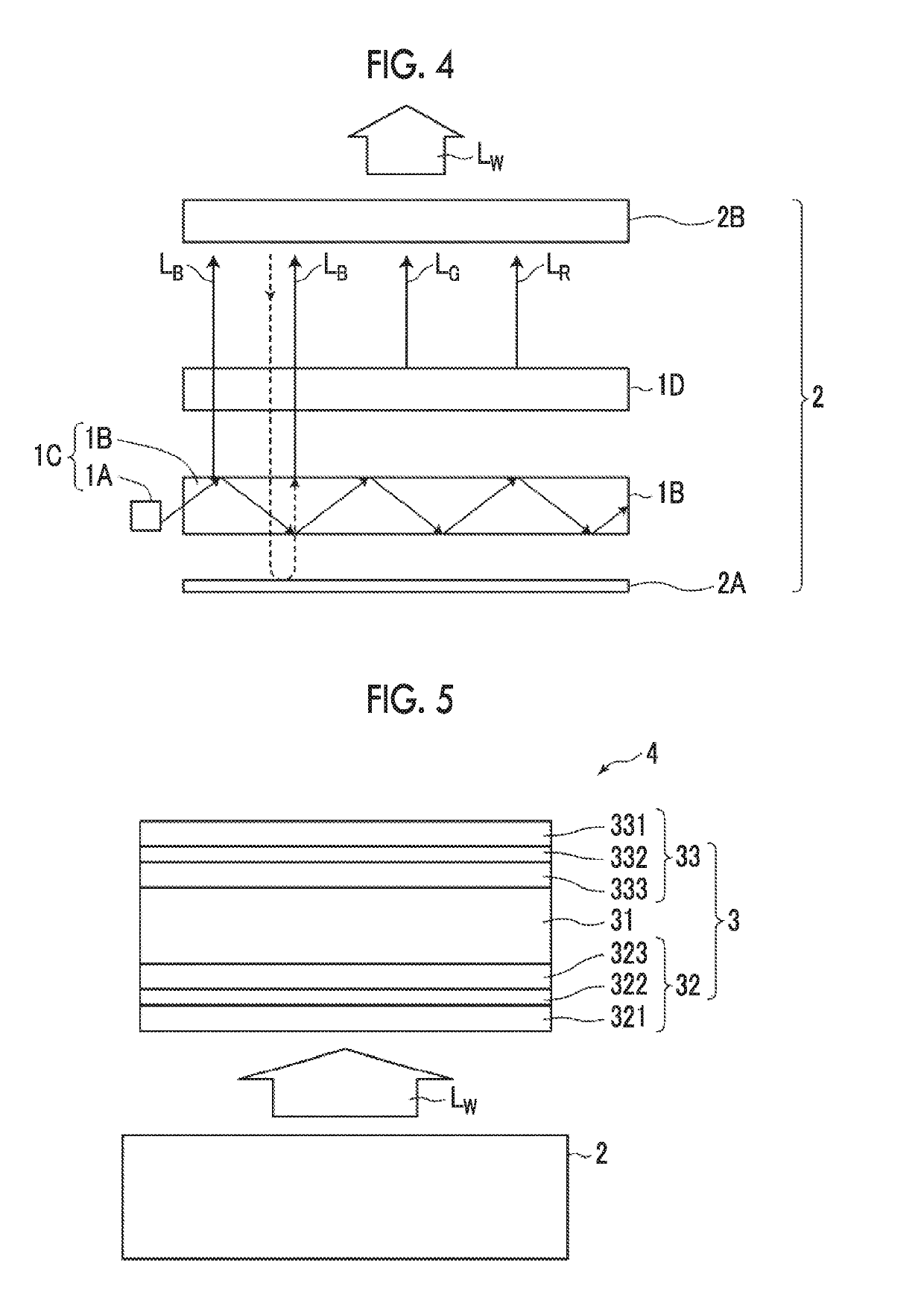

The integration of quantum dots into display technologies marked a pivotal advancement around 2013, when the first quantum dot-enhanced LCD televisions entered the market. These early implementations utilized quantum dots in enhancement films, positioned between the backlight and LCD panel to improve color gamut and efficiency. This approach represented the first generation of quantum dot displays, offering significant improvements over conventional LCD technology while maintaining manufacturing compatibility.

Subsequent evolution has seen quantum dots move closer to the light source in display architectures, with developments including quantum dot on-chip solutions and quantum dot color filters. Each iteration has improved energy efficiency, color performance, and manufacturing scalability. However, the application of quantum dots in reflective display technologies represents a relatively unexplored frontier with distinct technical challenges and opportunities.

The primary objective of current research on quantum dot stability in reflective display technologies is to develop materials and encapsulation methods that maintain quantum dot optical performance under ambient operating conditions. Unlike transmissive displays that utilize controlled backlighting, reflective displays operate by modulating ambient light, exposing quantum dots to variable illumination intensities, spectral distributions, and potentially harmful environmental factors including oxygen and moisture.

Secondary objectives include optimizing quantum dot integration with reflective display architectures, which differ fundamentally from transmissive designs. This encompasses developing deposition techniques compatible with reflective substrates, ensuring uniform quantum dot distribution, and maintaining structural integrity during manufacturing processes and throughout the product lifecycle.

Long-term research aims to achieve quantum dot reflective displays with stability metrics comparable to or exceeding current reflective technologies, including operational lifetimes exceeding 10,000 hours under standard indoor and outdoor conditions, color stability with less than 10% degradation over the product lifetime, and resilience to temperature fluctuations between -20°C and 60°C. These ambitious targets necessitate interdisciplinary approaches combining materials science, photophysics, and advanced manufacturing techniques.

The integration of quantum dots into display technologies marked a pivotal advancement around 2013, when the first quantum dot-enhanced LCD televisions entered the market. These early implementations utilized quantum dots in enhancement films, positioned between the backlight and LCD panel to improve color gamut and efficiency. This approach represented the first generation of quantum dot displays, offering significant improvements over conventional LCD technology while maintaining manufacturing compatibility.

Subsequent evolution has seen quantum dots move closer to the light source in display architectures, with developments including quantum dot on-chip solutions and quantum dot color filters. Each iteration has improved energy efficiency, color performance, and manufacturing scalability. However, the application of quantum dots in reflective display technologies represents a relatively unexplored frontier with distinct technical challenges and opportunities.

The primary objective of current research on quantum dot stability in reflective display technologies is to develop materials and encapsulation methods that maintain quantum dot optical performance under ambient operating conditions. Unlike transmissive displays that utilize controlled backlighting, reflective displays operate by modulating ambient light, exposing quantum dots to variable illumination intensities, spectral distributions, and potentially harmful environmental factors including oxygen and moisture.

Secondary objectives include optimizing quantum dot integration with reflective display architectures, which differ fundamentally from transmissive designs. This encompasses developing deposition techniques compatible with reflective substrates, ensuring uniform quantum dot distribution, and maintaining structural integrity during manufacturing processes and throughout the product lifecycle.

Long-term research aims to achieve quantum dot reflective displays with stability metrics comparable to or exceeding current reflective technologies, including operational lifetimes exceeding 10,000 hours under standard indoor and outdoor conditions, color stability with less than 10% degradation over the product lifetime, and resilience to temperature fluctuations between -20°C and 60°C. These ambitious targets necessitate interdisciplinary approaches combining materials science, photophysics, and advanced manufacturing techniques.

Market Analysis for Reflective Display Technologies

The reflective display technology market has witnessed significant growth in recent years, driven by increasing demand for energy-efficient display solutions across various sectors. Unlike traditional emissive displays that require backlighting, reflective displays utilize ambient light to create images, resulting in substantially lower power consumption and improved outdoor readability. The global market for reflective display technologies was valued at approximately $1.2 billion in 2022 and is projected to grow at a CAGR of 12.8% through 2028.

E-readers represent the largest application segment, accounting for nearly 40% of the market share. Amazon's Kindle devices continue to dominate this space, though competitors like Kobo and Barnes & Noble maintain significant presence. The e-reader market has stabilized after initial rapid growth, now showing steady but modest annual increases of 3-5% globally.

Electronic shelf labels (ESLs) constitute the fastest-growing segment within reflective displays, expanding at over 18% annually. Major retailers worldwide are adopting ESLs to improve operational efficiency and enable dynamic pricing strategies. European markets lead in ESL adoption, with North America showing accelerated implementation rates since 2020.

Quantum dot-enhanced reflective displays represent an emerging high-value segment with substantial growth potential. These displays offer superior color reproduction compared to traditional reflective technologies while maintaining energy efficiency benefits. Market analysis indicates consumer willingness to pay premium prices for improved color performance in reflective displays, particularly in portable devices and automotive applications.

Regional analysis shows Asia-Pacific leading market share at 42%, followed by North America (28%) and Europe (24%). China has emerged as both the largest manufacturing hub and consumption market for reflective display technologies, with significant investments in production capacity and R&D facilities.

Key market drivers include increasing environmental consciousness among consumers, regulatory pressure for energy-efficient devices, and growing demand for displays usable in bright outdoor conditions. The healthcare sector represents an untapped opportunity, with potential applications in medical devices requiring long battery life and readability in varied lighting conditions.

Market challenges include competition from increasingly efficient emissive displays, manufacturing scalability issues, and color reproduction limitations. Consumer expectations shaped by high-quality OLED and LCD displays create adoption barriers for reflective technologies in premium device segments where visual performance is prioritized over power efficiency.

E-readers represent the largest application segment, accounting for nearly 40% of the market share. Amazon's Kindle devices continue to dominate this space, though competitors like Kobo and Barnes & Noble maintain significant presence. The e-reader market has stabilized after initial rapid growth, now showing steady but modest annual increases of 3-5% globally.

Electronic shelf labels (ESLs) constitute the fastest-growing segment within reflective displays, expanding at over 18% annually. Major retailers worldwide are adopting ESLs to improve operational efficiency and enable dynamic pricing strategies. European markets lead in ESL adoption, with North America showing accelerated implementation rates since 2020.

Quantum dot-enhanced reflective displays represent an emerging high-value segment with substantial growth potential. These displays offer superior color reproduction compared to traditional reflective technologies while maintaining energy efficiency benefits. Market analysis indicates consumer willingness to pay premium prices for improved color performance in reflective displays, particularly in portable devices and automotive applications.

Regional analysis shows Asia-Pacific leading market share at 42%, followed by North America (28%) and Europe (24%). China has emerged as both the largest manufacturing hub and consumption market for reflective display technologies, with significant investments in production capacity and R&D facilities.

Key market drivers include increasing environmental consciousness among consumers, regulatory pressure for energy-efficient devices, and growing demand for displays usable in bright outdoor conditions. The healthcare sector represents an untapped opportunity, with potential applications in medical devices requiring long battery life and readability in varied lighting conditions.

Market challenges include competition from increasingly efficient emissive displays, manufacturing scalability issues, and color reproduction limitations. Consumer expectations shaped by high-quality OLED and LCD displays create adoption barriers for reflective technologies in premium device segments where visual performance is prioritized over power efficiency.

Quantum Dot Stability Challenges and Limitations

Quantum dot (QD) stability remains a critical challenge in the development of reflective display technologies. Despite their exceptional optical properties, including high color purity and tunable emission wavelengths, quantum dots suffer from several degradation mechanisms that significantly limit their commercial viability in display applications. The primary stability issues stem from photo-oxidation processes, where exposure to oxygen and light triggers chemical changes in the QD structure, resulting in decreased quantum yield and color shift over time.

Environmental factors play a substantial role in QD degradation. Temperature fluctuations can accelerate deterioration processes, with elevated temperatures causing ligand detachment and subsequent aggregation of quantum dots. Humidity presents another significant challenge, as water molecules can penetrate protective layers and interact with QD surfaces, leading to oxidation and structural changes. These environmental sensitivities make maintaining consistent performance in variable operating conditions particularly difficult.

The core-shell structure of quantum dots, while designed to enhance stability, introduces its own limitations. Interface defects between core and shell materials can serve as trapping sites for charge carriers, reducing luminescence efficiency. Shell thickness optimization presents a delicate balance – thicker shells provide better protection but may introduce lattice strain and new defect sites, while thinner shells offer insufficient protection against environmental factors.

Surface chemistry represents another critical aspect of QD stability. The ligands that passivate QD surfaces are susceptible to detachment or degradation, exposing the QD core to oxidative processes. Current ligand systems often struggle to provide long-term stability while maintaining the optical and electronic properties required for display applications. The trade-off between stability and performance remains a significant hurdle in QD development.

Manufacturing consistency presents additional challenges. Batch-to-batch variations in QD synthesis can result in inconsistent stability profiles, complicating quality control processes. The scalability of production methods that yield highly stable QDs remains limited, creating barriers to mass production and commercialization.

Encapsulation technologies, while promising, have not fully resolved stability issues. Current encapsulation materials may not provide sufficient oxygen and moisture barriers while maintaining optical clarity and flexibility required for display applications. The integration of QDs into device architectures introduces additional stress factors that can accelerate degradation processes.

Regulatory concerns regarding heavy metal content in certain QD compositions (particularly cadmium-based systems) have driven research toward alternative materials, but these often exhibit inferior stability profiles compared to their traditional counterparts. This regulatory pressure creates additional constraints on material selection and design strategies for enhancing QD stability in commercial applications.

Environmental factors play a substantial role in QD degradation. Temperature fluctuations can accelerate deterioration processes, with elevated temperatures causing ligand detachment and subsequent aggregation of quantum dots. Humidity presents another significant challenge, as water molecules can penetrate protective layers and interact with QD surfaces, leading to oxidation and structural changes. These environmental sensitivities make maintaining consistent performance in variable operating conditions particularly difficult.

The core-shell structure of quantum dots, while designed to enhance stability, introduces its own limitations. Interface defects between core and shell materials can serve as trapping sites for charge carriers, reducing luminescence efficiency. Shell thickness optimization presents a delicate balance – thicker shells provide better protection but may introduce lattice strain and new defect sites, while thinner shells offer insufficient protection against environmental factors.

Surface chemistry represents another critical aspect of QD stability. The ligands that passivate QD surfaces are susceptible to detachment or degradation, exposing the QD core to oxidative processes. Current ligand systems often struggle to provide long-term stability while maintaining the optical and electronic properties required for display applications. The trade-off between stability and performance remains a significant hurdle in QD development.

Manufacturing consistency presents additional challenges. Batch-to-batch variations in QD synthesis can result in inconsistent stability profiles, complicating quality control processes. The scalability of production methods that yield highly stable QDs remains limited, creating barriers to mass production and commercialization.

Encapsulation technologies, while promising, have not fully resolved stability issues. Current encapsulation materials may not provide sufficient oxygen and moisture barriers while maintaining optical clarity and flexibility required for display applications. The integration of QDs into device architectures introduces additional stress factors that can accelerate degradation processes.

Regulatory concerns regarding heavy metal content in certain QD compositions (particularly cadmium-based systems) have driven research toward alternative materials, but these often exhibit inferior stability profiles compared to their traditional counterparts. This regulatory pressure creates additional constraints on material selection and design strategies for enhancing QD stability in commercial applications.

Current Stability Enhancement Solutions

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell quantum dot structures significantly enhance stability by providing physical barriers against environmental factors. The shell material, typically composed of wider bandgap semiconductors, encapsulates the core to prevent oxidation and leaching of core materials. This architecture also reduces surface defects and improves quantum yield while maintaining optical properties over extended periods under various environmental conditions.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation provides an effective method for stabilizing quantum dots against environmental degradation. By embedding quantum dots within polymer matrices or coating them with polymer layers, their resistance to oxidation, moisture, and temperature fluctuations is significantly improved. This approach also enables better dispersion in various solvents and compatibility with different application environments while maintaining optical and electronic properties.

- Environmental stability factors for quantum dots: The stability of quantum dots is significantly affected by environmental factors such as temperature, humidity, oxygen exposure, and UV radiation. Research focuses on developing quantum dots that maintain their optical and electronic properties under these challenging conditions. Strategies include incorporating stabilizing additives, optimizing synthesis parameters, and developing specialized storage conditions to extend the functional lifetime of quantum dot materials.

- Manufacturing processes affecting quantum dot stability: The stability of quantum dots is heavily influenced by their manufacturing processes. Precise control over synthesis parameters such as temperature, reaction time, precursor ratios, and purification methods directly impacts the structural integrity and long-term stability of the resulting quantum dots. Advanced manufacturing techniques focus on reducing defects, improving size distribution uniformity, and enhancing surface passivation to produce quantum dots with superior stability characteristics.

02 Core-shell structures for improved quantum dot stability

Core-shell quantum dot structures significantly enhance stability by providing a protective layer around the core material. This architecture helps to passivate surface defects, reduce non-radiative recombination, and protect the core from environmental factors. Different shell materials and thicknesses can be optimized to achieve desired stability characteristics while maintaining the optical and electronic properties of the quantum dots.Expand Specific Solutions03 Polymer encapsulation for quantum dot stabilization

Encapsulating quantum dots within polymer matrices provides enhanced environmental stability. Polymers create a physical barrier that protects quantum dots from oxygen, moisture, and other degradation factors. Various polymers with different properties can be selected based on the specific application requirements. This approach is particularly useful for quantum dots used in display technologies, biomedical applications, and sensing devices.Expand Specific Solutions04 Chemical stabilization methods for quantum dots

Chemical approaches to stabilize quantum dots include the use of specific ligands, antioxidants, and stabilizing agents that can prevent degradation mechanisms. These methods often involve modifying the chemical environment around the quantum dots to neutralize reactive species, prevent photo-oxidation, and maintain colloidal stability. Chemical stabilization is crucial for applications requiring long-term stability under challenging environmental conditions.Expand Specific Solutions05 Manufacturing processes affecting quantum dot stability

The stability of quantum dots is significantly influenced by their manufacturing processes. Parameters such as synthesis temperature, reaction time, precursor ratios, and purification methods can all affect the defect density, crystallinity, and surface properties of quantum dots, which in turn determine their stability. Advanced manufacturing techniques have been developed to produce quantum dots with improved stability characteristics for various applications.Expand Specific Solutions

Leading Companies in Quantum Dot Display Industry

The quantum dot stability in reflective display technologies market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is expanding steadily, driven by demand for energy-efficient, high-performance display solutions. Technologically, quantum dot stability remains a challenge, with varying maturity levels across competitors. Leading players like Samsung Display, BOE Technology, and Nanosys have made significant advancements in stability enhancement, while companies such as TCL China Star, LG Display, and Najing Technology are developing proprietary solutions to address degradation issues. Emerging players like Qustomdot and Ningbo Exciton Technology are introducing innovative approaches to quantum dot encapsulation and environmental protection, gradually improving the technology's commercial viability for reflective display applications.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed a comprehensive quantum dot stability solution for reflective displays called "QD-Reflect" technology. Their approach centers on a multi-layered protection strategy that addresses the primary degradation mechanisms affecting quantum dots in ambient light conditions. BOE's research has yielded specialized siloxane-based encapsulation materials that form hermetic seals around individual quantum dots, dramatically reducing oxidation rates[5]. Their quantum dot formulations incorporate gradient alloy structures (CdSe/ZnS with intermediate composition layers) that minimize lattice mismatch and enhance photostability by reducing surface defects. BOE has demonstrated reflective display prototypes using these stabilized quantum dots that maintain over 90% of initial brightness after 5,000 hours of accelerated aging tests. The company has also pioneered a unique "dual barrier" approach where quantum dots are protected both at the particle level and at the display module level, effectively creating redundant protection against moisture and oxygen penetration[6]. Their latest research focuses on self-healing polymer matrices that can repair microfractures that might otherwise expose quantum dots to environmental degradation.

Strengths: Comprehensive approach addressing multiple stability factors; established mass production capabilities; strong integration with existing display manufacturing; advanced encapsulation technologies. Weaknesses: Higher material costs compared to conventional reflective technologies; complex manufacturing process; still working to achieve ultra-long term stability beyond 10,000 hours in extreme conditions.

SAMSUNG DISPLAY CO LTD

Technical Solution: Samsung Display has developed an innovative approach to quantum dot stability in reflective displays through their "QD-EL" (Quantum Dot Electroluminescent) technology. Their research focuses on creating highly stable quantum dot structures using a multi-layer encapsulation strategy that shields dots from environmental degradation factors. Samsung's proprietary "QD-on-Glass" technology for reflective applications incorporates zinc selenide-based quantum dots with specialized silica encapsulation that demonstrates exceptional stability under varying light conditions and temperatures[3]. Their research has achieved quantum dot formulations with less than 5% efficiency degradation after 1,000 hours of continuous operation in reflective mode. Samsung has also pioneered hybrid organic-inorganic barrier films that reduce water vapor transmission rates to below 10^-6 g/m²/day, effectively isolating quantum dots from moisture-induced degradation[4]. Their latest advancements include photo-patternable quantum dot arrays specifically designed for high-resolution reflective displays with enhanced stability.

Strengths: Extensive manufacturing infrastructure; advanced encapsulation technologies; strong integration with existing display production lines; comprehensive intellectual property portfolio. Weaknesses: Higher production costs compared to conventional reflective technologies; complex manufacturing process requiring specialized equipment; still working to achieve full-spectrum color stability in outdoor conditions.

Key Patents in Quantum Dot Encapsulation Techniques

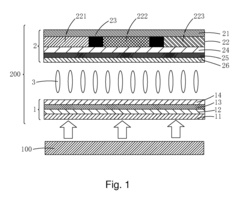

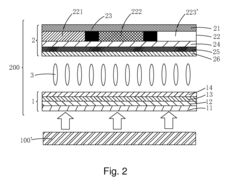

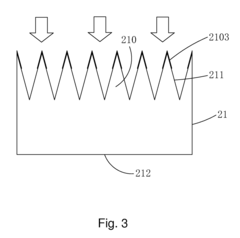

Liquid crystal display

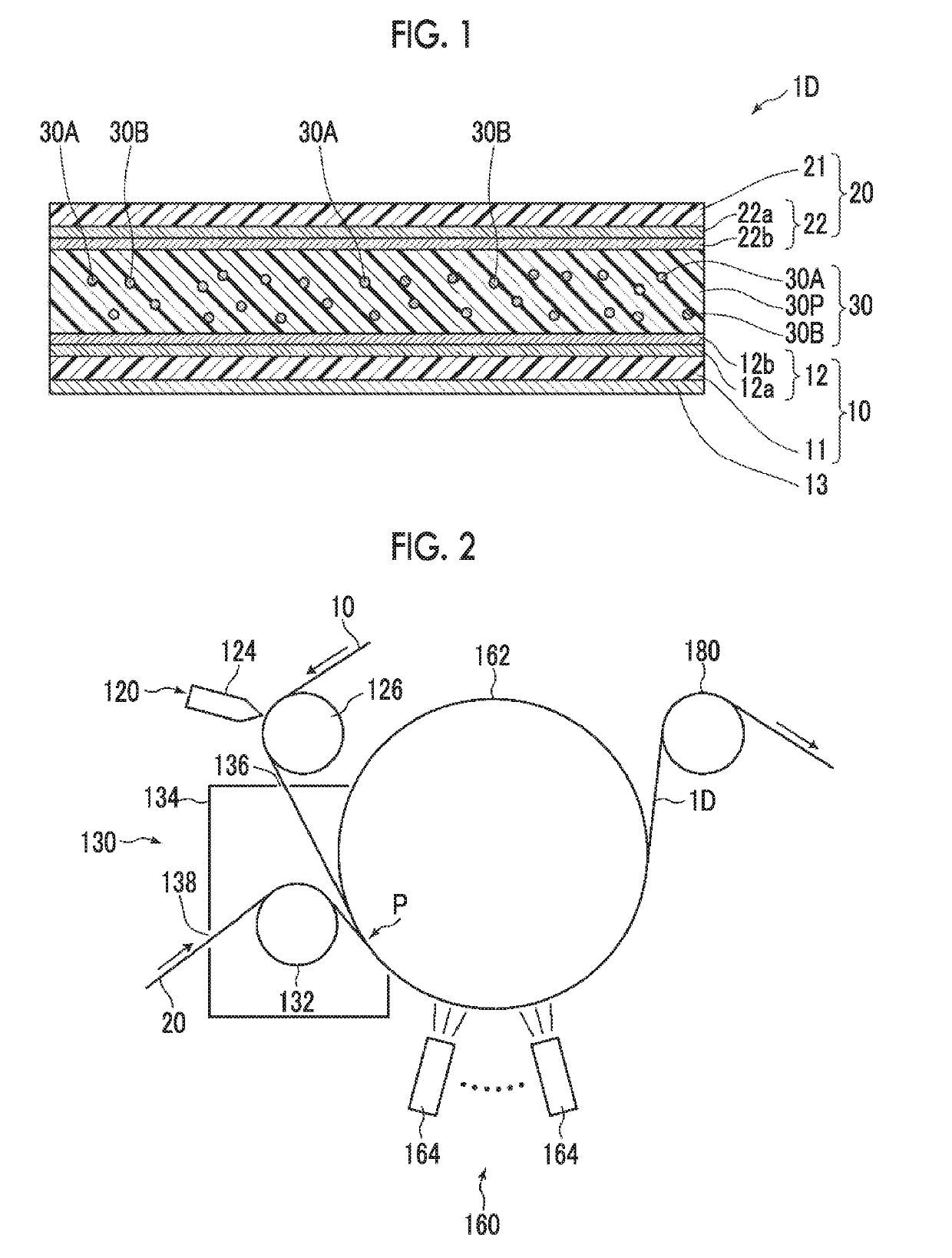

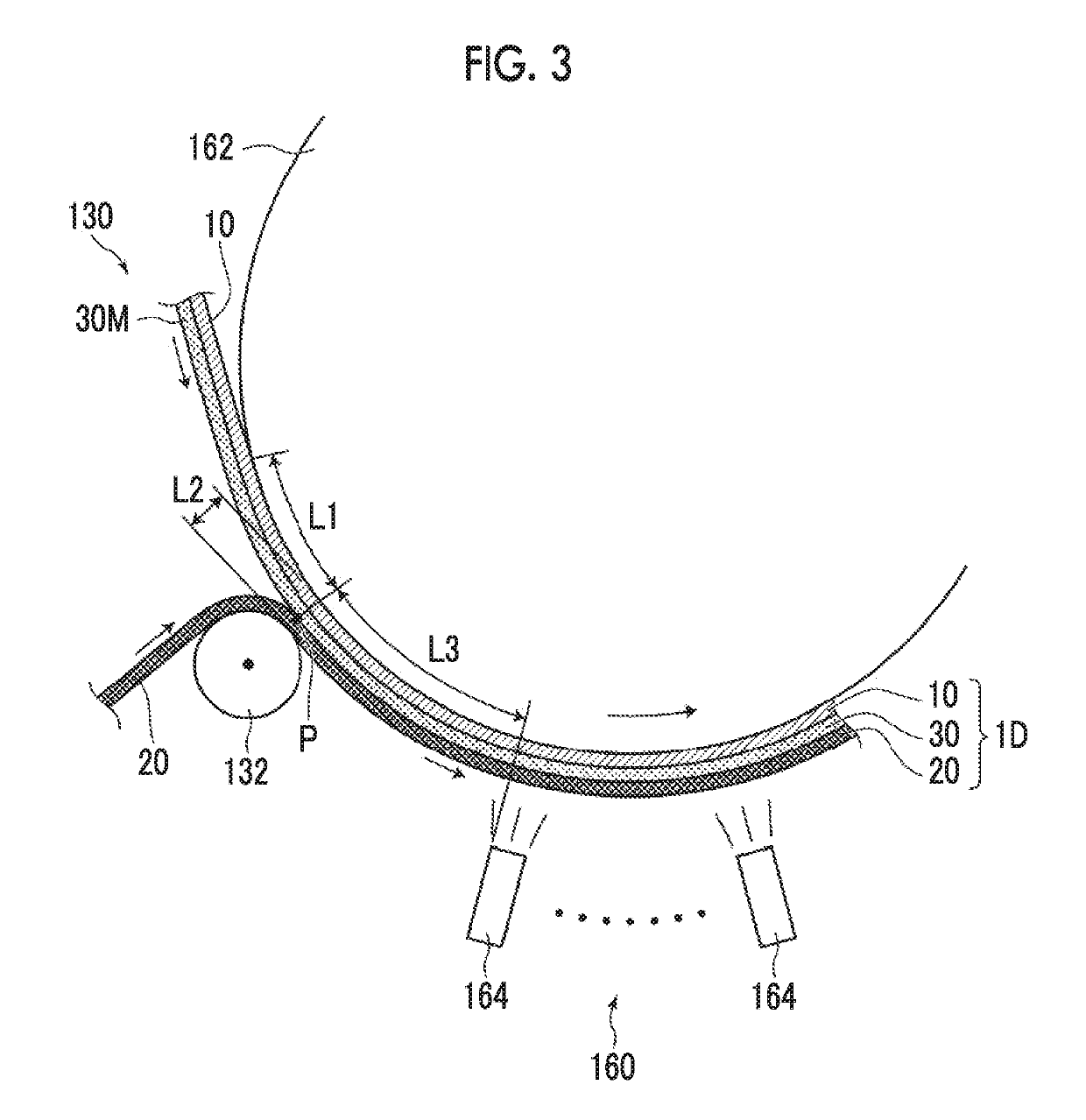

PatentActiveUS20170160585A1

Innovation

- Incorporating a unidirectional light guide thin film at the illuminating side of the liquid crystal display panel to block exterior light from reaching the quantum dot color light emitting layer, ensuring that only the backlight source excites the quantum dots, thereby maintaining display quality.

Quantum dot-containing composition, wavelength conversion member, backlight unit, and liquid crystal display device

PatentActiveUS20190144689A1

Innovation

- A quantum dot-containing composition with a ligand having coordinating groups represented by specific formulas, which strongly coordinates with the quantum dots to prevent ligand detachment and oxidation, allowing for high concentration dispersion in acrylate resin, thereby maintaining brightness and enabling a thinner wavelength conversion layer.

Environmental Impact of Quantum Dot Materials

The environmental impact of quantum dot materials in reflective display technologies represents a critical consideration for sustainable technology development. Quantum dots (QDs), while offering exceptional optical properties, contain heavy metals such as cadmium, lead, and selenium that pose significant environmental and health risks throughout their lifecycle. The production process of these nanomaterials requires substantial energy input and generates hazardous waste, contributing to their environmental footprint.

When improperly disposed of, quantum dot displays can leach toxic substances into soil and groundwater systems. This is particularly concerning given the increasing adoption of QD technology in consumer electronics and the subsequent growth in electronic waste. Studies have shown that cadmium-based quantum dots can persist in environmental systems and potentially bioaccumulate in food chains, presenting long-term ecological risks.

Regulatory frameworks worldwide are evolving to address these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has placed limitations on cadmium content in electronic displays, driving research toward cadmium-free alternatives. Similarly, the United States Environmental Protection Agency has classified several quantum dot components as priority pollutants, necessitating stringent handling and disposal protocols.

Industry response has focused on developing more environmentally benign quantum dot formulations. Indium phosphide-based quantum dots have emerged as a promising alternative to cadmium-based materials, offering comparable optical performance with reduced toxicity. However, these substitutes still present their own environmental challenges, including resource scarcity and energy-intensive manufacturing processes.

Life cycle assessment (LCA) studies comparing quantum dot displays with conventional technologies reveal complex trade-offs. While QD displays may consume less energy during operation, their production and end-of-life phases often carry higher environmental burdens. Recent research indicates that improving quantum dot stability in reflective display applications could extend device lifespans, thereby reducing overall environmental impact through decreased replacement frequency.

Green chemistry approaches are gaining traction in quantum dot synthesis, with aqueous-based production methods reducing dependence on toxic solvents. Additionally, encapsulation technologies that prevent leaching of harmful components are advancing, though their long-term effectiveness remains under investigation. These developments are crucial for mitigating environmental risks while maintaining the technological advantages of quantum dot displays.

The path toward truly sustainable quantum dot technology requires holistic consideration of material selection, manufacturing processes, product longevity, and end-of-life management. As reflective display technologies incorporating quantum dots move toward commercialization, environmental impact assessments must be integrated into research and development frameworks to ensure responsible innovation.

When improperly disposed of, quantum dot displays can leach toxic substances into soil and groundwater systems. This is particularly concerning given the increasing adoption of QD technology in consumer electronics and the subsequent growth in electronic waste. Studies have shown that cadmium-based quantum dots can persist in environmental systems and potentially bioaccumulate in food chains, presenting long-term ecological risks.

Regulatory frameworks worldwide are evolving to address these concerns. The European Union's Restriction of Hazardous Substances (RoHS) directive has placed limitations on cadmium content in electronic displays, driving research toward cadmium-free alternatives. Similarly, the United States Environmental Protection Agency has classified several quantum dot components as priority pollutants, necessitating stringent handling and disposal protocols.

Industry response has focused on developing more environmentally benign quantum dot formulations. Indium phosphide-based quantum dots have emerged as a promising alternative to cadmium-based materials, offering comparable optical performance with reduced toxicity. However, these substitutes still present their own environmental challenges, including resource scarcity and energy-intensive manufacturing processes.

Life cycle assessment (LCA) studies comparing quantum dot displays with conventional technologies reveal complex trade-offs. While QD displays may consume less energy during operation, their production and end-of-life phases often carry higher environmental burdens. Recent research indicates that improving quantum dot stability in reflective display applications could extend device lifespans, thereby reducing overall environmental impact through decreased replacement frequency.

Green chemistry approaches are gaining traction in quantum dot synthesis, with aqueous-based production methods reducing dependence on toxic solvents. Additionally, encapsulation technologies that prevent leaching of harmful components are advancing, though their long-term effectiveness remains under investigation. These developments are crucial for mitigating environmental risks while maintaining the technological advantages of quantum dot displays.

The path toward truly sustainable quantum dot technology requires holistic consideration of material selection, manufacturing processes, product longevity, and end-of-life management. As reflective display technologies incorporating quantum dots move toward commercialization, environmental impact assessments must be integrated into research and development frameworks to ensure responsible innovation.

Manufacturing Scalability Assessment

The scalability of quantum dot manufacturing processes represents a critical factor in the commercial viability of reflective display technologies incorporating these nanomaterials. Current production methods for high-stability quantum dots suitable for reflective displays face significant challenges when transitioning from laboratory to industrial scale. Batch-to-batch consistency remains problematic, with yield rates for premium-grade quantum dots typically ranging between 65-78% in optimized production environments, significantly lower than the 90%+ yields required for cost-effective mass production.

Production throughput presents another substantial hurdle, as conventional colloidal synthesis methods require precise temperature control and extended reaction times. Advanced continuous flow reactors have demonstrated promising results, increasing production rates by approximately 300% compared to batch processes while maintaining quality parameters. However, these systems require substantial capital investment, with setup costs averaging $3-5 million for production lines capable of annual output sufficient for approximately 500,000 display units.

Material input requirements pose additional scaling challenges. High-purity precursors necessary for quantum dot synthesis with appropriate stability characteristics for reflective display applications command premium prices, with costs typically 4-8 times higher than standard-grade alternatives. This price differential significantly impacts unit economics when scaling to commercial volumes, necessitating either vertical integration of precursor production or strategic supplier partnerships.

Equipment standardization across manufacturing facilities represents another critical consideration. Current quantum dot production equipment exhibits considerable variability in output quality, with specialized reactors often requiring customization for specific quantum dot formulations. This lack of standardization complicates technology transfer between research and production environments, extending commercialization timelines by an estimated 8-14 months for new quantum dot variants with enhanced stability profiles.

Quality control methodologies must also evolve to support scaled production. Laboratory characterization techniques like transmission electron microscopy and photoluminescence spectroscopy, while precise, cannot match the throughput requirements of industrial production. Emerging high-throughput analytical methods utilizing automated spectral analysis and machine learning algorithms show promise, potentially reducing quality assessment times by 85% while maintaining detection accuracy for stability-compromising defects above 92%.

Regulatory considerations further impact manufacturing scalability, particularly regarding environmental controls and worker safety protocols. Quantum dot production often involves hazardous materials that require specialized handling and waste management systems, adding approximately 12-18% to facility operational costs compared to conventional electronic material production facilities.

Production throughput presents another substantial hurdle, as conventional colloidal synthesis methods require precise temperature control and extended reaction times. Advanced continuous flow reactors have demonstrated promising results, increasing production rates by approximately 300% compared to batch processes while maintaining quality parameters. However, these systems require substantial capital investment, with setup costs averaging $3-5 million for production lines capable of annual output sufficient for approximately 500,000 display units.

Material input requirements pose additional scaling challenges. High-purity precursors necessary for quantum dot synthesis with appropriate stability characteristics for reflective display applications command premium prices, with costs typically 4-8 times higher than standard-grade alternatives. This price differential significantly impacts unit economics when scaling to commercial volumes, necessitating either vertical integration of precursor production or strategic supplier partnerships.

Equipment standardization across manufacturing facilities represents another critical consideration. Current quantum dot production equipment exhibits considerable variability in output quality, with specialized reactors often requiring customization for specific quantum dot formulations. This lack of standardization complicates technology transfer between research and production environments, extending commercialization timelines by an estimated 8-14 months for new quantum dot variants with enhanced stability profiles.

Quality control methodologies must also evolve to support scaled production. Laboratory characterization techniques like transmission electron microscopy and photoluminescence spectroscopy, while precise, cannot match the throughput requirements of industrial production. Emerging high-throughput analytical methods utilizing automated spectral analysis and machine learning algorithms show promise, potentially reducing quality assessment times by 85% while maintaining detection accuracy for stability-compromising defects above 92%.

Regulatory considerations further impact manufacturing scalability, particularly regarding environmental controls and worker safety protocols. Quantum dot production often involves hazardous materials that require specialized handling and waste management systems, adding approximately 12-18% to facility operational costs compared to conventional electronic material production facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!