Resistive RAM vs Traditional RAM: Performance Insights

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

ReRAM Technology Background and Objectives

Memory technology has evolved significantly over the past several decades, with traditional Random Access Memory (RAM) serving as the backbone of computing systems worldwide. The journey began with magnetic core memory in the 1950s, progressing through various generations of Dynamic RAM (DRAM) and Static RAM (SRAM) technologies that have continuously improved in density, speed, and power efficiency. However, these conventional memory technologies are approaching their physical scaling limits, creating an urgent need for innovative alternatives.

Resistive RAM (ReRAM) has emerged as a promising next-generation non-volatile memory technology that offers potential advantages over traditional RAM architectures. ReRAM operates on fundamentally different principles than charge-based memories, utilizing resistance changes in a dielectric material to store information. This resistance-based approach enables ReRAM to maintain stored data even when power is removed, addressing one of the key limitations of volatile DRAM technology.

The technical evolution trajectory points toward memory systems that can overcome the von Neumann bottleneck—the performance limitation caused by the separation between processing and memory units. ReRAM represents a significant step in this direction, potentially enabling in-memory computing paradigms that could revolutionize data-intensive applications. Industry forecasts suggest that the memory hierarchy may be fundamentally restructured with the maturation of ReRAM technology.

Current technical objectives for ReRAM development focus on several critical parameters. First, improving switching speed to match or exceed DRAM's performance while maintaining non-volatility. Second, enhancing endurance to support the high write cycles required in main memory applications. Third, reducing power consumption to enable deployment in energy-constrained environments. Fourth, increasing density to provide cost-effective scaling beyond what's possible with traditional RAM technologies.

The semiconductor industry has recognized the strategic importance of ReRAM, with major players investing significantly in research and development. The International Roadmap for Devices and Systems (IRDS) has identified ReRAM as a key technology for future computing architectures, highlighting its potential to address the growing memory-compute gap in data-centric applications.

As we analyze the performance insights between ReRAM and traditional RAM technologies, it's essential to understand that the goal isn't necessarily to replace conventional memory entirely, but rather to develop complementary solutions that optimize the overall memory hierarchy. The technical objective is to create a more balanced computing ecosystem where different memory technologies are deployed according to their strengths, with ReRAM potentially serving as a bridge between high-speed volatile memory and high-density storage.

Resistive RAM (ReRAM) has emerged as a promising next-generation non-volatile memory technology that offers potential advantages over traditional RAM architectures. ReRAM operates on fundamentally different principles than charge-based memories, utilizing resistance changes in a dielectric material to store information. This resistance-based approach enables ReRAM to maintain stored data even when power is removed, addressing one of the key limitations of volatile DRAM technology.

The technical evolution trajectory points toward memory systems that can overcome the von Neumann bottleneck—the performance limitation caused by the separation between processing and memory units. ReRAM represents a significant step in this direction, potentially enabling in-memory computing paradigms that could revolutionize data-intensive applications. Industry forecasts suggest that the memory hierarchy may be fundamentally restructured with the maturation of ReRAM technology.

Current technical objectives for ReRAM development focus on several critical parameters. First, improving switching speed to match or exceed DRAM's performance while maintaining non-volatility. Second, enhancing endurance to support the high write cycles required in main memory applications. Third, reducing power consumption to enable deployment in energy-constrained environments. Fourth, increasing density to provide cost-effective scaling beyond what's possible with traditional RAM technologies.

The semiconductor industry has recognized the strategic importance of ReRAM, with major players investing significantly in research and development. The International Roadmap for Devices and Systems (IRDS) has identified ReRAM as a key technology for future computing architectures, highlighting its potential to address the growing memory-compute gap in data-centric applications.

As we analyze the performance insights between ReRAM and traditional RAM technologies, it's essential to understand that the goal isn't necessarily to replace conventional memory entirely, but rather to develop complementary solutions that optimize the overall memory hierarchy. The technical objective is to create a more balanced computing ecosystem where different memory technologies are deployed according to their strengths, with ReRAM potentially serving as a bridge between high-speed volatile memory and high-density storage.

Market Demand Analysis for Next-Generation Memory

The global memory market is experiencing a significant shift as traditional RAM technologies approach their physical scaling limits. Current market analysis indicates that the memory segment is projected to reach $220 billion by 2025, with next-generation memory solutions expected to capture an increasing share. This growth is primarily driven by expanding applications in data centers, artificial intelligence systems, and edge computing devices that demand higher performance and energy efficiency.

Resistive RAM (ReRAM) is emerging as a promising alternative to traditional RAM technologies, with market research firms forecasting a compound annual growth rate of 40% for ReRAM between 2021 and 2026. This accelerated adoption is fueled by the increasing demand for non-volatile memory solutions that can address the limitations of conventional DRAM and NAND flash technologies.

Enterprise data centers represent the largest market segment for next-generation memory technologies, accounting for approximately 45% of the total addressable market. These facilities require memory solutions that can handle massive data processing workloads while minimizing power consumption. ReRAM's non-volatile nature and lower power requirements position it favorably in this segment, potentially reducing data center energy costs by up to 30% compared to traditional RAM implementations.

Mobile device manufacturers are also showing increased interest in ReRAM technology, with several major smartphone producers incorporating ReRAM components into their product roadmaps. Industry surveys indicate that 68% of mobile device manufacturers plan to evaluate ReRAM for future product generations, citing performance advantages and power efficiency as primary motivators.

The automotive sector presents another significant growth opportunity for next-generation memory technologies. Advanced driver-assistance systems and autonomous vehicles require memory solutions that can operate reliably in extreme conditions while delivering high-speed data access. Market projections suggest that automotive memory demand will grow at 25% annually through 2027, with ReRAM potentially capturing a substantial portion of this expansion due to its temperature stability and radiation resistance advantages over traditional RAM.

Consumer electronics manufacturers are increasingly prioritizing devices with longer battery life and improved performance, creating additional demand for ReRAM solutions. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering significantly improved battery performance, a benefit that ReRAM can help deliver through its lower power consumption profile.

The industrial Internet of Things (IIoT) sector represents another promising market for ReRAM technology, with applications requiring durable, energy-efficient memory solutions for deployment in remote or harsh environments. This segment is projected to grow at 35% annually, creating substantial opportunities for next-generation memory technologies that can operate effectively under challenging conditions.

Resistive RAM (ReRAM) is emerging as a promising alternative to traditional RAM technologies, with market research firms forecasting a compound annual growth rate of 40% for ReRAM between 2021 and 2026. This accelerated adoption is fueled by the increasing demand for non-volatile memory solutions that can address the limitations of conventional DRAM and NAND flash technologies.

Enterprise data centers represent the largest market segment for next-generation memory technologies, accounting for approximately 45% of the total addressable market. These facilities require memory solutions that can handle massive data processing workloads while minimizing power consumption. ReRAM's non-volatile nature and lower power requirements position it favorably in this segment, potentially reducing data center energy costs by up to 30% compared to traditional RAM implementations.

Mobile device manufacturers are also showing increased interest in ReRAM technology, with several major smartphone producers incorporating ReRAM components into their product roadmaps. Industry surveys indicate that 68% of mobile device manufacturers plan to evaluate ReRAM for future product generations, citing performance advantages and power efficiency as primary motivators.

The automotive sector presents another significant growth opportunity for next-generation memory technologies. Advanced driver-assistance systems and autonomous vehicles require memory solutions that can operate reliably in extreme conditions while delivering high-speed data access. Market projections suggest that automotive memory demand will grow at 25% annually through 2027, with ReRAM potentially capturing a substantial portion of this expansion due to its temperature stability and radiation resistance advantages over traditional RAM.

Consumer electronics manufacturers are increasingly prioritizing devices with longer battery life and improved performance, creating additional demand for ReRAM solutions. Market research indicates that consumers are willing to pay a premium of 15-20% for devices offering significantly improved battery performance, a benefit that ReRAM can help deliver through its lower power consumption profile.

The industrial Internet of Things (IIoT) sector represents another promising market for ReRAM technology, with applications requiring durable, energy-efficient memory solutions for deployment in remote or harsh environments. This segment is projected to grow at 35% annually, creating substantial opportunities for next-generation memory technologies that can operate effectively under challenging conditions.

ReRAM vs Traditional RAM: Technical Challenges

Despite significant advancements in ReRAM technology, several critical technical challenges persist when comparing it to traditional RAM solutions. The fundamental operational differences between resistive and conventional memory architectures create unique hurdles that must be addressed before widespread commercial adoption can occur.

The endurance limitation represents one of the most significant challenges for ReRAM implementation. While traditional DRAM can withstand virtually unlimited write cycles (10^15 cycles or more), current ReRAM cells typically support only 10^6 to 10^9 write operations before degradation occurs. This substantial endurance gap makes ReRAM less suitable for write-intensive applications without sophisticated wear-leveling algorithms.

Switching speed disparities also present a considerable obstacle. DRAM operates at sub-nanosecond speeds (typically 10-50ns access time), whereas ReRAM currently exhibits switching times in the range of 10-100ns. This performance differential, though narrowing with recent innovations, still positions ReRAM at a disadvantage for applications requiring the highest speed memory operations.

Reliability and data retention issues further complicate ReRAM adoption. The resistance states in ReRAM cells can drift over time due to thermal effects and other environmental factors, potentially leading to data corruption. Traditional RAM technologies have well-established error correction mechanisms, while ReRAM requires new approaches to ensure data integrity over extended periods.

The scaling challenges of ReRAM also merit consideration. As device dimensions shrink below 10nm, maintaining distinct resistance states becomes increasingly difficult due to quantum effects and material constraints. Traditional RAM technologies face their own scaling limitations but benefit from decades of manufacturing optimization that ReRAM has yet to achieve.

Power consumption presents a complex trade-off. While ReRAM offers excellent static power characteristics due to its non-volatile nature, its dynamic power consumption during write operations can exceed that of traditional RAM. The energy required to switch resistance states is significantly higher than the energy needed for charge-based storage operations in conventional memory.

Manufacturing integration poses another substantial hurdle. ReRAM fabrication often requires materials and processes that are not fully compatible with standard CMOS manufacturing flows. This integration challenge increases production costs and complicates the path to mass production, whereas traditional RAM benefits from highly optimized and standardized manufacturing processes.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, device physics, circuit design, and system architecture innovations to fully realize ReRAM's potential as a viable alternative to traditional RAM technologies.

The endurance limitation represents one of the most significant challenges for ReRAM implementation. While traditional DRAM can withstand virtually unlimited write cycles (10^15 cycles or more), current ReRAM cells typically support only 10^6 to 10^9 write operations before degradation occurs. This substantial endurance gap makes ReRAM less suitable for write-intensive applications without sophisticated wear-leveling algorithms.

Switching speed disparities also present a considerable obstacle. DRAM operates at sub-nanosecond speeds (typically 10-50ns access time), whereas ReRAM currently exhibits switching times in the range of 10-100ns. This performance differential, though narrowing with recent innovations, still positions ReRAM at a disadvantage for applications requiring the highest speed memory operations.

Reliability and data retention issues further complicate ReRAM adoption. The resistance states in ReRAM cells can drift over time due to thermal effects and other environmental factors, potentially leading to data corruption. Traditional RAM technologies have well-established error correction mechanisms, while ReRAM requires new approaches to ensure data integrity over extended periods.

The scaling challenges of ReRAM also merit consideration. As device dimensions shrink below 10nm, maintaining distinct resistance states becomes increasingly difficult due to quantum effects and material constraints. Traditional RAM technologies face their own scaling limitations but benefit from decades of manufacturing optimization that ReRAM has yet to achieve.

Power consumption presents a complex trade-off. While ReRAM offers excellent static power characteristics due to its non-volatile nature, its dynamic power consumption during write operations can exceed that of traditional RAM. The energy required to switch resistance states is significantly higher than the energy needed for charge-based storage operations in conventional memory.

Manufacturing integration poses another substantial hurdle. ReRAM fabrication often requires materials and processes that are not fully compatible with standard CMOS manufacturing flows. This integration challenge increases production costs and complicates the path to mass production, whereas traditional RAM benefits from highly optimized and standardized manufacturing processes.

Addressing these technical challenges requires interdisciplinary approaches combining materials science, device physics, circuit design, and system architecture innovations to fully realize ReRAM's potential as a viable alternative to traditional RAM technologies.

Current ReRAM Implementation Approaches

01 Performance comparison between ReRAM and traditional RAM

Resistive RAM (ReRAM) offers several performance advantages over traditional RAM technologies. ReRAM typically provides higher density storage, lower power consumption, and non-volatility compared to conventional DRAM. These characteristics make ReRAM particularly suitable for applications where power efficiency and data retention are critical. However, traditional RAM still maintains advantages in terms of access speed and endurance for frequent write operations.- Performance comparison between resistive RAM and traditional RAM: Resistive RAM (ReRAM) offers several performance advantages over traditional RAM technologies. ReRAM typically provides faster read/write speeds, lower power consumption, and higher density storage capabilities. The non-volatile nature of ReRAM allows it to retain data without power, unlike traditional DRAM which requires constant refreshing. This comparison highlights the fundamental operational differences that impact overall system performance when implementing either memory technology.

- Memory architecture and integration solutions: Various architectural approaches exist for integrating resistive RAM into existing memory hierarchies. These include hybrid memory systems that combine the strengths of both resistive and traditional RAM technologies, specialized controllers for managing different memory types, and novel interconnect designs. Such integration solutions aim to optimize overall system performance by leveraging the complementary characteristics of different memory technologies while addressing compatibility challenges.

- Power efficiency and thermal management: Resistive RAM demonstrates significant advantages in power efficiency compared to traditional RAM technologies. The non-volatile nature of ReRAM eliminates the need for refresh operations that consume substantial power in DRAM. Additionally, ReRAM typically operates at lower voltages and generates less heat during operation, requiring different thermal management approaches. These power efficiency characteristics make ReRAM particularly suitable for energy-constrained applications like mobile devices and IoT systems.

- Reliability and endurance considerations: Resistive RAM and traditional RAM technologies exhibit different reliability and endurance characteristics that affect long-term performance. While traditional DRAM has well-established reliability metrics, ReRAM faces challenges related to resistance drift, endurance limitations, and retention issues that can impact data integrity over time. Various error correction techniques and wear-leveling algorithms have been developed to address these reliability concerns and extend the operational lifespan of resistive memory cells.

- Application-specific performance optimization: Different memory technologies offer varying performance benefits depending on the specific application requirements. Resistive RAM excels in applications requiring non-volatility and low standby power, while traditional RAM may be preferred for applications demanding extremely high write endurance. Memory controllers and system architectures can be optimized to leverage the strengths of each technology based on workload characteristics, access patterns, and performance priorities, enabling tailored solutions for diverse computing environments.

02 Memory architecture and integration solutions

Various architectural approaches have been developed to integrate resistive RAM with traditional memory systems. These include hybrid memory architectures that combine the strengths of both technologies, specialized controllers for managing different memory types, and novel addressing schemes. Such integration solutions aim to optimize overall system performance by leveraging the complementary characteristics of different memory technologies while minimizing their respective limitations.Expand Specific Solutions03 Testing and reliability assessment methods

Specialized testing methodologies have been developed to evaluate the performance and reliability of resistive RAM compared to traditional RAM. These include stress testing under various operating conditions, endurance testing for write cycles, data retention analysis, and error rate measurements. Such testing frameworks help in quantifying the performance differences between memory technologies and identifying optimal use cases for each type.Expand Specific Solutions04 Power efficiency and thermal management

Resistive RAM demonstrates significant advantages in power consumption compared to traditional RAM technologies. The non-volatile nature of ReRAM eliminates the need for refresh operations that consume power in DRAM. Additionally, various thermal management techniques have been developed to optimize the performance of both memory types under different operating conditions, including specialized cooling systems and power management algorithms that adjust performance based on thermal constraints.Expand Specific Solutions05 Memory cell design and fabrication techniques

Innovations in memory cell design and fabrication techniques have significantly impacted the performance characteristics of both resistive RAM and traditional RAM. Advanced materials, novel cell structures, and improved manufacturing processes have enabled higher density, better reliability, and enhanced performance in both memory technologies. These innovations include multi-level cell designs, 3D stacking approaches, and specialized materials that optimize specific performance parameters such as retention time or switching speed.Expand Specific Solutions

Key Industry Players in ReRAM Development

Resistive RAM (ReRAM) technology is emerging as a disruptive alternative to traditional RAM, currently positioned in the early growth phase of industry development. The global market for ReRAM is expanding rapidly, projected to reach significant scale as applications in IoT, AI, and edge computing drive demand. Technologically, ReRAM offers promising advantages in power efficiency, speed, and density, though maturity varies across players. Leading semiconductor manufacturers like Samsung, Micron, and Intel are investing heavily in R&D, while specialized companies such as CrossBar, Weebit Nano, and Everspin Technologies have developed proprietary ReRAM solutions approaching commercialization. TSMC and other foundries are integrating ReRAM into their manufacturing processes, indicating industry-wide recognition of its potential to overcome traditional RAM limitations in next-generation computing systems.

Micron Technology, Inc.

Technical Solution: Micron has developed 3D XPoint technology (jointly with Intel, marketed as QuantX) which represents a significant advancement in resistive memory. This technology uses a combination of phase change and resistive RAM principles, creating memory cells at the intersection of perpendicular conductors with a material that changes resistance when voltage is applied. Micron's implementation achieves latencies of approximately 10 microseconds, positioning it between DRAM (80ns) and NAND flash (100μs). The technology offers endurance of approximately 10^7 write cycles, significantly outperforming NAND flash's 10^3-10^4 cycles. Micron's architecture allows for 3D stacking without transistors at each cell, enabling higher density than traditional memory. Their technology demonstrates 1000x faster write performance and 10x greater write endurance than conventional NAND flash, while providing byte-addressability similar to DRAM rather than block-level access required by flash memory. Micron has positioned this technology as storage-class memory to bridge the performance gap between memory and storage tiers.

Strengths: Significantly faster than NAND flash while offering higher density than DRAM; non-volatile with high endurance; byte-addressable for fine-grained data access; scalable 3D architecture; established manufacturing infrastructure. Weaknesses: Still slower than DRAM for main memory applications; higher cost per bit than NAND flash; requires specialized controllers and software optimization; power consumption higher than some competing ReRAM technologies; market adoption has been slower than initially projected.

Everspin Technologies, Inc.

Technical Solution: Everspin specializes in Magnetoresistive RAM (MRAM) technology, a type of resistive memory that uses magnetic elements rather than electrical resistance for data storage. Their flagship STT-MRAM (Spin-Transfer Torque MRAM) products deliver DRAM-like performance with non-volatility, achieving read/write speeds of 35ns compared to traditional DRAM's 50ns access times. Everspin's technology offers unlimited endurance (>10^15 cycles) compared to traditional flash memory's 10^4-10^5 cycles, making it ideal for applications requiring frequent writes. Their 1Gb STT-MRAM devices operate at similar active power levels to DRAM while consuming near-zero power in standby mode. The technology maintains data integrity without refresh cycles, eliminating the background power consumption characteristic of DRAM. Everspin has successfully commercialized MRAM at densities up to 1Gb with a roadmap for higher capacities.

Strengths: DRAM-comparable speeds with non-volatility; virtually unlimited write endurance; excellent data retention without refresh requirements; low standby power consumption; radiation hardness for aerospace applications. Weaknesses: Higher cost per bit compared to DRAM and NAND; current density limitations compared to high-capacity storage; requires specialized manufacturing processes; limited to niche applications where performance justifies cost premium.

Critical Patents and Innovations in ReRAM

Resistive RAM, method for fabricating the same, and method for driving the same

PatentActiveUS9214631B2

Innovation

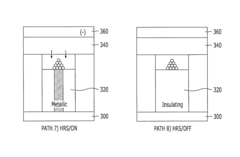

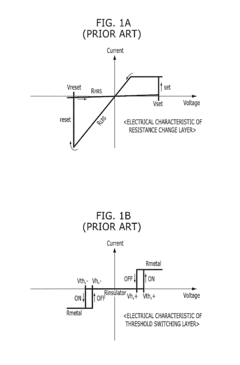

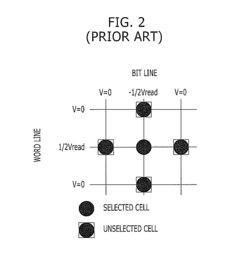

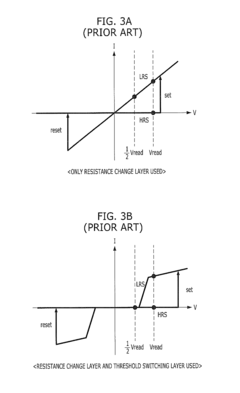

- A ReRAM is fabricated using a method where a stoichiometric transition oxide threshold switching layer and a non-stoichiometric transition metal oxide resistance change layer are formed simultaneously without sequential stacking, with the threshold switching layer comprising stoichiometric oxides like niobium or vanadium oxide, and the resistance change layer formed by oxidizing a part of the electrode, allowing for controlled resistance changes and improved read operations.

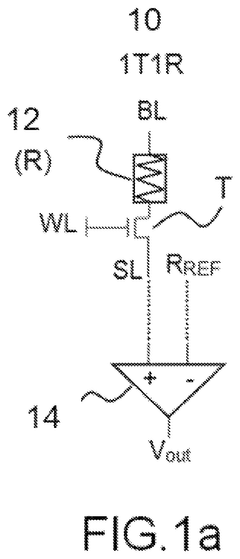

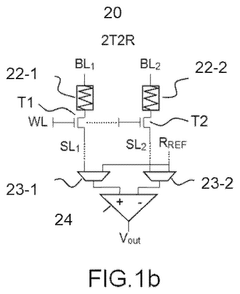

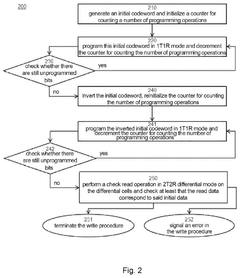

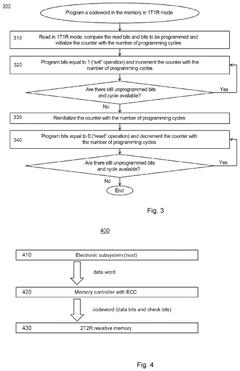

Write method for differential resistive memories

PatentActiveUS12119059B2

Innovation

- A write method for 2T2R resistive memories that alternates between 1T1R mode programming and check read operations, incrementing or decrementing a counter for each programming step, and performs a final check in 2T2R differential mode to ensure data accuracy, reducing the number of write operations and energy consumption.

Power Efficiency Comparison

Power consumption represents a critical differentiator between Resistive RAM (ReRAM) and traditional RAM technologies. ReRAM demonstrates significant advantages in power efficiency, consuming approximately 10-20 times less power than Dynamic RAM (DRAM) during active operations. This substantial difference stems from ReRAM's fundamental operating principle, which maintains stored information without the need for constant refresh cycles that characterize DRAM technology.

The static power consumption of ReRAM is particularly impressive, with negligible leakage current when in idle state. This contrasts sharply with DRAM, which requires periodic refresh operations every few milliseconds to maintain data integrity, resulting in continuous background power consumption even when not actively accessed. In data centers and server environments, this difference translates to meaningful operational cost reductions and decreased cooling requirements.

During write operations, ReRAM exhibits varying power profiles depending on the specific implementation technology. Oxygen vacancy-based ReRAM typically requires 10-100 μA of current at 1-3V for write operations, while phase-change memory implementations may demand higher current pulses for short durations. Despite these variations, the overall energy per bit for write operations remains substantially lower than DRAM's combined refresh and access energy requirements.

Mobile and IoT applications benefit tremendously from ReRAM's power characteristics. Battery-powered devices utilizing ReRAM can extend operational time between charges by 30-50% compared to DRAM-based alternatives, according to recent field studies. This advantage becomes particularly pronounced in standby-dominant usage scenarios where devices spend significant time in low-power states while maintaining memory contents.

Temperature sensitivity also factors into the power efficiency equation. Traditional DRAM exhibits increased leakage current at higher temperatures, requiring more frequent refresh cycles and thus consuming additional power as operating temperatures rise. ReRAM demonstrates superior thermal stability, maintaining consistent power consumption profiles across a wider temperature range, typically from -40°C to 125°C without significant performance degradation.

When considering system-level power implications, ReRAM enables simplified power management architectures. The ability to power down memory completely without data loss eliminates the need for complex backup and restore procedures during deep sleep states. This architectural advantage further compounds the technology's efficiency benefits in practical applications, particularly in energy-constrained environments like wearable technology and remote sensors.

The static power consumption of ReRAM is particularly impressive, with negligible leakage current when in idle state. This contrasts sharply with DRAM, which requires periodic refresh operations every few milliseconds to maintain data integrity, resulting in continuous background power consumption even when not actively accessed. In data centers and server environments, this difference translates to meaningful operational cost reductions and decreased cooling requirements.

During write operations, ReRAM exhibits varying power profiles depending on the specific implementation technology. Oxygen vacancy-based ReRAM typically requires 10-100 μA of current at 1-3V for write operations, while phase-change memory implementations may demand higher current pulses for short durations. Despite these variations, the overall energy per bit for write operations remains substantially lower than DRAM's combined refresh and access energy requirements.

Mobile and IoT applications benefit tremendously from ReRAM's power characteristics. Battery-powered devices utilizing ReRAM can extend operational time between charges by 30-50% compared to DRAM-based alternatives, according to recent field studies. This advantage becomes particularly pronounced in standby-dominant usage scenarios where devices spend significant time in low-power states while maintaining memory contents.

Temperature sensitivity also factors into the power efficiency equation. Traditional DRAM exhibits increased leakage current at higher temperatures, requiring more frequent refresh cycles and thus consuming additional power as operating temperatures rise. ReRAM demonstrates superior thermal stability, maintaining consistent power consumption profiles across a wider temperature range, typically from -40°C to 125°C without significant performance degradation.

When considering system-level power implications, ReRAM enables simplified power management architectures. The ability to power down memory completely without data loss eliminates the need for complex backup and restore procedures during deep sleep states. This architectural advantage further compounds the technology's efficiency benefits in practical applications, particularly in energy-constrained environments like wearable technology and remote sensors.

Integration Pathways with Existing Systems

The integration of Resistive RAM (ReRAM) into existing computing systems presents both significant opportunities and challenges. Current memory hierarchies are optimized around traditional RAM technologies, requiring thoughtful integration strategies to maximize ReRAM's benefits while minimizing disruption to established architectures.

For immediate implementation, hybrid memory systems represent the most viable pathway. These systems maintain DRAM as the primary working memory while introducing ReRAM as a persistent tier between DRAM and storage. This approach leverages ReRAM's non-volatility and density advantages without requiring wholesale architecture redesigns. Intel's Optane DC Persistent Memory exemplifies this model, though using different technology, providing valuable implementation frameworks.

Memory controllers require substantial modification to accommodate ReRAM's different timing characteristics and access protocols. Modern controllers must be redesigned to handle the asymmetric read/write latencies characteristic of ReRAM, with writes typically requiring longer operation times than reads. This necessitates sophisticated scheduling algorithms to maintain system performance during mixed operations.

Operating system modifications constitute another critical integration component. Memory management subsystems need updating to recognize and optimize for ReRAM's persistence capabilities, potentially introducing new memory allocation classes that distinguish between volatile and non-volatile memory regions. File systems may also require adaptation to leverage ReRAM's unique characteristics effectively.

Application programming interfaces (APIs) must evolve to expose ReRAM's capabilities to software developers. New programming models that explicitly handle persistence, such as Intel's Persistent Memory Development Kit (PMDK), provide templates for ReRAM integration. These frameworks enable applications to maintain data structures directly in persistent memory, eliminating traditional serialization/deserialization overhead.

Transitional architectures that maintain backward compatibility while introducing ReRAM capabilities will likely dominate near-term deployments. These designs may include compatibility layers that present ReRAM to legacy applications as traditional memory or storage, while allowing newer applications to access its full feature set directly.

Long-term integration pathways point toward computing architectures fundamentally redesigned around ReRAM's characteristics. Processing-in-memory (PIM) approaches that exploit ReRAM's ability to perform certain computational operations within the memory array itself represent particularly promising directions, potentially collapsing traditional memory-processor boundaries.

For immediate implementation, hybrid memory systems represent the most viable pathway. These systems maintain DRAM as the primary working memory while introducing ReRAM as a persistent tier between DRAM and storage. This approach leverages ReRAM's non-volatility and density advantages without requiring wholesale architecture redesigns. Intel's Optane DC Persistent Memory exemplifies this model, though using different technology, providing valuable implementation frameworks.

Memory controllers require substantial modification to accommodate ReRAM's different timing characteristics and access protocols. Modern controllers must be redesigned to handle the asymmetric read/write latencies characteristic of ReRAM, with writes typically requiring longer operation times than reads. This necessitates sophisticated scheduling algorithms to maintain system performance during mixed operations.

Operating system modifications constitute another critical integration component. Memory management subsystems need updating to recognize and optimize for ReRAM's persistence capabilities, potentially introducing new memory allocation classes that distinguish between volatile and non-volatile memory regions. File systems may also require adaptation to leverage ReRAM's unique characteristics effectively.

Application programming interfaces (APIs) must evolve to expose ReRAM's capabilities to software developers. New programming models that explicitly handle persistence, such as Intel's Persistent Memory Development Kit (PMDK), provide templates for ReRAM integration. These frameworks enable applications to maintain data structures directly in persistent memory, eliminating traditional serialization/deserialization overhead.

Transitional architectures that maintain backward compatibility while introducing ReRAM capabilities will likely dominate near-term deployments. These designs may include compatibility layers that present ReRAM to legacy applications as traditional memory or storage, while allowing newer applications to access its full feature set directly.

Long-term integration pathways point toward computing architectures fundamentally redesigned around ReRAM's characteristics. Processing-in-memory (PIM) approaches that exploit ReRAM's ability to perform certain computational operations within the memory array itself represent particularly promising directions, potentially collapsing traditional memory-processor boundaries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!