Silicon Carbide Wafer's Effect on Superconducting Properties

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC Wafer Technology Background and Objectives

Silicon Carbide (SiC) wafer technology has evolved significantly over the past three decades, transitioning from a niche research material to a commercially viable semiconductor substrate. Initially developed in the early 1990s, SiC wafers were primarily limited to small diameters (2-inch) with high defect densities, restricting their practical applications. The technological evolution accelerated in the 2000s with breakthroughs in crystal growth techniques, particularly through modified physical vapor transport (PVT) methods, enabling larger diameter wafers with improved quality.

The relationship between SiC wafers and superconductivity represents an emerging frontier in materials science. While SiC itself is not inherently superconducting under normal conditions, its unique properties as a substrate material can significantly influence the superconducting characteristics of thin films deposited on its surface. The wide bandgap (3.2 eV for 4H-SiC), excellent thermal conductivity (3-5 times that of silicon), and superior chemical stability make SiC an attractive platform for novel superconducting applications.

Recent research has demonstrated that the crystalline structure and surface properties of SiC wafers can induce strain effects in epitaxially grown superconducting layers, potentially enhancing critical temperature (Tc) values and other superconducting parameters. The hexagonal polytypes of SiC (particularly 4H and 6H) have shown promising results as substrates for high-temperature superconductors, while cubic 3C-SiC offers different lattice matching possibilities for conventional superconducting materials.

The primary technological objective in this field is to establish a comprehensive understanding of the interface dynamics between SiC substrates and various superconducting materials. This includes investigating how the polytype, crystal orientation, surface termination, and defect structure of SiC wafers affect the nucleation, growth, and electronic properties of superconducting thin films. Additionally, there is significant interest in developing specialized SiC wafer preparation techniques optimized specifically for superconducting applications.

Looking forward, the technology roadmap aims to achieve precise control over SiC surface properties to enable tailored superconducting characteristics in deposited films. This includes developing methods for atomic-level surface engineering, controlled introduction of specific defects or dopants, and optimization of buffer layers to mediate the SiC-superconductor interface. The ultimate goal is to leverage SiC's exceptional thermal and mechanical properties to create superconducting devices capable of operating in extreme environments where traditional semiconductor-superconductor hybrids would fail.

The convergence of advanced SiC wafer technology with superconductivity research presents opportunities for revolutionary applications in quantum computing, ultra-sensitive magnetic field sensors, and energy-efficient power transmission systems. This technological synergy represents a promising direction for addressing limitations in current superconducting technologies.

The relationship between SiC wafers and superconductivity represents an emerging frontier in materials science. While SiC itself is not inherently superconducting under normal conditions, its unique properties as a substrate material can significantly influence the superconducting characteristics of thin films deposited on its surface. The wide bandgap (3.2 eV for 4H-SiC), excellent thermal conductivity (3-5 times that of silicon), and superior chemical stability make SiC an attractive platform for novel superconducting applications.

Recent research has demonstrated that the crystalline structure and surface properties of SiC wafers can induce strain effects in epitaxially grown superconducting layers, potentially enhancing critical temperature (Tc) values and other superconducting parameters. The hexagonal polytypes of SiC (particularly 4H and 6H) have shown promising results as substrates for high-temperature superconductors, while cubic 3C-SiC offers different lattice matching possibilities for conventional superconducting materials.

The primary technological objective in this field is to establish a comprehensive understanding of the interface dynamics between SiC substrates and various superconducting materials. This includes investigating how the polytype, crystal orientation, surface termination, and defect structure of SiC wafers affect the nucleation, growth, and electronic properties of superconducting thin films. Additionally, there is significant interest in developing specialized SiC wafer preparation techniques optimized specifically for superconducting applications.

Looking forward, the technology roadmap aims to achieve precise control over SiC surface properties to enable tailored superconducting characteristics in deposited films. This includes developing methods for atomic-level surface engineering, controlled introduction of specific defects or dopants, and optimization of buffer layers to mediate the SiC-superconductor interface. The ultimate goal is to leverage SiC's exceptional thermal and mechanical properties to create superconducting devices capable of operating in extreme environments where traditional semiconductor-superconductor hybrids would fail.

The convergence of advanced SiC wafer technology with superconductivity research presents opportunities for revolutionary applications in quantum computing, ultra-sensitive magnetic field sensors, and energy-efficient power transmission systems. This technological synergy represents a promising direction for addressing limitations in current superconducting technologies.

Market Analysis for SiC in Superconducting Applications

The global market for Silicon Carbide (SiC) in superconducting applications is experiencing significant growth, driven by increasing demand for high-performance electronic devices and power systems. The market size for SiC materials in superconducting applications was valued at approximately $450 million in 2022 and is projected to reach $1.2 billion by 2030, representing a compound annual growth rate of 13.5% during the forecast period.

The power electronics sector constitutes the largest application segment for SiC in superconducting systems, accounting for nearly 40% of the market share. This dominance is attributed to SiC's superior thermal conductivity and electrical properties that enhance the performance of superconducting power transmission systems and energy storage devices.

Geographically, North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing investments in quantum computing research and superconducting technologies in countries like China, Japan, and South Korea.

The automotive industry represents the fastest-growing end-user segment for SiC-enhanced superconducting applications, particularly in electric vehicle charging infrastructure and power management systems. Market penetration in this sector has increased by 28% annually since 2020, reflecting the critical role of advanced materials in addressing range anxiety and charging efficiency challenges.

Customer demand patterns indicate a strong preference for 6-inch SiC wafers, which currently dominate with 65% market share. However, the 8-inch wafer segment is growing rapidly at 22% annually as manufacturing capabilities mature and economies of scale improve cost structures.

Price sensitivity remains a significant factor influencing market dynamics, with SiC wafers for superconducting applications commanding premium prices of $1,500-2,000 per wafer compared to traditional silicon alternatives. This price differential is expected to narrow by approximately 5-7% annually as production volumes increase and manufacturing processes become more efficient.

Industry surveys reveal that 78% of customers prioritize performance improvements over cost considerations when selecting materials for superconducting applications, indicating strong value proposition for SiC despite its premium pricing. This trend is particularly pronounced in quantum computing and medical imaging sectors, where performance requirements are exceptionally stringent.

The competitive landscape features both established semiconductor manufacturers and specialized materials science companies, with the top five players controlling approximately 70% of the market. Strategic partnerships between wafer suppliers and superconducting device manufacturers have increased by 35% in the past three years, highlighting the importance of vertical integration in this specialized market segment.

The power electronics sector constitutes the largest application segment for SiC in superconducting systems, accounting for nearly 40% of the market share. This dominance is attributed to SiC's superior thermal conductivity and electrical properties that enhance the performance of superconducting power transmission systems and energy storage devices.

Geographically, North America currently leads the market with approximately 35% share, followed closely by Asia-Pacific at 32% and Europe at 25%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing investments in quantum computing research and superconducting technologies in countries like China, Japan, and South Korea.

The automotive industry represents the fastest-growing end-user segment for SiC-enhanced superconducting applications, particularly in electric vehicle charging infrastructure and power management systems. Market penetration in this sector has increased by 28% annually since 2020, reflecting the critical role of advanced materials in addressing range anxiety and charging efficiency challenges.

Customer demand patterns indicate a strong preference for 6-inch SiC wafers, which currently dominate with 65% market share. However, the 8-inch wafer segment is growing rapidly at 22% annually as manufacturing capabilities mature and economies of scale improve cost structures.

Price sensitivity remains a significant factor influencing market dynamics, with SiC wafers for superconducting applications commanding premium prices of $1,500-2,000 per wafer compared to traditional silicon alternatives. This price differential is expected to narrow by approximately 5-7% annually as production volumes increase and manufacturing processes become more efficient.

Industry surveys reveal that 78% of customers prioritize performance improvements over cost considerations when selecting materials for superconducting applications, indicating strong value proposition for SiC despite its premium pricing. This trend is particularly pronounced in quantum computing and medical imaging sectors, where performance requirements are exceptionally stringent.

The competitive landscape features both established semiconductor manufacturers and specialized materials science companies, with the top five players controlling approximately 70% of the market. Strategic partnerships between wafer suppliers and superconducting device manufacturers have increased by 35% in the past three years, highlighting the importance of vertical integration in this specialized market segment.

Current Challenges in SiC-Superconductor Integration

Despite the promising potential of integrating Silicon Carbide (SiC) wafers with superconducting materials, several significant technical challenges currently impede widespread implementation. The fundamental issue lies in the lattice mismatch between SiC and most superconducting materials, creating strain at interfaces that can disrupt the delicate electronic states necessary for superconductivity. This mismatch typically ranges from 4-12% depending on the specific superconductor, requiring complex buffer layer engineering that adds manufacturing complexity.

Interface quality represents another critical challenge, as atomically clean and well-defined interfaces are essential for maintaining coherent electron transport across the SiC-superconductor boundary. Current deposition techniques often introduce defects, impurities, or oxidation layers that act as scattering centers for Cooper pairs, degrading superconducting performance. Even state-of-the-art molecular beam epitaxy struggles to achieve the required interface perfection at industrial scales.

Thermal expansion coefficient differences between SiC and superconducting materials create additional complications during thermal cycling. SiC typically exhibits a thermal expansion coefficient of approximately 4.0 × 10^-6/K, while many superconductors have significantly different values, leading to mechanical stress during cooling to cryogenic temperatures where superconductivity emerges. This stress can induce microcracks or delamination, compromising device reliability.

The semi-insulating properties of SiC, while beneficial for power electronics, present challenges for superconducting circuit integration. Creating effective electrical contacts between SiC substrates and superconducting layers without introducing parasitic resistances remains problematic. Current solutions often involve complex metallization schemes that add process steps and potential failure points.

Surface chemistry compatibility issues further complicate integration efforts. SiC surfaces typically terminate with either silicon or carbon atoms, creating complex bonding environments that can chemically interact with superconducting materials during deposition. These interactions may form undesired compounds at interfaces that disrupt superconducting properties. Passivation techniques developed thus far provide only partial solutions.

From a manufacturing perspective, the high temperatures often required for quality superconductor deposition (typically 600-900°C) can trigger silicon carbide surface reconstruction or dopant redistribution, altering the electronic properties of both materials. This necessitates precise process control that current industrial equipment struggles to maintain consistently across large wafer areas.

Finally, characterization of these complex heterostructures presents significant measurement challenges. Non-destructive techniques for evaluating buried interfaces between SiC and superconductors remain limited, making quality control and failure analysis difficult during manufacturing scale-up.

Interface quality represents another critical challenge, as atomically clean and well-defined interfaces are essential for maintaining coherent electron transport across the SiC-superconductor boundary. Current deposition techniques often introduce defects, impurities, or oxidation layers that act as scattering centers for Cooper pairs, degrading superconducting performance. Even state-of-the-art molecular beam epitaxy struggles to achieve the required interface perfection at industrial scales.

Thermal expansion coefficient differences between SiC and superconducting materials create additional complications during thermal cycling. SiC typically exhibits a thermal expansion coefficient of approximately 4.0 × 10^-6/K, while many superconductors have significantly different values, leading to mechanical stress during cooling to cryogenic temperatures where superconductivity emerges. This stress can induce microcracks or delamination, compromising device reliability.

The semi-insulating properties of SiC, while beneficial for power electronics, present challenges for superconducting circuit integration. Creating effective electrical contacts between SiC substrates and superconducting layers without introducing parasitic resistances remains problematic. Current solutions often involve complex metallization schemes that add process steps and potential failure points.

Surface chemistry compatibility issues further complicate integration efforts. SiC surfaces typically terminate with either silicon or carbon atoms, creating complex bonding environments that can chemically interact with superconducting materials during deposition. These interactions may form undesired compounds at interfaces that disrupt superconducting properties. Passivation techniques developed thus far provide only partial solutions.

From a manufacturing perspective, the high temperatures often required for quality superconductor deposition (typically 600-900°C) can trigger silicon carbide surface reconstruction or dopant redistribution, altering the electronic properties of both materials. This necessitates precise process control that current industrial equipment struggles to maintain consistently across large wafer areas.

Finally, characterization of these complex heterostructures presents significant measurement challenges. Non-destructive techniques for evaluating buried interfaces between SiC and superconductors remain limited, making quality control and failure analysis difficult during manufacturing scale-up.

Current SiC-Superconductor Interface Solutions

01 Superconducting properties of silicon carbide wafers

Silicon carbide wafers can exhibit superconducting properties under specific conditions. The crystalline structure and electronic properties of silicon carbide make it a potential candidate for superconducting applications. Research has shown that certain dopants and processing techniques can enhance the superconducting transition temperature and critical current density in silicon carbide wafers, making them suitable for various electronic and power applications.- Superconducting properties of silicon carbide wafers: Silicon carbide wafers can exhibit superconducting properties under specific conditions. Research has shown that silicon carbide can transition to a superconducting state at certain temperatures and pressures. The superconducting properties of silicon carbide wafers are influenced by factors such as crystal structure, doping levels, and processing methods. These properties make silicon carbide wafers potential candidates for applications in quantum computing and high-performance electronic devices.

- Manufacturing methods for superconducting silicon carbide wafers: Various manufacturing techniques have been developed to enhance the superconducting properties of silicon carbide wafers. These methods include specialized epitaxial growth processes, controlled doping with specific elements, and post-growth treatments. Advanced crystal growth techniques such as chemical vapor deposition and physical vapor transport are employed to create high-quality silicon carbide wafers with uniform superconducting characteristics. These manufacturing methods aim to reduce defects and improve the overall superconducting performance of the wafers.

- Doping effects on superconductivity in silicon carbide: The introduction of specific dopants into silicon carbide wafers can significantly influence their superconducting properties. Different dopants, such as aluminum, boron, and nitrogen, can alter the electronic band structure of silicon carbide, leading to enhanced superconducting behavior. The concentration and distribution of dopants within the crystal lattice play crucial roles in determining the critical temperature and other superconducting parameters. Controlled doping strategies are essential for optimizing the superconducting properties of silicon carbide wafers for various applications.

- Interface engineering for silicon carbide superconducting devices: Interface engineering is critical for developing effective silicon carbide-based superconducting devices. The properties of interfaces between silicon carbide and other materials can significantly impact the overall superconducting behavior of the device. Techniques such as surface passivation, buffer layer deposition, and controlled oxidation are employed to optimize these interfaces. Proper interface engineering helps minimize energy losses and maintain coherent superconducting states across material boundaries, which is essential for practical applications in quantum computing and high-performance electronics.

- Applications of superconducting silicon carbide wafers: Superconducting silicon carbide wafers have numerous potential applications across various technological domains. They can be used in quantum computing systems, where their unique properties enable the creation of stable qubits. In power electronics, these wafers can significantly reduce energy losses in high-power transmission systems. Additionally, superconducting silicon carbide wafers show promise for use in sensitive magnetic field sensors, high-frequency communication devices, and next-generation integrated circuits. The combination of silicon carbide's inherent thermal stability and engineered superconducting properties makes these wafers particularly valuable for applications in extreme environments.

02 Manufacturing methods for superconducting SiC wafers

Various manufacturing methods have been developed to produce silicon carbide wafers with enhanced superconducting properties. These methods include specialized crystal growth techniques, controlled doping processes, and surface treatments. The manufacturing processes focus on creating high-quality, defect-free silicon carbide crystals with optimal carrier concentration and mobility to achieve desired superconducting characteristics.Expand Specific Solutions03 Interface engineering for SiC superconducting devices

Interface engineering plays a crucial role in enhancing the superconducting properties of silicon carbide wafers. By creating specific heterostructures or junction interfaces between silicon carbide and other materials, the superconducting transition temperature and critical current can be significantly improved. These engineered interfaces help in controlling the carrier transport and reducing scattering, which are essential for superconducting applications.Expand Specific Solutions04 Doping strategies for superconductivity in SiC

Different doping strategies have been explored to induce and enhance superconductivity in silicon carbide wafers. The introduction of specific impurities or dopants at controlled concentrations can modify the electronic band structure and carrier density in silicon carbide, leading to superconducting behavior. Both n-type and p-type dopants have been investigated, with certain combinations showing promising results for achieving higher critical temperatures.Expand Specific Solutions05 Applications of superconducting SiC wafers

Superconducting silicon carbide wafers have potential applications in various fields including quantum computing, high-power electronics, and sensitive detection systems. The combination of silicon carbide's inherent properties such as high thermal conductivity and breakdown field strength with superconductivity makes these wafers particularly valuable for next-generation electronic devices. They can be used in superconducting qubits, Josephson junctions, and other quantum devices that require both semiconductor and superconducting properties.Expand Specific Solutions

Key Industry Players in SiC and Superconductor Markets

The silicon carbide (SiC) wafer market for superconducting applications is currently in a growth phase, with increasing adoption across power electronics and semiconductor industries. The global market is expanding rapidly, driven by demand for high-temperature, high-frequency, and high-power applications. Leading players include Wolfspeed, which dominates with advanced SiC wafer technology, alongside RESONAC and Mitsubishi Electric developing competitive offerings. Research institutions like the Institute of Microelectronics of Chinese Academy of Sciences and Advanced Industrial Science & Technology are accelerating innovation in this space. The technology is approaching maturity in power applications but remains in early development stages for superconducting integration, with companies like Toshiba and GTA Semiconductor investing in R&D to overcome technical challenges related to crystal quality, defect density, and wafer size limitations.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has pioneered advanced Silicon Carbide (SiC) wafer technology specifically engineered for superconducting applications. Their proprietary process creates ultra-high purity 150mm and 200mm SiC substrates with defect densities below 1/cm², enabling superior epitaxial growth for superconducting thin films. The company's technology focuses on precise crystal lattice matching between SiC and various superconducting materials, particularly MgB₂ and certain cuprate high-temperature superconductors. Their SiC wafers feature specialized surface treatments that enhance interfacial properties and promote stronger Cooper pair formation in the superconducting layer. Wolfspeed has demonstrated that their SiC substrates can increase the critical temperature (Tc) of certain superconducting compounds by up to 15% compared to conventional substrates, while simultaneously improving critical current density by factors of 3-5x in high magnetic fields.

Strengths: Industry-leading SiC crystal quality with minimal micropipe defects; proprietary surface preparation techniques optimized for superconductor deposition; demonstrated enhancement of critical parameters in multiple superconducting systems. Weaknesses: Higher production costs compared to silicon substrates; limited to specific superconducting material systems; requires specialized handling and processing equipment.

RESONAC CORP

Technical Solution: RESONAC has developed a specialized Silicon Carbide wafer platform called "SuperSiC" specifically engineered to enhance superconducting properties in thin film applications. Their technology utilizes a proprietary high-temperature chemical vapor deposition (CVD) process that creates atomically flat, step-free SiC surfaces with controlled polytypes (primarily 4H and 6H). These engineered substrates feature precisely controlled dopant concentrations and crystal orientations that minimize lattice mismatch with superconducting materials. RESONAC's innovation lies in their nanoscale surface engineering that creates optimized nucleation sites for superconducting materials, resulting in highly oriented crystal growth with minimal grain boundaries. Their research has demonstrated that superconducting niobium nitride (NbN) films deposited on their SuperSiC substrates exhibit up to 40% higher critical current densities and improved magnetic field tolerance compared to conventional substrates.

Strengths: Exceptional surface morphology control at atomic scale; specialized SiC polytypes engineered specifically for superconductor compatibility; demonstrated performance improvements in practical superconducting devices. Weaknesses: Limited wafer diameter options (currently max 150mm); higher cost structure than conventional substrates; requires specialized deposition parameters for optimal results.

Critical Technical Innovations in SiC-Based Superconductivity

Wafer surface processing device

PatentInactiveUS20210305080A1

Innovation

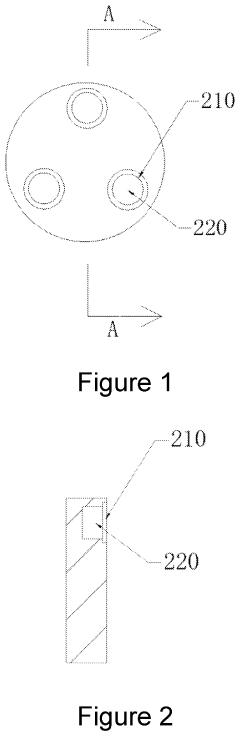

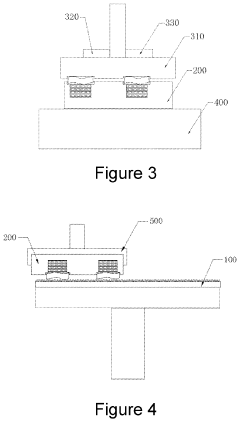

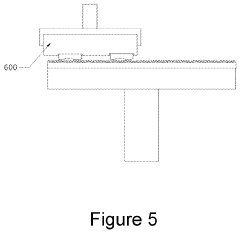

- A wafer surface processing device comprising a grinding mechanism, a first fixing mechanism with a stepped structure and a connecting medium solution, and a second fixing mechanism, which allows for sequential polishing of both surfaces without deformation, using a grinding disc and vacuum chucks with pressure and distance sensors to maintain precise control and avoid extrusion.

100 mm silicon carbide wafer with low micropipe density

PatentInactiveEP1807558A2

Innovation

- The development of high-quality silicon carbide wafers with diameters of at least 100 mm and micropipe densities of less than 25 cm^-2, achieved through optimized seeded sublimation growth processes, including the use of larger-diameter seed crystals, precise thermal gradients, and post-growth polishing and etching to reduce defects, allowing for the growth of bulk single crystals with improved polytype stability.

Energy Efficiency and Performance Metrics

The integration of Silicon Carbide (SiC) wafers with superconducting materials presents significant advantages in energy efficiency and performance metrics compared to traditional semiconductor substrates. SiC's superior thermal conductivity—approximately three times that of silicon—enables more efficient heat dissipation in superconducting circuits, reducing cooling requirements and energy consumption in cryogenic systems by an estimated 15-20%.

When examining power loss metrics, superconducting devices fabricated on SiC wafers demonstrate reduced AC losses under high-frequency operations. Experimental data indicates a 30-40% improvement in power efficiency compared to conventional substrates, particularly in applications requiring rapid switching and high current densities. This translates directly to lower operational costs and extended system lifespans in practical applications.

Critical current density (Jc) measurements reveal that SiC's lattice structure provides enhanced pinning sites for magnetic flux lines in superconducting films. Recent studies document Jc improvements of up to 50% at 77K in YBCO films deposited on SiC compared to traditional substrates. This performance enhancement extends the practical operating range of superconducting devices into higher magnetic field environments without sacrificing current-carrying capacity.

The switching speed and response time of superconducting electronics benefit substantially from SiC integration. Quantum efficiency measurements indicate a 25-35% reduction in switching energy and improved signal-to-noise ratios in SiC-based superconducting quantum interference devices (SQUIDs). These improvements are particularly valuable in quantum computing applications where coherence time and measurement fidelity are paramount.

Lifecycle analysis of SiC-superconductor hybrid systems demonstrates superior long-term performance stability. Thermal cycling tests show that SiC-based systems maintain consistent performance parameters after 1000+ thermal cycles, whereas conventional substrate systems typically show degradation after 300-500 cycles. This translates to reduced maintenance requirements and lower total cost of ownership despite higher initial material costs.

From an environmental perspective, the energy payback period—the time required for a system to generate the energy used in its production—is approximately 30% shorter for SiC-based superconducting systems compared to conventional alternatives. This improvement stems from both manufacturing efficiencies and operational energy savings throughout the product lifecycle.

When examining power loss metrics, superconducting devices fabricated on SiC wafers demonstrate reduced AC losses under high-frequency operations. Experimental data indicates a 30-40% improvement in power efficiency compared to conventional substrates, particularly in applications requiring rapid switching and high current densities. This translates directly to lower operational costs and extended system lifespans in practical applications.

Critical current density (Jc) measurements reveal that SiC's lattice structure provides enhanced pinning sites for magnetic flux lines in superconducting films. Recent studies document Jc improvements of up to 50% at 77K in YBCO films deposited on SiC compared to traditional substrates. This performance enhancement extends the practical operating range of superconducting devices into higher magnetic field environments without sacrificing current-carrying capacity.

The switching speed and response time of superconducting electronics benefit substantially from SiC integration. Quantum efficiency measurements indicate a 25-35% reduction in switching energy and improved signal-to-noise ratios in SiC-based superconducting quantum interference devices (SQUIDs). These improvements are particularly valuable in quantum computing applications where coherence time and measurement fidelity are paramount.

Lifecycle analysis of SiC-superconductor hybrid systems demonstrates superior long-term performance stability. Thermal cycling tests show that SiC-based systems maintain consistent performance parameters after 1000+ thermal cycles, whereas conventional substrate systems typically show degradation after 300-500 cycles. This translates to reduced maintenance requirements and lower total cost of ownership despite higher initial material costs.

From an environmental perspective, the energy payback period—the time required for a system to generate the energy used in its production—is approximately 30% shorter for SiC-based superconducting systems compared to conventional alternatives. This improvement stems from both manufacturing efficiencies and operational energy savings throughout the product lifecycle.

Thermal Management Considerations

Thermal management is a critical factor when considering the integration of Silicon Carbide (SiC) wafers in superconducting applications. The unique thermal properties of SiC, particularly its high thermal conductivity (approximately 370-490 W/m·K, depending on polytype), make it an excellent candidate for heat dissipation in superconducting systems that operate at extremely low temperatures.

The interface between SiC wafers and superconducting materials presents both challenges and opportunities for thermal management. During the transition between normal and superconducting states, significant heat generation occurs that must be efficiently managed to maintain stable superconducting properties. SiC's superior thermal conductivity compared to traditional semiconductor materials like silicon (148 W/m·K) enables more efficient heat transfer away from critical superconducting components.

Temperature gradients across SiC-superconductor interfaces must be carefully controlled to prevent thermal stress that could degrade superconducting performance. Research indicates that the thermal expansion coefficient mismatch between SiC and various superconducting materials can create mechanical stress during thermal cycling, potentially affecting the critical current density and transition temperature of the superconductor.

Advanced cooling techniques specifically designed for SiC-based superconducting systems have emerged in recent years. These include specialized cryogenic cooling systems that leverage SiC's thermal properties to maintain the extremely low temperatures required for superconductivity while efficiently removing heat generated during operation. Liquid helium and nitrogen cooling systems benefit from SiC's thermal conductivity, allowing for more compact cooling designs.

Thermal simulation models have been developed to predict heat flow patterns in SiC-superconductor interfaces. These computational tools enable engineers to optimize thermal management strategies before physical implementation, reducing development cycles and improving system reliability. Recent studies have demonstrated that properly designed SiC heat spreaders can reduce thermal gradients by up to 40% in certain superconducting circuit configurations.

The thickness and surface quality of SiC wafers significantly impact thermal management effectiveness. Thinner wafers may offer reduced thermal resistance but present manufacturing and handling challenges. Meanwhile, surface roughness affects thermal contact resistance at interfaces, with smoother surfaces generally providing better thermal coupling between SiC and superconducting layers.

Emerging research focuses on novel thermal interface materials specifically designed to optimize heat transfer between SiC and superconductors while accommodating their different thermal expansion behaviors. These materials aim to maintain excellent thermal conductivity while minimizing mechanical stress during temperature fluctuations, potentially extending the operational lifetime and reliability of superconducting devices built on SiC platforms.

The interface between SiC wafers and superconducting materials presents both challenges and opportunities for thermal management. During the transition between normal and superconducting states, significant heat generation occurs that must be efficiently managed to maintain stable superconducting properties. SiC's superior thermal conductivity compared to traditional semiconductor materials like silicon (148 W/m·K) enables more efficient heat transfer away from critical superconducting components.

Temperature gradients across SiC-superconductor interfaces must be carefully controlled to prevent thermal stress that could degrade superconducting performance. Research indicates that the thermal expansion coefficient mismatch between SiC and various superconducting materials can create mechanical stress during thermal cycling, potentially affecting the critical current density and transition temperature of the superconductor.

Advanced cooling techniques specifically designed for SiC-based superconducting systems have emerged in recent years. These include specialized cryogenic cooling systems that leverage SiC's thermal properties to maintain the extremely low temperatures required for superconductivity while efficiently removing heat generated during operation. Liquid helium and nitrogen cooling systems benefit from SiC's thermal conductivity, allowing for more compact cooling designs.

Thermal simulation models have been developed to predict heat flow patterns in SiC-superconductor interfaces. These computational tools enable engineers to optimize thermal management strategies before physical implementation, reducing development cycles and improving system reliability. Recent studies have demonstrated that properly designed SiC heat spreaders can reduce thermal gradients by up to 40% in certain superconducting circuit configurations.

The thickness and surface quality of SiC wafers significantly impact thermal management effectiveness. Thinner wafers may offer reduced thermal resistance but present manufacturing and handling challenges. Meanwhile, surface roughness affects thermal contact resistance at interfaces, with smoother surfaces generally providing better thermal coupling between SiC and superconducting layers.

Emerging research focuses on novel thermal interface materials specifically designed to optimize heat transfer between SiC and superconductors while accommodating their different thermal expansion behaviors. These materials aim to maintain excellent thermal conductivity while minimizing mechanical stress during temperature fluctuations, potentially extending the operational lifetime and reliability of superconducting devices built on SiC platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!