Standards for Thermal Runaway Testing in Battery Manufacturing Processes

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Thermal Runaway Background and Objectives

Thermal runaway in batteries represents one of the most critical safety concerns in the energy storage industry. This phenomenon occurs when a battery cell enters an uncontrollable, self-heating state that can lead to violent cell rupture, fire, or explosion. The historical development of battery technology shows a clear correlation between increased energy density and heightened thermal runaway risks, particularly evident in the evolution from lead-acid to lithium-ion chemistries.

The technical landscape of thermal runaway has evolved significantly since the commercialization of lithium-ion batteries in the early 1990s. Initial research focused primarily on understanding the fundamental mechanisms, while current efforts concentrate on prevention, early detection, and containment strategies. This evolution reflects the growing importance of battery safety as these technologies penetrate critical applications including electric vehicles, grid storage, and consumer electronics.

Testing standards for thermal runaway have developed in response to high-profile battery failure incidents, such as the Boeing 787 Dreamliner battery fires in 2013 and numerous electric vehicle thermal events. These incidents highlighted the inadequacy of existing safety protocols and accelerated the development of more rigorous testing methodologies. Current standards vary significantly across regions and applications, creating challenges for global manufacturers.

The primary objective of thermal runaway testing standards is to establish consistent, reliable methodologies for evaluating battery safety performance under various abuse conditions. These standards aim to simulate real-world failure scenarios while providing quantifiable metrics for comparison across different battery designs and chemistries. Additionally, they seek to establish minimum safety thresholds that all commercial batteries must meet before market entry.

Technical goals in this domain include developing testing protocols that can accurately predict field performance, standardizing methodologies across international boundaries, and creating tests that remain relevant as battery technology continues to evolve. There is particular emphasis on establishing standards that address the unique challenges of large-format batteries used in electric vehicles and grid storage applications, where the consequences of thermal events are most severe.

The trajectory of thermal runaway testing standards points toward more sophisticated approaches that incorporate real-time diagnostics, non-destructive evaluation techniques, and accelerated testing methodologies. These advancements aim to reduce testing time and costs while improving the predictive capability of safety assessments. The ultimate goal remains consistent: ensuring that battery technologies can deliver their performance benefits without compromising safety across their operational lifetime.

The technical landscape of thermal runaway has evolved significantly since the commercialization of lithium-ion batteries in the early 1990s. Initial research focused primarily on understanding the fundamental mechanisms, while current efforts concentrate on prevention, early detection, and containment strategies. This evolution reflects the growing importance of battery safety as these technologies penetrate critical applications including electric vehicles, grid storage, and consumer electronics.

Testing standards for thermal runaway have developed in response to high-profile battery failure incidents, such as the Boeing 787 Dreamliner battery fires in 2013 and numerous electric vehicle thermal events. These incidents highlighted the inadequacy of existing safety protocols and accelerated the development of more rigorous testing methodologies. Current standards vary significantly across regions and applications, creating challenges for global manufacturers.

The primary objective of thermal runaway testing standards is to establish consistent, reliable methodologies for evaluating battery safety performance under various abuse conditions. These standards aim to simulate real-world failure scenarios while providing quantifiable metrics for comparison across different battery designs and chemistries. Additionally, they seek to establish minimum safety thresholds that all commercial batteries must meet before market entry.

Technical goals in this domain include developing testing protocols that can accurately predict field performance, standardizing methodologies across international boundaries, and creating tests that remain relevant as battery technology continues to evolve. There is particular emphasis on establishing standards that address the unique challenges of large-format batteries used in electric vehicles and grid storage applications, where the consequences of thermal events are most severe.

The trajectory of thermal runaway testing standards points toward more sophisticated approaches that incorporate real-time diagnostics, non-destructive evaluation techniques, and accelerated testing methodologies. These advancements aim to reduce testing time and costs while improving the predictive capability of safety assessments. The ultimate goal remains consistent: ensuring that battery technologies can deliver their performance benefits without compromising safety across their operational lifetime.

Market Demand for Battery Safety Testing Standards

The global market for battery safety testing standards has experienced significant growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. As of 2023, the global lithium-ion battery market is valued at approximately $59 billion and is projected to reach $182 billion by 2030, with a compound annual growth rate of 18.1%. This explosive growth has intensified the demand for comprehensive thermal runaway testing standards to ensure consumer safety and product reliability.

The automotive sector represents the largest market segment demanding rigorous battery safety testing standards. With major automotive manufacturers committing to electrification targets, the need for standardized thermal runaway testing has become critical. The industry has witnessed several high-profile battery failure incidents that have heightened consumer safety concerns and regulatory scrutiny, creating urgent market pressure for improved testing protocols.

Energy storage system (ESS) applications constitute another rapidly growing segment requiring advanced thermal runaway testing standards. The global grid-scale battery storage capacity is expected to grow 20-fold by 2030, with safety concerns representing a significant barrier to wider adoption. Utility companies, commercial building operators, and residential consumers are increasingly demanding products that adhere to stringent safety standards.

Consumer electronics manufacturers represent a mature but still expanding market for battery safety testing. With over 1.5 billion smartphones sold annually worldwide, along with millions of laptops, tablets, and wearable devices, manufacturers face intense pressure to ensure battery safety while maintaining competitive performance specifications.

Regulatory bodies worldwide have responded to these market demands by developing and updating safety standards. The UN Transportation Testing requirements, IEC 62133, UL 1642, and UL 2054 standards have seen significant revisions to address thermal runaway concerns. However, industry stakeholders report that current standards often lag behind technological advancements, creating a market gap for more responsive and comprehensive testing frameworks.

Insurance companies have emerged as significant drivers of market demand for improved testing standards. Many insurers now require certification to specific battery safety standards before providing coverage for facilities manufacturing or storing large quantities of lithium-ion batteries, creating financial incentives for companies to adopt rigorous testing protocols.

The geographical distribution of market demand shows particular strength in regions with high EV adoption rates and renewable energy investments, including China, Europe, North America, and South Korea. China, as the world's largest EV market and battery manufacturer, has implemented some of the most stringent thermal runaway testing requirements, establishing a benchmark that influences global standards.

The automotive sector represents the largest market segment demanding rigorous battery safety testing standards. With major automotive manufacturers committing to electrification targets, the need for standardized thermal runaway testing has become critical. The industry has witnessed several high-profile battery failure incidents that have heightened consumer safety concerns and regulatory scrutiny, creating urgent market pressure for improved testing protocols.

Energy storage system (ESS) applications constitute another rapidly growing segment requiring advanced thermal runaway testing standards. The global grid-scale battery storage capacity is expected to grow 20-fold by 2030, with safety concerns representing a significant barrier to wider adoption. Utility companies, commercial building operators, and residential consumers are increasingly demanding products that adhere to stringent safety standards.

Consumer electronics manufacturers represent a mature but still expanding market for battery safety testing. With over 1.5 billion smartphones sold annually worldwide, along with millions of laptops, tablets, and wearable devices, manufacturers face intense pressure to ensure battery safety while maintaining competitive performance specifications.

Regulatory bodies worldwide have responded to these market demands by developing and updating safety standards. The UN Transportation Testing requirements, IEC 62133, UL 1642, and UL 2054 standards have seen significant revisions to address thermal runaway concerns. However, industry stakeholders report that current standards often lag behind technological advancements, creating a market gap for more responsive and comprehensive testing frameworks.

Insurance companies have emerged as significant drivers of market demand for improved testing standards. Many insurers now require certification to specific battery safety standards before providing coverage for facilities manufacturing or storing large quantities of lithium-ion batteries, creating financial incentives for companies to adopt rigorous testing protocols.

The geographical distribution of market demand shows particular strength in regions with high EV adoption rates and renewable energy investments, including China, Europe, North America, and South Korea. China, as the world's largest EV market and battery manufacturer, has implemented some of the most stringent thermal runaway testing requirements, establishing a benchmark that influences global standards.

Current Thermal Runaway Testing Challenges

Despite significant advancements in battery technology, thermal runaway testing faces numerous challenges that impede standardization and reliability across the industry. One primary challenge is the lack of globally harmonized testing protocols. Currently, different regions and regulatory bodies maintain varying standards, creating confusion for manufacturers operating in multiple markets. For instance, UN 38.3, IEC 62133, UL 1642, and GB/T 31485 each prescribe different testing methodologies, making compliance a complex and resource-intensive process.

The reproducibility of test results presents another significant challenge. Thermal runaway events are inherently chaotic and can be influenced by subtle variations in test conditions, battery state of charge, ambient temperature, and even minor manufacturing inconsistencies. This variability makes it difficult to establish consistent pass/fail criteria that accurately predict real-world battery behavior.

Scale-up issues further complicate testing procedures. While single-cell testing protocols are relatively well-established, translating these to module or pack-level testing introduces new variables related to thermal propagation, heat dissipation, and system-level interactions. The behavior of a single cell in isolation often differs significantly from its behavior within a complete battery system, creating a disconnect between test results and real-world performance.

Current testing methods also struggle with the rapid pace of battery technology evolution. As manufacturers introduce new chemistries, form factors, and cell designs, existing test protocols may not adequately address their unique failure modes or thermal characteristics. This creates a perpetual lag between innovation and safety validation.

The time and cost constraints of comprehensive thermal runaway testing pose practical challenges for manufacturers. Destructive testing of production batteries represents a significant expense, particularly for high-capacity automotive or grid storage applications. This economic pressure can lead to insufficient sampling or testing shortcuts that compromise safety assurance.

Data interpretation remains subjective in many cases, with different experts drawing varying conclusions from the same test results. The industry lacks standardized metrics for quantifying thermal runaway severity, propagation rates, and overall safety margins, making comparative assessments difficult across different battery designs or manufacturers.

Finally, there is an ongoing challenge in correlating accelerated testing with real-world aging and failure scenarios. Current test methods often employ extreme conditions to induce thermal runaway, but these may not accurately represent the gradual degradation mechanisms that lead to failures in actual usage environments.

The reproducibility of test results presents another significant challenge. Thermal runaway events are inherently chaotic and can be influenced by subtle variations in test conditions, battery state of charge, ambient temperature, and even minor manufacturing inconsistencies. This variability makes it difficult to establish consistent pass/fail criteria that accurately predict real-world battery behavior.

Scale-up issues further complicate testing procedures. While single-cell testing protocols are relatively well-established, translating these to module or pack-level testing introduces new variables related to thermal propagation, heat dissipation, and system-level interactions. The behavior of a single cell in isolation often differs significantly from its behavior within a complete battery system, creating a disconnect between test results and real-world performance.

Current testing methods also struggle with the rapid pace of battery technology evolution. As manufacturers introduce new chemistries, form factors, and cell designs, existing test protocols may not adequately address their unique failure modes or thermal characteristics. This creates a perpetual lag between innovation and safety validation.

The time and cost constraints of comprehensive thermal runaway testing pose practical challenges for manufacturers. Destructive testing of production batteries represents a significant expense, particularly for high-capacity automotive or grid storage applications. This economic pressure can lead to insufficient sampling or testing shortcuts that compromise safety assurance.

Data interpretation remains subjective in many cases, with different experts drawing varying conclusions from the same test results. The industry lacks standardized metrics for quantifying thermal runaway severity, propagation rates, and overall safety margins, making comparative assessments difficult across different battery designs or manufacturers.

Finally, there is an ongoing challenge in correlating accelerated testing with real-world aging and failure scenarios. Current test methods often employ extreme conditions to induce thermal runaway, but these may not accurately represent the gradual degradation mechanisms that lead to failures in actual usage environments.

Existing Thermal Runaway Testing Protocols

01 Thermal runaway testing methods and standards

Various testing methods and standards have been developed to evaluate battery thermal runaway behavior. These include standardized protocols for inducing thermal runaway under controlled conditions, measuring temperature rise rates, gas emissions, and propagation characteristics. Testing standards often specify parameters such as heating rates, temperature thresholds, and safety criteria that batteries must meet to be considered safe for commercial use.- Thermal runaway testing methods and standards: Various testing methods and standards have been developed to evaluate battery thermal runaway behavior. These include standardized protocols for inducing thermal runaway under controlled conditions, measuring temperature rise rates, gas emissions, and propagation characteristics. Testing standards often specify parameters such as heating rates, temperature thresholds, and safety criteria that batteries must meet to be considered safe for commercial use.

- Battery design features to prevent thermal runaway: Innovative battery designs incorporate features specifically aimed at preventing thermal runaway or mitigating its effects. These include specialized separator materials with thermal shutdown properties, heat-resistant electrode coatings, and novel cell architectures that physically isolate cells from each other. Some designs also incorporate pressure relief mechanisms, thermal fuses, or phase-change materials that absorb excess heat during abnormal conditions.

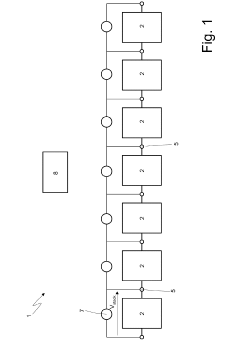

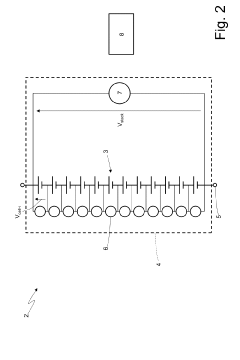

- Battery management systems for thermal runaway prevention: Advanced battery management systems (BMS) play a crucial role in preventing thermal runaway by continuously monitoring critical parameters such as temperature, voltage, and current. These systems employ algorithms to detect early signs of abnormal behavior and can take preventive actions like reducing charging current, activating cooling systems, or disconnecting cells. Some BMS designs incorporate machine learning to improve prediction accuracy of potential thermal events.

- Thermal runaway propagation prevention techniques: Preventing the spread of thermal runaway from one cell to adjacent cells is critical for battery pack safety. Techniques include physical barriers between cells, heat-absorbing materials, fire-resistant coatings, and strategic cell arrangement patterns. Some designs incorporate thermal isolation structures or intumescent materials that expand when heated to create insulating barriers. Testing standards specifically evaluate a battery's ability to contain thermal events without propagation.

- Cooling systems and thermal management for batteries: Effective thermal management systems are essential for preventing conditions that could lead to thermal runaway. These include active cooling methods using air, liquid, or refrigerant circulation, as well as passive approaches using phase change materials or heat pipes. Advanced thermal management designs target uniform temperature distribution across battery packs and rapid heat dissipation during high-load conditions. Testing protocols evaluate the effectiveness of these systems under various operating scenarios.

02 Battery design for thermal runaway prevention

Innovative battery designs incorporate features specifically aimed at preventing thermal runaway or mitigating its effects. These designs include improved electrode materials, separator technologies with thermal shutdown capabilities, and novel cell architectures that limit heat propagation. Some designs focus on structural modifications that can physically contain thermal events or incorporate heat dissipation pathways to reduce the risk of cascading failures.Expand Specific Solutions03 Thermal management systems for battery safety

Advanced thermal management systems are crucial for preventing thermal runaway in battery packs. These systems include active cooling mechanisms, phase change materials, and intelligent temperature monitoring solutions. Some approaches utilize liquid cooling circuits, while others employ air cooling or hybrid systems. The thermal management strategies are designed to maintain optimal operating temperatures and quickly respond to potential thermal events before they escalate.Expand Specific Solutions04 Detection and early warning systems for thermal runaway

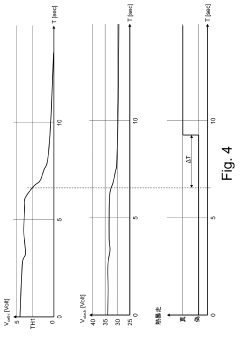

Early detection systems for thermal runaway employ various sensors and monitoring technologies to identify precursors to thermal events. These systems analyze parameters such as voltage fluctuations, internal resistance changes, gas emissions, and temperature gradients to predict potential failures. Advanced algorithms process this data in real-time to trigger preventive measures or safety protocols before a full thermal runaway occurs, significantly enhancing battery safety.Expand Specific Solutions05 Regulatory compliance and safety certification for battery systems

Battery systems must comply with various regulatory standards and undergo certification processes to ensure safety against thermal runaway. These regulations specify testing requirements, performance criteria, and safety features that must be incorporated into battery designs. Certification processes may include abuse testing, environmental exposure tests, and transportation safety evaluations. Compliance with these standards is essential for market approval and consumer confidence in battery technologies.Expand Specific Solutions

Key Industry Players in Battery Testing Standards

The thermal runaway testing standards landscape in battery manufacturing is evolving rapidly as the industry transitions from early development to commercial scale. The market is projected to grow significantly with increasing EV adoption, creating a competitive environment where established players and new entrants vie for position. Leading companies like Contemporary Amperex Technology, Samsung SDI, and EVE Energy are advancing proprietary testing protocols, while automotive manufacturers including Volkswagen, Hyundai Mobis, and Ferrari are integrating these standards into their supply chains. Research institutions such as Tsinghua University and certification bodies like UL LLC are collaborating with industry to develop unified standards that balance innovation with safety requirements across global markets.

Volkswagen AG

Technical Solution: Volkswagen has developed comprehensive thermal runaway testing standards specifically optimized for automotive applications, with particular emphasis on large-format cells used in their MEB electric vehicle platform. Their testing protocol includes vehicle-level crash simulation tests that evaluate thermal behavior during mechanical impacts, vibration profile testing that simulates real-world driving conditions over hundreds of thousands of kilometers, and environmental cycling tests that combine temperature extremes with rapid charging scenarios. Volkswagen's approach incorporates specialized testing for thermal propagation between cells in module configurations, using both physical testing and computational fluid dynamics modeling to predict heat transfer pathways. Their standards include evaluation of thermal management system effectiveness under various failure modes, with particular attention to coolant leakage scenarios. Volkswagen has implemented automated production line testing that incorporates thermal imaging and impedance spectroscopy to detect manufacturing defects that could lead to thermal instability. Their testing methodology includes long-duration testing (>1000 hours) under boundary operating conditions to evaluate gradual degradation mechanisms that might compromise thermal stability.

Strengths: Testing protocols reflect real-world automotive use cases with high fidelity; integration of thermal runaway testing with broader vehicle safety systems provides comprehensive safety evaluation. Weakness: Testing standards are primarily developed for their specific battery suppliers and cell formats; heavy focus on automotive use cases limits applicability to other battery applications such as stationary storage.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive multi-stage thermal runaway testing protocol that combines mechanical, electrical, and thermal abuse tests to evaluate battery safety. Their approach includes nail penetration tests with real-time thermal imaging, overcharge tests up to 200% of rated capacity, and thermal propagation tests using specialized heating elements to simulate cell-to-cell propagation. Samsung's testing standards incorporate a proprietary Battery Management System (BMS) that continuously monitors for thermal anomalies with temperature gradient mapping across cells. Their protocol exceeds the requirements of international standards like IEC 62133 and UN 38.3, implementing stricter pass/fail criteria with safety margins 20-30% higher than industry minimums. Samsung also utilizes accelerated aging tests to evaluate thermal stability degradation over battery lifetime, simulating up to 10 years of operational conditions.

Strengths: Industry-leading thermal imaging technology provides microsecond-level detection of thermal events; comprehensive testing across multiple abuse scenarios ensures robust safety validation. Weakness: Their proprietary testing equipment and protocols create barriers to standardization across the industry; testing methodology is optimized for their specific cell chemistry and may not translate well to other manufacturers' cells.

Critical Technologies for Thermal Event Detection

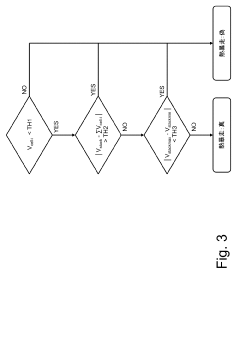

Method for diagnosis of thermal runaway in electric battery

PatentPendingJP2023072679A

Innovation

- A diagnostic method using voltage measurements across individual and stacked electrochemical cells, comparing cell and stack voltages against predefined thresholds, with confirmation times to ensure accuracy, without relying on thermal information.

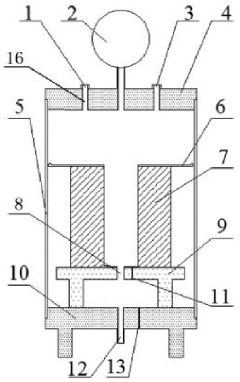

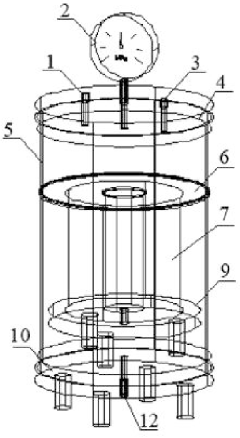

Method For Collecting And Testing Lithium Ion Battery Thermal Runaway Products

PatentInactiveAU2020100862A4

Innovation

- A method involving a lithium ion battery thermal runaway gas and solid product collecting and testing system that induces thermal runaway through electrical heating, separates and filters gas and solid products, and performs online and offline tests using gas analyzers and chromatography-mass spectrometry for gas analysis and thermal stability testing of solids.

Regulatory Framework for Battery Manufacturing

The regulatory landscape for battery manufacturing has evolved significantly in response to safety concerns, particularly regarding thermal runaway events. International organizations such as the International Electrotechnical Commission (IEC) have established comprehensive standards, with IEC 62133 serving as a cornerstone for safety requirements in portable batteries. This standard specifically addresses thermal abuse testing protocols to evaluate battery behavior under extreme temperature conditions.

In the United States, the regulatory framework is primarily governed by UL (Underwriters Laboratories) standards, particularly UL 1642 for lithium batteries and UL 2054 for household batteries. These standards mandate specific thermal runaway testing procedures, including nail penetration tests, crush tests, and thermal shock evaluations. The Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have also implemented regulations for the safe transport of lithium batteries, requiring manufacturers to demonstrate thermal stability through standardized testing.

The European Union has established the Battery Directive (2006/66/EC, updated in 2013) which, while primarily focused on environmental aspects, incorporates safety requirements that necessitate thermal runaway testing. Additionally, the UN Manual of Tests and Criteria, particularly Test Series T.6, provides internationally recognized protocols for thermal testing that manufacturers must adhere to for global market access.

China's regulatory framework has become increasingly stringent, with GB/T 31485-2015 standard specifically addressing safety requirements for traction battery packs and systems in electric vehicles. This standard includes detailed thermal runaway testing protocols that manufacturers must follow to obtain market certification.

Japan's regulatory approach, led by the Ministry of Economy, Trade and Industry (METI), has implemented technical standards for electrical appliances that include specific requirements for battery safety testing. The JIS C8714 standard provides detailed guidelines for abuse testing of portable lithium-ion cells and batteries.

Recent regulatory developments have focused on harmonizing global standards while addressing emerging battery technologies. The Global Technical Regulation (GTR) No. 20 on Electric Vehicle Safety represents a significant step toward international regulatory alignment, including standardized approaches to thermal runaway testing and mitigation strategies.

Compliance with these regulatory frameworks requires manufacturers to implement robust quality control systems and testing protocols throughout the production process. This includes in-line testing capabilities, batch sampling methodologies, and documentation procedures that demonstrate adherence to the prescribed safety standards.

In the United States, the regulatory framework is primarily governed by UL (Underwriters Laboratories) standards, particularly UL 1642 for lithium batteries and UL 2054 for household batteries. These standards mandate specific thermal runaway testing procedures, including nail penetration tests, crush tests, and thermal shock evaluations. The Department of Transportation (DOT) and the Pipeline and Hazardous Materials Safety Administration (PHMSA) have also implemented regulations for the safe transport of lithium batteries, requiring manufacturers to demonstrate thermal stability through standardized testing.

The European Union has established the Battery Directive (2006/66/EC, updated in 2013) which, while primarily focused on environmental aspects, incorporates safety requirements that necessitate thermal runaway testing. Additionally, the UN Manual of Tests and Criteria, particularly Test Series T.6, provides internationally recognized protocols for thermal testing that manufacturers must adhere to for global market access.

China's regulatory framework has become increasingly stringent, with GB/T 31485-2015 standard specifically addressing safety requirements for traction battery packs and systems in electric vehicles. This standard includes detailed thermal runaway testing protocols that manufacturers must follow to obtain market certification.

Japan's regulatory approach, led by the Ministry of Economy, Trade and Industry (METI), has implemented technical standards for electrical appliances that include specific requirements for battery safety testing. The JIS C8714 standard provides detailed guidelines for abuse testing of portable lithium-ion cells and batteries.

Recent regulatory developments have focused on harmonizing global standards while addressing emerging battery technologies. The Global Technical Regulation (GTR) No. 20 on Electric Vehicle Safety represents a significant step toward international regulatory alignment, including standardized approaches to thermal runaway testing and mitigation strategies.

Compliance with these regulatory frameworks requires manufacturers to implement robust quality control systems and testing protocols throughout the production process. This includes in-line testing capabilities, batch sampling methodologies, and documentation procedures that demonstrate adherence to the prescribed safety standards.

Environmental Impact of Battery Testing Procedures

Battery testing procedures, particularly those focused on thermal runaway events, have significant environmental implications that extend beyond the immediate safety concerns. The environmental footprint of these testing protocols encompasses multiple dimensions, from resource consumption to waste generation and emissions. Standard thermal runaway tests typically require multiple battery units to be sacrificed during the validation process, contributing to resource depletion and electronic waste accumulation.

The energy consumption associated with thermal runaway testing is substantial. High-temperature ovens, thermal chambers, and specialized equipment used in these procedures often operate continuously for extended periods, resulting in considerable electricity usage. This energy demand translates to indirect carbon emissions, particularly in regions where the energy grid relies heavily on fossil fuels. A single comprehensive battery testing program can consume energy equivalent to powering dozens of households for several days.

Chemical emissions present another environmental concern. During controlled thermal runaway events, batteries release various gases including hydrogen fluoride, carbon monoxide, and volatile organic compounds. While testing facilities typically employ filtration and scrubbing systems, the complete capture of all emissions remains challenging. Residual releases contribute to air pollution and potential soil contamination in surrounding areas if not properly managed.

Water usage in cooling systems and fire suppression equipment represents another environmental impact vector. Advanced testing facilities may require thousands of gallons of water for safety systems, with potential for contamination by electrolytes and heavy metals if wastewater treatment is inadequate. The chemical-laden water requires specialized treatment before environmental release, adding another layer of resource consumption.

The disposal of post-test materials presents significant challenges. Batteries that have undergone thermal events contain degraded materials that are difficult to recycle through conventional means. The altered chemical composition often renders standard recycling processes ineffective, resulting in specialized waste streams that frequently end up in hazardous waste facilities rather than being reclaimed.

Recent innovations are beginning to address these environmental concerns. Virtual testing environments using sophisticated computational models can reduce the number of physical tests required. Closed-loop testing systems that capture and neutralize emissions are becoming more common in advanced facilities. Additionally, some manufacturers are developing specialized recycling processes specifically designed for post-test battery materials, allowing for higher material recovery rates from these previously problematic waste streams.

The energy consumption associated with thermal runaway testing is substantial. High-temperature ovens, thermal chambers, and specialized equipment used in these procedures often operate continuously for extended periods, resulting in considerable electricity usage. This energy demand translates to indirect carbon emissions, particularly in regions where the energy grid relies heavily on fossil fuels. A single comprehensive battery testing program can consume energy equivalent to powering dozens of households for several days.

Chemical emissions present another environmental concern. During controlled thermal runaway events, batteries release various gases including hydrogen fluoride, carbon monoxide, and volatile organic compounds. While testing facilities typically employ filtration and scrubbing systems, the complete capture of all emissions remains challenging. Residual releases contribute to air pollution and potential soil contamination in surrounding areas if not properly managed.

Water usage in cooling systems and fire suppression equipment represents another environmental impact vector. Advanced testing facilities may require thousands of gallons of water for safety systems, with potential for contamination by electrolytes and heavy metals if wastewater treatment is inadequate. The chemical-laden water requires specialized treatment before environmental release, adding another layer of resource consumption.

The disposal of post-test materials presents significant challenges. Batteries that have undergone thermal events contain degraded materials that are difficult to recycle through conventional means. The altered chemical composition often renders standard recycling processes ineffective, resulting in specialized waste streams that frequently end up in hazardous waste facilities rather than being reclaimed.

Recent innovations are beginning to address these environmental concerns. Virtual testing environments using sophisticated computational models can reduce the number of physical tests required. Closed-loop testing systems that capture and neutralize emissions are becoming more common in advanced facilities. Additionally, some manufacturers are developing specialized recycling processes specifically designed for post-test battery materials, allowing for higher material recovery rates from these previously problematic waste streams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!