Strategic Role of Ethyl Acetate in Next‑Gen Manufacturing

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ethyl Acetate Evolution

Ethyl acetate has undergone a significant evolution in its role within manufacturing processes, transitioning from a simple solvent to a key component in next-generation production techniques. Initially discovered in the 19th century, ethyl acetate's journey began as a byproduct of ethanol fermentation. Its early applications were limited to basic solvent uses in industries such as paints and coatings.

The mid-20th century marked a turning point for ethyl acetate as its potential in various industrial processes became more apparent. Advancements in chemical engineering and production methods led to more efficient and cost-effective synthesis of ethyl acetate, primarily through the esterification of ethanol and acetic acid. This development expanded its availability and opened doors to new applications across diverse sectors.

In recent decades, ethyl acetate has seen a remarkable transformation in its strategic importance. The rise of green chemistry principles and the push for more sustainable manufacturing practices have positioned ethyl acetate as a preferred alternative to more harmful solvents. Its low toxicity, biodegradability, and relatively low environmental impact have made it increasingly attractive in industries striving for eco-friendly solutions.

The electronics industry, in particular, has embraced ethyl acetate as a crucial component in the production of advanced materials. Its role in the manufacture of flexible displays, printed electronics, and other cutting-edge technologies has solidified its position as a strategic material in high-tech manufacturing. The compound's unique properties, including its ability to dissolve a wide range of substances without damaging sensitive electronic components, have made it indispensable in precision cleaning and etching processes.

Furthermore, the pharmaceutical industry has leveraged ethyl acetate's properties in drug development and production. Its use in extraction processes, chromatography, and as a reaction medium has contributed to more efficient and environmentally friendly drug manufacturing techniques. This evolution has positioned ethyl acetate as a critical component in the development of next-generation pharmaceuticals and biotechnology products.

Looking ahead, the trajectory of ethyl acetate in next-gen manufacturing appears poised for continued growth and innovation. Emerging technologies such as 3D printing and nanomaterials production are exploring new applications for ethyl acetate, further expanding its strategic importance. Additionally, ongoing research into bio-based production methods for ethyl acetate aligns with the global trend towards sustainable and circular economy principles, potentially revolutionizing its sourcing and environmental footprint in the coming years.

The mid-20th century marked a turning point for ethyl acetate as its potential in various industrial processes became more apparent. Advancements in chemical engineering and production methods led to more efficient and cost-effective synthesis of ethyl acetate, primarily through the esterification of ethanol and acetic acid. This development expanded its availability and opened doors to new applications across diverse sectors.

In recent decades, ethyl acetate has seen a remarkable transformation in its strategic importance. The rise of green chemistry principles and the push for more sustainable manufacturing practices have positioned ethyl acetate as a preferred alternative to more harmful solvents. Its low toxicity, biodegradability, and relatively low environmental impact have made it increasingly attractive in industries striving for eco-friendly solutions.

The electronics industry, in particular, has embraced ethyl acetate as a crucial component in the production of advanced materials. Its role in the manufacture of flexible displays, printed electronics, and other cutting-edge technologies has solidified its position as a strategic material in high-tech manufacturing. The compound's unique properties, including its ability to dissolve a wide range of substances without damaging sensitive electronic components, have made it indispensable in precision cleaning and etching processes.

Furthermore, the pharmaceutical industry has leveraged ethyl acetate's properties in drug development and production. Its use in extraction processes, chromatography, and as a reaction medium has contributed to more efficient and environmentally friendly drug manufacturing techniques. This evolution has positioned ethyl acetate as a critical component in the development of next-generation pharmaceuticals and biotechnology products.

Looking ahead, the trajectory of ethyl acetate in next-gen manufacturing appears poised for continued growth and innovation. Emerging technologies such as 3D printing and nanomaterials production are exploring new applications for ethyl acetate, further expanding its strategic importance. Additionally, ongoing research into bio-based production methods for ethyl acetate aligns with the global trend towards sustainable and circular economy principles, potentially revolutionizing its sourcing and environmental footprint in the coming years.

Market Demand Analysis

The market demand for ethyl acetate in next-generation manufacturing is experiencing significant growth, driven by its versatile applications across various industries. As a key solvent and reagent, ethyl acetate plays a crucial role in the production of advanced materials, pharmaceuticals, and electronic components.

In the pharmaceutical sector, the increasing focus on personalized medicine and biopharmaceuticals has led to a surge in demand for high-purity solvents like ethyl acetate. Its use in the extraction and purification of active pharmaceutical ingredients (APIs) is becoming more prevalent, particularly in the production of complex drug formulations and novel therapies.

The electronics industry, a cornerstone of next-generation manufacturing, is another major driver of ethyl acetate demand. As consumer electronics become more sophisticated and miniaturized, the need for precision cleaning agents in the production of semiconductors, printed circuit boards, and display panels has intensified. Ethyl acetate's low toxicity and excellent solvency properties make it an ideal choice for these applications.

In the realm of advanced materials, ethyl acetate is gaining traction in the production of high-performance coatings, adhesives, and composites. The automotive and aerospace industries, in particular, are increasingly adopting these materials to enhance fuel efficiency and reduce weight, thereby driving up the demand for ethyl acetate in their manufacturing processes.

The global shift towards sustainable manufacturing practices has also influenced the market dynamics of ethyl acetate. Its biodegradability and potential for bio-based production align well with the growing emphasis on green chemistry and circular economy principles. This has opened up new market opportunities, especially in regions with stringent environmental regulations.

Geographically, the Asia-Pacific region is expected to dominate the ethyl acetate market, fueled by rapid industrialization and the expansion of manufacturing capabilities in countries like China and India. North America and Europe are also significant markets, primarily driven by innovations in pharmaceuticals and advanced materials.

The market demand for ethyl acetate is further bolstered by its role in emerging technologies such as 3D printing and nanotechnology. These cutting-edge fields require high-purity solvents for material processing and surface treatments, positioning ethyl acetate as a critical component in their development and scaling.

As industries continue to evolve and embrace more sophisticated manufacturing techniques, the strategic importance of ethyl acetate is likely to grow. Its ability to meet the diverse needs of next-generation manufacturing processes, coupled with its environmental credentials, positions it as a key chemical in the ongoing industrial transformation.

In the pharmaceutical sector, the increasing focus on personalized medicine and biopharmaceuticals has led to a surge in demand for high-purity solvents like ethyl acetate. Its use in the extraction and purification of active pharmaceutical ingredients (APIs) is becoming more prevalent, particularly in the production of complex drug formulations and novel therapies.

The electronics industry, a cornerstone of next-generation manufacturing, is another major driver of ethyl acetate demand. As consumer electronics become more sophisticated and miniaturized, the need for precision cleaning agents in the production of semiconductors, printed circuit boards, and display panels has intensified. Ethyl acetate's low toxicity and excellent solvency properties make it an ideal choice for these applications.

In the realm of advanced materials, ethyl acetate is gaining traction in the production of high-performance coatings, adhesives, and composites. The automotive and aerospace industries, in particular, are increasingly adopting these materials to enhance fuel efficiency and reduce weight, thereby driving up the demand for ethyl acetate in their manufacturing processes.

The global shift towards sustainable manufacturing practices has also influenced the market dynamics of ethyl acetate. Its biodegradability and potential for bio-based production align well with the growing emphasis on green chemistry and circular economy principles. This has opened up new market opportunities, especially in regions with stringent environmental regulations.

Geographically, the Asia-Pacific region is expected to dominate the ethyl acetate market, fueled by rapid industrialization and the expansion of manufacturing capabilities in countries like China and India. North America and Europe are also significant markets, primarily driven by innovations in pharmaceuticals and advanced materials.

The market demand for ethyl acetate is further bolstered by its role in emerging technologies such as 3D printing and nanotechnology. These cutting-edge fields require high-purity solvents for material processing and surface treatments, positioning ethyl acetate as a critical component in their development and scaling.

As industries continue to evolve and embrace more sophisticated manufacturing techniques, the strategic importance of ethyl acetate is likely to grow. Its ability to meet the diverse needs of next-generation manufacturing processes, coupled with its environmental credentials, positions it as a key chemical in the ongoing industrial transformation.

Technical Challenges

The adoption of ethyl acetate in next-generation manufacturing faces several significant technical challenges that need to be addressed for its widespread implementation. One of the primary obstacles is the optimization of production processes to enhance efficiency and reduce costs. Current manufacturing methods often involve energy-intensive steps and generate substantial waste, making large-scale production economically challenging.

Another critical issue is the development of more sustainable and environmentally friendly production routes. Traditional synthesis of ethyl acetate relies heavily on petrochemical feedstocks, which raises concerns about long-term sustainability and environmental impact. Researchers are exploring bio-based alternatives and green chemistry approaches, but these methods often struggle with scalability and cost-effectiveness.

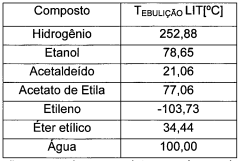

The purification and separation of ethyl acetate from reaction mixtures present additional technical hurdles. Conventional distillation techniques are energy-intensive and may not be suitable for all manufacturing scenarios. Advanced separation technologies, such as membrane-based processes or reactive distillation, show promise but require further development to meet industrial-scale requirements.

Storage and handling of ethyl acetate pose challenges due to its volatility and flammability. Next-generation manufacturing facilities need to implement robust safety measures and develop innovative containment solutions to mitigate risks associated with large-scale storage and transportation.

The integration of ethyl acetate production and utilization into existing manufacturing processes is another area of technical complexity. Many industries are exploring the potential of ethyl acetate as a greener solvent alternative, but retrofitting existing equipment and processes to accommodate this shift can be technically demanding and costly.

Quality control and purity standards present ongoing challenges, particularly as ethyl acetate finds applications in sensitive industries such as pharmaceuticals and electronics. Developing reliable, cost-effective methods for real-time monitoring and ensuring consistent product quality is crucial for widespread adoption.

Lastly, the development of novel applications for ethyl acetate in advanced materials and processes is hindered by limitations in our understanding of its behavior in complex systems. Further research is needed to explore its potential in areas such as nanotechnology, advanced coatings, and smart materials, which could open new avenues for next-generation manufacturing but require overcoming significant technical barriers.

Another critical issue is the development of more sustainable and environmentally friendly production routes. Traditional synthesis of ethyl acetate relies heavily on petrochemical feedstocks, which raises concerns about long-term sustainability and environmental impact. Researchers are exploring bio-based alternatives and green chemistry approaches, but these methods often struggle with scalability and cost-effectiveness.

The purification and separation of ethyl acetate from reaction mixtures present additional technical hurdles. Conventional distillation techniques are energy-intensive and may not be suitable for all manufacturing scenarios. Advanced separation technologies, such as membrane-based processes or reactive distillation, show promise but require further development to meet industrial-scale requirements.

Storage and handling of ethyl acetate pose challenges due to its volatility and flammability. Next-generation manufacturing facilities need to implement robust safety measures and develop innovative containment solutions to mitigate risks associated with large-scale storage and transportation.

The integration of ethyl acetate production and utilization into existing manufacturing processes is another area of technical complexity. Many industries are exploring the potential of ethyl acetate as a greener solvent alternative, but retrofitting existing equipment and processes to accommodate this shift can be technically demanding and costly.

Quality control and purity standards present ongoing challenges, particularly as ethyl acetate finds applications in sensitive industries such as pharmaceuticals and electronics. Developing reliable, cost-effective methods for real-time monitoring and ensuring consistent product quality is crucial for widespread adoption.

Lastly, the development of novel applications for ethyl acetate in advanced materials and processes is hindered by limitations in our understanding of its behavior in complex systems. Further research is needed to explore its potential in areas such as nanotechnology, advanced coatings, and smart materials, which could open new avenues for next-generation manufacturing but require overcoming significant technical barriers.

Current Production Methods

01 Production and purification of ethyl acetate

Various methods for producing and purifying ethyl acetate are described, including esterification processes, distillation techniques, and the use of catalysts. These processes aim to improve the yield and purity of ethyl acetate, which is an important industrial solvent and chemical intermediate.- Production and purification of ethyl acetate: Various methods for producing and purifying ethyl acetate are described. These include esterification processes, distillation techniques, and the use of specific catalysts to improve yield and purity. The processes aim to optimize the production of ethyl acetate for industrial applications.

- Applications of ethyl acetate in chemical processes: Ethyl acetate is utilized in diverse chemical processes, including as a solvent in extractions, as a reaction medium, and in the synthesis of other compounds. Its properties make it suitable for use in various industries such as pharmaceuticals, coatings, and adhesives.

- Ethyl acetate in polymer and material science: Ethyl acetate plays a role in polymer and material science applications. It is used in the preparation of polymers, as a solvent in coating formulations, and in the development of advanced materials with specific properties.

- Environmental and safety considerations for ethyl acetate: Research and development efforts focus on improving the environmental impact and safety aspects of ethyl acetate production and use. This includes developing greener production methods, improving handling and storage techniques, and assessing potential health effects.

- Novel applications and derivatives of ethyl acetate: Ongoing research explores new applications and derivatives of ethyl acetate. This includes its use in emerging technologies, development of novel compounds based on ethyl acetate, and investigation of its potential in fields such as energy storage and biotechnology.

02 Applications of ethyl acetate in chemical processes

Ethyl acetate is utilized in diverse chemical processes, such as extraction, separation, and as a reaction medium. Its properties make it suitable for use in the production of various compounds, including pharmaceuticals, polymers, and other industrial chemicals.Expand Specific Solutions03 Ethyl acetate in coating and adhesive formulations

Ethyl acetate is a key component in many coating and adhesive formulations due to its solvent properties and low toxicity. It is used in the production of paints, varnishes, and adhesives, contributing to improved application characteristics and performance of these products.Expand Specific Solutions04 Recovery and recycling of ethyl acetate

Methods for recovering and recycling ethyl acetate from industrial processes are described. These techniques aim to reduce waste, improve process efficiency, and minimize environmental impact by reusing the solvent in various applications.Expand Specific Solutions05 Ethyl acetate as a green solvent alternative

Ethyl acetate is explored as an environmentally friendly alternative to more hazardous solvents in various industrial applications. Its relatively low toxicity and biodegradability make it an attractive option for sustainable chemical processes and product formulations.Expand Specific Solutions

Industry Leaders

The strategic role of ethyl acetate in next-generation manufacturing is characterized by a competitive landscape in a mature yet evolving industry. The market is substantial, with key players like Celanese International Corp., Eastman Chemical Co., and China Petroleum & Chemical Corp. dominating production. Technological maturity is high, but innovation continues, particularly in sustainable production methods. Research institutions such as Dalian Institute of Chemical Physics and universities like Tianjin University and Rice University are driving advancements. Emerging companies like Viridis Chemical LLC are focusing on bio-based ethyl acetate, indicating a shift towards greener manufacturing processes. This trend suggests that while the industry is established, there's potential for disruption through eco-friendly innovations.

Celanese International Corp.

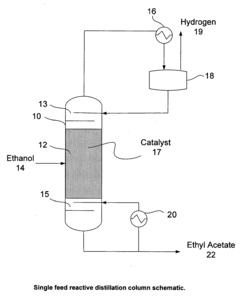

Technical Solution: Celanese has developed an innovative process for ethyl acetate production using advanced catalysts and reactive distillation technology. This method allows for the direct esterification of ethanol and acetic acid in a single step, significantly improving efficiency and reducing energy consumption[1]. The company has also implemented a bio-based feedstock approach, utilizing renewable ethanol sources to produce more sustainable ethyl acetate[2]. Additionally, Celanese has invested in process intensification techniques, such as membrane separation, to further optimize production and reduce environmental impact[3].

Strengths: High efficiency, reduced energy consumption, sustainable feedstock options. Weaknesses: Potential higher initial investment costs, dependence on ethanol and acetic acid market prices.

Eastman Chemical Co.

Technical Solution: Eastman Chemical has developed a proprietary hydrogenation process for ethyl acetate production, which utilizes ethylene and acetic acid as raw materials. This method offers improved atom economy and reduces waste generation compared to traditional processes[4]. The company has also implemented advanced process control systems and machine learning algorithms to optimize reaction conditions and product quality in real-time[5]. Furthermore, Eastman has explored the use of bio-based acetic acid in their ethyl acetate production, aligning with sustainability goals and reducing carbon footprint[6].

Strengths: Improved atom economy, reduced waste, advanced process control. Weaknesses: Reliance on ethylene availability, potential complexity in process control systems.

Key Innovations

Ethyl Acetate Production

PatentActiveUS20120178962A1

Innovation

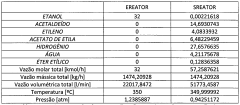

- A reactive distillation process using a single reactive distillation column where ethanol is dehydrogenated over a catalyst to produce ethyl acetate and hydrogen, with optional hydrogenation of byproducts to simplify separation and achieve high purity ethyl acetate, utilizing catalysts like copper, ruthenium, and platinum supported on materials like carbon or alumina.

Integrated system for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, integrated process for producing ethyl acetate, acetaldehyde, hydrogen and ethylene, and products thereby produced

PatentWO2013029129A1

Innovation

- An integrated system utilizing a fixed-bed reactor with a calcined hydrotalcite catalyst for dehydrogenation and dehydration of ethanol, followed by a series of distillation columns for efficient separation and purification, employing ethylene glycol as a solvent to separate ethyl acetate from water, thereby reducing energy expenditure and minimizing azeotropy issues.

Sustainability Aspects

Ethyl acetate's role in next-generation manufacturing is increasingly being scrutinized through the lens of sustainability. As industries strive to reduce their environmental footprint, the production and use of ethyl acetate present both challenges and opportunities for sustainable practices.

The manufacturing process of ethyl acetate traditionally involves the reaction of ethanol with acetic acid, often using sulfuric acid as a catalyst. This process, while efficient, raises sustainability concerns due to the use of fossil fuel-derived feedstocks and energy-intensive production methods. However, recent advancements in green chemistry have led to the development of more sustainable production routes.

One promising approach is the use of bio-based feedstocks for ethyl acetate production. Ethanol derived from renewable sources such as corn or sugarcane can replace petroleum-based ethanol, significantly reducing the carbon footprint of the production process. Similarly, acetic acid can be produced through fermentation of biomass, further enhancing the sustainability profile of ethyl acetate.

Energy efficiency in manufacturing is another critical aspect of sustainability. Next-generation production facilities are implementing advanced process control systems and heat integration techniques to minimize energy consumption. Additionally, the use of renewable energy sources in manufacturing plants is becoming more prevalent, further reducing the environmental impact of ethyl acetate production.

Waste reduction and circular economy principles are also being applied to ethyl acetate manufacturing. Improved catalysts and reaction conditions are enabling higher yields and selectivity, reducing the generation of by-products and waste. Furthermore, innovative recycling technologies are being developed to recover and reuse ethyl acetate from industrial processes, closing the loop in its lifecycle.

The end-use applications of ethyl acetate also contribute to its sustainability profile. As a less toxic alternative to many other solvents, ethyl acetate plays a role in reducing the overall environmental impact of various industries. Its use in water-based coatings and adhesives, for instance, helps in reducing volatile organic compound (VOC) emissions.

However, challenges remain in fully realizing the sustainable potential of ethyl acetate. The scale-up of bio-based production methods, the development of more efficient catalysts, and the implementation of comprehensive recycling systems are areas that require continued research and investment. Additionally, life cycle assessments are crucial to accurately quantify the environmental benefits of different production and use scenarios.

As industries move towards more sustainable practices, the strategic role of ethyl acetate in next-generation manufacturing will likely be defined by its ability to meet both performance and environmental criteria. The ongoing efforts to enhance its sustainability aspects will be key to its continued importance in various industrial applications.

The manufacturing process of ethyl acetate traditionally involves the reaction of ethanol with acetic acid, often using sulfuric acid as a catalyst. This process, while efficient, raises sustainability concerns due to the use of fossil fuel-derived feedstocks and energy-intensive production methods. However, recent advancements in green chemistry have led to the development of more sustainable production routes.

One promising approach is the use of bio-based feedstocks for ethyl acetate production. Ethanol derived from renewable sources such as corn or sugarcane can replace petroleum-based ethanol, significantly reducing the carbon footprint of the production process. Similarly, acetic acid can be produced through fermentation of biomass, further enhancing the sustainability profile of ethyl acetate.

Energy efficiency in manufacturing is another critical aspect of sustainability. Next-generation production facilities are implementing advanced process control systems and heat integration techniques to minimize energy consumption. Additionally, the use of renewable energy sources in manufacturing plants is becoming more prevalent, further reducing the environmental impact of ethyl acetate production.

Waste reduction and circular economy principles are also being applied to ethyl acetate manufacturing. Improved catalysts and reaction conditions are enabling higher yields and selectivity, reducing the generation of by-products and waste. Furthermore, innovative recycling technologies are being developed to recover and reuse ethyl acetate from industrial processes, closing the loop in its lifecycle.

The end-use applications of ethyl acetate also contribute to its sustainability profile. As a less toxic alternative to many other solvents, ethyl acetate plays a role in reducing the overall environmental impact of various industries. Its use in water-based coatings and adhesives, for instance, helps in reducing volatile organic compound (VOC) emissions.

However, challenges remain in fully realizing the sustainable potential of ethyl acetate. The scale-up of bio-based production methods, the development of more efficient catalysts, and the implementation of comprehensive recycling systems are areas that require continued research and investment. Additionally, life cycle assessments are crucial to accurately quantify the environmental benefits of different production and use scenarios.

As industries move towards more sustainable practices, the strategic role of ethyl acetate in next-generation manufacturing will likely be defined by its ability to meet both performance and environmental criteria. The ongoing efforts to enhance its sustainability aspects will be key to its continued importance in various industrial applications.

Regulatory Compliance

Regulatory compliance plays a crucial role in the strategic implementation of ethyl acetate in next-generation manufacturing processes. As industries increasingly adopt this versatile solvent, adherence to evolving regulatory frameworks becomes paramount for sustainable and responsible production practices.

The regulatory landscape for ethyl acetate encompasses various aspects, including environmental protection, workplace safety, and product quality standards. Environmental regulations focus on emissions control, waste management, and the prevention of soil and water contamination. Manufacturers must implement robust systems to monitor and mitigate potential environmental impacts associated with ethyl acetate usage.

Occupational health and safety regulations govern the handling, storage, and use of ethyl acetate in industrial settings. These regulations typically mandate proper ventilation systems, personal protective equipment, and employee training programs to minimize exposure risks. Compliance with these standards is essential for maintaining a safe working environment and avoiding potential legal liabilities.

Product quality and safety regulations are particularly relevant for industries utilizing ethyl acetate in consumer goods production. These regulations often specify permissible levels of ethyl acetate residues in final products, necessitating stringent quality control measures throughout the manufacturing process.

The global nature of modern supply chains introduces additional complexity to regulatory compliance. Manufacturers must navigate varying regulatory requirements across different jurisdictions, ensuring their ethyl acetate-based processes and products meet the most stringent standards applicable in their target markets.

Emerging trends in regulatory frameworks include a growing emphasis on circular economy principles and lifecycle assessments. This shift may lead to new regulations promoting the recycling and reuse of ethyl acetate in manufacturing processes, as well as requirements for more comprehensive environmental impact reporting.

To effectively manage regulatory compliance, companies integrating ethyl acetate into their next-generation manufacturing processes should adopt proactive strategies. These may include implementing robust compliance management systems, engaging in regular regulatory monitoring and impact assessments, and participating in industry initiatives to shape future regulatory developments.

Collaboration with regulatory bodies, industry associations, and research institutions can provide valuable insights into upcoming regulatory changes and help companies align their ethyl acetate utilization strategies with evolving compliance requirements. This proactive approach not only ensures regulatory adherence but also positions companies as responsible industry leaders, potentially offering competitive advantages in increasingly environmentally conscious markets.

The regulatory landscape for ethyl acetate encompasses various aspects, including environmental protection, workplace safety, and product quality standards. Environmental regulations focus on emissions control, waste management, and the prevention of soil and water contamination. Manufacturers must implement robust systems to monitor and mitigate potential environmental impacts associated with ethyl acetate usage.

Occupational health and safety regulations govern the handling, storage, and use of ethyl acetate in industrial settings. These regulations typically mandate proper ventilation systems, personal protective equipment, and employee training programs to minimize exposure risks. Compliance with these standards is essential for maintaining a safe working environment and avoiding potential legal liabilities.

Product quality and safety regulations are particularly relevant for industries utilizing ethyl acetate in consumer goods production. These regulations often specify permissible levels of ethyl acetate residues in final products, necessitating stringent quality control measures throughout the manufacturing process.

The global nature of modern supply chains introduces additional complexity to regulatory compliance. Manufacturers must navigate varying regulatory requirements across different jurisdictions, ensuring their ethyl acetate-based processes and products meet the most stringent standards applicable in their target markets.

Emerging trends in regulatory frameworks include a growing emphasis on circular economy principles and lifecycle assessments. This shift may lead to new regulations promoting the recycling and reuse of ethyl acetate in manufacturing processes, as well as requirements for more comprehensive environmental impact reporting.

To effectively manage regulatory compliance, companies integrating ethyl acetate into their next-generation manufacturing processes should adopt proactive strategies. These may include implementing robust compliance management systems, engaging in regular regulatory monitoring and impact assessments, and participating in industry initiatives to shape future regulatory developments.

Collaboration with regulatory bodies, industry associations, and research institutions can provide valuable insights into upcoming regulatory changes and help companies align their ethyl acetate utilization strategies with evolving compliance requirements. This proactive approach not only ensures regulatory adherence but also positions companies as responsible industry leaders, potentially offering competitive advantages in increasingly environmentally conscious markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!