TIM Dielectric Versus Conductive: When Electrical Insulation Matters

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Types and Development Objectives

Thermal Interface Materials (TIMs) can be broadly categorized into two main types based on their electrical properties: dielectric (electrically insulating) and conductive. This distinction plays a crucial role in determining the appropriate application scenarios for each type. Dielectric TIMs maintain electrical isolation between components while facilitating thermal transfer, making them ideal for applications where preventing electrical shorts is paramount, such as between semiconductor devices and heat sinks in consumer electronics.

Conductive TIMs, conversely, provide both thermal and electrical conductivity pathways. These materials are typically utilized in applications requiring electrical grounding or EMI shielding alongside thermal management, such as in power electronics or certain military and aerospace applications where electrical continuity between components is beneficial rather than problematic.

The development objectives for TIMs have evolved significantly over recent years, driven by increasing power densities in electronic devices and the miniaturization trend across industries. Primary objectives now include achieving higher thermal conductivity values (exceeding 10 W/m·K) while maintaining appropriate electrical properties for specific applications. For dielectric TIMs, this means preserving high electrical resistance (typically >10^9 ohm·cm) while improving thermal performance.

Another critical development goal is enhancing reliability under thermal cycling conditions. Modern TIMs must maintain performance integrity through thousands of thermal cycles without degradation, pump-out, or dry-out effects. This is particularly challenging for dielectric materials, which often rely on polymer matrices that can be susceptible to thermal aging.

Application-specific customization represents another key objective in TIM development. Industries such as electric vehicles, 5G infrastructure, and high-performance computing each present unique thermal management challenges requiring tailored solutions. For instance, EV battery thermal management systems demand dielectric TIMs with exceptional flame retardancy and chemical stability alongside thermal performance.

Sustainability has also emerged as a significant development objective, with manufacturers seeking to reduce or eliminate environmentally harmful components such as certain silicones, halogens, or heavy metals while maintaining performance characteristics. This includes developing bio-based alternatives and materials with reduced environmental footprints throughout their lifecycle.

Cost-effectiveness remains a persistent objective, particularly for consumer electronics applications where price sensitivity is high. The challenge lies in achieving the desired thermal and electrical properties while keeping manufacturing costs competitive, often requiring innovations in material formulation and processing techniques.

Conductive TIMs, conversely, provide both thermal and electrical conductivity pathways. These materials are typically utilized in applications requiring electrical grounding or EMI shielding alongside thermal management, such as in power electronics or certain military and aerospace applications where electrical continuity between components is beneficial rather than problematic.

The development objectives for TIMs have evolved significantly over recent years, driven by increasing power densities in electronic devices and the miniaturization trend across industries. Primary objectives now include achieving higher thermal conductivity values (exceeding 10 W/m·K) while maintaining appropriate electrical properties for specific applications. For dielectric TIMs, this means preserving high electrical resistance (typically >10^9 ohm·cm) while improving thermal performance.

Another critical development goal is enhancing reliability under thermal cycling conditions. Modern TIMs must maintain performance integrity through thousands of thermal cycles without degradation, pump-out, or dry-out effects. This is particularly challenging for dielectric materials, which often rely on polymer matrices that can be susceptible to thermal aging.

Application-specific customization represents another key objective in TIM development. Industries such as electric vehicles, 5G infrastructure, and high-performance computing each present unique thermal management challenges requiring tailored solutions. For instance, EV battery thermal management systems demand dielectric TIMs with exceptional flame retardancy and chemical stability alongside thermal performance.

Sustainability has also emerged as a significant development objective, with manufacturers seeking to reduce or eliminate environmentally harmful components such as certain silicones, halogens, or heavy metals while maintaining performance characteristics. This includes developing bio-based alternatives and materials with reduced environmental footprints throughout their lifecycle.

Cost-effectiveness remains a persistent objective, particularly for consumer electronics applications where price sensitivity is high. The challenge lies in achieving the desired thermal and electrical properties while keeping manufacturing costs competitive, often requiring innovations in material formulation and processing techniques.

Market Analysis of Dielectric vs Conductive TIMs

The global Thermal Interface Materials (TIM) market continues to experience robust growth, driven by increasing demand for efficient thermal management solutions across various industries. The market is segmented into two primary categories: dielectric (electrically insulating) and conductive TIMs, each serving distinct application requirements and market segments.

The dielectric TIM segment currently holds approximately 65% of the market share, valued at $2.3 billion in 2022, with projections indicating growth to $3.5 billion by 2027 at a CAGR of 8.7%. This dominance stems from the widespread need for electrical isolation in consumer electronics, automotive electronics, and telecommunications equipment where preventing electrical shorts is critical while maintaining thermal conductivity.

Conductive TIMs, though representing a smaller market segment at $1.2 billion in 2022, are experiencing faster growth with a projected CAGR of 11.3% through 2027. This accelerated growth is primarily driven by high-performance computing applications, power electronics, and electric vehicle battery thermal management systems where electrical conductivity offers advantages in certain designs.

Regional analysis reveals Asia-Pacific as the dominant market for both TIM types, accounting for 58% of global consumption, with China, Taiwan, South Korea, and Japan leading manufacturing and implementation. North America follows at 22% market share, with particularly strong demand in the high-performance computing sector and aerospace applications requiring specialized thermal solutions.

End-user segmentation shows consumer electronics remaining the largest application sector at 37% of the total TIM market, followed by automotive applications at 24%, telecommunications at 18%, and industrial electronics at 14%. The remaining 7% encompasses various specialized applications including medical devices and aerospace systems.

Price point analysis indicates significant differentiation between the two categories. Standard dielectric TIMs typically range from $10-50 per kg, while specialized high-performance variants can reach $100-200 per kg. Conductive TIMs command premium pricing, typically 30-80% higher than comparable dielectric alternatives, with metal-based conductive solutions reaching $300-500 per kg for specialized applications.

Market trends indicate growing demand for hybrid TIMs that offer customizable electrical properties, allowing manufacturers to fine-tune conductivity based on specific application requirements. Additionally, environmentally sustainable TIM formulations are gaining traction, with 28% of new product launches in 2022 emphasizing eco-friendly characteristics and reduced environmental impact throughout their lifecycle.

The dielectric TIM segment currently holds approximately 65% of the market share, valued at $2.3 billion in 2022, with projections indicating growth to $3.5 billion by 2027 at a CAGR of 8.7%. This dominance stems from the widespread need for electrical isolation in consumer electronics, automotive electronics, and telecommunications equipment where preventing electrical shorts is critical while maintaining thermal conductivity.

Conductive TIMs, though representing a smaller market segment at $1.2 billion in 2022, are experiencing faster growth with a projected CAGR of 11.3% through 2027. This accelerated growth is primarily driven by high-performance computing applications, power electronics, and electric vehicle battery thermal management systems where electrical conductivity offers advantages in certain designs.

Regional analysis reveals Asia-Pacific as the dominant market for both TIM types, accounting for 58% of global consumption, with China, Taiwan, South Korea, and Japan leading manufacturing and implementation. North America follows at 22% market share, with particularly strong demand in the high-performance computing sector and aerospace applications requiring specialized thermal solutions.

End-user segmentation shows consumer electronics remaining the largest application sector at 37% of the total TIM market, followed by automotive applications at 24%, telecommunications at 18%, and industrial electronics at 14%. The remaining 7% encompasses various specialized applications including medical devices and aerospace systems.

Price point analysis indicates significant differentiation between the two categories. Standard dielectric TIMs typically range from $10-50 per kg, while specialized high-performance variants can reach $100-200 per kg. Conductive TIMs command premium pricing, typically 30-80% higher than comparable dielectric alternatives, with metal-based conductive solutions reaching $300-500 per kg for specialized applications.

Market trends indicate growing demand for hybrid TIMs that offer customizable electrical properties, allowing manufacturers to fine-tune conductivity based on specific application requirements. Additionally, environmentally sustainable TIM formulations are gaining traction, with 28% of new product launches in 2022 emphasizing eco-friendly characteristics and reduced environmental impact throughout their lifecycle.

Technical Barriers in TIM Electrical Properties

The development of thermal interface materials (TIMs) faces significant technical barriers related to their electrical properties, particularly in the dichotomy between dielectric and conductive behaviors. One of the primary challenges is achieving optimal thermal conductivity without compromising electrical insulation requirements in sensitive electronic applications. Traditional high thermal conductivity fillers such as metal particles and carbon-based materials inherently increase electrical conductivity, creating a fundamental trade-off between thermal performance and electrical isolation.

Material scientists encounter substantial difficulties in developing TIMs that maintain consistent electrical properties across varying operating conditions. Temperature fluctuations, mechanical stress, and aging can all alter the electrical characteristics of TIMs over time. For instance, thermal cycling can lead to filler particle migration within polymer matrices, potentially creating conductive pathways in previously insulating materials.

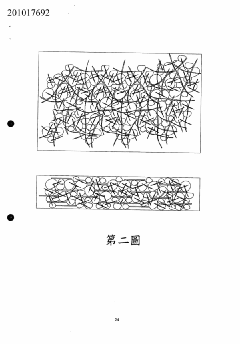

Manufacturing processes present another significant barrier, as achieving homogeneous dispersion of fillers within the base matrix is technically challenging. Agglomeration of conductive particles can create localized areas with dramatically different electrical properties, leading to unpredictable performance and potential failure points. The processing parameters must be precisely controlled to ensure uniform electrical properties throughout the material.

The interface between TIMs and adjacent components introduces additional complexities. Surface roughness, contact pressure, and chemical compatibility can all affect the effective electrical properties at the interface. These factors are particularly critical in applications requiring precise electrical isolation, such as power electronics where high voltage isolation must be maintained alongside effective heat dissipation.

Measurement and characterization of electrical properties in TIMs present methodological challenges. Standard testing protocols may not accurately reflect real-world performance, especially for composite materials with anisotropic electrical properties. The development of reliable testing methodologies that correlate with actual application performance remains an ongoing challenge in the field.

Emerging applications in high-power electronics, electric vehicles, and 5G infrastructure are pushing the boundaries of TIM electrical requirements. These applications demand materials that can simultaneously provide excellent thermal conductivity, reliable electrical insulation, and long-term stability under extreme operating conditions. The technical barriers become even more pronounced when considering the need for TIMs to maintain their electrical properties while exposed to high electric fields, elevated temperatures, and mechanical stresses.

Cost-effective scalability represents another significant barrier, as laboratory-developed solutions often prove difficult to translate into mass-produced products with consistent electrical properties. The complex formulations required to balance thermal and electrical performance often involve specialized materials and processing techniques that challenge conventional manufacturing approaches.

Material scientists encounter substantial difficulties in developing TIMs that maintain consistent electrical properties across varying operating conditions. Temperature fluctuations, mechanical stress, and aging can all alter the electrical characteristics of TIMs over time. For instance, thermal cycling can lead to filler particle migration within polymer matrices, potentially creating conductive pathways in previously insulating materials.

Manufacturing processes present another significant barrier, as achieving homogeneous dispersion of fillers within the base matrix is technically challenging. Agglomeration of conductive particles can create localized areas with dramatically different electrical properties, leading to unpredictable performance and potential failure points. The processing parameters must be precisely controlled to ensure uniform electrical properties throughout the material.

The interface between TIMs and adjacent components introduces additional complexities. Surface roughness, contact pressure, and chemical compatibility can all affect the effective electrical properties at the interface. These factors are particularly critical in applications requiring precise electrical isolation, such as power electronics where high voltage isolation must be maintained alongside effective heat dissipation.

Measurement and characterization of electrical properties in TIMs present methodological challenges. Standard testing protocols may not accurately reflect real-world performance, especially for composite materials with anisotropic electrical properties. The development of reliable testing methodologies that correlate with actual application performance remains an ongoing challenge in the field.

Emerging applications in high-power electronics, electric vehicles, and 5G infrastructure are pushing the boundaries of TIM electrical requirements. These applications demand materials that can simultaneously provide excellent thermal conductivity, reliable electrical insulation, and long-term stability under extreme operating conditions. The technical barriers become even more pronounced when considering the need for TIMs to maintain their electrical properties while exposed to high electric fields, elevated temperatures, and mechanical stresses.

Cost-effective scalability represents another significant barrier, as laboratory-developed solutions often prove difficult to translate into mass-produced products with consistent electrical properties. The complex formulations required to balance thermal and electrical performance often involve specialized materials and processing techniques that challenge conventional manufacturing approaches.

Current Solutions for Electrical Isolation in TIMs

01 Electrically insulating TIM compositions

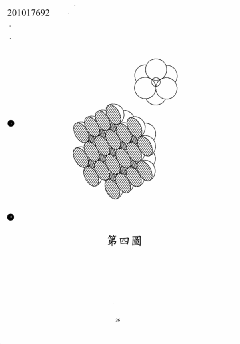

Thermal interface materials can be formulated with specific compositions to provide both thermal conductivity and electrical insulation properties. These compositions typically include thermally conductive fillers embedded in electrically insulating polymer matrices. The balance between these components allows for efficient heat transfer while preventing electrical current flow, making them suitable for applications where electrical isolation between components is required while maintaining thermal management.- Electrically insulating TIM compositions: Thermal interface materials can be formulated with specific compositions to provide both thermal conductivity and electrical insulation properties. These materials typically incorporate electrically insulating fillers such as boron nitride, aluminum oxide, or silicon dioxide within a polymer matrix. The combination allows for efficient heat transfer while preventing electrical current flow between components, which is crucial for many electronic applications where electrical isolation is required alongside thermal management.

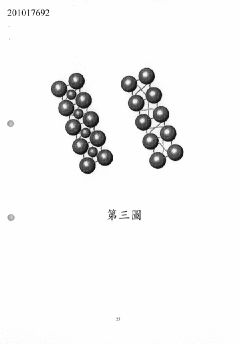

- Ceramic-based TIMs for electrical isolation: Ceramic-based thermal interface materials offer excellent electrical insulation properties while maintaining high thermal conductivity. These materials typically utilize ceramic particles such as aluminum nitride, aluminum oxide, or boron nitride dispersed in a suitable binder. The ceramic particles provide the electrical insulation while creating pathways for heat conduction. These materials are particularly useful in high-power electronics where electrical isolation between components is critical for safety and performance.

- Polymer-based electrically insulating TIMs: Polymer-based thermal interface materials can be engineered to provide electrical insulation while maintaining good thermal conductivity. These materials typically consist of thermally conductive but electrically insulating fillers dispersed in polymer matrices such as silicone, epoxy, or polyurethane. The polymer matrix provides electrical insulation while the fillers create thermal pathways. These materials often offer advantages in terms of flexibility, ease of application, and resistance to thermal cycling, making them suitable for various electronic applications.

- Layered TIM structures for electrical isolation: Layered or composite thermal interface materials can be designed with specific layers dedicated to electrical insulation while other layers focus on thermal conductivity. These structures may include dielectric films or coatings combined with thermally conductive materials. The layered approach allows for optimization of both electrical insulation and thermal performance independently. Such materials are particularly useful in applications where precise control over both thermal and electrical properties is required.

- Testing and characterization of electrically insulating TIMs: Methods and apparatus for testing and characterizing the electrical insulation properties of thermal interface materials are essential for ensuring their performance in applications. These techniques may include measurement of dielectric strength, volume resistivity, and surface resistivity alongside thermal conductivity testing. Advanced characterization methods may also evaluate the stability of electrical insulation properties under various conditions such as high temperature, humidity, or mechanical stress, ensuring reliable performance throughout the product lifecycle.

02 Ceramic-based TIMs for electrical isolation

Ceramic materials are incorporated into thermal interface materials to provide electrical insulation while maintaining high thermal conductivity. Materials such as aluminum oxide, boron nitride, and aluminum nitride are commonly used as they possess excellent dielectric properties combined with good thermal conductivity. These ceramic-based TIMs can be formulated as pastes, pads, or films depending on the application requirements and installation method.Expand Specific Solutions03 Polymer-based electrically insulating TIMs

Polymer matrices such as silicones, epoxies, and acrylics serve as the base for electrically insulating thermal interface materials. These polymers provide the electrical insulation properties while allowing for the incorporation of thermally conductive fillers. The polymer selection affects properties such as compliance, adhesion, and long-term reliability. Cross-linking mechanisms and curing processes can be optimized to enhance both the thermal and electrical properties of these materials.Expand Specific Solutions04 Novel filler materials for electrically insulating TIMs

Advanced filler materials are being developed to enhance the performance of electrically insulating thermal interface materials. These include surface-modified particles, hybrid fillers, and nano-structured materials that can improve thermal conductivity without compromising electrical insulation. The particle size distribution, shape, and surface chemistry of these fillers are carefully controlled to optimize the balance between thermal and electrical properties while maintaining processability of the TIM.Expand Specific Solutions05 Application-specific TIM designs for electrical isolation

Thermal interface materials can be specifically designed for applications requiring electrical isolation in electronic assemblies. These designs consider factors such as operating temperature range, pressure requirements, and installation methods. For semiconductor packaging, power electronics, and LED applications, specialized TIM formulations provide the necessary electrical insulation while efficiently transferring heat from the heat-generating components to heat sinks or other cooling systems.Expand Specific Solutions

Industry Leaders in TIM Manufacturing

The thermal interface materials (TIM) market is currently in a growth phase, with increasing demand driven by electronics miniaturization and thermal management challenges. The market is segmented between dielectric and conductive TIMs, with selection depending on electrical insulation requirements. Key players include 3M Innovative Properties, offering advanced polymer-based solutions; Dow Silicones (formerly Dow Corning), dominating silicone-based TIMs; and Texas Instruments, integrating TIM technology into semiconductor packages. The semiconductor industry leaders like TSMC and Intel are driving innovation in high-performance TIMs for advanced chips. Material science companies such as Momentive Performance Materials and SABIC Global Technologies are developing next-generation composites with enhanced thermal conductivity while maintaining electrical isolation properties where required.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced Thermal Interface Materials (TIMs) that strategically balance dielectric and thermal properties. Their technology focuses on polymer-based TIMs with ceramic fillers that maintain electrical isolation while maximizing heat transfer. 3M's approach includes silicone-based gap pads and thermally conductive adhesive tapes with controlled dielectric strength (>10 kV/mm) that prevent electrical leakage between components. Their multi-layer TIM solutions incorporate dedicated insulation layers alongside thermally conductive materials, allowing engineers to optimize both thermal conductivity (typically 3-5 W/m·K) and electrical isolation. 3M has also pioneered phase-change materials that transform from solid to semi-liquid at operating temperatures, ensuring complete surface contact while maintaining dielectric properties across temperature ranges from -40°C to 125°C.

Strengths: Excellent balance between thermal conductivity and dielectric strength; versatile form factors (pads, tapes, pastes); proven reliability in high-voltage applications. Weaknesses: Generally lower thermal conductivity compared to metal-based solutions; some formulations may experience performance degradation at extreme temperatures; higher cost compared to basic thermal compounds.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced Thermal Interface Materials specifically designed for semiconductor packaging applications where electrical isolation is critical. Their technology focuses on composite materials that combine ceramic fillers in polymer matrices to achieve thermal conductivity values of 2-7 W/m·K while maintaining dielectric strength exceeding 10 kV/mm. TSMC's approach includes ultra-thin (25-100 μm) dielectric TIMs that minimize thermal resistance while ensuring complete electrical isolation between die and heat spreaders. Their solutions incorporate specialized surface treatments that enhance wetting and adhesion to silicon, copper, and ceramic substrates, reducing interfacial thermal resistance. TSMC has also pioneered pre-applied TIMs that are integrated during the packaging process, ensuring consistent application and performance. Their materials undergo rigorous reliability testing, including thermal cycling (-65°C to 150°C), high temperature storage (150°C for 1000 hours), and humidity testing (85°C/85% RH) to ensure maintained dielectric properties throughout the semiconductor device lifetime.

Strengths: Specifically optimized for semiconductor applications; ultra-thin formulations minimize thermal resistance; excellent compatibility with semiconductor manufacturing processes. Weaknesses: Often designed for specific package types and may not be versatile across applications; some formulations require specialized application equipment; generally higher cost compared to standard TIMs.

Key Innovations in Dielectric TIM Technology

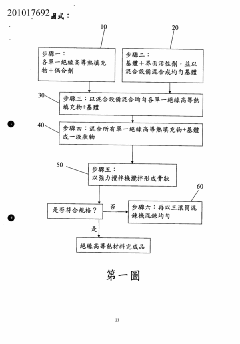

A material with high electrical insulation and thermal conductivity and a method to make the material

PatentInactiveTW201017692A

Innovation

- A high insulation and thermal conductivity material composed of a matrix with high-purity silicone oil or epoxy resin, coupled with high-insulation fillers such as inorganic materials, ceramic materials, and nanomaterials, treated with coupling agents and surfactants to enhance dispersion and compatibility, resulting in a low dielectric constant and improved thermal conductivity.

Composition

PatentWO2023238797A1

Innovation

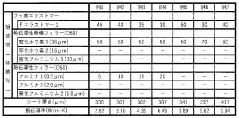

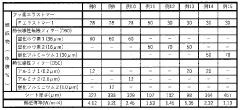

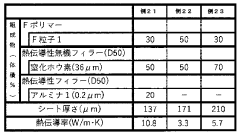

- A composition comprising a fluoroelastomer or tetrafluoroethylene polymer combined with thermally conductive inorganic and filler materials, where the fillers have specific particle size and volume ratios to enhance dispersibility and interaction, resulting in improved mechanical properties, heat resistance, and thermal conductivity while maintaining electrical insulation.

Thermal-Electrical Performance Trade-offs

The selection of thermal interface materials (TIMs) involves a critical balance between thermal conductivity and electrical properties. When designing electronic systems, engineers must carefully evaluate whether electrical insulation is necessary or if electrically conductive TIMs can be utilized. This trade-off significantly impacts overall system performance and reliability.

Thermally conductive but electrically insulating TIMs typically utilize ceramic fillers such as aluminum oxide, boron nitride, or aluminum nitride. These materials achieve thermal conductivity values ranging from 1-5 W/mK while maintaining electrical resistivity above 10^12 ohm-cm. However, this electrical insulation capability comes at the cost of lower thermal performance compared to their conductive counterparts.

Electrically conductive TIMs, incorporating metal fillers like silver, copper, or graphite, can achieve superior thermal conductivity values of 5-20+ W/mK. This enhanced thermal performance enables more efficient heat dissipation, potentially allowing for higher power densities and improved device performance. However, their implementation requires careful system design to prevent electrical shorts or interference.

The application environment significantly influences this trade-off decision. In high-voltage applications exceeding 600V, electrically insulating TIMs are often mandatory for safety and regulatory compliance. Similarly, in sensitive signal processing circuits, electrically insulating TIMs help prevent signal interference and maintain signal integrity, despite their thermal limitations.

Power electronics present a particularly challenging scenario where both high thermal conductivity and electrical isolation are simultaneously required. In these applications, engineers often implement composite solutions, such as electrically insulating TIMs with embedded heat spreaders or specialized ceramic substrates with optimized thermal pathways.

Recent advancements in material science have begun addressing this fundamental trade-off. Nano-engineered ceramics with aligned thermal pathways can now achieve thermal conductivity values approaching 10 W/mK while maintaining electrical isolation. Similarly, polymer matrices with specialized fillers can be tailored to provide customized combinations of thermal and electrical properties based on specific application requirements.

The economic implications of this trade-off are substantial. While electrically conductive TIMs may offer superior thermal performance, they often require additional design considerations and isolation components, potentially increasing overall system complexity and cost. Conversely, electrically insulating TIMs may simplify design but could necessitate larger thermal management systems to compensate for their lower thermal efficiency.

Thermally conductive but electrically insulating TIMs typically utilize ceramic fillers such as aluminum oxide, boron nitride, or aluminum nitride. These materials achieve thermal conductivity values ranging from 1-5 W/mK while maintaining electrical resistivity above 10^12 ohm-cm. However, this electrical insulation capability comes at the cost of lower thermal performance compared to their conductive counterparts.

Electrically conductive TIMs, incorporating metal fillers like silver, copper, or graphite, can achieve superior thermal conductivity values of 5-20+ W/mK. This enhanced thermal performance enables more efficient heat dissipation, potentially allowing for higher power densities and improved device performance. However, their implementation requires careful system design to prevent electrical shorts or interference.

The application environment significantly influences this trade-off decision. In high-voltage applications exceeding 600V, electrically insulating TIMs are often mandatory for safety and regulatory compliance. Similarly, in sensitive signal processing circuits, electrically insulating TIMs help prevent signal interference and maintain signal integrity, despite their thermal limitations.

Power electronics present a particularly challenging scenario where both high thermal conductivity and electrical isolation are simultaneously required. In these applications, engineers often implement composite solutions, such as electrically insulating TIMs with embedded heat spreaders or specialized ceramic substrates with optimized thermal pathways.

Recent advancements in material science have begun addressing this fundamental trade-off. Nano-engineered ceramics with aligned thermal pathways can now achieve thermal conductivity values approaching 10 W/mK while maintaining electrical isolation. Similarly, polymer matrices with specialized fillers can be tailored to provide customized combinations of thermal and electrical properties based on specific application requirements.

The economic implications of this trade-off are substantial. While electrically conductive TIMs may offer superior thermal performance, they often require additional design considerations and isolation components, potentially increasing overall system complexity and cost. Conversely, electrically insulating TIMs may simplify design but could necessitate larger thermal management systems to compensate for their lower thermal efficiency.

Application-Specific TIM Selection Guidelines

When selecting thermal interface materials (TIMs) for specific applications, understanding the electrical properties becomes crucial, particularly the distinction between dielectric and conductive materials. For applications involving exposed electrical components or circuits, dielectric (electrically insulating) TIMs are essential to prevent short circuits and ensure system reliability. These materials typically incorporate ceramic fillers like aluminum oxide or boron nitride that provide thermal conductivity without electrical conductivity.

In power electronics applications such as inverters, motor drives, and power supplies, dielectric TIMs with high breakdown voltage ratings are preferred to maintain isolation between high-voltage components and grounded heat sinks. The dielectric strength, measured in volts per mil (V/mil) or kilovolts per millimeter (kV/mm), should be carefully evaluated against the maximum operating voltage with appropriate safety margins.

Conversely, applications like CPU cooling in consumer electronics may benefit from electrically conductive TIMs when proper electrical isolation exists elsewhere in the system. These materials, often containing metal fillers like silver or aluminum, can offer superior thermal performance but must be implemented with caution to avoid creating unintended electrical pathways.

Environmental factors also influence TIM selection. In high-humidity environments or applications subject to condensation, dielectric TIMs with moisture resistance help maintain electrical isolation properties over time. Similarly, applications exposed to ionizing radiation may require specially formulated dielectric TIMs that resist degradation of their insulating properties.

The physical configuration of the thermal interface should be considered as well. Gap pads and putties may be preferred for applications with irregular surfaces or multiple components at different heights, while thin bond-line materials like phase-change TIMs might be suitable for tightly controlled interfaces. Each form factor presents different trade-offs between thermal performance and electrical isolation.

For applications requiring both electrical isolation and EMI shielding, specialized TIMs containing ferrite materials can provide electromagnetic interference protection while maintaining dielectric properties. These hybrid materials address multiple engineering challenges simultaneously, particularly valuable in sensitive electronic equipment or medical devices.

In power electronics applications such as inverters, motor drives, and power supplies, dielectric TIMs with high breakdown voltage ratings are preferred to maintain isolation between high-voltage components and grounded heat sinks. The dielectric strength, measured in volts per mil (V/mil) or kilovolts per millimeter (kV/mm), should be carefully evaluated against the maximum operating voltage with appropriate safety margins.

Conversely, applications like CPU cooling in consumer electronics may benefit from electrically conductive TIMs when proper electrical isolation exists elsewhere in the system. These materials, often containing metal fillers like silver or aluminum, can offer superior thermal performance but must be implemented with caution to avoid creating unintended electrical pathways.

Environmental factors also influence TIM selection. In high-humidity environments or applications subject to condensation, dielectric TIMs with moisture resistance help maintain electrical isolation properties over time. Similarly, applications exposed to ionizing radiation may require specially formulated dielectric TIMs that resist degradation of their insulating properties.

The physical configuration of the thermal interface should be considered as well. Gap pads and putties may be preferred for applications with irregular surfaces or multiple components at different heights, while thin bond-line materials like phase-change TIMs might be suitable for tightly controlled interfaces. Each form factor presents different trade-offs between thermal performance and electrical isolation.

For applications requiring both electrical isolation and EMI shielding, specialized TIMs containing ferrite materials can provide electromagnetic interference protection while maintaining dielectric properties. These hybrid materials address multiple engineering challenges simultaneously, particularly valuable in sensitive electronic equipment or medical devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!