TIM Thermal Cycling Tests: Methods, Duration, And Failure Modes

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TIM Thermal Cycling Background and Objectives

Thermal Interface Materials (TIMs) have become increasingly critical components in modern electronic systems as power densities continue to rise and thermal management challenges intensify. The evolution of TIM technology spans several decades, beginning with simple thermal greases in the 1970s and progressing through various material innovations including phase change materials, thermal pads, and advanced composite solutions incorporating nanomaterials. This technological progression has been driven by the semiconductor industry's relentless pursuit of higher performance and miniaturization, creating ever more demanding thermal management requirements.

Thermal cycling testing represents a fundamental reliability assessment methodology for TIMs, designed to evaluate their performance under conditions that simulate real-world operational environments. These tests subject materials to repeated temperature fluctuations that mimic the heating and cooling cycles experienced during device operation, startup, and shutdown sequences. The primary objective of thermal cycling tests is to accelerate potential failure mechanisms that might occur over years of normal operation into a compressed timeframe, allowing for meaningful reliability predictions.

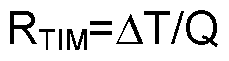

The technical goals of TIM thermal cycling testing are multifaceted. First, these tests aim to quantify the degradation of thermal performance over time, measuring changes in thermal conductivity, thermal resistance, and heat transfer efficiency. Second, they seek to identify specific failure modes including material pump-out, dry-out, delamination, cracking, and phase separation that can compromise thermal interface integrity. Third, they establish correlations between accelerated test conditions and real-world reliability expectations, enabling the development of predictive models for TIM lifespan.

Current industry trends are moving toward more rigorous and standardized testing protocols as TIMs are increasingly deployed in mission-critical applications such as automotive electronics, aerospace systems, and data center infrastructure. The temperature ranges employed in testing have expanded significantly, with some applications requiring cycling from -65°C to +150°C to accommodate extreme environment operations. Additionally, there is growing interest in understanding the combined effects of thermal cycling with other environmental stressors such as humidity, vibration, and electrical loading.

The ultimate objective of advancing TIM thermal cycling test methodologies is to develop more reliable electronic systems with extended operational lifespans and reduced failure rates. This requires establishing industry-standard test protocols that accurately predict field performance while balancing the need for accelerated testing timeframes with the validity of results. As electronic systems continue to evolve, thermal cycling test methodologies must similarly advance to address emerging challenges in thermal management reliability.

Thermal cycling testing represents a fundamental reliability assessment methodology for TIMs, designed to evaluate their performance under conditions that simulate real-world operational environments. These tests subject materials to repeated temperature fluctuations that mimic the heating and cooling cycles experienced during device operation, startup, and shutdown sequences. The primary objective of thermal cycling tests is to accelerate potential failure mechanisms that might occur over years of normal operation into a compressed timeframe, allowing for meaningful reliability predictions.

The technical goals of TIM thermal cycling testing are multifaceted. First, these tests aim to quantify the degradation of thermal performance over time, measuring changes in thermal conductivity, thermal resistance, and heat transfer efficiency. Second, they seek to identify specific failure modes including material pump-out, dry-out, delamination, cracking, and phase separation that can compromise thermal interface integrity. Third, they establish correlations between accelerated test conditions and real-world reliability expectations, enabling the development of predictive models for TIM lifespan.

Current industry trends are moving toward more rigorous and standardized testing protocols as TIMs are increasingly deployed in mission-critical applications such as automotive electronics, aerospace systems, and data center infrastructure. The temperature ranges employed in testing have expanded significantly, with some applications requiring cycling from -65°C to +150°C to accommodate extreme environment operations. Additionally, there is growing interest in understanding the combined effects of thermal cycling with other environmental stressors such as humidity, vibration, and electrical loading.

The ultimate objective of advancing TIM thermal cycling test methodologies is to develop more reliable electronic systems with extended operational lifespans and reduced failure rates. This requires establishing industry-standard test protocols that accurately predict field performance while balancing the need for accelerated testing timeframes with the validity of results. As electronic systems continue to evolve, thermal cycling test methodologies must similarly advance to address emerging challenges in thermal management reliability.

Market Demand Analysis for Reliable TIMs

The thermal interface materials (TIMs) market is experiencing robust growth driven by increasing demand for efficient thermal management solutions across multiple industries. The global TIM market was valued at approximately 2.5 billion USD in 2021 and is projected to reach 4.8 billion USD by 2027, growing at a CAGR of around 11.4% during the forecast period. This growth trajectory is primarily fueled by the rapid expansion of electronics manufacturing, particularly in consumer electronics, automotive electronics, and telecommunications sectors.

The demand for reliable TIMs is particularly acute in high-performance computing applications, where thermal management has become a critical bottleneck for system performance. Data centers, which are proliferating globally to support cloud computing and AI applications, require increasingly effective thermal solutions to manage heat dissipation from densely packed server racks. The failure of thermal management systems in these environments can lead to catastrophic downtime, with costs estimated at $5,600 per minute for large enterprises.

In the automotive industry, the transition toward electric vehicles (EVs) has created significant new demand for advanced TIMs. Electric powertrains generate substantial heat during operation, and battery thermal management is crucial for both performance and safety. The EV thermal management market is expected to grow from 3.7 billion USD in 2021 to 8.2 billion USD by 2026, representing a substantial opportunity for TIM manufacturers.

Consumer electronics manufacturers are also driving demand for reliable TIMs as devices become smaller and more powerful. The trend toward miniaturization coupled with increased processing power creates thermal challenges that require innovative interface materials. Smartphones, tablets, and wearable devices all benefit from advanced TIMs that can withstand thousands of thermal cycles without degradation.

Market research indicates that reliability under thermal cycling conditions has become a key differentiator for TIM products. End-users are increasingly willing to pay premium prices for materials that demonstrate superior longevity and consistent performance under variable thermal conditions. This trend is reflected in procurement specifications that now commonly include requirements for thermal cycling test results and expected lifetime under specific operating conditions.

Regional analysis shows that Asia-Pacific dominates the TIM market, accounting for approximately 45% of global demand, followed by North America and Europe. This regional distribution aligns with the concentration of electronics manufacturing facilities and the rapid growth of data center infrastructure in these regions. The market is expected to see further geographic diversification as manufacturing capabilities expand in emerging economies.

The demand for reliable TIMs is particularly acute in high-performance computing applications, where thermal management has become a critical bottleneck for system performance. Data centers, which are proliferating globally to support cloud computing and AI applications, require increasingly effective thermal solutions to manage heat dissipation from densely packed server racks. The failure of thermal management systems in these environments can lead to catastrophic downtime, with costs estimated at $5,600 per minute for large enterprises.

In the automotive industry, the transition toward electric vehicles (EVs) has created significant new demand for advanced TIMs. Electric powertrains generate substantial heat during operation, and battery thermal management is crucial for both performance and safety. The EV thermal management market is expected to grow from 3.7 billion USD in 2021 to 8.2 billion USD by 2026, representing a substantial opportunity for TIM manufacturers.

Consumer electronics manufacturers are also driving demand for reliable TIMs as devices become smaller and more powerful. The trend toward miniaturization coupled with increased processing power creates thermal challenges that require innovative interface materials. Smartphones, tablets, and wearable devices all benefit from advanced TIMs that can withstand thousands of thermal cycles without degradation.

Market research indicates that reliability under thermal cycling conditions has become a key differentiator for TIM products. End-users are increasingly willing to pay premium prices for materials that demonstrate superior longevity and consistent performance under variable thermal conditions. This trend is reflected in procurement specifications that now commonly include requirements for thermal cycling test results and expected lifetime under specific operating conditions.

Regional analysis shows that Asia-Pacific dominates the TIM market, accounting for approximately 45% of global demand, followed by North America and Europe. This regional distribution aligns with the concentration of electronics manufacturing facilities and the rapid growth of data center infrastructure in these regions. The market is expected to see further geographic diversification as manufacturing capabilities expand in emerging economies.

Current TIM Testing Challenges and Limitations

Despite significant advancements in thermal interface materials (TIMs) testing methodologies, the industry continues to face substantial challenges that limit the accuracy, reliability, and applicability of thermal cycling tests. One primary limitation is the lack of standardization across testing protocols. Different manufacturers and research institutions employ varying parameters for temperature ranges, ramp rates, and dwell times, making direct comparisons between studies nearly impossible and hindering industry-wide consensus on material performance.

The time-intensive nature of thermal cycling tests presents another significant hurdle. Comprehensive reliability testing often requires thousands of cycles to accurately predict long-term performance, translating to weeks or months of continuous testing. This extended duration creates bottlenecks in product development cycles and delays time-to-market for new TIM solutions, particularly problematic in rapidly evolving industries like electronics and automotive.

Current testing methodologies also struggle with accurately simulating real-world conditions. Laboratory tests frequently fail to replicate the complex combination of thermal, mechanical, and environmental stresses that TIMs experience in actual applications. This disconnect between testing environments and operational realities leads to performance discrepancies when materials are deployed in field applications, undermining confidence in test results.

The detection and characterization of failure modes present additional challenges. Many testing setups can identify when thermal performance degrades but lack the capability to determine precisely how or why the failure occurred. Without sophisticated in-situ monitoring techniques, researchers must rely on post-mortem analysis, which may not capture the progressive nature of failure mechanisms such as pump-out, delamination, or material degradation.

Scale-related issues further complicate testing efforts. Tests conducted on small sample sizes may not accurately represent the behavior of materials when applied across larger surfaces, as found in many commercial applications. Edge effects, material distribution inconsistencies, and clamping pressure variations become more pronounced at larger scales but are often overlooked in standard testing protocols.

Accelerated testing methods, while necessary for practical development timelines, introduce their own set of limitations. The assumption that higher temperatures or more extreme cycling conditions can proportionally predict long-term reliability often proves inaccurate, as some failure mechanisms only manifest under specific conditions that may be bypassed in accelerated tests.

Finally, there exists a significant gap between academic research methodologies and industrial testing requirements. Academic studies frequently focus on fundamental material properties and novel characterization techniques, while industry needs emphasize reproducibility, cost-effectiveness, and direct correlation to field performance—creating a disconnect that impedes the translation of research advances into practical testing improvements.

The time-intensive nature of thermal cycling tests presents another significant hurdle. Comprehensive reliability testing often requires thousands of cycles to accurately predict long-term performance, translating to weeks or months of continuous testing. This extended duration creates bottlenecks in product development cycles and delays time-to-market for new TIM solutions, particularly problematic in rapidly evolving industries like electronics and automotive.

Current testing methodologies also struggle with accurately simulating real-world conditions. Laboratory tests frequently fail to replicate the complex combination of thermal, mechanical, and environmental stresses that TIMs experience in actual applications. This disconnect between testing environments and operational realities leads to performance discrepancies when materials are deployed in field applications, undermining confidence in test results.

The detection and characterization of failure modes present additional challenges. Many testing setups can identify when thermal performance degrades but lack the capability to determine precisely how or why the failure occurred. Without sophisticated in-situ monitoring techniques, researchers must rely on post-mortem analysis, which may not capture the progressive nature of failure mechanisms such as pump-out, delamination, or material degradation.

Scale-related issues further complicate testing efforts. Tests conducted on small sample sizes may not accurately represent the behavior of materials when applied across larger surfaces, as found in many commercial applications. Edge effects, material distribution inconsistencies, and clamping pressure variations become more pronounced at larger scales but are often overlooked in standard testing protocols.

Accelerated testing methods, while necessary for practical development timelines, introduce their own set of limitations. The assumption that higher temperatures or more extreme cycling conditions can proportionally predict long-term reliability often proves inaccurate, as some failure mechanisms only manifest under specific conditions that may be bypassed in accelerated tests.

Finally, there exists a significant gap between academic research methodologies and industrial testing requirements. Academic studies frequently focus on fundamental material properties and novel characterization techniques, while industry needs emphasize reproducibility, cost-effectiveness, and direct correlation to field performance—creating a disconnect that impedes the translation of research advances into practical testing improvements.

Standard TIM Thermal Cycling Test Protocols

01 Composition of thermal interface materials for improved cycling performance

Thermal interface materials can be formulated with specific compositions to enhance their thermal cycling performance. These compositions may include polymer matrices, fillers, and additives that work together to maintain thermal conductivity and mechanical integrity during repeated thermal cycles. The materials are designed to minimize thermal resistance while accommodating the expansion and contraction that occurs during temperature fluctuations, thereby extending the operational life of electronic components.- Composition of thermal interface materials for improved cycling performance: Thermal interface materials can be formulated with specific compositions to enhance their thermal cycling performance. These compositions may include polymer matrices, fillers, and additives that work together to maintain thermal conductivity and mechanical integrity during repeated temperature cycles. The materials are designed to minimize thermal resistance while accommodating the expansion and contraction that occurs during thermal cycling, thereby extending the operational life of electronic components.

- Testing methods for thermal cycling performance of TIMs: Various testing methodologies are employed to evaluate the thermal cycling performance of thermal interface materials. These methods subject the materials to repeated temperature fluctuations that simulate real-world operating conditions. The tests measure parameters such as thermal resistance, mechanical integrity, and reliability over time. Advanced testing techniques can accelerate the aging process to predict long-term performance and identify potential failure modes under thermal stress.

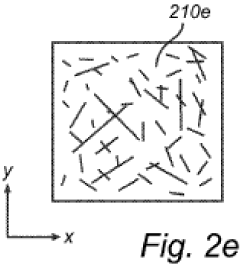

- Nanostructured thermal interface materials for enhanced cycling stability: Incorporating nanostructured materials into thermal interface materials can significantly improve their thermal cycling performance. Nanomaterials such as carbon nanotubes, graphene, and metallic nanoparticles provide enhanced thermal conductivity while maintaining flexibility during temperature fluctuations. These nanostructured TIMs can better withstand the mechanical stresses induced by thermal cycling, resulting in more reliable and durable thermal management solutions for electronic devices.

- Application-specific TIM designs for thermal cycling environments: Thermal interface materials can be specifically engineered for applications that undergo frequent thermal cycling. These specialized TIMs consider factors such as the operating temperature range, cycling frequency, and mechanical constraints of the specific application. For high-reliability applications like automotive electronics, aerospace systems, or outdoor telecommunications equipment, TIMs may incorporate phase-change materials, specialized adhesives, or reinforcing structures to maintain performance through thousands of thermal cycles.

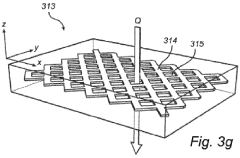

- Integration techniques for TIMs to improve thermal cycling reliability: The method of integrating thermal interface materials into electronic assemblies significantly impacts their thermal cycling performance. Techniques such as pre-applied TIMs, in-situ curing processes, and mechanical clamping systems can enhance the reliability of the thermal interface during cycling. Proper integration considers the coefficient of thermal expansion mismatch between components and implements strategies to minimize interfacial stresses. These techniques help maintain consistent thermal conductivity and mechanical integrity throughout the product lifecycle.

02 Testing methods for thermal cycling performance evaluation

Various testing methodologies are employed to evaluate the thermal cycling performance of TIMs. These methods subject the materials to repeated temperature fluctuations that simulate real-world operating conditions. Performance metrics include thermal resistance stability, mechanical integrity, and reliability over time. Advanced testing equipment and protocols help manufacturers assess how well TIMs maintain their properties after numerous thermal cycles, which is critical for applications in electronics that experience frequent temperature changes.Expand Specific Solutions03 Integration of TIMs in semiconductor packaging for thermal cycling resilience

The integration of thermal interface materials in semiconductor packaging requires careful consideration of thermal cycling effects. Designs that properly account for coefficient of thermal expansion mismatches between different materials can significantly improve reliability. Advanced packaging techniques incorporate TIMs that maintain contact pressure and thermal conductivity throughout temperature fluctuations. These integration approaches help prevent delamination, cracking, and other failure modes that can occur during thermal cycling.Expand Specific Solutions04 Novel TIM structures and form factors for enhanced thermal cycling

Innovative structural designs and form factors for thermal interface materials can significantly improve thermal cycling performance. These include phase-change materials, thermal greases with specialized additives, gap pads with reinforced structures, and graphene or carbon nanotube-based TIMs. The novel structures are engineered to maintain contact under thermal stress while providing consistent heat transfer pathways. Some designs incorporate self-healing properties or gradient structures that accommodate dimensional changes during thermal cycling.Expand Specific Solutions05 Thermal management systems incorporating cycling-resistant TIMs

Complete thermal management systems that incorporate cycling-resistant thermal interface materials are designed to maintain optimal performance in demanding environments. These systems may include heat sinks, heat pipes, vapor chambers, and liquid cooling solutions that work in conjunction with specialized TIMs. The integrated approach ensures that thermal pathways remain intact throughout numerous thermal cycles, preventing hotspots and thermal runaway conditions in electronic devices. These systems often employ redundant thermal paths or adaptive mechanisms to compensate for any degradation in TIM performance over time.Expand Specific Solutions

Key Industry Players in TIM Development and Testing

The thermal interface materials (TIM) thermal cycling testing market is currently in a growth phase, characterized by increasing demand for reliable thermal management solutions in electronics. The market size is expanding due to the proliferation of high-performance computing and electric vehicles, with an estimated CAGR of 8-10%. Technologically, the field shows varying maturity levels across different testing methodologies. Leading players like Mitsubishi Electric, ABB Group, and Robert Bosch GmbH have established standardized testing protocols, while companies such as Micron Technology and GlobalFoundries are advancing specialized TIM solutions for semiconductor applications. Research institutions like Southwest Research Institute and Chongqing University are contributing to fundamental understanding of failure modes, creating a competitive landscape that balances established industrial practices with emerging innovative approaches to thermal cycling reliability assessment.

ABB Group

Technical Solution: ABB Group has established a comprehensive TIM thermal cycling test framework specifically designed for high-power industrial applications. Their methodology employs large-scale test fixtures that accurately replicate the mechanical constraints and thermal gradients found in power conversion systems and industrial drives. ABB's testing protocol combines traditional thermal cycling (ranging from -40°C to 200°C) with mechanical stress cycling to evaluate the combined effects of thermal expansion and vibration on TIM performance. Their approach includes extended duration testing, with some protocols exceeding 10,000 cycles to validate materials for mission-critical applications with 20+ year service life requirements. ABB has developed specialized instrumentation for detecting subtle changes in thermal interface performance, including distributed temperature sensing arrays and thermal impedance spectroscopy that can identify early indicators of degradation before catastrophic failure occurs. Their failure analysis methodology incorporates both physical examination and chemical analysis to determine degradation mechanisms at the molecular level.

Strengths: Testing methodology specifically addresses the unique requirements of high-power industrial applications; extended duration testing provides high confidence for long-lifecycle applications. Weakness: Test protocols require significant time investment (often 6+ months for complete qualification), creating challenges for rapid product development cycles.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered advanced TIM thermal cycling test methodologies specifically designed for power electronics applications. Their approach features dual-phase testing that combines power cycling (active) with environmental cycling (passive) to comprehensively evaluate TIM reliability. The company's proprietary test chambers implement precise temperature control with ±0.5°C accuracy across the test range (-55°C to 175°C), with specialized fixtures that maintain consistent pressure on TIM samples throughout cycling. Mitsubishi's methodology includes in-situ electrical and thermal measurements during cycling, allowing for real-time detection of performance degradation. Their test duration protocols are tiered based on application requirements: 1,000 cycles for consumer electronics, 3,000 cycles for industrial applications, and 5,000+ cycles for automotive and aerospace applications. Mitsubishi has developed specific failure mode identification techniques including cross-sectional analysis and chemical composition evaluation to determine root causes of TIM degradation.

Strengths: Specialized expertise in power electronics applications provides highly relevant test data for high-power density systems; advanced in-situ measurement capabilities enable precise failure point determination. Weakness: Testing infrastructure requires significant capital investment and specialized expertise to implement properly, limiting accessibility for smaller organizations.

Critical Analysis of TIM Failure Mechanisms

Method and measuring arrangement for characterizing a thermal interface material

PatentWO2012107355A1

Innovation

- A method and measuring arrangement that simulate the conditions and loads of TIM in its application, allowing for the determination of thermal properties and interfaces under mechanical loading, including power cycling and mechanical cycling, to evaluate the aging behavior and thermal resistance of TIM samples with varying layer thicknesses, and enabling the calculation of bulk and interface resistances.

Thermal interface material

PatentActiveIN7138CHENP2014A

Innovation

- A TIM with an activable shrinkage material that increases in thickness upon activation, providing enhanced contact pressure and robustness by expanding in the z-direction, thus eliminating the need for external pressure and addressing surface curvature and roughness, using heat-sensitive fibers or monomers that polymerize or expand to enhance thermal interface performance.

Industry Standards and Certification Requirements

Thermal Interface Materials (TIMs) must adhere to rigorous industry standards to ensure reliability in various applications. The Joint Electron Device Engineering Council (JEDEC) has established JESD22-A104 as a primary standard for thermal cycling testing of electronic components, which includes specific protocols for TIM evaluation. This standard outlines temperature ranges, ramp rates, and dwell times that simulate real-world thermal stress conditions.

The Automotive Electronics Council's AEC-Q100 standard is particularly relevant for TIMs used in automotive applications, requiring materials to withstand extreme temperature cycling from -40°C to 125°C for up to 1000 cycles. This certification is mandatory for components in modern vehicles where thermal management is critical for safety and reliability.

For consumer electronics, the International Electrotechnical Commission (IEC) provides standards such as IEC 60068-2-14, which defines thermal cycling test procedures specifically applicable to TIM performance evaluation. These tests typically require 500-1000 cycles to validate long-term reliability under normal operating conditions.

Military and aerospace applications follow MIL-STD-883 Method 1010, which prescribes more severe thermal cycling conditions, often ranging from -65°C to 150°C. TIMs used in these high-reliability environments must maintain performance through a minimum of 1000 cycles, with some critical applications requiring up to 3000 cycles.

The ASTM D5470 standard specifically addresses thermal conductivity measurement methods for TIMs, providing a standardized approach to evaluate performance degradation after thermal cycling. This standard is often referenced in certification requirements as the baseline for thermal performance verification.

ISO/TS 16949 certification, while not specific to thermal cycling, establishes quality management requirements for automotive supply chains and includes provisions for thermal reliability testing of components including TIMs. Manufacturers seeking to supply to major automotive OEMs must comply with these requirements.

The Underwriters Laboratories (UL) provides UL 746B standard for polymeric materials used in electrical equipment, which includes thermal aging tests applicable to many polymer-based TIMs. This certification is often required for consumer electronics and industrial applications where fire safety is a concern.

Emerging standards from organizations like SEMI for semiconductor manufacturing equipment are beginning to address the unique thermal cycling requirements for TIMs in advanced computing applications, particularly for artificial intelligence and high-performance computing systems where thermal loads are increasingly dynamic and intense.

The Automotive Electronics Council's AEC-Q100 standard is particularly relevant for TIMs used in automotive applications, requiring materials to withstand extreme temperature cycling from -40°C to 125°C for up to 1000 cycles. This certification is mandatory for components in modern vehicles where thermal management is critical for safety and reliability.

For consumer electronics, the International Electrotechnical Commission (IEC) provides standards such as IEC 60068-2-14, which defines thermal cycling test procedures specifically applicable to TIM performance evaluation. These tests typically require 500-1000 cycles to validate long-term reliability under normal operating conditions.

Military and aerospace applications follow MIL-STD-883 Method 1010, which prescribes more severe thermal cycling conditions, often ranging from -65°C to 150°C. TIMs used in these high-reliability environments must maintain performance through a minimum of 1000 cycles, with some critical applications requiring up to 3000 cycles.

The ASTM D5470 standard specifically addresses thermal conductivity measurement methods for TIMs, providing a standardized approach to evaluate performance degradation after thermal cycling. This standard is often referenced in certification requirements as the baseline for thermal performance verification.

ISO/TS 16949 certification, while not specific to thermal cycling, establishes quality management requirements for automotive supply chains and includes provisions for thermal reliability testing of components including TIMs. Manufacturers seeking to supply to major automotive OEMs must comply with these requirements.

The Underwriters Laboratories (UL) provides UL 746B standard for polymeric materials used in electrical equipment, which includes thermal aging tests applicable to many polymer-based TIMs. This certification is often required for consumer electronics and industrial applications where fire safety is a concern.

Emerging standards from organizations like SEMI for semiconductor manufacturing equipment are beginning to address the unique thermal cycling requirements for TIMs in advanced computing applications, particularly for artificial intelligence and high-performance computing systems where thermal loads are increasingly dynamic and intense.

Environmental Impact of TIM Materials and Testing

The environmental impact of thermal interface materials (TIMs) and their testing procedures represents a growing concern in the electronics industry. As thermal management becomes increasingly critical for electronic devices, the ecological footprint of TIM materials throughout their lifecycle demands thorough examination. Traditional TIMs often contain environmentally problematic components such as heavy metals, silicones, and other non-biodegradable substances that pose significant disposal challenges.

Thermal cycling tests, while essential for reliability assessment, contribute to environmental burden through energy consumption and waste generation. A standard thermal cycling test may run continuously for weeks or months, consuming substantial electrical power. For instance, a typical thermal chamber operating at temperature extremes of -40°C to 125°C can consume between 2-5 kWh during each cycle, resulting in significant carbon emissions over extended test periods.

The disposal of tested TIM samples presents another environmental challenge. After thermal cycling, these materials often contain degraded compounds that may leach into soil or water systems if improperly discarded. Research indicates that silicone-based TIMs can take hundreds of years to decompose naturally, while metal-loaded variants may release toxic elements into the environment.

Recent industry trends show movement toward more sustainable alternatives. Bio-based TIMs derived from renewable resources such as cellulose, vegetable oils, and agricultural by-products demonstrate promising thermal performance while offering improved environmental profiles. These materials typically require 40-60% less energy to produce compared to conventional petroleum-based options and generate significantly lower greenhouse gas emissions during manufacturing.

Testing methodologies are also evolving to reduce environmental impact. Accelerated testing protocols that maintain reliability predictions while reducing test duration can decrease energy consumption by up to 30%. Additionally, computational modeling and simulation approaches are increasingly supplementing physical tests, further reducing material waste and energy usage.

Regulatory frameworks worldwide are beginning to address the environmental aspects of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain compounds commonly found in TIMs, pushing manufacturers toward greener formulations.

Looking forward, the industry faces the challenge of balancing thermal performance requirements with environmental sustainability. Life cycle assessment (LCA) studies suggest that environmentally optimized TIMs may reduce overall ecological impact by 25-40% compared to conventional materials, highlighting the significant potential for improvement in this critical component of electronic thermal management.

Thermal cycling tests, while essential for reliability assessment, contribute to environmental burden through energy consumption and waste generation. A standard thermal cycling test may run continuously for weeks or months, consuming substantial electrical power. For instance, a typical thermal chamber operating at temperature extremes of -40°C to 125°C can consume between 2-5 kWh during each cycle, resulting in significant carbon emissions over extended test periods.

The disposal of tested TIM samples presents another environmental challenge. After thermal cycling, these materials often contain degraded compounds that may leach into soil or water systems if improperly discarded. Research indicates that silicone-based TIMs can take hundreds of years to decompose naturally, while metal-loaded variants may release toxic elements into the environment.

Recent industry trends show movement toward more sustainable alternatives. Bio-based TIMs derived from renewable resources such as cellulose, vegetable oils, and agricultural by-products demonstrate promising thermal performance while offering improved environmental profiles. These materials typically require 40-60% less energy to produce compared to conventional petroleum-based options and generate significantly lower greenhouse gas emissions during manufacturing.

Testing methodologies are also evolving to reduce environmental impact. Accelerated testing protocols that maintain reliability predictions while reducing test duration can decrease energy consumption by up to 30%. Additionally, computational modeling and simulation approaches are increasingly supplementing physical tests, further reducing material waste and energy usage.

Regulatory frameworks worldwide are beginning to address the environmental aspects of electronic components, including TIMs. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have already limited certain compounds commonly found in TIMs, pushing manufacturers toward greener formulations.

Looking forward, the industry faces the challenge of balancing thermal performance requirements with environmental sustainability. Life cycle assessment (LCA) studies suggest that environmentally optimized TIMs may reduce overall ecological impact by 25-40% compared to conventional materials, highlighting the significant potential for improvement in this critical component of electronic thermal management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!