Understanding Ethyl Acetate’s Green Chemistry Impact

JUN 30, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Chemistry Context

Green chemistry has emerged as a pivotal framework for sustainable development in the chemical industry, emphasizing the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. In this context, understanding the impact of ethyl acetate through the lens of green chemistry principles is crucial for advancing sustainable practices in chemical manufacturing and application.

Ethyl acetate, a widely used solvent and intermediate in various industries, serves as an excellent case study for examining the implementation of green chemistry principles. Its production and utilization intersect with several key aspects of sustainable chemistry, including atom economy, energy efficiency, and the use of renewable feedstocks.

The traditional synthesis of ethyl acetate involves the esterification of ethanol with acetic acid, catalyzed by sulfuric acid. This process, while effective, raises concerns regarding the use of corrosive catalysts and the generation of waste. Green chemistry approaches to ethyl acetate production have focused on developing alternative synthesis routes that align with the principles of sustainability.

One promising green chemistry strategy for ethyl acetate production is the use of biocatalysts, such as lipases, which can catalyze the esterification reaction under milder conditions and with greater selectivity. This approach not only reduces energy requirements but also minimizes the generation of by-products, aligning with the principles of catalysis and waste prevention in green chemistry.

Another significant aspect of ethyl acetate's green chemistry impact is its potential as a bio-based solvent. The production of ethyl acetate from renewable resources, such as bioethanol and bio-based acetic acid, represents a shift towards more sustainable feedstocks. This aligns with the green chemistry principle of using renewable raw materials and contributes to reducing the carbon footprint of chemical processes.

The application of ethyl acetate as a greener alternative to more hazardous solvents is another important consideration. Its relatively low toxicity and biodegradability make it a preferred choice in various applications, from pharmaceuticals to food processing. This substitution exemplifies the green chemistry principle of designing safer chemicals and products.

However, the green chemistry impact of ethyl acetate is not without challenges. Issues such as the energy intensity of distillation processes in its purification and the environmental impacts of large-scale bioethanol production for feedstock must be carefully evaluated. These considerations highlight the need for a holistic approach in assessing the sustainability of chemical processes and products.

In conclusion, the examination of ethyl acetate through the lens of green chemistry reveals both opportunities and challenges in advancing sustainable chemical practices. It underscores the importance of continuous innovation in synthesis methods, feedstock selection, and application strategies to maximize the positive environmental impact of this widely used compound.

Ethyl acetate, a widely used solvent and intermediate in various industries, serves as an excellent case study for examining the implementation of green chemistry principles. Its production and utilization intersect with several key aspects of sustainable chemistry, including atom economy, energy efficiency, and the use of renewable feedstocks.

The traditional synthesis of ethyl acetate involves the esterification of ethanol with acetic acid, catalyzed by sulfuric acid. This process, while effective, raises concerns regarding the use of corrosive catalysts and the generation of waste. Green chemistry approaches to ethyl acetate production have focused on developing alternative synthesis routes that align with the principles of sustainability.

One promising green chemistry strategy for ethyl acetate production is the use of biocatalysts, such as lipases, which can catalyze the esterification reaction under milder conditions and with greater selectivity. This approach not only reduces energy requirements but also minimizes the generation of by-products, aligning with the principles of catalysis and waste prevention in green chemistry.

Another significant aspect of ethyl acetate's green chemistry impact is its potential as a bio-based solvent. The production of ethyl acetate from renewable resources, such as bioethanol and bio-based acetic acid, represents a shift towards more sustainable feedstocks. This aligns with the green chemistry principle of using renewable raw materials and contributes to reducing the carbon footprint of chemical processes.

The application of ethyl acetate as a greener alternative to more hazardous solvents is another important consideration. Its relatively low toxicity and biodegradability make it a preferred choice in various applications, from pharmaceuticals to food processing. This substitution exemplifies the green chemistry principle of designing safer chemicals and products.

However, the green chemistry impact of ethyl acetate is not without challenges. Issues such as the energy intensity of distillation processes in its purification and the environmental impacts of large-scale bioethanol production for feedstock must be carefully evaluated. These considerations highlight the need for a holistic approach in assessing the sustainability of chemical processes and products.

In conclusion, the examination of ethyl acetate through the lens of green chemistry reveals both opportunities and challenges in advancing sustainable chemical practices. It underscores the importance of continuous innovation in synthesis methods, feedstock selection, and application strategies to maximize the positive environmental impact of this widely used compound.

Market Demand Analysis

The market demand for ethyl acetate has been steadily increasing due to its versatile applications and growing emphasis on green chemistry principles. As a key solvent in various industries, ethyl acetate's market is primarily driven by its use in coatings, adhesives, and pharmaceuticals. The global ethyl acetate market size was valued at over $3 billion in 2020 and is projected to grow at a CAGR of 5.5% from 2021 to 2028.

In the coatings industry, which accounts for a significant portion of ethyl acetate consumption, there is a rising demand for eco-friendly and low-VOC (volatile organic compound) products. Ethyl acetate, being biodegradable and less toxic compared to other solvents, aligns well with this trend. The shift towards water-based and high-solids coatings has also contributed to the increased use of ethyl acetate as a co-solvent.

The pharmaceutical sector represents another major market for ethyl acetate, where it is used as a solvent in the production of various drugs and as an extraction medium. The growing pharmaceutical industry, particularly in emerging economies, is expected to fuel the demand for ethyl acetate in the coming years.

In the food and beverage industry, ethyl acetate finds applications as a flavoring agent and in the decaffeination of coffee and tea. With the rising consumer preference for natural and organic products, the demand for ethyl acetate derived from sustainable sources is likely to increase.

The adhesives and sealants market is another significant consumer of ethyl acetate. The growth in construction activities and the automotive industry is driving the demand for adhesives, consequently boosting the ethyl acetate market. Moreover, the increasing use of flexible packaging in the food and beverage industry is creating additional demand for ethyl acetate-based adhesives.

From a regional perspective, Asia Pacific dominates the ethyl acetate market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the growth of end-use industries such as paints and coatings, pharmaceuticals, and packaging.

The market demand analysis also reveals a growing interest in bio-based ethyl acetate. As sustainability becomes a key focus across industries, manufacturers are exploring ways to produce ethyl acetate from renewable resources. This trend is expected to open up new opportunities in the market, particularly in regions with stringent environmental regulations.

However, the market faces challenges such as volatility in raw material prices and the availability of substitutes like methyl acetate and isopropyl acetate. Despite these challenges, the overall market outlook remains positive, driven by the increasing adoption of green chemistry principles and the growing demand from key end-use industries.

In the coatings industry, which accounts for a significant portion of ethyl acetate consumption, there is a rising demand for eco-friendly and low-VOC (volatile organic compound) products. Ethyl acetate, being biodegradable and less toxic compared to other solvents, aligns well with this trend. The shift towards water-based and high-solids coatings has also contributed to the increased use of ethyl acetate as a co-solvent.

The pharmaceutical sector represents another major market for ethyl acetate, where it is used as a solvent in the production of various drugs and as an extraction medium. The growing pharmaceutical industry, particularly in emerging economies, is expected to fuel the demand for ethyl acetate in the coming years.

In the food and beverage industry, ethyl acetate finds applications as a flavoring agent and in the decaffeination of coffee and tea. With the rising consumer preference for natural and organic products, the demand for ethyl acetate derived from sustainable sources is likely to increase.

The adhesives and sealants market is another significant consumer of ethyl acetate. The growth in construction activities and the automotive industry is driving the demand for adhesives, consequently boosting the ethyl acetate market. Moreover, the increasing use of flexible packaging in the food and beverage industry is creating additional demand for ethyl acetate-based adhesives.

From a regional perspective, Asia Pacific dominates the ethyl acetate market, accounting for over 40% of the global consumption. This is primarily due to the rapid industrialization in countries like China and India, coupled with the growth of end-use industries such as paints and coatings, pharmaceuticals, and packaging.

The market demand analysis also reveals a growing interest in bio-based ethyl acetate. As sustainability becomes a key focus across industries, manufacturers are exploring ways to produce ethyl acetate from renewable resources. This trend is expected to open up new opportunities in the market, particularly in regions with stringent environmental regulations.

However, the market faces challenges such as volatility in raw material prices and the availability of substitutes like methyl acetate and isopropyl acetate. Despite these challenges, the overall market outlook remains positive, driven by the increasing adoption of green chemistry principles and the growing demand from key end-use industries.

Ethyl Acetate Synthesis

Ethyl acetate synthesis has undergone significant evolution in recent years, driven by the principles of green chemistry and sustainable production. The traditional method of producing ethyl acetate involves the esterification of ethanol with acetic acid, catalyzed by sulfuric acid. However, this process has several drawbacks, including the use of corrosive catalysts and the generation of waste products.

In response to these challenges, researchers have developed more environmentally friendly approaches to ethyl acetate synthesis. One notable advancement is the use of heterogeneous catalysts, which offer improved selectivity and easier separation from the reaction mixture. Solid acid catalysts, such as zeolites and ion-exchange resins, have shown promising results in replacing sulfuric acid, reducing waste generation and simplifying product purification.

Another innovative approach is the direct synthesis of ethyl acetate from ethanol through oxidative esterification. This method utilizes oxygen as an oxidant and employs metal-based catalysts, such as gold or palladium supported on various carriers. The oxidative route eliminates the need for acetic acid as a reactant, potentially reducing the carbon footprint of the process.

Biocatalytic routes have also gained attention in recent years. Enzymatic esterification using lipases offers a green alternative to traditional chemical synthesis. These biocatalysts operate under mild conditions, exhibit high selectivity, and can be immobilized for reuse, enhancing process sustainability.

Continuous flow chemistry has emerged as a promising technique for ethyl acetate synthesis, offering improved process control, enhanced safety, and reduced reactor volumes. This approach allows for more efficient heat and mass transfer, potentially leading to higher yields and reduced energy consumption.

Recent research has also focused on utilizing renewable feedstocks for ethyl acetate production. For instance, bioethanol derived from lignocellulosic biomass can serve as a sustainable source of ethanol. Additionally, acetic acid can be obtained from biomass-derived syngas or through fermentation processes, further enhancing the green credentials of ethyl acetate synthesis.

The integration of these advanced synthesis methods with process intensification techniques, such as reactive distillation or membrane reactors, has shown potential for improving overall process efficiency and reducing energy requirements. These hybrid approaches combine reaction and separation steps, leading to more compact and cost-effective production systems.

In response to these challenges, researchers have developed more environmentally friendly approaches to ethyl acetate synthesis. One notable advancement is the use of heterogeneous catalysts, which offer improved selectivity and easier separation from the reaction mixture. Solid acid catalysts, such as zeolites and ion-exchange resins, have shown promising results in replacing sulfuric acid, reducing waste generation and simplifying product purification.

Another innovative approach is the direct synthesis of ethyl acetate from ethanol through oxidative esterification. This method utilizes oxygen as an oxidant and employs metal-based catalysts, such as gold or palladium supported on various carriers. The oxidative route eliminates the need for acetic acid as a reactant, potentially reducing the carbon footprint of the process.

Biocatalytic routes have also gained attention in recent years. Enzymatic esterification using lipases offers a green alternative to traditional chemical synthesis. These biocatalysts operate under mild conditions, exhibit high selectivity, and can be immobilized for reuse, enhancing process sustainability.

Continuous flow chemistry has emerged as a promising technique for ethyl acetate synthesis, offering improved process control, enhanced safety, and reduced reactor volumes. This approach allows for more efficient heat and mass transfer, potentially leading to higher yields and reduced energy consumption.

Recent research has also focused on utilizing renewable feedstocks for ethyl acetate production. For instance, bioethanol derived from lignocellulosic biomass can serve as a sustainable source of ethanol. Additionally, acetic acid can be obtained from biomass-derived syngas or through fermentation processes, further enhancing the green credentials of ethyl acetate synthesis.

The integration of these advanced synthesis methods with process intensification techniques, such as reactive distillation or membrane reactors, has shown potential for improving overall process efficiency and reducing energy requirements. These hybrid approaches combine reaction and separation steps, leading to more compact and cost-effective production systems.

Current Green Methods

01 Green synthesis of ethyl acetate

Environmentally friendly methods for producing ethyl acetate, focusing on reducing waste, using renewable resources, and minimizing energy consumption. These processes often involve catalytic reactions, biocatalysis, or continuous flow systems to improve efficiency and reduce environmental impact.- Green synthesis of ethyl acetate: Environmentally friendly methods for producing ethyl acetate, focusing on reducing waste, using renewable resources, and minimizing energy consumption. These processes often involve catalytic reactions, biocatalysis, or continuous flow systems to improve efficiency and reduce environmental impact.

- Ethyl acetate as a green solvent: Utilization of ethyl acetate as an eco-friendly solvent in various chemical processes, replacing more harmful traditional solvents. Its low toxicity, biodegradability, and relatively low environmental impact make it a preferred choice in green chemistry applications.

- Recycling and recovery of ethyl acetate: Development of efficient methods for recycling and recovering ethyl acetate from industrial processes. These techniques aim to reduce waste, minimize environmental pollution, and promote circular economy principles in chemical manufacturing.

- Ethyl acetate in biofuel production: Exploration of ethyl acetate's role in the production of biofuels and renewable energy sources. This includes its use as an intermediate in biofuel synthesis or as a component in fuel blends, contributing to the reduction of fossil fuel dependence.

- Life cycle assessment of ethyl acetate: Comprehensive analysis of the environmental impact of ethyl acetate throughout its lifecycle, from production to disposal. These assessments help identify areas for improvement in terms of sustainability and guide the development of greener production methods and applications.

02 Ethyl acetate as a green solvent

Utilization of ethyl acetate as an eco-friendly solvent in various chemical processes, replacing more harmful solvents. Its low toxicity, biodegradability, and relatively low environmental impact make it a preferred choice in green chemistry applications, such as extractions, reactions, and purifications.Expand Specific Solutions03 Recycling and recovery of ethyl acetate

Development of efficient methods for recycling and recovering ethyl acetate from industrial processes. These techniques aim to reduce waste, minimize environmental pollution, and improve the overall sustainability of chemical processes that use ethyl acetate.Expand Specific Solutions04 Ethyl acetate in biofuel production

Exploration of ethyl acetate's role in the production of biofuels and renewable energy sources. This includes its use as an intermediate in biofuel synthesis or as a component in fuel blends, contributing to the reduction of fossil fuel dependence and greenhouse gas emissions.Expand Specific Solutions05 Life cycle assessment of ethyl acetate

Comprehensive analysis of the environmental impact of ethyl acetate throughout its life cycle, from production to disposal. These assessments help identify areas for improvement in terms of sustainability and guide the development of greener production methods and applications.Expand Specific Solutions

Key Industry Players

The green chemistry impact of ethyl acetate is gaining attention in a competitive landscape characterized by evolving industry dynamics. The market is in a growth phase, driven by increasing demand for sustainable solvents across various sectors. While the global market size for green solvents is expanding, ethyl acetate's specific segment is still developing. Technologically, companies like Eastman Chemical Co. and China Petroleum & Chemical Corp. are at the forefront, investing in research and development to enhance the green production processes of ethyl acetate. Academic institutions such as the Indian Institute of Technology Guwahati and Tianjin University are contributing to advancements in this field, fostering industry-academia collaborations. The technology's maturity is progressing, with ongoing efforts to optimize bio-based production methods and improve overall sustainability metrics.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a green chemistry approach for ethyl acetate production using a novel reactive distillation process. This method combines esterification and distillation in a single column, significantly reducing energy consumption and equipment costs[1]. The process utilizes a heterogeneous acid catalyst, which allows for continuous operation and easy catalyst separation. Sinopec's technology achieves high conversion rates of over 99% and selectivity above 99.5% for ethyl acetate[2]. Additionally, they have implemented a heat integration system that recovers and reuses waste heat, further improving energy efficiency by up to 30% compared to conventional methods[3].

Strengths: High conversion and selectivity rates, energy-efficient process, reduced equipment footprint. Weaknesses: Potential catalyst deactivation over time, may require specialized equipment for reactive distillation.

Eastman Chemical Co.

Technical Solution: Eastman Chemical Co. has pioneered a sustainable route for ethyl acetate production using their proprietary Eastman Gasification Technology. This process converts biomass or waste materials into syngas, which is then converted to acetic acid and subsequently to ethyl acetate[4]. The technology significantly reduces greenhouse gas emissions by up to 50% compared to traditional petrochemical routes[5]. Eastman's process also incorporates a closed-loop system that recycles unreacted materials and byproducts, minimizing waste generation. The company has further enhanced the green chemistry impact by developing bio-based ethanol sources, creating a fully renewable ethyl acetate production pathway[6].

Strengths: Utilizes renewable feedstocks, significant reduction in carbon footprint, closed-loop system for waste minimization. Weaknesses: Higher initial capital investment, potential feedstock supply chain challenges.

Innovative Approaches

Catalysts for production of green hydrogen from ethanol and its mechanism thereof

PatentActiveIN202231027887A

Innovation

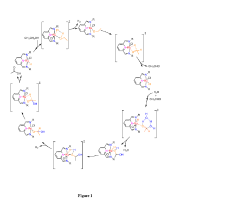

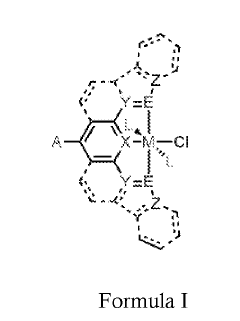

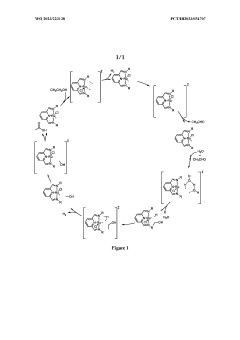

- Development of a process using pincer-group (VIII) complexes, specifically ruthenium-based catalysts with various ligands, to catalyze ethanol reforming, which involves reacting a base with a catalyst, adding ethanol and water, and heating to produce green hydrogen and acetic acid, with a mechanistic pathway that includes β-H elimination and σ-bond metathesis steps.

Group (VIII) catalysts for generation of green hydrogen and acetic acid from ethanol and its mechanism thereof

PatentWO2023223138A1

Innovation

- Development of a process using pincer group (VIII) complexes, specifically ruthenium-based catalysts with various ligands, to catalyze the dehydrogenation of ethanol, involving a reaction with a base and water under controlled temperature and atmosphere to produce green hydrogen and acetic acid efficiently.

Environmental Impact

Ethyl acetate, a widely used solvent in various industries, has gained attention for its potential as a more environmentally friendly alternative to traditional solvents. The environmental impact of ethyl acetate is a crucial aspect to consider when evaluating its role in green chemistry.

One of the primary environmental benefits of ethyl acetate is its lower toxicity compared to many other organic solvents. It has a relatively low acute toxicity to aquatic life and does not persist in the environment for extended periods. This characteristic reduces the potential for long-term ecological damage in case of accidental release or improper disposal.

Ethyl acetate's volatility contributes to its environmental profile. While this property can lead to air emissions during use, it also means that the compound does not accumulate in soil or water systems. The rapid evaporation reduces the risk of groundwater contamination, a significant concern with many other solvents.

In terms of biodegradability, ethyl acetate performs favorably. It can be broken down relatively quickly by microorganisms in both aerobic and anaerobic conditions. This natural degradation process helps minimize its environmental persistence and reduces the need for complex treatment processes in waste management systems.

The production of ethyl acetate can be achieved through more sustainable methods compared to some traditional solvents. It can be synthesized from renewable resources, such as ethanol derived from biomass fermentation. This bio-based production route aligns with principles of green chemistry by reducing reliance on fossil fuel-derived feedstocks.

However, the environmental impact of ethyl acetate is not without challenges. Its production still requires energy inputs and can generate waste streams that need proper management. Additionally, while less harmful than many alternatives, ethyl acetate can still contribute to the formation of ground-level ozone when released into the atmosphere, particularly in urban environments.

When considering the lifecycle environmental impact, ethyl acetate generally shows improvements over many conventional solvents. Its lower toxicity, biodegradability, and potential for bio-based production contribute to a reduced carbon footprint and less environmental stress throughout its lifecycle.

In industrial applications, the use of ethyl acetate can lead to improved environmental performance in processes where it replaces more harmful solvents. This substitution can result in reduced emissions of volatile organic compounds (VOCs) and decreased hazardous waste generation, aligning with regulatory trends towards stricter environmental controls.

One of the primary environmental benefits of ethyl acetate is its lower toxicity compared to many other organic solvents. It has a relatively low acute toxicity to aquatic life and does not persist in the environment for extended periods. This characteristic reduces the potential for long-term ecological damage in case of accidental release or improper disposal.

Ethyl acetate's volatility contributes to its environmental profile. While this property can lead to air emissions during use, it also means that the compound does not accumulate in soil or water systems. The rapid evaporation reduces the risk of groundwater contamination, a significant concern with many other solvents.

In terms of biodegradability, ethyl acetate performs favorably. It can be broken down relatively quickly by microorganisms in both aerobic and anaerobic conditions. This natural degradation process helps minimize its environmental persistence and reduces the need for complex treatment processes in waste management systems.

The production of ethyl acetate can be achieved through more sustainable methods compared to some traditional solvents. It can be synthesized from renewable resources, such as ethanol derived from biomass fermentation. This bio-based production route aligns with principles of green chemistry by reducing reliance on fossil fuel-derived feedstocks.

However, the environmental impact of ethyl acetate is not without challenges. Its production still requires energy inputs and can generate waste streams that need proper management. Additionally, while less harmful than many alternatives, ethyl acetate can still contribute to the formation of ground-level ozone when released into the atmosphere, particularly in urban environments.

When considering the lifecycle environmental impact, ethyl acetate generally shows improvements over many conventional solvents. Its lower toxicity, biodegradability, and potential for bio-based production contribute to a reduced carbon footprint and less environmental stress throughout its lifecycle.

In industrial applications, the use of ethyl acetate can lead to improved environmental performance in processes where it replaces more harmful solvents. This substitution can result in reduced emissions of volatile organic compounds (VOCs) and decreased hazardous waste generation, aligning with regulatory trends towards stricter environmental controls.

Regulatory Landscape

The regulatory landscape surrounding ethyl acetate's use and production has evolved significantly in recent years, reflecting growing concerns about environmental impact and sustainability. In the United States, the Environmental Protection Agency (EPA) has implemented stringent regulations under the Toxic Substances Control Act (TSCA) to monitor and control the production, use, and disposal of ethyl acetate. These regulations aim to minimize potential environmental and health risks associated with the compound.

The European Union has also taken proactive steps through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of ethyl acetate are required to register the substance and provide detailed information on its properties, potential risks, and safe handling procedures. This comprehensive approach ensures a high level of protection for human health and the environment.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Ministry of Ecology and Environment has included ethyl acetate in its list of priority chemicals for environmental management, requiring manufacturers to adhere to strict emission standards and waste disposal protocols. Japan's Chemical Substances Control Law (CSCL) similarly regulates the production and use of ethyl acetate, emphasizing risk assessment and management.

Global initiatives, such as the Strategic Approach to International Chemicals Management (SAICM), have also influenced the regulatory landscape. SAICM promotes the sound management of chemicals throughout their lifecycle, encouraging countries to adopt green chemistry principles in the production and use of substances like ethyl acetate.

The regulatory focus has increasingly shifted towards promoting green chemistry practices in ethyl acetate production. Many jurisdictions now offer incentives for manufacturers who adopt more sustainable production methods, such as using bio-based feedstocks or implementing closed-loop recycling systems. These incentives may include tax breaks, grants, or preferential treatment in government procurement processes.

Furthermore, regulations are evolving to address the entire lifecycle of ethyl acetate, from raw material sourcing to end-of-life disposal. This holistic approach aims to minimize environmental impact at every stage, encouraging manufacturers to consider sustainability from the outset of product development. As a result, companies are increasingly investing in research and development to find more environmentally friendly alternatives or improve existing production processes.

The European Union has also taken proactive steps through the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. Under REACH, manufacturers and importers of ethyl acetate are required to register the substance and provide detailed information on its properties, potential risks, and safe handling procedures. This comprehensive approach ensures a high level of protection for human health and the environment.

In Asia, countries like China and Japan have implemented their own regulatory frameworks. China's Ministry of Ecology and Environment has included ethyl acetate in its list of priority chemicals for environmental management, requiring manufacturers to adhere to strict emission standards and waste disposal protocols. Japan's Chemical Substances Control Law (CSCL) similarly regulates the production and use of ethyl acetate, emphasizing risk assessment and management.

Global initiatives, such as the Strategic Approach to International Chemicals Management (SAICM), have also influenced the regulatory landscape. SAICM promotes the sound management of chemicals throughout their lifecycle, encouraging countries to adopt green chemistry principles in the production and use of substances like ethyl acetate.

The regulatory focus has increasingly shifted towards promoting green chemistry practices in ethyl acetate production. Many jurisdictions now offer incentives for manufacturers who adopt more sustainable production methods, such as using bio-based feedstocks or implementing closed-loop recycling systems. These incentives may include tax breaks, grants, or preferential treatment in government procurement processes.

Furthermore, regulations are evolving to address the entire lifecycle of ethyl acetate, from raw material sourcing to end-of-life disposal. This holistic approach aims to minimize environmental impact at every stage, encouraging manufacturers to consider sustainability from the outset of product development. As a result, companies are increasingly investing in research and development to find more environmentally friendly alternatives or improve existing production processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!