Volumetric Additive Manufacturing For Functional Gradient Materials

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VAM Technology Background and Objectives

Volumetric Additive Manufacturing (VAM) represents a paradigm shift in the field of additive manufacturing, emerging as a revolutionary approach that transcends the limitations of traditional layer-by-layer 3D printing methods. Unlike conventional techniques that build objects sequentially, VAM enables the simultaneous solidification of an entire volume of photopolymer resin, dramatically reducing production time from hours to minutes or even seconds.

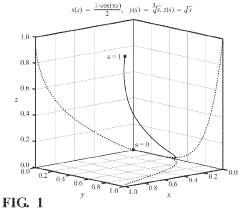

The evolution of VAM technology can be traced back to the early 2010s, with significant breakthroughs occurring around 2017-2019 when researchers at Lawrence Livermore National Laboratory and the University of California, Berkeley demonstrated the feasibility of creating complex 3D structures through computed axial lithography. This approach leverages principles from computed tomography but in reverse—projecting calculated light patterns into a photosensitive resin to achieve controlled solidification throughout the volume.

The integration of VAM with Functional Gradient Materials (FGMs) represents a particularly promising frontier. FGMs are characterized by spatially varying composition, structure, or properties that enable unprecedented performance characteristics in engineered components. Traditional manufacturing methods have struggled to efficiently produce FGMs with precise control over property gradients, making this intersection with VAM especially significant.

The primary technical objectives for VAM in FGM applications include achieving multi-material capabilities with seamless property transitions, enhancing spatial resolution to microscale precision, increasing production speed while maintaining quality, and developing specialized photopolymer resins that can support functional property gradients. These objectives align with broader industry trends toward mass customization, sustainable manufacturing, and the development of materials with application-specific performance profiles.

Current research is focused on overcoming several key challenges, including the development of optical systems capable of projecting complex light patterns with high precision, formulating photopolymer resins that respond predictably to controlled light exposure, and creating computational algorithms that can translate desired material property distributions into appropriate light projection patterns.

The technology aims to enable the creation of components with seamless transitions between different mechanical, thermal, optical, or electrical properties—a capability that could revolutionize industries ranging from aerospace and biomedical engineering to consumer electronics and automotive manufacturing. As VAM technology matures, it promises to unlock new design possibilities that were previously unattainable, allowing engineers to optimize material distribution at unprecedented levels of precision and complexity.

The evolution of VAM technology can be traced back to the early 2010s, with significant breakthroughs occurring around 2017-2019 when researchers at Lawrence Livermore National Laboratory and the University of California, Berkeley demonstrated the feasibility of creating complex 3D structures through computed axial lithography. This approach leverages principles from computed tomography but in reverse—projecting calculated light patterns into a photosensitive resin to achieve controlled solidification throughout the volume.

The integration of VAM with Functional Gradient Materials (FGMs) represents a particularly promising frontier. FGMs are characterized by spatially varying composition, structure, or properties that enable unprecedented performance characteristics in engineered components. Traditional manufacturing methods have struggled to efficiently produce FGMs with precise control over property gradients, making this intersection with VAM especially significant.

The primary technical objectives for VAM in FGM applications include achieving multi-material capabilities with seamless property transitions, enhancing spatial resolution to microscale precision, increasing production speed while maintaining quality, and developing specialized photopolymer resins that can support functional property gradients. These objectives align with broader industry trends toward mass customization, sustainable manufacturing, and the development of materials with application-specific performance profiles.

Current research is focused on overcoming several key challenges, including the development of optical systems capable of projecting complex light patterns with high precision, formulating photopolymer resins that respond predictably to controlled light exposure, and creating computational algorithms that can translate desired material property distributions into appropriate light projection patterns.

The technology aims to enable the creation of components with seamless transitions between different mechanical, thermal, optical, or electrical properties—a capability that could revolutionize industries ranging from aerospace and biomedical engineering to consumer electronics and automotive manufacturing. As VAM technology matures, it promises to unlock new design possibilities that were previously unattainable, allowing engineers to optimize material distribution at unprecedented levels of precision and complexity.

Market Analysis for Functional Gradient Materials

The global market for Functional Gradient Materials (FGMs) is experiencing significant growth, driven by increasing demand across multiple industries seeking advanced materials with spatially varying compositions and properties. The market size for FGMs was valued at approximately $2.1 billion in 2022 and is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 13.5%.

Aerospace and defense sectors currently dominate the FGM market, accounting for nearly 35% of total demand. These industries leverage FGMs for thermal barrier coatings, structural components, and radiation shields, where the ability to withstand extreme conditions while maintaining structural integrity is paramount. The automotive sector follows closely, with growing adoption of FGMs in engine components, exhaust systems, and lightweight structural parts to enhance fuel efficiency and reduce emissions.

Medical and dental applications represent the fastest-growing segment, with a projected CAGR of 17.2% through 2028. The biocompatibility of certain FGMs, combined with their ability to mimic natural tissue gradients, makes them ideal for implants, prosthetics, and tissue engineering scaffolds. This application area is expected to revolutionize personalized medicine approaches.

Regionally, North America leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the highest growth rate, fueled by rapid industrialization in China, Japan, and South Korea, along with increasing R&D investments in advanced materials.

Key market drivers include technological advancements in manufacturing processes, particularly Volumetric Additive Manufacturing (VAM), which enables more precise control over material gradients. Additionally, growing emphasis on lightweight materials in transportation, increasing healthcare expenditure, and stringent environmental regulations promoting sustainable materials are propelling market expansion.

Challenges hindering market growth include high production costs, limited standardization, and technical complexities in manufacturing consistent gradient structures at scale. The average cost premium for FGM components remains 30-40% higher than conventional materials, presenting a significant barrier to widespread adoption in price-sensitive applications.

Customer demand patterns indicate growing interest in multi-functional FGMs that can simultaneously address thermal, mechanical, and electrical requirements. End-users increasingly seek customized gradient profiles tailored to specific application environments, driving manufacturers toward more flexible production capabilities and collaborative design approaches.

Aerospace and defense sectors currently dominate the FGM market, accounting for nearly 35% of total demand. These industries leverage FGMs for thermal barrier coatings, structural components, and radiation shields, where the ability to withstand extreme conditions while maintaining structural integrity is paramount. The automotive sector follows closely, with growing adoption of FGMs in engine components, exhaust systems, and lightweight structural parts to enhance fuel efficiency and reduce emissions.

Medical and dental applications represent the fastest-growing segment, with a projected CAGR of 17.2% through 2028. The biocompatibility of certain FGMs, combined with their ability to mimic natural tissue gradients, makes them ideal for implants, prosthetics, and tissue engineering scaffolds. This application area is expected to revolutionize personalized medicine approaches.

Regionally, North America leads the market with approximately 38% share, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is witnessing the highest growth rate, fueled by rapid industrialization in China, Japan, and South Korea, along with increasing R&D investments in advanced materials.

Key market drivers include technological advancements in manufacturing processes, particularly Volumetric Additive Manufacturing (VAM), which enables more precise control over material gradients. Additionally, growing emphasis on lightweight materials in transportation, increasing healthcare expenditure, and stringent environmental regulations promoting sustainable materials are propelling market expansion.

Challenges hindering market growth include high production costs, limited standardization, and technical complexities in manufacturing consistent gradient structures at scale. The average cost premium for FGM components remains 30-40% higher than conventional materials, presenting a significant barrier to widespread adoption in price-sensitive applications.

Customer demand patterns indicate growing interest in multi-functional FGMs that can simultaneously address thermal, mechanical, and electrical requirements. End-users increasingly seek customized gradient profiles tailored to specific application environments, driving manufacturers toward more flexible production capabilities and collaborative design approaches.

Current VAM Technical Challenges

Volumetric Additive Manufacturing (VAM) for Functional Gradient Materials faces several significant technical challenges that currently limit its widespread industrial adoption. The primary obstacle remains the resolution limitations in complex gradient structures. While VAM offers unprecedented speed advantages through simultaneous solidification, achieving microscale precision for functional gradient materials requires overcoming optical diffraction limits and light scattering effects that occur within photopolymer resins.

Material compatibility presents another substantial hurdle. The current range of photosensitive resins capable of producing functional gradient properties is severely restricted. Most commercially available resins are designed for homogeneous properties, making it difficult to create true property gradients without significant material development. Additionally, multi-material VAM systems struggle with cross-contamination between different material zones during the printing process.

Process control and repeatability remain challenging due to the complex photochemistry involved in VAM. Light intensity distribution, photoinitiator concentration gradients, and oxygen inhibition effects all contribute to inconsistent curing patterns. These variables become even more difficult to manage when attempting to create controlled property gradients across a single part, often resulting in unpredictable mechanical performance.

Computational modeling limitations further complicate VAM implementation. Current simulation tools inadequately predict light propagation through complex gradient structures, particularly when dealing with varying material properties within the same build volume. This creates a significant gap between designed gradients and actual manufactured outcomes, hampering precise engineering applications.

Post-processing techniques for VAM-produced functional gradient materials remain underdeveloped. Unlike traditional additive manufacturing, where post-processing methods are well-established, VAM parts with property gradients often exhibit inconsistent shrinkage, internal stress distributions, and surface quality issues that are difficult to address with conventional finishing techniques.

Characterization and quality control methods specific to functional gradient materials produced via VAM are also lacking. Traditional testing approaches designed for homogeneous materials fail to adequately assess the performance of gradient structures, making it difficult to validate design specifications and ensure reproducibility across production runs.

Scaling VAM technology for larger functional gradient components introduces additional challenges related to light penetration depth, curing uniformity, and thermal management during the printing process. These factors currently limit the practical build volume for gradient structures with reliable property transitions.

Material compatibility presents another substantial hurdle. The current range of photosensitive resins capable of producing functional gradient properties is severely restricted. Most commercially available resins are designed for homogeneous properties, making it difficult to create true property gradients without significant material development. Additionally, multi-material VAM systems struggle with cross-contamination between different material zones during the printing process.

Process control and repeatability remain challenging due to the complex photochemistry involved in VAM. Light intensity distribution, photoinitiator concentration gradients, and oxygen inhibition effects all contribute to inconsistent curing patterns. These variables become even more difficult to manage when attempting to create controlled property gradients across a single part, often resulting in unpredictable mechanical performance.

Computational modeling limitations further complicate VAM implementation. Current simulation tools inadequately predict light propagation through complex gradient structures, particularly when dealing with varying material properties within the same build volume. This creates a significant gap between designed gradients and actual manufactured outcomes, hampering precise engineering applications.

Post-processing techniques for VAM-produced functional gradient materials remain underdeveloped. Unlike traditional additive manufacturing, where post-processing methods are well-established, VAM parts with property gradients often exhibit inconsistent shrinkage, internal stress distributions, and surface quality issues that are difficult to address with conventional finishing techniques.

Characterization and quality control methods specific to functional gradient materials produced via VAM are also lacking. Traditional testing approaches designed for homogeneous materials fail to adequately assess the performance of gradient structures, making it difficult to validate design specifications and ensure reproducibility across production runs.

Scaling VAM technology for larger functional gradient components introduces additional challenges related to light penetration depth, curing uniformity, and thermal management during the printing process. These factors currently limit the practical build volume for gradient structures with reliable property transitions.

Current VAM Solutions for FGM Production

01 Volumetric additive manufacturing techniques for functional gradient materials

Volumetric additive manufacturing enables the creation of functional gradient materials through techniques that allow for the simultaneous fabrication of entire volumes rather than layer-by-layer approaches. These methods include computed axial lithography, holographic stereolithography, and tomographic volumetric printing, which can create complex 3D structures with controlled material gradients in seconds to minutes, significantly faster than traditional additive manufacturing methods.- Volumetric additive manufacturing techniques for functional gradient materials: Various volumetric additive manufacturing techniques can be used to create functional gradient materials with controlled spatial distribution of properties. These techniques include computed axial lithography, holographic stereolithography, and tomographic volumetric printing, which allow for the creation of complex 3D structures with gradient properties in a single step, without the need for layer-by-layer processing. These methods enable faster production times and improved mechanical properties in the resulting materials.

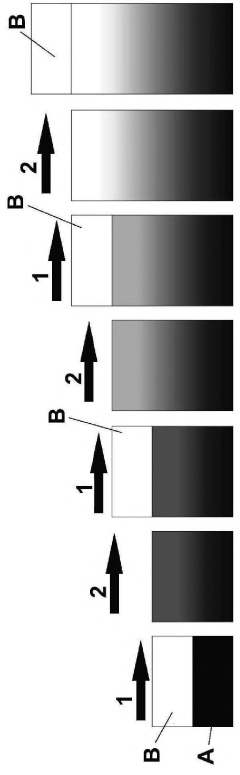

- Material composition control for functional gradient structures: Controlling the composition of materials during the additive manufacturing process is crucial for creating functional gradient materials. This involves precise mixing and deposition of different materials or varying the concentration of specific components to achieve gradual transitions in properties such as density, strength, or thermal conductivity. Advanced material feeding systems and multi-material printing heads are used to control the spatial distribution of different materials within a single structure.

- Process parameters optimization for gradient property control: Optimizing process parameters is essential for controlling the gradient properties in volumetrically manufactured parts. Parameters such as light intensity, exposure time, temperature gradients, and material flow rates can be precisely controlled to achieve desired property variations across the manufactured component. Advanced algorithms and machine learning techniques are employed to optimize these parameters for specific gradient material applications.

- Design methodologies for functional gradient materials: Specialized design methodologies are developed for creating functional gradient materials through volumetric additive manufacturing. These include topology optimization, generative design algorithms, and computational modeling approaches that can predict the performance of gradient structures. These design tools enable engineers to create optimized gradient structures that meet specific functional requirements while considering manufacturing constraints.

- Applications of volumetrically manufactured functional gradient materials: Volumetrically manufactured functional gradient materials find applications in various fields including biomedical implants, aerospace components, energy absorption structures, and thermal management systems. The ability to create controlled property gradients allows for components with location-specific functionalities, such as implants with varying stiffness to match surrounding tissues or heat exchangers with optimized thermal conductivity distributions.

02 Material composition control for functional gradient properties

Controlling material composition during the volumetric additive manufacturing process allows for the creation of functional gradient materials with tailored properties. By precisely varying the concentration, distribution, or type of materials across the volume, manufacturers can achieve gradual transitions in mechanical, thermal, optical, or electrical properties. This approach enables the development of components with location-specific functionalities and performance characteristics.Expand Specific Solutions03 Process parameters and control systems for gradient material fabrication

Advanced control systems and process parameters are essential for successful fabrication of functional gradient materials using volumetric additive manufacturing. These systems manage variables such as light intensity, exposure time, material flow, and temperature gradients to achieve precise material transitions. Real-time monitoring and feedback mechanisms ensure consistent quality and reproducibility in the manufacturing of gradient structures.Expand Specific Solutions04 Multi-material integration and interface engineering

Volumetric additive manufacturing enables the integration of multiple materials with different properties into a single component with engineered interfaces. This capability is crucial for functional gradient materials where the transition between different materials must be carefully controlled to avoid stress concentrations, delamination, or other interface failures. Advanced techniques allow for smooth property transitions across material boundaries.Expand Specific Solutions05 Applications and performance optimization of functional gradient materials

Functional gradient materials produced through volumetric additive manufacturing find applications in various fields including aerospace, biomedical, electronics, and energy sectors. These materials can be optimized for specific performance requirements such as improved mechanical strength, thermal management, wear resistance, or biocompatibility. The ability to create customized property gradients enables the development of components with enhanced functionality and durability for demanding applications.Expand Specific Solutions

Leading Companies in VAM Industry

Volumetric Additive Manufacturing for Functional Gradient Materials is currently in an emerging growth phase, with the market expected to expand significantly as industries recognize its potential for creating complex, multi-material structures with tailored properties. The global market is estimated to reach $2-3 billion by 2028, driven by applications in aerospace, medical, and automotive sectors. Technologically, the field shows varying maturity levels across players: established companies like Stratasys, Xerox, and Rolls-Royce are advancing commercial applications, while research institutions such as Lawrence Livermore National Laboratory, EPFL, and Chinese academic institutions (University of Science & Technology Beijing, Northwestern Polytechnical University) are pushing fundamental innovations. Specialized firms like Readily3D and Additive Marking are developing niche solutions, while industrial giants including Siemens Energy, Halliburton, and GKN Sinter Metals are integrating this technology into manufacturing workflows.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has developed advanced volumetric additive manufacturing (VAM) techniques for functional gradient materials using their proprietary Direct Ink Writing (DIW) technology. Their approach enables precise control over material composition throughout the printed structure by dynamically mixing multiple materials during the printing process. The technology utilizes high-precision multi-material extruders with mixing chambers that can create continuous gradients between different materials, allowing for seamless transitions in mechanical, thermal, and electrical properties. Their system incorporates real-time feedback control that monitors material flow rates and adjusts parameters to maintain consistent gradient profiles[1]. LLNL has particularly focused on developing functionally graded metal-ceramic composites for extreme environment applications, where they've demonstrated the ability to create components with heat-resistant ceramic exteriors that gradually transition to tough metallic cores[3]. Their technology has been successfully applied to create components for nuclear applications, defense systems, and energy storage devices that require specific property gradients to function optimally.

Strengths: Superior control over material composition gradients with precision down to microscale; ability to create complex 3D structures with functional gradients in multiple directions; extensive experience with high-performance materials for extreme environments. Weaknesses: Higher manufacturing costs compared to conventional methods; longer production times due to complex material handling; requires specialized expertise to operate and maintain the advanced systems.

The Regents of the University of California

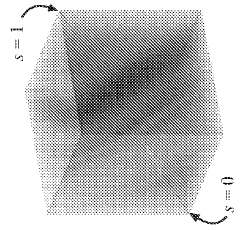

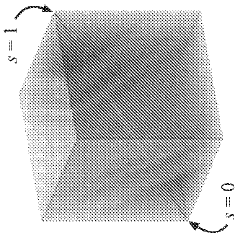

Technical Solution: The University of California has pioneered volumetric additive manufacturing for functional gradient materials through their innovative Computed Axial Lithography (CAL) technology. This approach represents a paradigm shift in 3D printing by creating entire volumes simultaneously rather than layer-by-layer. Their system projects synchronized patterns of light into a rotating volume of photosensitive resin, creating complex 3D structures in seconds to minutes[7]. For functional gradient materials, they've developed specialized photopolymer formulations with varying concentrations of functional additives that respond differently to specific light wavelengths. This enables the creation of components with continuously varying mechanical, optical, and electrical properties throughout the volume. The UC system has demonstrated the ability to create gradient structures with 100-micron resolution and smooth property transitions without the layer lines typical in conventional additive manufacturing[8]. Their research has expanded to include multi-material systems that can incorporate ceramic particles, conductive elements, and even biological materials within a single print. Applications include patient-specific medical devices with biomimetic property gradients, optical components with refractive index gradients, and structural components with optimized stress distribution through strategic property variation.

Strengths: Revolutionary speed (10-100x faster than conventional methods); ability to create truly volumetric gradients without layer artifacts; excellent for creating optically clear components with property gradients; suitable for biomedical applications requiring smooth transitions. Weaknesses: Currently limited to photopolymer-based materials; size constraints on buildable volumes; challenges in creating sharp boundaries between different material regions; relatively new technology with fewer established industrial applications.

Key Patents in Volumetric Printing Technology

Systems and methods for predictive tool path planning for additive manufacturing of functionally graded materials

PatentWO2024129177A1

Innovation

- A predictive tool path planning method using a control system that adjusts the mixing ratio in real-time to generate optimized G-code for FGMs, incorporating a look-ahead routine and purge routine to minimize material waste and ensure accurate gradient transitions, allowing for consistent line spacing and orientation adjustments to follow the contours of the gradient.

Process for producing functionally graded multi-material materials and components from functionally graded multi-material materials

PatentPendingDE102022131122A1

Innovation

- A method involving additive manufacturing with remelting steps to create a continuous gradient by applying and remelting layers of materials, using laser energy to enhance in-situ mixing and control chemical composition along a component axis.

Material Science Developments for VAM

Material science advancements have been pivotal in expanding the capabilities of Volumetric Additive Manufacturing (VAM) for functional gradient materials. Recent developments have focused on photopolymer resins with enhanced mechanical properties, thermal stability, and optical characteristics specifically tailored for VAM processes. These materials exhibit controlled curing kinetics that allow for precise solidification within predetermined volumetric regions when exposed to specific light patterns.

Significant progress has been made in developing dual-cure resin systems that combine photopolymerization with secondary curing mechanisms such as thermal or moisture-activated processes. This approach enables the creation of materials with hierarchical structures and improved mechanical integrity. The incorporation of nanoparticles, including silica, carbon nanotubes, and metallic nanoparticles, has further expanded the functional properties of VAM-compatible materials, allowing for the production of components with gradient electrical conductivity, thermal management capabilities, and magnetic responsiveness.

Biomaterial science has contributed substantially to VAM material development, with hydrogel formulations that maintain structural integrity during the printing process while supporting cellular viability. These materials feature tunable degradation rates and mechanical properties that can be spatially varied to mimic biological tissues, making them particularly valuable for medical applications such as tissue engineering and drug delivery systems.

Ceramic-polymer composites represent another frontier in VAM material science. These materials combine the processability of photopolymers with the high-temperature resistance and mechanical strength of ceramics. Post-processing techniques, including debinding and sintering protocols, have been optimized to convert printed polymer-ceramic composites into fully ceramic structures while maintaining dimensional accuracy and functional gradients.

Smart materials with stimuli-responsive properties have emerged as a promising direction for VAM. These include shape memory polymers, self-healing materials, and photochromic substances that can change properties in response to environmental triggers. The ability to precisely distribute these responsive elements throughout a component enables the creation of 4D printed structures that can transform or adapt their functionality over time.

Computational materials science has become increasingly integrated with VAM material development, employing machine learning algorithms to predict material behavior during the printing process and optimize formulations for specific applications. These computational approaches have accelerated the discovery of novel material compositions with predetermined property gradients, reducing the traditional trial-and-error approach to material development.

Significant progress has been made in developing dual-cure resin systems that combine photopolymerization with secondary curing mechanisms such as thermal or moisture-activated processes. This approach enables the creation of materials with hierarchical structures and improved mechanical integrity. The incorporation of nanoparticles, including silica, carbon nanotubes, and metallic nanoparticles, has further expanded the functional properties of VAM-compatible materials, allowing for the production of components with gradient electrical conductivity, thermal management capabilities, and magnetic responsiveness.

Biomaterial science has contributed substantially to VAM material development, with hydrogel formulations that maintain structural integrity during the printing process while supporting cellular viability. These materials feature tunable degradation rates and mechanical properties that can be spatially varied to mimic biological tissues, making them particularly valuable for medical applications such as tissue engineering and drug delivery systems.

Ceramic-polymer composites represent another frontier in VAM material science. These materials combine the processability of photopolymers with the high-temperature resistance and mechanical strength of ceramics. Post-processing techniques, including debinding and sintering protocols, have been optimized to convert printed polymer-ceramic composites into fully ceramic structures while maintaining dimensional accuracy and functional gradients.

Smart materials with stimuli-responsive properties have emerged as a promising direction for VAM. These include shape memory polymers, self-healing materials, and photochromic substances that can change properties in response to environmental triggers. The ability to precisely distribute these responsive elements throughout a component enables the creation of 4D printed structures that can transform or adapt their functionality over time.

Computational materials science has become increasingly integrated with VAM material development, employing machine learning algorithms to predict material behavior during the printing process and optimize formulations for specific applications. These computational approaches have accelerated the discovery of novel material compositions with predetermined property gradients, reducing the traditional trial-and-error approach to material development.

Sustainability Impact of VAM Technologies

Volumetric Additive Manufacturing (VAM) technologies represent a significant advancement in sustainable manufacturing practices, offering numerous environmental benefits compared to traditional manufacturing methods. The holistic approach of VAM for Functional Gradient Materials (FGM) substantially reduces material waste through its precise volumetric fabrication process, eliminating the need for support structures and minimizing post-processing requirements that typically generate substantial waste in conventional additive manufacturing.

Energy efficiency stands as another critical sustainability advantage of VAM technologies. The simultaneous curing process employed in VAM significantly reduces energy consumption compared to layer-by-layer approaches, with some studies indicating energy savings of up to 40-60% depending on the specific application and material system. This efficiency is particularly pronounced when producing complex FGM structures that would otherwise require multiple manufacturing steps.

The life cycle assessment (LCA) of VAM technologies reveals favorable environmental metrics across multiple categories. Carbon footprint analyses demonstrate that VAM processes can reduce greenhouse gas emissions by 25-35% compared to traditional manufacturing methods for equivalent FGM components. Additionally, the technology enables more efficient material utilization, with material efficiency rates often exceeding 90%, substantially higher than conventional subtractive manufacturing techniques.

VAM technologies also contribute to circular economy principles through enhanced product longevity and recyclability. The precise control over material composition and distribution in FGMs allows for optimized performance characteristics, extending product lifespan and reducing replacement frequency. Furthermore, the ability to create multi-material structures with predetermined separation points facilitates end-of-life disassembly and material recovery.

Water conservation represents another sustainability benefit, as VAM processes typically require minimal water usage compared to traditional manufacturing methods that often involve water-intensive cooling and cleaning processes. This aspect is particularly relevant in regions facing water scarcity challenges.

Looking forward, the sustainability impact of VAM technologies is expected to further improve through ongoing research into bio-based and recyclable photopolymers specifically designed for volumetric manufacturing processes. These developments aim to address current limitations related to resin recyclability and biodegradability, potentially creating fully sustainable manufacturing ecosystems for next-generation functional gradient materials.

Energy efficiency stands as another critical sustainability advantage of VAM technologies. The simultaneous curing process employed in VAM significantly reduces energy consumption compared to layer-by-layer approaches, with some studies indicating energy savings of up to 40-60% depending on the specific application and material system. This efficiency is particularly pronounced when producing complex FGM structures that would otherwise require multiple manufacturing steps.

The life cycle assessment (LCA) of VAM technologies reveals favorable environmental metrics across multiple categories. Carbon footprint analyses demonstrate that VAM processes can reduce greenhouse gas emissions by 25-35% compared to traditional manufacturing methods for equivalent FGM components. Additionally, the technology enables more efficient material utilization, with material efficiency rates often exceeding 90%, substantially higher than conventional subtractive manufacturing techniques.

VAM technologies also contribute to circular economy principles through enhanced product longevity and recyclability. The precise control over material composition and distribution in FGMs allows for optimized performance characteristics, extending product lifespan and reducing replacement frequency. Furthermore, the ability to create multi-material structures with predetermined separation points facilitates end-of-life disassembly and material recovery.

Water conservation represents another sustainability benefit, as VAM processes typically require minimal water usage compared to traditional manufacturing methods that often involve water-intensive cooling and cleaning processes. This aspect is particularly relevant in regions facing water scarcity challenges.

Looking forward, the sustainability impact of VAM technologies is expected to further improve through ongoing research into bio-based and recyclable photopolymers specifically designed for volumetric manufacturing processes. These developments aim to address current limitations related to resin recyclability and biodegradability, potentially creating fully sustainable manufacturing ecosystems for next-generation functional gradient materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!