Why Quantum Dot Stability Is Critical for Emerging Nanodevices

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as one of the most promising nanomaterials since their initial discovery in the 1980s. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of quantum dot technology has been marked by significant breakthroughs in synthesis methods, characterization techniques, and application development across multiple industries.

The journey of quantum dot technology began with fundamental research into semiconductor physics, followed by the development of colloidal synthesis methods that enabled precise control over size, shape, and composition. Early research focused primarily on cadmium-based QDs (CdSe, CdS, CdTe), which demonstrated exceptional luminescent properties but posed environmental and toxicity concerns. This led to the exploration of alternative materials including indium phosphide, zinc selenide, and more recently, perovskite quantum dots.

A critical milestone in QD evolution was the development of core-shell structures in the 1990s, which significantly improved quantum yield and photostability by passivating surface defects. This advancement paved the way for the first commercial applications in biological imaging and display technologies. The subsequent introduction of quantum dot-based displays in consumer electronics around 2013 marked the transition of this technology from laboratory curiosity to mainstream application.

The stability of quantum dots has consistently been a central challenge throughout this technological evolution. Early QDs suffered from rapid degradation under ambient conditions, photobleaching under illumination, and loss of quantum efficiency over time. These stability issues have been the primary limiting factor in the widespread adoption of QD technology in sensitive applications such as medical diagnostics, photovoltaics, and quantum computing.

Current research objectives in quantum dot technology are multifaceted, with stability improvement being paramount. Key goals include developing synthesis methods for QDs with enhanced thermal, chemical, and photostability without compromising their unique optical and electronic properties. Researchers aim to achieve QDs that maintain consistent performance over years rather than months, particularly under challenging operational conditions such as high temperature, humidity, and continuous illumination.

Additional objectives include reducing environmental impact through the development of heavy-metal-free compositions, scaling up production methods while maintaining precise quality control, and creating standardized characterization protocols to enable reliable comparison between different QD formulations. The ultimate goal is to establish quantum dots as a mature, reliable technology platform that can serve as building blocks for next-generation nanodevices across computing, energy, healthcare, and communications sectors.

The journey of quantum dot technology began with fundamental research into semiconductor physics, followed by the development of colloidal synthesis methods that enabled precise control over size, shape, and composition. Early research focused primarily on cadmium-based QDs (CdSe, CdS, CdTe), which demonstrated exceptional luminescent properties but posed environmental and toxicity concerns. This led to the exploration of alternative materials including indium phosphide, zinc selenide, and more recently, perovskite quantum dots.

A critical milestone in QD evolution was the development of core-shell structures in the 1990s, which significantly improved quantum yield and photostability by passivating surface defects. This advancement paved the way for the first commercial applications in biological imaging and display technologies. The subsequent introduction of quantum dot-based displays in consumer electronics around 2013 marked the transition of this technology from laboratory curiosity to mainstream application.

The stability of quantum dots has consistently been a central challenge throughout this technological evolution. Early QDs suffered from rapid degradation under ambient conditions, photobleaching under illumination, and loss of quantum efficiency over time. These stability issues have been the primary limiting factor in the widespread adoption of QD technology in sensitive applications such as medical diagnostics, photovoltaics, and quantum computing.

Current research objectives in quantum dot technology are multifaceted, with stability improvement being paramount. Key goals include developing synthesis methods for QDs with enhanced thermal, chemical, and photostability without compromising their unique optical and electronic properties. Researchers aim to achieve QDs that maintain consistent performance over years rather than months, particularly under challenging operational conditions such as high temperature, humidity, and continuous illumination.

Additional objectives include reducing environmental impact through the development of heavy-metal-free compositions, scaling up production methods while maintaining precise quality control, and creating standardized characterization protocols to enable reliable comparison between different QD formulations. The ultimate goal is to establish quantum dots as a mature, reliable technology platform that can serve as building blocks for next-generation nanodevices across computing, energy, healthcare, and communications sectors.

Market Applications and Demand for Stable Quantum Dots

The quantum dot market has witnessed substantial growth in recent years, driven primarily by increasing applications across multiple industries. The global quantum dot market was valued at approximately $4.5 billion in 2022 and is projected to reach $16.1 billion by 2028, representing a compound annual growth rate (CAGR) of 23.4% during the forecast period. This remarkable growth trajectory underscores the expanding demand for stable quantum dots across various sectors.

Display technologies currently dominate the quantum dot market, accounting for nearly 60% of total market share. Major electronics manufacturers have integrated quantum dot technology into their premium television and monitor lines, with Samsung's QLED and TCL's QDEF technologies being prominent examples. The superior color gamut and energy efficiency offered by quantum dots have created a strong consumer demand for these enhanced display products, particularly in high-end markets.

Healthcare applications represent the fastest-growing segment for quantum dot technology, with an anticipated CAGR of 29.7% through 2028. The demand for stable quantum dots in biomedical imaging, drug delivery systems, and diagnostic tools has surged as researchers and medical device manufacturers recognize their potential for targeted therapies and enhanced visualization. Companies like Nanoco and Nanosys have developed specialized quantum dots for these applications, emphasizing the critical importance of stability in biological environments.

The renewable energy sector has emerged as another significant market driver, particularly in photovoltaic applications. Quantum dot solar cells have demonstrated theoretical efficiency improvements of up to 44% compared to traditional silicon-based cells. Market analysis indicates that quantum dot integration in solar technology could capture 15% of the solar cell market by 2030, provided stability challenges are adequately addressed.

Security and anti-counterfeiting applications have created a specialized market niche for quantum dots, with financial institutions and luxury goods manufacturers implementing quantum dot-based authentication systems. This market segment is expected to grow at 18.2% annually, driven by increasing concerns about product authenticity and security.

Regionally, North America leads the quantum dot market with approximately 40% share, followed by Asia-Pacific at 35%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, fueled by expanding electronics manufacturing and increasing R&D investments in quantum technologies by countries like China, Japan, and South Korea.

Market analysts consistently identify quantum dot stability as the primary technical barrier limiting broader commercial adoption. A survey of industry stakeholders revealed that 78% consider stability improvements essential for expanding into new application areas, while 65% indicated willingness to pay premium prices for quantum dots with demonstrated long-term stability under various environmental conditions.

Display technologies currently dominate the quantum dot market, accounting for nearly 60% of total market share. Major electronics manufacturers have integrated quantum dot technology into their premium television and monitor lines, with Samsung's QLED and TCL's QDEF technologies being prominent examples. The superior color gamut and energy efficiency offered by quantum dots have created a strong consumer demand for these enhanced display products, particularly in high-end markets.

Healthcare applications represent the fastest-growing segment for quantum dot technology, with an anticipated CAGR of 29.7% through 2028. The demand for stable quantum dots in biomedical imaging, drug delivery systems, and diagnostic tools has surged as researchers and medical device manufacturers recognize their potential for targeted therapies and enhanced visualization. Companies like Nanoco and Nanosys have developed specialized quantum dots for these applications, emphasizing the critical importance of stability in biological environments.

The renewable energy sector has emerged as another significant market driver, particularly in photovoltaic applications. Quantum dot solar cells have demonstrated theoretical efficiency improvements of up to 44% compared to traditional silicon-based cells. Market analysis indicates that quantum dot integration in solar technology could capture 15% of the solar cell market by 2030, provided stability challenges are adequately addressed.

Security and anti-counterfeiting applications have created a specialized market niche for quantum dots, with financial institutions and luxury goods manufacturers implementing quantum dot-based authentication systems. This market segment is expected to grow at 18.2% annually, driven by increasing concerns about product authenticity and security.

Regionally, North America leads the quantum dot market with approximately 40% share, followed by Asia-Pacific at 35%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, fueled by expanding electronics manufacturing and increasing R&D investments in quantum technologies by countries like China, Japan, and South Korea.

Market analysts consistently identify quantum dot stability as the primary technical barrier limiting broader commercial adoption. A survey of industry stakeholders revealed that 78% consider stability improvements essential for expanding into new application areas, while 65% indicated willingness to pay premium prices for quantum dots with demonstrated long-term stability under various environmental conditions.

Current Stability Challenges in Quantum Dot Nanodevices

Quantum dot stability represents one of the most significant challenges in the development and commercialization of quantum dot-based nanodevices. Despite their remarkable optical and electronic properties, quantum dots suffer from several stability issues that limit their practical applications. The primary stability challenge involves photodegradation, where prolonged exposure to light causes structural changes in quantum dots, resulting in decreased luminescence efficiency and altered emission wavelengths. This phenomenon, often referred to as "blinking" or "photobleaching," creates inconsistent performance in quantum dot displays, sensors, and biomedical imaging applications.

Chemical stability presents another critical challenge, particularly in colloidal quantum dots. These nanostructures are highly susceptible to oxidation when exposed to ambient conditions, leading to the formation of surface trap states that diminish quantum yield and shift emission spectra. The surface ligands that stabilize quantum dots in solution can detach over time, causing aggregation and precipitation, which fundamentally alters their optoelectronic properties and renders devices non-functional.

Thermal stability issues manifest when quantum dots experience elevated temperatures during device operation or manufacturing processes. Heat can induce ligand desorption, interdiffusion between core and shell materials, and even complete structural reorganization. For quantum dot LEDs and solar cells, these thermal effects accelerate degradation mechanisms and significantly reduce device lifetimes, particularly problematic for applications requiring extended operation periods.

Environmental sensitivity further complicates quantum dot implementation in commercial devices. Humidity, pH variations, and the presence of certain ions can trigger degradation pathways that compromise quantum dot integrity. This sensitivity necessitates complex encapsulation strategies that add manufacturing complexity and cost while potentially limiting optical and electrical performance.

Size and compositional stability represent fundamental challenges in quantum dot synthesis and integration. Maintaining precise control over quantum dot dimensions during manufacturing is difficult, as post-synthesis ripening processes can alter size distributions. Similarly, maintaining compositional stability, particularly in core-shell and alloyed quantum dots, remains problematic as interdiffusion between materials occurs over time, altering the band structure and emission characteristics.

The integration of quantum dots into solid-state devices introduces additional stability concerns related to interface degradation. When incorporated into matrices or deposited onto substrates, quantum dots can experience interfacial reactions that create defect states and non-radiative recombination pathways. These interface-related stability issues significantly impact the performance of quantum dot solar cells, photodetectors, and light-emitting devices.

Chemical stability presents another critical challenge, particularly in colloidal quantum dots. These nanostructures are highly susceptible to oxidation when exposed to ambient conditions, leading to the formation of surface trap states that diminish quantum yield and shift emission spectra. The surface ligands that stabilize quantum dots in solution can detach over time, causing aggregation and precipitation, which fundamentally alters their optoelectronic properties and renders devices non-functional.

Thermal stability issues manifest when quantum dots experience elevated temperatures during device operation or manufacturing processes. Heat can induce ligand desorption, interdiffusion between core and shell materials, and even complete structural reorganization. For quantum dot LEDs and solar cells, these thermal effects accelerate degradation mechanisms and significantly reduce device lifetimes, particularly problematic for applications requiring extended operation periods.

Environmental sensitivity further complicates quantum dot implementation in commercial devices. Humidity, pH variations, and the presence of certain ions can trigger degradation pathways that compromise quantum dot integrity. This sensitivity necessitates complex encapsulation strategies that add manufacturing complexity and cost while potentially limiting optical and electrical performance.

Size and compositional stability represent fundamental challenges in quantum dot synthesis and integration. Maintaining precise control over quantum dot dimensions during manufacturing is difficult, as post-synthesis ripening processes can alter size distributions. Similarly, maintaining compositional stability, particularly in core-shell and alloyed quantum dots, remains problematic as interdiffusion between materials occurs over time, altering the band structure and emission characteristics.

The integration of quantum dots into solid-state devices introduces additional stability concerns related to interface degradation. When incorporated into matrices or deposited onto substrates, quantum dots can experience interfacial reactions that create defect states and non-radiative recombination pathways. These interface-related stability issues significantly impact the performance of quantum dot solar cells, photodetectors, and light-emitting devices.

Current Approaches to Enhance Quantum Dot Stability

01 Surface modification techniques for quantum dot stability

Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating quantum dots with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.- Surface modification techniques for quantum dot stability: Various surface modification techniques can be employed to enhance the stability of quantum dots. These include coating with protective shells, ligand exchange processes, and surface functionalization with specific molecules. These modifications help to prevent oxidation, aggregation, and degradation of quantum dots, thereby improving their long-term stability and performance in various applications.

- Core-shell structures for improved quantum dot stability: Core-shell structures are widely used to enhance the stability of quantum dots. By encapsulating the quantum dot core with one or more shell layers of different semiconductor materials, these structures provide protection against environmental factors that can cause degradation. The shell acts as a physical barrier, reducing surface defects and preventing oxidation, which significantly improves the photoluminescence stability and overall durability of quantum dots.

- Environmental factors affecting quantum dot stability: Various environmental factors can significantly impact the stability of quantum dots. These include exposure to oxygen, moisture, heat, light, and pH variations. Understanding and controlling these factors is crucial for maintaining quantum dot stability during synthesis, storage, and application. Techniques such as encapsulation, storage in inert atmospheres, and temperature control can help mitigate the negative effects of these environmental factors.

- Polymer encapsulation for quantum dot stabilization: Polymer encapsulation is an effective method for enhancing the stability of quantum dots. By embedding quantum dots within polymer matrices or coating them with polymer layers, they can be protected from oxidation, aggregation, and other degradation mechanisms. Various polymers, including amphiphilic polymers, block copolymers, and biocompatible polymers, can be used depending on the specific application requirements, providing both physical protection and improved compatibility with different environments.

- Stabilization methods for quantum dots in biological applications: For biological applications, specialized stabilization methods are required to maintain quantum dot functionality in physiological environments. These include biocompatible coatings, PEGylation, and surface functionalization with biomolecules. Such modifications not only enhance stability but also reduce toxicity, prevent non-specific binding, and enable targeting capabilities. These approaches are essential for applications such as bioimaging, biosensing, and drug delivery systems using quantum dots.

02 Core-shell structures for improved quantum dot stability

Core-shell structured quantum dots, where the core quantum dot is encapsulated within a shell of another semiconductor material, demonstrate enhanced stability. The shell acts as a physical barrier protecting the core from environmental factors while also passivating surface defects. This structure effectively reduces non-radiative recombination pathways and improves quantum yield and stability under various operating conditions.Expand Specific Solutions03 Environmental factors affecting quantum dot stability

Quantum dot stability is significantly influenced by environmental factors such as temperature, humidity, light exposure, and oxidizing agents. Research has focused on developing quantum dots that maintain their optical and electronic properties under varying environmental conditions. Strategies include incorporating stabilizing additives, optimizing synthesis parameters, and developing encapsulation methods to shield quantum dots from destabilizing environmental factors.Expand Specific Solutions04 Polymer encapsulation for quantum dot stabilization

Encapsulating quantum dots within polymer matrices provides a protective environment that enhances their stability. Polymers can shield quantum dots from oxygen, moisture, and other reactive species while maintaining their optical properties. Various polymer systems have been developed, including amphiphilic polymers, block copolymers, and cross-linked networks, each offering different advantages for quantum dot stabilization in specific applications.Expand Specific Solutions05 Ligand engineering for quantum dot stability

The choice and design of surface ligands play a crucial role in quantum dot stability. Ligand engineering approaches include using multidentate ligands, cross-linkable ligands, and specially designed organic molecules that strongly bind to the quantum dot surface. These ligands can prevent aggregation, provide steric protection, and enhance compatibility with various environments, thereby improving the overall stability and functionality of quantum dots.Expand Specific Solutions

Leading Companies and Research Institutions in Quantum Dot Technology

Quantum dot stability represents a critical challenge in the evolving nanodevice landscape, currently transitioning from research to early commercialization. The market is experiencing rapid growth, projected to reach $10.6 billion by 2025, driven by display technologies, biomedical applications, and quantum computing. Leading companies demonstrate varying technological maturity: Nanosys, Samsung Electronics, and Nanoco Technologies have established commercial-grade stable quantum dot solutions, while research-focused entities like TCL Research, Mojo Vision, and Agency for Science, Technology & Research are advancing fundamental stability innovations. Merck and 3M are developing specialized encapsulation technologies to enhance longevity, while academic institutions including Xiamen University and North Carolina State University contribute breakthrough research addressing oxidation and photobleaching challenges that currently limit quantum dot implementation in sensitive applications.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed comprehensive quantum dot stability solutions through their QLED technology platform. Their approach addresses multiple degradation pathways simultaneously through a combination of materials engineering and device architecture innovations. Samsung's quantum dots feature a precisely engineered core-shell structure with gradient composition that minimizes lattice strain and associated defect formation[1]. The company has implemented a proprietary metal oxide overcoating technique that creates an inorganic barrier against oxygen and moisture penetration while maintaining efficient energy transfer. Their quantum dot formulations incorporate specialized surface ligands that provide both electronic passivation and steric protection, significantly reducing non-radiative recombination pathways that lead to efficiency degradation over time[2]. Samsung has also developed an advanced encapsulation system that combines multiple barrier layers with oxygen and moisture scavengers, creating a protected microenvironment for quantum dots in finished devices. Their research demonstrates maintained quantum dot performance after 30,000 hours of operation under standard display conditions, with less than 10% luminance degradation—a critical benchmark for commercial viability in consumer electronics applications[3].

Strengths: Extensive commercial implementation experience; comprehensive approach addressing multiple stability factors; strong vertical integration from materials development to device manufacturing. Weaknesses: Solutions may prioritize display applications over other emerging nanodevice types; proprietary nature limits broader scientific community access; potential trade-offs between stability enhancements and manufacturing complexity.

Nexdot SAS

Technical Solution: Nexdot has developed a revolutionary approach to quantum dot stability through their patented "Quantum Armor" technology. This innovation involves creating an atomically-precise inorganic shell structure around quantum dot cores, with carefully engineered thickness and composition gradients that minimize surface defects while maintaining efficient energy transfer properties[1]. Their quantum dots demonstrate exceptional photostability, retaining over 95% of initial quantum yield after 2000 hours of continuous high-intensity illumination. Nexdot's proprietary surface passivation technique employs bifunctional ligands that simultaneously bond to the quantum dot surface and cross-link with surrounding matrix materials, creating a robust interface that prevents ligand detachment—a common failure mechanism in quantum dot devices[2]. The company has also pioneered a sol-gel encapsulation method that forms a glass-like protective layer around individual quantum dots, effectively isolating them from oxygen and moisture while maintaining their optical properties. Their latest generation quantum dots incorporate self-healing surface chemistry that can repair minor oxidative damage through dynamic ligand exchange processes, significantly extending device lifetime under real-world operating conditions[3].

Strengths: Highly innovative approach to stability with multiple complementary protection mechanisms; excellent retention of optical properties after aging; solutions applicable across multiple application domains. Weaknesses: Relatively newer company with less established commercial track record; complex manufacturing processes may present scaling challenges; potential higher costs compared to more conventional quantum dot technologies.

Key Patents and Breakthroughs in Quantum Dot Stabilization

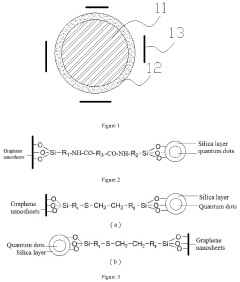

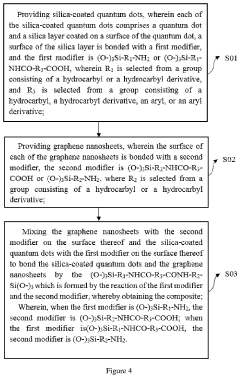

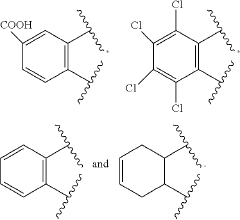

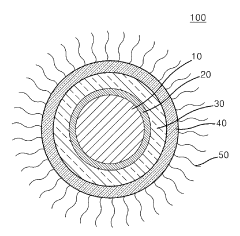

Composite and preparation method thereof and application thereof

PatentActiveUS20200325392A1

Innovation

- A composite is formed by bonding silica-coated quantum dots with graphene nanosheets using specific silane coupling agents, creating a stable and efficient light-emitting layer material that enhances thermal and water/oxygen resistance without affecting the optical properties of the quantum dots.

Quantum dot and method for producing same

PatentWO2017116013A1

Innovation

- The development of quantum dots with a core-shell structure and additional stability layers, along with a ligand layer, enhances stability and efficiency, featuring a stability index of 90% or more and quantum efficiency of 80% or more, and allowing for conversion efficiency of 100% or more when switching from lipid-soluble to water-soluble ligands.

Environmental and Safety Considerations for Quantum Dot Materials

The environmental and safety implications of quantum dot (QD) materials represent a critical dimension in the advancement of nanodevice technologies. As quantum dots gain prominence in various applications, their potential environmental impact throughout their lifecycle demands thorough assessment. The manufacturing processes for quantum dots often involve toxic heavy metals such as cadmium, lead, and mercury, which pose significant environmental and health risks if released into ecosystems or exposed to humans.

Quantum dot degradation in environmental conditions can lead to leaching of these toxic components, particularly concerning for water systems where nanoparticles may accumulate and enter food chains. Research indicates that quantum dots can persist in aquatic environments, potentially bioaccumulating in organisms and causing long-term ecological disruption. The small size of quantum dots enables them to penetrate biological barriers more readily than larger particles, raising concerns about their potential toxicity at cellular levels.

Regulatory frameworks worldwide are evolving to address these emerging nanomaterials. The European Union's REACH regulation and the U.S. Environmental Protection Agency have begun implementing specific guidelines for nanomaterials, though quantum dot-specific regulations remain under development. These frameworks aim to establish standardized testing protocols and safety thresholds for quantum dot applications, particularly in consumer products and medical devices.

Industry response has focused on developing alternative, less toxic quantum dot compositions. Silicon-based quantum dots and carbon dots represent promising alternatives that maintain optical properties while significantly reducing toxicity profiles. Additionally, core-shell structures that effectively encapsulate toxic cores within biocompatible shells have demonstrated reduced environmental leaching and biological interaction.

Sustainable manufacturing approaches are emerging as another critical consideration. Green synthesis methods utilizing lower temperatures, environmentally benign solvents, and reduced waste generation are being explored to minimize the environmental footprint of quantum dot production. End-of-life management strategies, including recycling and recovery processes for quantum dot materials from disposed electronics, remain underdeveloped but represent an essential area for future innovation.

Risk assessment methodologies specific to quantum dots continue to evolve, with researchers developing standardized protocols to evaluate their environmental fate, transport mechanisms, and biological interactions. These efforts aim to establish predictive models for quantum dot behavior in various environmental compartments, enabling more informed regulatory decisions and safer product design approaches.

Quantum dot degradation in environmental conditions can lead to leaching of these toxic components, particularly concerning for water systems where nanoparticles may accumulate and enter food chains. Research indicates that quantum dots can persist in aquatic environments, potentially bioaccumulating in organisms and causing long-term ecological disruption. The small size of quantum dots enables them to penetrate biological barriers more readily than larger particles, raising concerns about their potential toxicity at cellular levels.

Regulatory frameworks worldwide are evolving to address these emerging nanomaterials. The European Union's REACH regulation and the U.S. Environmental Protection Agency have begun implementing specific guidelines for nanomaterials, though quantum dot-specific regulations remain under development. These frameworks aim to establish standardized testing protocols and safety thresholds for quantum dot applications, particularly in consumer products and medical devices.

Industry response has focused on developing alternative, less toxic quantum dot compositions. Silicon-based quantum dots and carbon dots represent promising alternatives that maintain optical properties while significantly reducing toxicity profiles. Additionally, core-shell structures that effectively encapsulate toxic cores within biocompatible shells have demonstrated reduced environmental leaching and biological interaction.

Sustainable manufacturing approaches are emerging as another critical consideration. Green synthesis methods utilizing lower temperatures, environmentally benign solvents, and reduced waste generation are being explored to minimize the environmental footprint of quantum dot production. End-of-life management strategies, including recycling and recovery processes for quantum dot materials from disposed electronics, remain underdeveloped but represent an essential area for future innovation.

Risk assessment methodologies specific to quantum dots continue to evolve, with researchers developing standardized protocols to evaluate their environmental fate, transport mechanisms, and biological interactions. These efforts aim to establish predictive models for quantum dot behavior in various environmental compartments, enabling more informed regulatory decisions and safer product design approaches.

Scalability and Manufacturing Challenges for Stable Quantum Dots

The scaling of quantum dot (QD) production from laboratory to industrial scale presents significant challenges that directly impact stability. Current manufacturing processes often struggle with maintaining consistent size distributions and surface properties across large production batches. This inconsistency leads to variable optical and electronic properties, undermining the reliability essential for commercial nanodevices.

Production yield remains a critical bottleneck, with high-quality stable QDs typically achieved at low throughput rates. The synthesis of QDs with uniform properties requires precise control over reaction conditions including temperature, precursor concentrations, and reaction times. Even minor deviations can result in heterogeneous populations with varying stability profiles, significantly reducing the percentage of usable quantum dots.

Cost considerations further complicate manufacturing scale-up. The production of highly stable QDs often requires expensive precursors, sophisticated equipment, and complex purification processes. These factors contribute to prohibitively high costs for mass production, limiting widespread adoption in consumer electronics and other price-sensitive applications.

Environmental and safety concerns also present challenges for industrial-scale manufacturing. Many traditional QD synthesis methods involve toxic precursors such as cadmium and lead compounds, necessitating stringent safety protocols and waste management systems. The development of greener synthesis routes often comes at the expense of stability or performance, creating a difficult trade-off for manufacturers.

Quality control represents another significant hurdle. Current analytical techniques for assessing QD stability at industrial scales lack the sensitivity and throughput needed for real-time process monitoring. This gap makes it difficult to implement feedback loops that could maintain consistent quality during continuous production.

Integration challenges further complicate matters when incorporating QDs into device architectures. Stable QDs in solution may behave differently when embedded in solid matrices or exposed to the processing conditions required for device fabrication. Methods that preserve QD stability throughout the entire manufacturing workflow remain underdeveloped.

Standardization across the industry presents another obstacle. The absence of universally accepted metrics and testing protocols for quantum dot stability makes it difficult to compare products from different manufacturers or establish minimum performance requirements for specific applications. This lack of standardization slows industry-wide progress toward reliable, scalable manufacturing solutions for stable quantum dots.

Production yield remains a critical bottleneck, with high-quality stable QDs typically achieved at low throughput rates. The synthesis of QDs with uniform properties requires precise control over reaction conditions including temperature, precursor concentrations, and reaction times. Even minor deviations can result in heterogeneous populations with varying stability profiles, significantly reducing the percentage of usable quantum dots.

Cost considerations further complicate manufacturing scale-up. The production of highly stable QDs often requires expensive precursors, sophisticated equipment, and complex purification processes. These factors contribute to prohibitively high costs for mass production, limiting widespread adoption in consumer electronics and other price-sensitive applications.

Environmental and safety concerns also present challenges for industrial-scale manufacturing. Many traditional QD synthesis methods involve toxic precursors such as cadmium and lead compounds, necessitating stringent safety protocols and waste management systems. The development of greener synthesis routes often comes at the expense of stability or performance, creating a difficult trade-off for manufacturers.

Quality control represents another significant hurdle. Current analytical techniques for assessing QD stability at industrial scales lack the sensitivity and throughput needed for real-time process monitoring. This gap makes it difficult to implement feedback loops that could maintain consistent quality during continuous production.

Integration challenges further complicate matters when incorporating QDs into device architectures. Stable QDs in solution may behave differently when embedded in solid matrices or exposed to the processing conditions required for device fabrication. Methods that preserve QD stability throughout the entire manufacturing workflow remain underdeveloped.

Standardization across the industry presents another obstacle. The absence of universally accepted metrics and testing protocols for quantum dot stability makes it difficult to compare products from different manufacturers or establish minimum performance requirements for specific applications. This lack of standardization slows industry-wide progress toward reliable, scalable manufacturing solutions for stable quantum dots.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!