Process for the production of enamelled steel sheet or part

A technology for steel sheets and parts, applied in the field of producing enamel steel sheets or parts, can solve the problems of time and temperature no longer meeting industrial requirements, and achieve the effect of reducing the firing temperature and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] specific implementation plan

[0073] The invention will now be illustrated by means of non-limiting illustrated examples.

[0074] Tests were carried out using samples from steel plates suitable for enamelling, which according to standard EN10209 are called DC03ED (also called ).

[0075] The aim was to compare the adhesion of samples enamelled according to the invention with conventionally enamelled samples.

[0076] 1- Production of conventional enamelled steel sheets

[0077] After removing the protective oil from the surface of the sample by conventional alkaline degreasing, a layer of conventional underglaze called PP 12189 manufactured by Pemco International was applied to one side of the sample in order to obtain an enamel layer which was 110 μm thick after firing, i.e. about 400 g / m 2 .

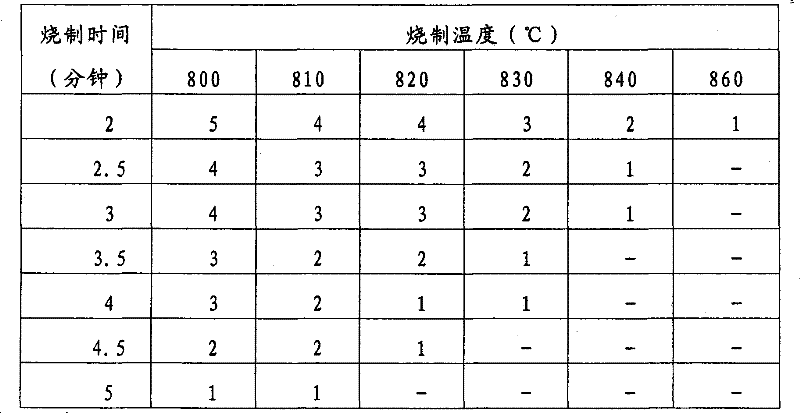

[0078] The enamel samples were fired at different firing temperatures and times in a conventional furnace for enamelling, and the adhesion level of the enamel layer wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| coating mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com