Titanium alloy having excellent corrosion resistance in environment containing bromine ions

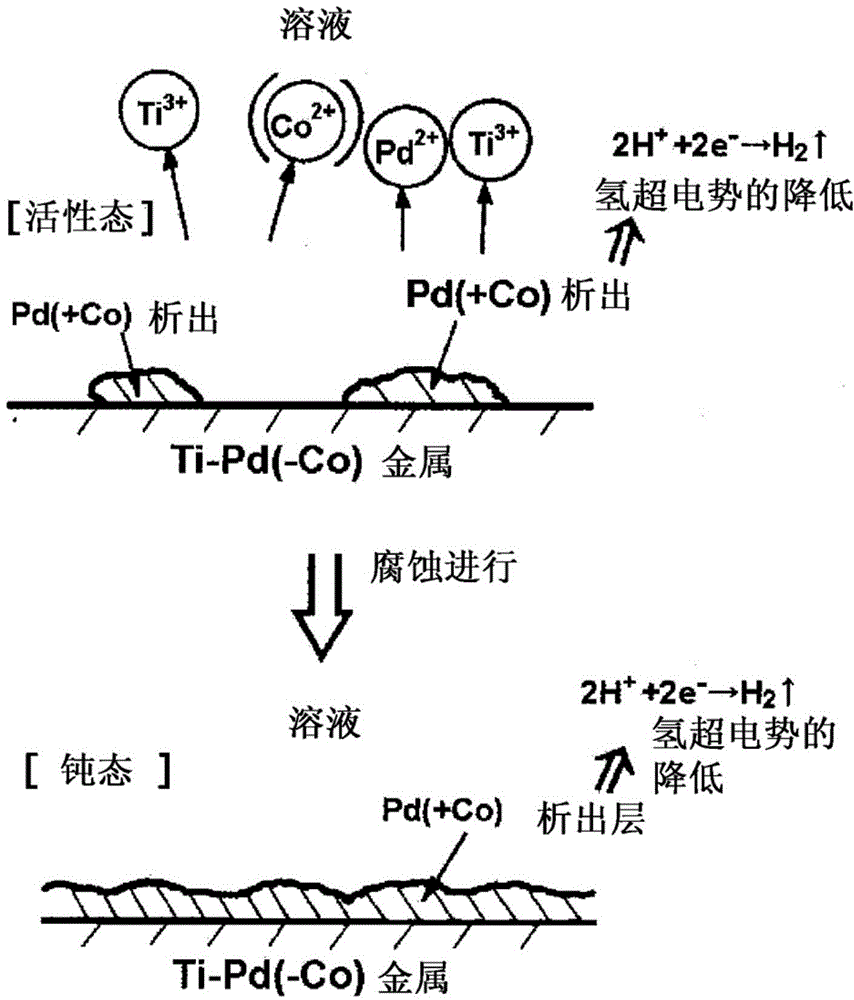

A technology of titanium alloy and bromide ion, applied in the field of titanium alloy, can solve the problems of insufficient corrosion resistance, not involving corrosion resistance, not considering corrosion resistance, etc., and achieving excellent corrosion resistance and reducing the cost of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

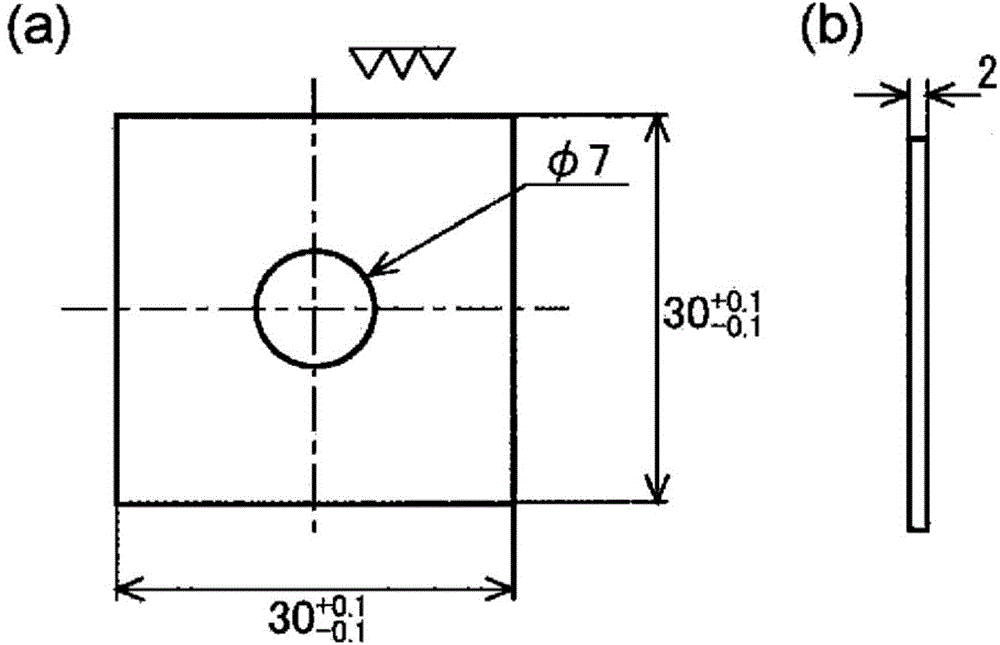

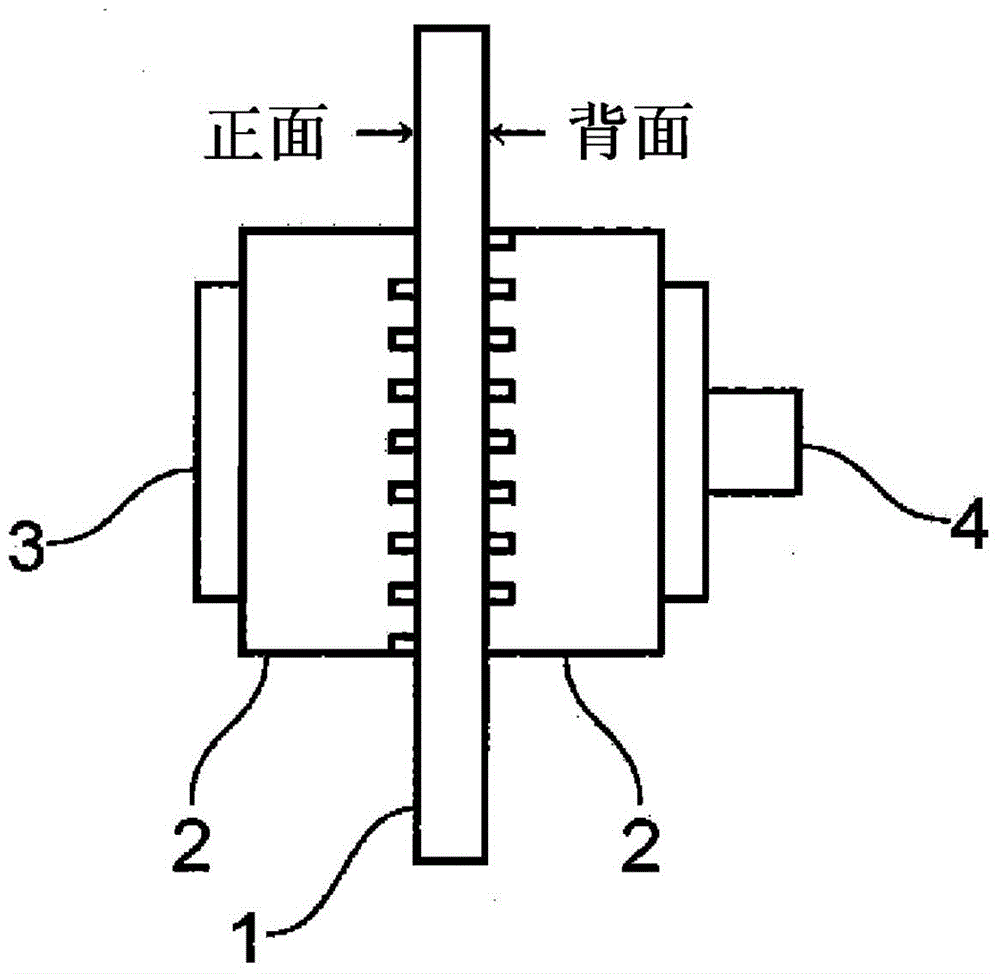

[0083] In order to confirm the crevice corrosion resistance and workability (flexibility and elongation) of the titanium alloy of the present invention, the following tests were carried out, and the results were evaluated.

[0084] 1. Test Method 1-1. Samples Table 1 shows the samples used in the test and their compositions (analytical values for elements other than Ti, and the balance (bal.) for Ti).

[0085] [Table 1]

[0086]

[0087] As samples for the test, comparative materials (sample numbers 1 to 4) belonging to conventional materials, examples of the present invention (sample numbers 5 to 8 corresponding to claim 1, and samples corresponding to claim 1) were prepared in the form of plate samples. 2 corresponding to sample numbers 12 to 18), and titanium alloys that are not conventional materials but are examples outside the scope of the present invention (hereinafter simply referred to as "examples outside the scope of the present invention"; sample numbers 9 to ...

Embodiment 2

[0136] 2.1 Composition of the titanium alloy used in Example 2 In order to clarify the optimum rare earth element content and confirm that Ru has excellent bromine corrosion resistance among platinum group species, the following confirmation experiments were carried out. Table 6 shows the composition of the titanium alloy used in Example 2. According to the preparation method of the sample shown in Example 1, the alloys with the compositions shown in Table 6 were obtained.

[0137] [Table 6]

[0138] category

rare earth element

platinum group elements

Ni

Cr

co

Mo

W

V

O

C

H

N

Fe

margin

Comparative material 5

-

Ru; 0.02

<0.01

<0.01

<0.01

<0.01

<0.01

<0.01

0.05

0.004

0.0024

0.008

0.05

Ti+ impurity

Comparative material 6

Y; 4ppm

Ru; 0.02

<0.01

<0.01

<0.01

<0.01

<0.01

<0.01

0.08

0.006

0.0032

0.005 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com