Bonded assembly provided with an intermediate deformation layer with variable flexibility

An intermediate layer and bonding technology, applied in the connection of rods, connecting components, lamination, etc., can solve problems such as difficulty in implementation, uncertainty, and limited benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

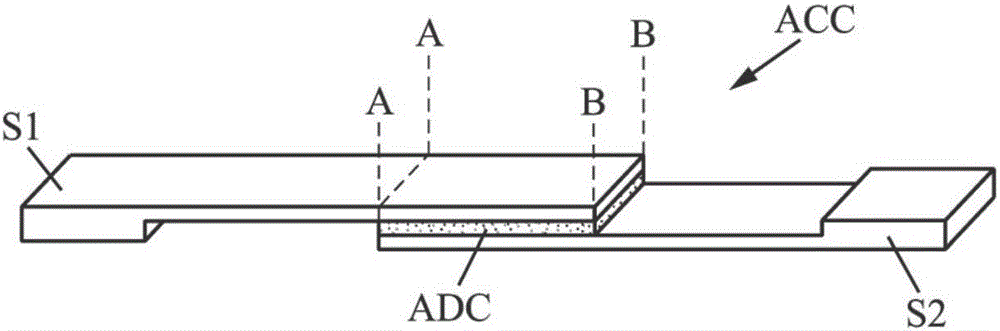

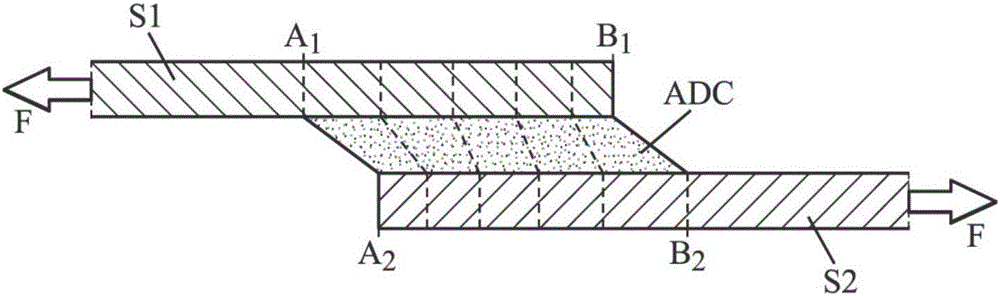

[0094] reference Figure 4A to Figure 4C These figures show examples of the glued assembly AC according to the present invention. The bonding assembly includes a first substrate S1 and a second substrate S2.

[0095] In the example shown, the first substrate S1 is a reinforcement element used to repair, protect and / or reinforce the structure including the second substrate S2. The reinforcement element may take the form of a plate superimposed on the structural wall, usually a plate made of metal, composite material, or any other material rigid enough to reinforce the structure.

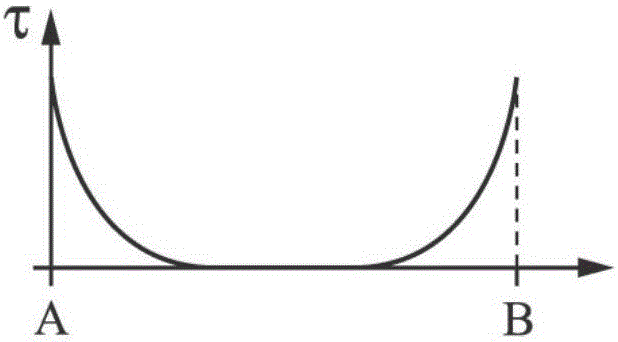

[0096] The component AC includes an intermediate layer CID called "deformation" and a glue AD, which constitutes the unit E. The adhesive AD is arranged between the substrates S1 and S2, and it is intended to rigidly connect them together by means of the CID layer. The adhesive AD includes the bonding interface with the substrate S2 and the CID layer. The CID layer includes a first interface INT1 for rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com