Defect detection device

A defect detection and defect technology, applied in measurement devices, optical testing flaws/defects, wire break detectors, etc., can solve problems such as difficulty in improving inspection accuracy, wrinkles in sewn products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] First, embodiments of the present invention will be listed and described.

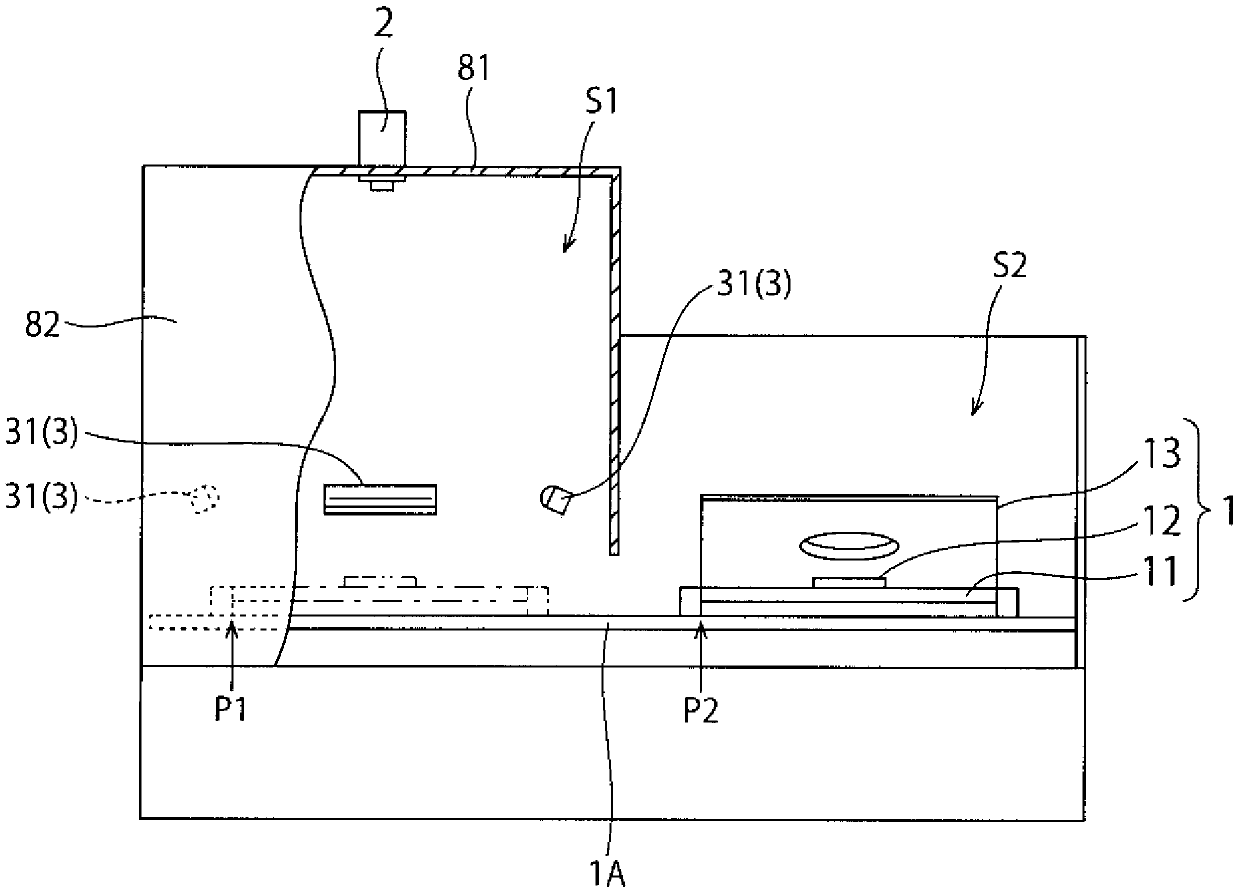

[0026] The defect detection device according to the embodiment of the present invention is a device for detecting a defect in an inspection object having a locally loose slack portion, and includes: a workpiece clamping device for holding the inspection object; an imaging unit for acquiring and holding The image data of the object to be inspected in the workpiece clamping device; and the defect detection unit detects the defect based on the image data or processed image data generated by applying image processing to the image data. The workpiece clamping device includes: an inspection table having a mounting surface on which an object to be inspected is placed; a base provided on the mounting surface of the inspection table; and a pressure plate. When the object to be inspected is placed at a predetermined position on the mounting surface, the base is in a state of sneaking behind the slack port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com