Micro non-premixed combustor suitable for thermal power generation

A miniature, non-premixed technology, used in burners, gas fuel burners, combustion types, etc., can solve the problems of unstable non-premixed combustion, affecting the power generation efficiency of thermal photovoltaic and thermoelectric equipment, and reduce heat dissipation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

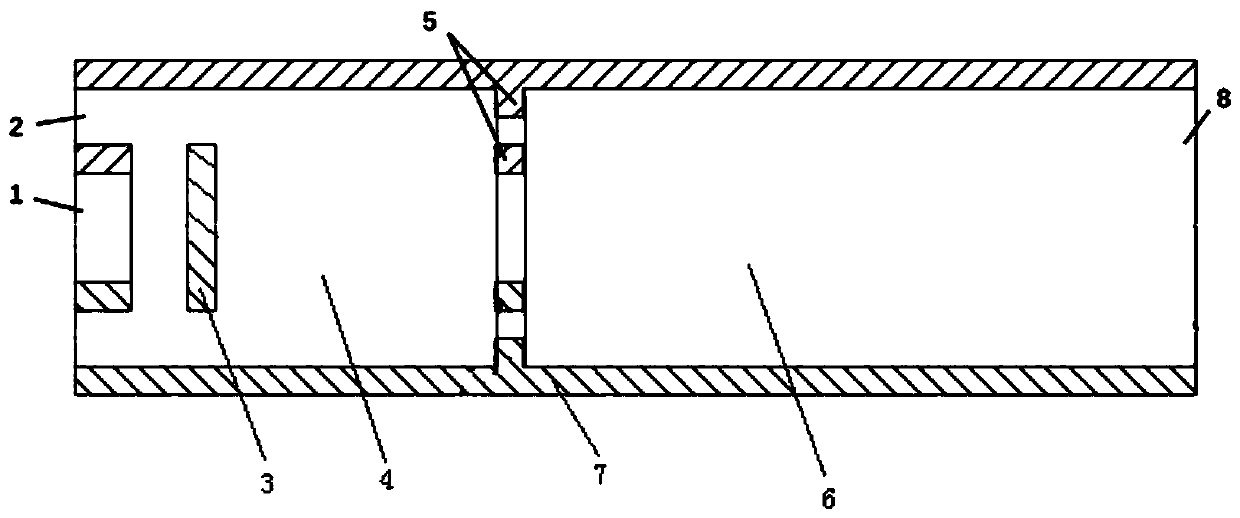

[0035] In this embodiment, methane is used as fuel, and air is used as an oxidant. The inner diameter of the fuel inlet is 1 mm, and the length is 2 mm; the inner diameter of the air inlet is 3 mm, and the outer diameter is 5 mm; the thickness of the fuel baffle is 0.5 mm, and the diameter is 3 mm; The outer diameter of the shell is 6mm, the wall thickness is 0.5mm; the length of the mixing chamber is 5mm; the thickness of the partition is 0.5mm, and the diameter of the first through hole is 2mm. To simplify the two-dimensional calculation, the holes around the partition are regarded as a ring with an inner diameter of 3mm and an outer diameter of 4mm. The combustion chamber length is 12mm. The entire burner length is 20mm, such as figure 1 As shown, the cylindrical shell is made of SUS316 material, and its density, specific heat capacity, thermal conductivity and normal emissivity at room temperature are respectively 8000kg / m 3 ,

[0036] 520J / (kg·K), 12.4W / (m 2 • K) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com