Autoclave Pre-Vacuum vs. Gravity Displacement: Technique Comparison

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Autoclave Sterilization Evolution and Objectives

Autoclave sterilization technology has evolved significantly since its inception in the late 19th century when Charles Chamberland developed the first pressure steam sterilizer. This evolution has been driven by the fundamental need for effective microbial elimination in healthcare settings, laboratories, and industrial applications. The progression from basic steam chambers to sophisticated computerized systems represents a continuous refinement in sterilization efficacy, safety, and efficiency.

Early autoclave designs relied primarily on gravity displacement methods, where steam naturally displaces air due to density differences. This technique, while revolutionary at its time, presented limitations in air removal efficiency, particularly from porous materials and complex instruments. The mid-20th century witnessed a significant technological leap with the introduction of pre-vacuum systems, which actively extract air before steam introduction, addressing many limitations of gravity displacement methods.

The objectives of modern autoclave sterilization technology center around several critical parameters. Foremost is the achievement of complete sterility assurance, typically quantified as a Sterility Assurance Level (SAL) of 10^-6, indicating a one-in-a-million probability of microbial survival. This level of assurance is particularly crucial in medical settings where sterilization failure can lead to healthcare-associated infections.

Energy efficiency represents another key objective in autoclave technology development. Traditional sterilization cycles consume significant energy through prolonged exposure times and high temperatures. Contemporary research focuses on optimizing cycle parameters to reduce energy consumption while maintaining sterilization efficacy, aligning with broader sustainability goals in healthcare and industry.

Process validation and monitoring capabilities have become increasingly sophisticated, transitioning from basic pressure and temperature gauges to integrated electronic systems that provide real-time cycle data, automated documentation, and failure alerts. This evolution supports regulatory compliance and quality assurance requirements across various industries.

The comparison between pre-vacuum and gravity displacement techniques must be understood within this evolutionary context. Each represents a different approach to achieving the same fundamental objective: creating conditions where saturated steam can effectively penetrate materials and destroy microorganisms through protein denaturation and coagulation.

Current technological objectives include developing more adaptive systems capable of optimizing cycle parameters based on load characteristics, further reducing cycle times without compromising sterility, and integrating with broader facility management systems. Additionally, there is growing interest in alternative low-temperature sterilization methods for heat-sensitive materials, though traditional autoclave technology remains the gold standard for most applications due to its reliability and proven efficacy.

Early autoclave designs relied primarily on gravity displacement methods, where steam naturally displaces air due to density differences. This technique, while revolutionary at its time, presented limitations in air removal efficiency, particularly from porous materials and complex instruments. The mid-20th century witnessed a significant technological leap with the introduction of pre-vacuum systems, which actively extract air before steam introduction, addressing many limitations of gravity displacement methods.

The objectives of modern autoclave sterilization technology center around several critical parameters. Foremost is the achievement of complete sterility assurance, typically quantified as a Sterility Assurance Level (SAL) of 10^-6, indicating a one-in-a-million probability of microbial survival. This level of assurance is particularly crucial in medical settings where sterilization failure can lead to healthcare-associated infections.

Energy efficiency represents another key objective in autoclave technology development. Traditional sterilization cycles consume significant energy through prolonged exposure times and high temperatures. Contemporary research focuses on optimizing cycle parameters to reduce energy consumption while maintaining sterilization efficacy, aligning with broader sustainability goals in healthcare and industry.

Process validation and monitoring capabilities have become increasingly sophisticated, transitioning from basic pressure and temperature gauges to integrated electronic systems that provide real-time cycle data, automated documentation, and failure alerts. This evolution supports regulatory compliance and quality assurance requirements across various industries.

The comparison between pre-vacuum and gravity displacement techniques must be understood within this evolutionary context. Each represents a different approach to achieving the same fundamental objective: creating conditions where saturated steam can effectively penetrate materials and destroy microorganisms through protein denaturation and coagulation.

Current technological objectives include developing more adaptive systems capable of optimizing cycle parameters based on load characteristics, further reducing cycle times without compromising sterility, and integrating with broader facility management systems. Additionally, there is growing interest in alternative low-temperature sterilization methods for heat-sensitive materials, though traditional autoclave technology remains the gold standard for most applications due to its reliability and proven efficacy.

Market Demand Analysis for Advanced Sterilization Technologies

The global sterilization equipment market is experiencing robust growth, driven by increasing healthcare expenditures, rising surgical procedures, and growing awareness of infection control. The market was valued at approximately 12.5 billion USD in 2022 and is projected to reach 20.3 billion USD by 2030, representing a compound annual growth rate of 6.2%. Within this expanding market, autoclave sterilization technologies remain dominant, accounting for over 40% of the total market share.

Healthcare facilities worldwide are demonstrating increased demand for more efficient and reliable sterilization methods. This trend is particularly evident in hospitals and surgical centers where the need for rapid instrument turnover is critical. A survey of 500 healthcare facilities across North America, Europe, and Asia revealed that 78% of respondents prioritize sterilization efficiency and reliability over initial equipment costs, highlighting a market willing to invest in advanced technologies.

The comparison between Pre-Vacuum and Gravity Displacement autoclave technologies reflects this market dynamic. Pre-Vacuum autoclaves, despite their higher price point (typically 30-40% more expensive than Gravity Displacement models), are gaining market share due to their superior air removal capabilities and reduced cycle times. Market data indicates a 15% year-over-year increase in Pre-Vacuum autoclave sales compared to 7% for Gravity Displacement models.

Regulatory pressures are significantly influencing market demand. Stringent standards from organizations such as the FDA, CDC, and international equivalents are compelling healthcare facilities to adopt more sophisticated sterilization technologies. The Joint Commission's emphasis on infection prevention has directly contributed to increased adoption of Pre-Vacuum technology in accredited facilities.

Emerging markets present substantial growth opportunities. Countries like India, China, and Brazil are rapidly expanding their healthcare infrastructure, creating new demand for advanced sterilization equipment. These markets are expected to grow at rates exceeding 9% annually through 2030, outpacing mature markets.

The COVID-19 pandemic has accelerated market demand for effective sterilization technologies across all sectors. Healthcare facilities reported a 23% increase in sterilization equipment purchases during 2020-2022, with a notable preference for technologies offering faster cycle times and validated efficacy against resistant pathogens.

Consumer awareness and patient safety concerns are additional market drivers. Public reporting of healthcare-associated infections has created market pressure for facilities to invest in demonstrably superior sterilization technologies. This trend benefits Pre-Vacuum technology, which offers documented advantages in challenging sterilization scenarios involving porous loads and complex instruments.

Healthcare facilities worldwide are demonstrating increased demand for more efficient and reliable sterilization methods. This trend is particularly evident in hospitals and surgical centers where the need for rapid instrument turnover is critical. A survey of 500 healthcare facilities across North America, Europe, and Asia revealed that 78% of respondents prioritize sterilization efficiency and reliability over initial equipment costs, highlighting a market willing to invest in advanced technologies.

The comparison between Pre-Vacuum and Gravity Displacement autoclave technologies reflects this market dynamic. Pre-Vacuum autoclaves, despite their higher price point (typically 30-40% more expensive than Gravity Displacement models), are gaining market share due to their superior air removal capabilities and reduced cycle times. Market data indicates a 15% year-over-year increase in Pre-Vacuum autoclave sales compared to 7% for Gravity Displacement models.

Regulatory pressures are significantly influencing market demand. Stringent standards from organizations such as the FDA, CDC, and international equivalents are compelling healthcare facilities to adopt more sophisticated sterilization technologies. The Joint Commission's emphasis on infection prevention has directly contributed to increased adoption of Pre-Vacuum technology in accredited facilities.

Emerging markets present substantial growth opportunities. Countries like India, China, and Brazil are rapidly expanding their healthcare infrastructure, creating new demand for advanced sterilization equipment. These markets are expected to grow at rates exceeding 9% annually through 2030, outpacing mature markets.

The COVID-19 pandemic has accelerated market demand for effective sterilization technologies across all sectors. Healthcare facilities reported a 23% increase in sterilization equipment purchases during 2020-2022, with a notable preference for technologies offering faster cycle times and validated efficacy against resistant pathogens.

Consumer awareness and patient safety concerns are additional market drivers. Public reporting of healthcare-associated infections has created market pressure for facilities to invest in demonstrably superior sterilization technologies. This trend benefits Pre-Vacuum technology, which offers documented advantages in challenging sterilization scenarios involving porous loads and complex instruments.

Current Challenges in Autoclave Sterilization Techniques

Despite significant advancements in sterilization technology, autoclave sterilization techniques continue to face several critical challenges that impact their efficiency, reliability, and applicability across different settings. Both Pre-Vacuum and Gravity Displacement methods encounter specific limitations that necessitate ongoing research and development.

One of the primary challenges in autoclave sterilization is achieving consistent steam penetration throughout complex medical devices with narrow lumens, multiple connections, or dense packaging. Pre-Vacuum systems, while generally superior for these applications, still struggle with extremely complex geometries where air pockets may persist despite the vacuum phase. Gravity displacement autoclaves face even greater difficulties with these items, as their reliance on gravity for air removal is inherently less efficient.

Energy consumption represents another significant challenge, particularly for healthcare facilities in resource-limited settings. Pre-Vacuum systems require substantial power to operate vacuum pumps, making them costly to run continuously. Gravity displacement autoclaves, though less energy-intensive, require longer cycle times to achieve equivalent sterilization, creating a trade-off between energy efficiency and operational throughput.

Validation and monitoring of sterilization cycles present ongoing challenges, especially in ensuring that sterilization parameters are consistently met throughout the load. Current biological and chemical indicators have limitations in providing real-time feedback, and their placement may not accurately represent conditions in the most challenging areas of complex loads.

Material compatibility issues continue to constrain autoclave applications. High-temperature steam can damage heat-sensitive materials, including many modern polymers and electronic components found in sophisticated medical devices. This limitation has become more pronounced as medical technology increasingly incorporates these materials.

Water quality variations significantly impact autoclave performance, with mineral deposits causing instrument staining, reducing steam quality, and damaging autoclave components. This challenge is particularly acute in regions with hard water or inadequate water treatment infrastructure.

Cycle time optimization remains problematic, especially for gravity displacement systems. The balance between ensuring complete sterilization and minimizing processing time affects operational efficiency and instrument turnover rates in busy healthcare settings.

Finally, there are emerging concerns regarding prion inactivation and biofilm penetration. Standard autoclave cycles may be insufficient for certain prions, while biofilms can protect microorganisms from steam contact, potentially compromising sterilization outcomes even when standard parameters are met.

One of the primary challenges in autoclave sterilization is achieving consistent steam penetration throughout complex medical devices with narrow lumens, multiple connections, or dense packaging. Pre-Vacuum systems, while generally superior for these applications, still struggle with extremely complex geometries where air pockets may persist despite the vacuum phase. Gravity displacement autoclaves face even greater difficulties with these items, as their reliance on gravity for air removal is inherently less efficient.

Energy consumption represents another significant challenge, particularly for healthcare facilities in resource-limited settings. Pre-Vacuum systems require substantial power to operate vacuum pumps, making them costly to run continuously. Gravity displacement autoclaves, though less energy-intensive, require longer cycle times to achieve equivalent sterilization, creating a trade-off between energy efficiency and operational throughput.

Validation and monitoring of sterilization cycles present ongoing challenges, especially in ensuring that sterilization parameters are consistently met throughout the load. Current biological and chemical indicators have limitations in providing real-time feedback, and their placement may not accurately represent conditions in the most challenging areas of complex loads.

Material compatibility issues continue to constrain autoclave applications. High-temperature steam can damage heat-sensitive materials, including many modern polymers and electronic components found in sophisticated medical devices. This limitation has become more pronounced as medical technology increasingly incorporates these materials.

Water quality variations significantly impact autoclave performance, with mineral deposits causing instrument staining, reducing steam quality, and damaging autoclave components. This challenge is particularly acute in regions with hard water or inadequate water treatment infrastructure.

Cycle time optimization remains problematic, especially for gravity displacement systems. The balance between ensuring complete sterilization and minimizing processing time affects operational efficiency and instrument turnover rates in busy healthcare settings.

Finally, there are emerging concerns regarding prion inactivation and biofilm penetration. Standard autoclave cycles may be insufficient for certain prions, while biofilms can protect microorganisms from steam contact, potentially compromising sterilization outcomes even when standard parameters are met.

Comparative Analysis of Pre-Vacuum and Gravity Displacement Methods

01 Pre-vacuum autoclave sterilization principles

Pre-vacuum autoclave sterilization involves removing air from the chamber before introducing steam, which enhances steam penetration into porous materials and hollow instruments. This technique creates a vacuum before steam injection, allowing for faster and more efficient sterilization at higher temperatures (typically 132-134°C). The removal of air pockets prevents the formation of cold spots that might harbor microorganisms, resulting in superior sterilization efficiency compared to gravity displacement methods, especially for complex medical instruments and porous loads.- Pre-vacuum autoclave sterilization principles and advantages: Pre-vacuum autoclave sterilization involves removing air from the sterilization chamber before introducing steam, which enhances steam penetration into porous materials and hollow instruments. This technique achieves more efficient sterilization by eliminating air pockets that could prevent steam contact with all surfaces. Pre-vacuum cycles typically operate at higher temperatures (132-135°C) and shorter cycle times compared to gravity displacement, making them more efficient for processing wrapped instruments and porous loads.

- Gravity displacement autoclave operation and applications: Gravity displacement autoclaves rely on the principle that steam, being lighter than air, naturally pushes air downward and out through a drain. This technique operates at temperatures typically between 121-123°C with longer cycle times. While less efficient than pre-vacuum for complex instruments, gravity displacement is suitable for non-porous items, unwrapped instruments, and laboratory media. These systems are generally simpler in design, more affordable, and require less maintenance than pre-vacuum systems.

- Sterilization cycle monitoring and validation methods: Effective autoclave sterilization requires comprehensive monitoring and validation through biological indicators, chemical indicators, and physical parameter monitoring. Biological indicators containing resistant bacterial spores verify sterilization efficacy, while chemical indicators confirm exposure to sterilization conditions. Modern autoclaves incorporate electronic monitoring systems that track critical parameters such as temperature, pressure, and time throughout the cycle, ensuring consistent sterilization results and providing documentation for regulatory compliance.

- Load configuration and packaging impact on sterilization efficiency: The arrangement and packaging of items within an autoclave significantly affects sterilization efficiency. Proper spacing between items allows steam circulation, while overloading prevents adequate steam penetration. Packaging materials must permit steam penetration while maintaining sterility after processing. Different wrapping materials and container systems have varying effects on steam penetration and drying efficiency. Validation studies show that improper loading patterns can create cold spots where sterilization parameters are not met, compromising the entire process.

- Innovations in autoclave technology for enhanced efficiency: Recent innovations in autoclave technology focus on improving sterilization efficiency while reducing cycle times and resource consumption. These include pulsed vacuum systems that create multiple vacuum phases for better air removal, advanced steam generation systems that provide more consistent steam quality, and precise electronic controls that optimize cycle parameters based on load characteristics. Some modern autoclaves incorporate air detection systems to verify complete air removal and feature rapid cooling mechanisms to reduce overall processing time without compromising sterilization efficacy.

02 Gravity displacement autoclave operation

Gravity displacement autoclaves operate on the principle that steam, being lighter than air, naturally pushes air downward and out through a drain. This method requires longer cycle times (typically 30-60 minutes at 121°C) to ensure complete air removal and effective sterilization. The process is simpler but less efficient for dense loads or hollow instruments where air pockets may remain. Gravity displacement autoclaves are generally suitable for non-porous items, laboratory media, and waste materials where complete air removal is less critical for sterilization success.Expand Specific Solutions03 Comparative efficiency of sterilization techniques

Studies comparing pre-vacuum and gravity displacement methods demonstrate significant differences in sterilization efficiency. Pre-vacuum cycles typically achieve sterilization in 3-4 minutes at 132-134°C, while gravity displacement requires 15-30 minutes at 121°C for equivalent results. The efficiency gap widens with complex instruments, porous materials, and dense loads. Pre-vacuum systems show superior penetration capabilities, more consistent temperature distribution, and higher sterility assurance levels, particularly for challenging loads. However, gravity displacement may be sufficient and more energy-efficient for simple solid instruments and non-porous materials.Expand Specific Solutions04 Monitoring and validation of sterilization processes

Effective monitoring and validation are essential for ensuring autoclave sterilization efficiency. This includes the use of biological indicators containing resistant bacterial spores, chemical indicators that change color upon exposure to sterilization conditions, and physical monitors tracking temperature, pressure, and time parameters. Modern autoclaves incorporate automated monitoring systems with digital records and alarms for cycle deviations. Regular validation protocols include Bowie-Dick tests for pre-vacuum systems to detect air leaks and penetration failures, and parametric release methods to verify critical process parameters meet predetermined specifications.Expand Specific Solutions05 Innovations in autoclave design and efficiency

Recent innovations in autoclave technology focus on improving sterilization efficiency while reducing cycle times and resource consumption. These include pulsed vacuum systems that create multiple vacuum phases for enhanced air removal, microprocessor controls for precise cycle management, steam quality monitoring systems, and rapid cooling mechanisms. Advanced door sealing technologies prevent leakage and maintain chamber pressure integrity. Some modern autoclaves incorporate water recirculation systems and energy recovery features to reduce water and energy consumption. Specialized chamber designs accommodate specific load configurations, while connectivity features enable remote monitoring and integration with facility management systems.Expand Specific Solutions

Key Manufacturers and Industry Leaders in Autoclave Technology

The autoclave sterilization market is currently in a mature growth phase, characterized by established technologies and a global market size exceeding $2 billion. Pre-vacuum technology has emerged as the dominant approach due to its superior air removal efficiency and faster cycle times compared to gravity displacement methods. Leading players include Shinva Medical Instrument and American Sterilizer (STERIS), who have developed advanced pre-vacuum systems with enhanced steam penetration capabilities. Japanese manufacturers Olympus and SANYO Electric focus on specialized medical applications, while European companies like EVAC GmbH concentrate on compact, energy-efficient designs. The technology continues to evolve toward more automated, energy-efficient systems with improved validation protocols, with recent innovations focusing on integration with IoT for remote monitoring and predictive maintenance capabilities.

Shinva Medical Instrument Co., Ltd.

Technical Solution: Shinva Medical has developed comprehensive autoclave sterilization solutions featuring both pre-vacuum and gravity displacement technologies. Their pre-vacuum systems employ multiple vacuum pulses (typically 3-4) before steam injection to achieve >99.9999% sterilization efficacy with penetration into porous loads and hollow instruments. The company's SMIC series autoclaves utilize advanced microprocessor controls with precision temperature and pressure sensors to maintain optimal sterilization parameters (134°C at 2.1 bar for pre-vacuum; 121°C at 1.1 bar for gravity). Their pre-vacuum technology reduces cycle times by approximately 40% compared to gravity displacement, with typical cycles completing in 30-45 minutes versus 60-75 minutes. Shinva's systems incorporate air detection systems to prevent "cold spots" and ensure steam penetration throughout the load, addressing the primary limitation of gravity displacement methods.

Strengths: Superior penetration into complex instruments and porous materials; faster cycle times; better removal of non-condensable gases; higher sterilization assurance levels. Weaknesses: Higher equipment complexity and cost; requires more maintenance; greater energy consumption; more sophisticated validation procedures required.

Olympus Corp.

Technical Solution: Olympus has developed specialized autoclave sterilization systems primarily focused on their endoscopic and surgical instruments. Their pre-vacuum technology employs a multi-phase approach with initial vacuum pulses reaching -0.8 bar to remove >99% of air from the chamber and instrument channels. This is followed by steam injection at 134°C and 2.1 bar pressure. For their complex hollow instruments, Olympus has engineered specific pre-vacuum parameters that ensure steam penetration through channels as narrow as 0.5mm diameter and up to 3.5 meters long. Their comparative testing shows pre-vacuum achieving sterility assurance levels (SAL) of 10^-6 in these challenging devices, while gravity displacement methods failed to achieve consistent sterilization in the same instruments. Olympus's systems incorporate specialized adapters and connectors to ensure steam access to all internal surfaces during the pre-vacuum phase, addressing a critical limitation of gravity displacement for complex medical devices.

Strengths: Optimized specifically for complex hollow instruments; validated for the most challenging endoscopic devices; excellent documentation and traceability features; compatible with Olympus's full instrument range. Weaknesses: Less versatile for general-purpose sterilization; higher operational complexity; requires specialized training; more expensive than standard autoclave systems.

Critical Patents and Innovations in Autoclave Technology

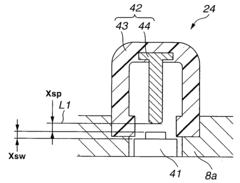

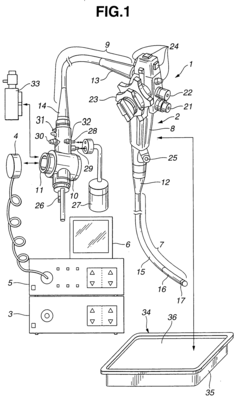

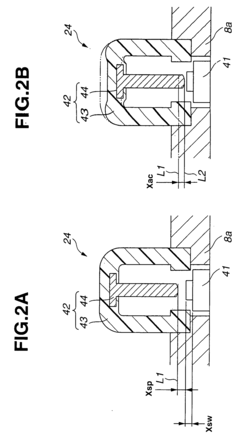

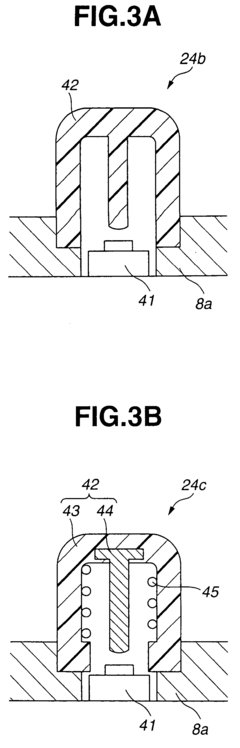

Endoscope suitable for autoclaving

PatentInactiveUS20040082835A1

Innovation

- The endoscope design incorporates a soft barrier to manage pressure and thermal loads during autoclaving, using a pressure-regulating valve and waterproof cap to prevent steam invasion and ensure a fluid-tight seal, while maintaining the integrity of resin tubes and switches.

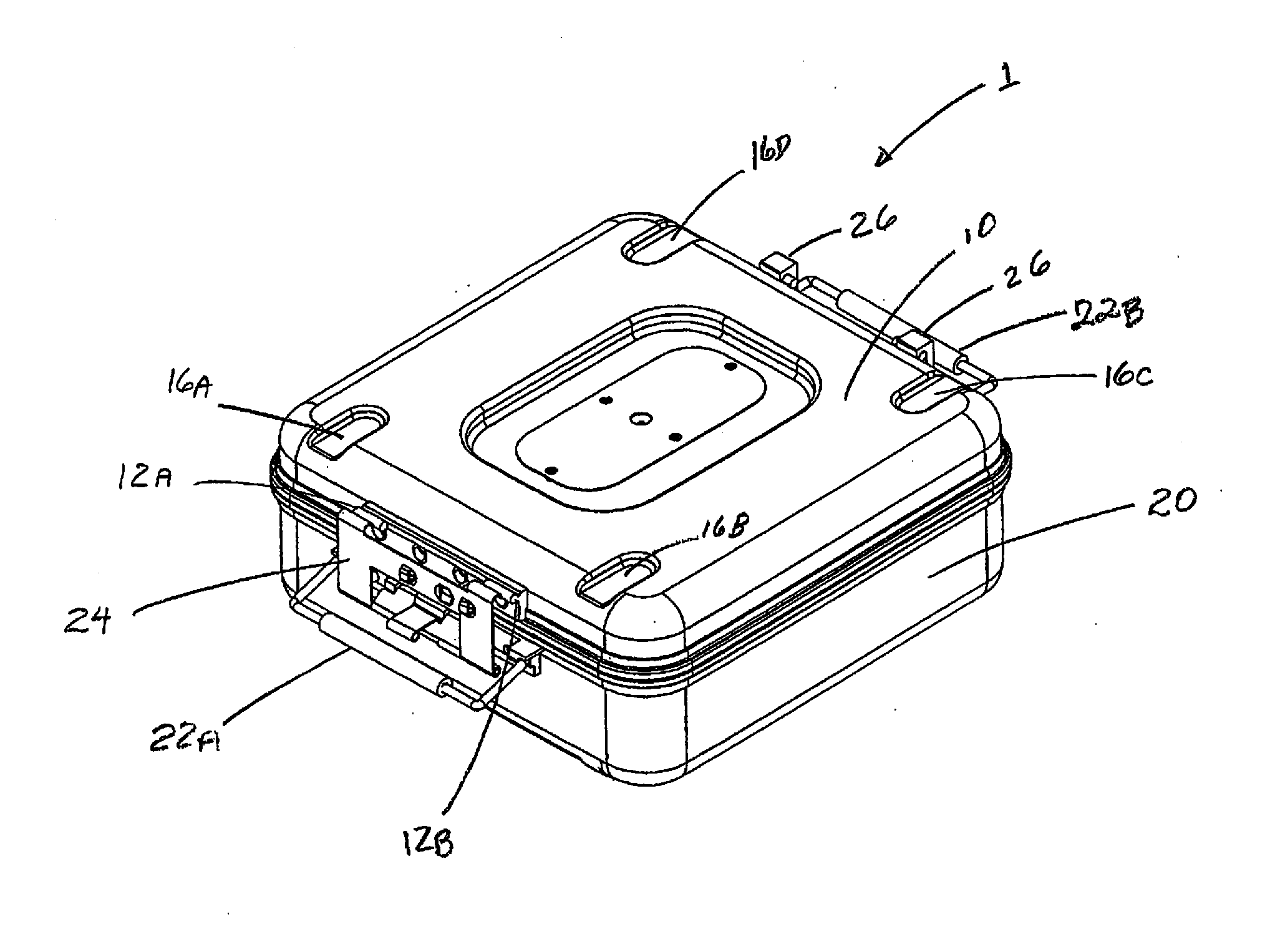

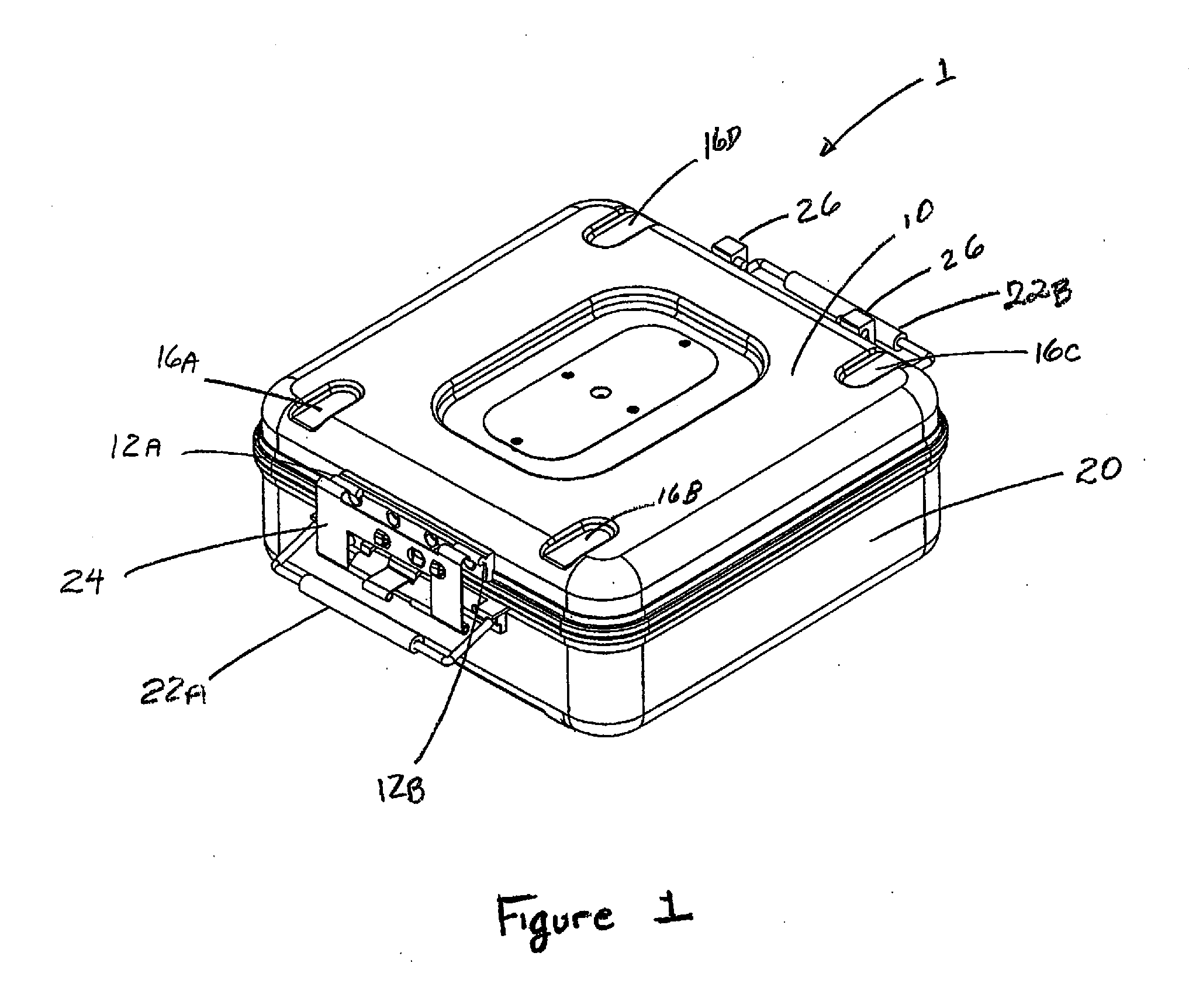

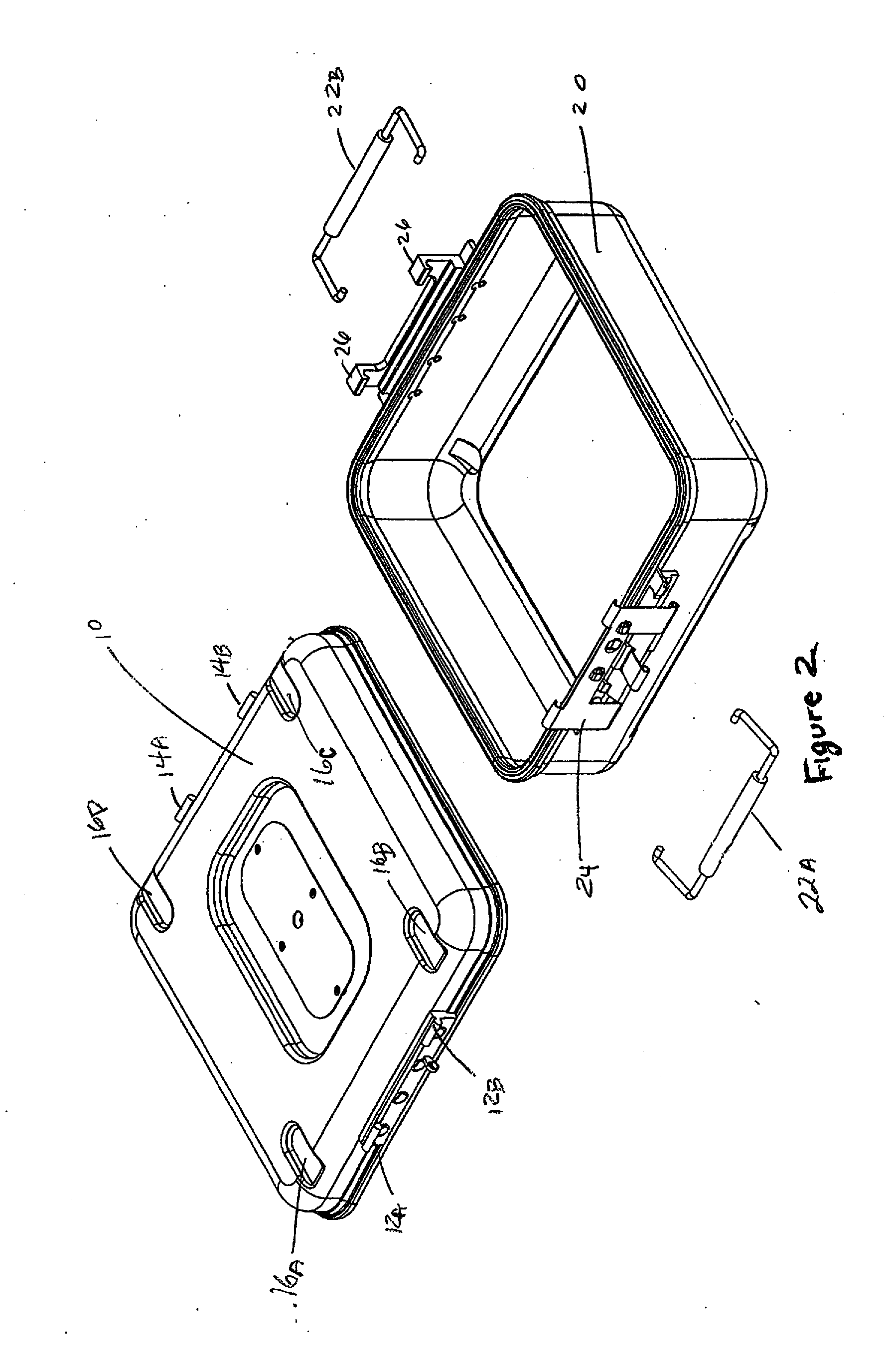

Sterilization container

PatentInactiveUS20130280134A1

Innovation

- A flash sterilization container with a bimetal thermally responsive valve system and a pressure equalizing valve, combined with a lightweight and durable design, featuring a latching mechanism and handle system for easy handling and stacking, ensuring complete closure before removal from the autoclave and facilitating safe transport.

Regulatory Standards and Compliance Requirements for Sterilization

Sterilization processes in healthcare and industrial settings are governed by stringent regulatory frameworks that ensure patient safety and product integrity. For autoclave sterilization methods, both Pre-Vacuum and Gravity Displacement techniques must adhere to specific standards established by international and national regulatory bodies.

The Association for the Advancement of Medical Instrumentation (AAMI) provides comprehensive guidelines through standards such as ANSI/AAMI ST79, which outlines the requirements for steam sterilization in healthcare facilities. This standard specifically addresses the validation, routine monitoring, and quality assurance for both Pre-Vacuum and Gravity Displacement methods, with more stringent parameters typically applied to Pre-Vacuum due to its enhanced capabilities.

The International Organization for Standardization (ISO) has established ISO 17665 as the global standard for moist heat sterilization validation and routine control. This standard requires more rigorous validation protocols for Pre-Vacuum cycles compared to Gravity Displacement, reflecting the technical differences between these methodologies.

In the United States, the Food and Drug Administration (FDA) regulates sterilization processes under 21 CFR Part 820 (Quality System Regulation), with specific guidance documents addressing steam sterilization validation. The FDA typically requires more comprehensive documentation and validation data for Pre-Vacuum systems due to their complexity and critical applications in medical device sterilization.

European regulations, particularly the Medical Device Regulation (MDR 2017/745), impose strict requirements on sterilization processes. The European Committee for Standardization (CEN) has developed EN 285 specifically for large steam sterilizers, which includes detailed specifications for Pre-Vacuum systems that are more technically demanding than those for Gravity Displacement autoclaves.

Compliance verification differs significantly between the two techniques. Pre-Vacuum systems require more sophisticated biological indicators, air removal tests (Bowie-Dick), and parametric monitoring systems to ensure proper air evacuation and steam penetration. Gravity Displacement systems, while still requiring biological indicators and chemical integrators, typically have less complex monitoring requirements.

Documentation requirements also vary, with Pre-Vacuum systems generally necessitating more comprehensive record-keeping due to their additional process parameters and critical control points. This includes detailed vacuum pulse records, air leak test results, and specific temperature-pressure correlation data that are not typically required for Gravity Displacement systems.

Regular certification and validation schedules are more frequent and rigorous for Pre-Vacuum systems in most regulatory frameworks, reflecting their application in more critical sterilization scenarios and their technical complexity.

The Association for the Advancement of Medical Instrumentation (AAMI) provides comprehensive guidelines through standards such as ANSI/AAMI ST79, which outlines the requirements for steam sterilization in healthcare facilities. This standard specifically addresses the validation, routine monitoring, and quality assurance for both Pre-Vacuum and Gravity Displacement methods, with more stringent parameters typically applied to Pre-Vacuum due to its enhanced capabilities.

The International Organization for Standardization (ISO) has established ISO 17665 as the global standard for moist heat sterilization validation and routine control. This standard requires more rigorous validation protocols for Pre-Vacuum cycles compared to Gravity Displacement, reflecting the technical differences between these methodologies.

In the United States, the Food and Drug Administration (FDA) regulates sterilization processes under 21 CFR Part 820 (Quality System Regulation), with specific guidance documents addressing steam sterilization validation. The FDA typically requires more comprehensive documentation and validation data for Pre-Vacuum systems due to their complexity and critical applications in medical device sterilization.

European regulations, particularly the Medical Device Regulation (MDR 2017/745), impose strict requirements on sterilization processes. The European Committee for Standardization (CEN) has developed EN 285 specifically for large steam sterilizers, which includes detailed specifications for Pre-Vacuum systems that are more technically demanding than those for Gravity Displacement autoclaves.

Compliance verification differs significantly between the two techniques. Pre-Vacuum systems require more sophisticated biological indicators, air removal tests (Bowie-Dick), and parametric monitoring systems to ensure proper air evacuation and steam penetration. Gravity Displacement systems, while still requiring biological indicators and chemical integrators, typically have less complex monitoring requirements.

Documentation requirements also vary, with Pre-Vacuum systems generally necessitating more comprehensive record-keeping due to their additional process parameters and critical control points. This includes detailed vacuum pulse records, air leak test results, and specific temperature-pressure correlation data that are not typically required for Gravity Displacement systems.

Regular certification and validation schedules are more frequent and rigorous for Pre-Vacuum systems in most regulatory frameworks, reflecting their application in more critical sterilization scenarios and their technical complexity.

Energy Efficiency and Sustainability Considerations in Autoclave Design

Energy efficiency and sustainability have become critical considerations in modern autoclave design, particularly when comparing pre-vacuum and gravity displacement sterilization techniques. The energy consumption profiles of these two methods differ significantly, with pre-vacuum systems generally demonstrating superior efficiency despite their higher initial power requirements. Pre-vacuum autoclaves achieve faster cycle times by rapidly removing air before steam introduction, resulting in shorter overall operation periods and consequently reduced energy consumption per sterilization cycle.

Gravity displacement autoclaves, while simpler in design, typically require longer cycle times to achieve effective sterilization, leading to extended energy consumption periods. This difference becomes particularly significant in high-volume healthcare settings where multiple sterilization cycles are performed daily. Studies indicate that facilities transitioning from gravity to pre-vacuum systems can realize energy savings of 15-30% depending on usage patterns and specific equipment configurations.

Water consumption represents another crucial sustainability factor. Pre-vacuum systems generally utilize water more efficiently through advanced steam generation and condensate recovery systems. Modern pre-vacuum autoclaves incorporate water recycling technologies that can reduce water usage by up to 40% compared to traditional gravity displacement models. This efficiency gain becomes particularly important in regions facing water scarcity challenges.

Carbon footprint considerations extend beyond operational energy to include manufacturing impacts and lifecycle assessments. The more complex components required for pre-vacuum systems initially create a higher embodied carbon footprint. However, this initial carbon investment is typically offset within 2-3 years through operational efficiency gains. Manufacturers have begun implementing sustainable materials and production processes to further reduce this initial environmental impact.

Waste heat recovery systems represent an emerging area of sustainability innovation in autoclave design. Advanced pre-vacuum systems now incorporate heat exchangers that capture and repurpose waste heat for facility heating or preheating incoming water. These systems can recapture up to 25% of the energy that would otherwise be lost, significantly improving overall facility energy efficiency. Gravity displacement systems have seen fewer innovations in this area due to their simpler design constraints.

Maintenance requirements also factor into sustainability assessments. Pre-vacuum systems, while more complex, often incorporate predictive maintenance technologies that optimize component lifespans and reduce replacement frequency. This approach minimizes waste generation and extends equipment operational life, contributing to overall sustainability through reduced manufacturing demands for replacement parts and systems.

Gravity displacement autoclaves, while simpler in design, typically require longer cycle times to achieve effective sterilization, leading to extended energy consumption periods. This difference becomes particularly significant in high-volume healthcare settings where multiple sterilization cycles are performed daily. Studies indicate that facilities transitioning from gravity to pre-vacuum systems can realize energy savings of 15-30% depending on usage patterns and specific equipment configurations.

Water consumption represents another crucial sustainability factor. Pre-vacuum systems generally utilize water more efficiently through advanced steam generation and condensate recovery systems. Modern pre-vacuum autoclaves incorporate water recycling technologies that can reduce water usage by up to 40% compared to traditional gravity displacement models. This efficiency gain becomes particularly important in regions facing water scarcity challenges.

Carbon footprint considerations extend beyond operational energy to include manufacturing impacts and lifecycle assessments. The more complex components required for pre-vacuum systems initially create a higher embodied carbon footprint. However, this initial carbon investment is typically offset within 2-3 years through operational efficiency gains. Manufacturers have begun implementing sustainable materials and production processes to further reduce this initial environmental impact.

Waste heat recovery systems represent an emerging area of sustainability innovation in autoclave design. Advanced pre-vacuum systems now incorporate heat exchangers that capture and repurpose waste heat for facility heating or preheating incoming water. These systems can recapture up to 25% of the energy that would otherwise be lost, significantly improving overall facility energy efficiency. Gravity displacement systems have seen fewer innovations in this area due to their simpler design constraints.

Maintenance requirements also factor into sustainability assessments. Pre-vacuum systems, while more complex, often incorporate predictive maintenance technologies that optimize component lifespans and reduce replacement frequency. This approach minimizes waste generation and extends equipment operational life, contributing to overall sustainability through reduced manufacturing demands for replacement parts and systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!