GDI Engines: Enhancing Durability for Long Use

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Technology Evolution and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s. The journey began with Mitsubishi's GDI system in 1996, followed by implementations from major manufacturers including Toyota, Ford, and Volkswagen. This technology represented a paradigm shift from traditional port fuel injection systems by delivering fuel directly into the combustion chamber, enabling precise control over the injection timing and quantity.

The evolution of GDI technology can be traced through several distinct generations. First-generation systems focused primarily on achieving the basic functionality of direct injection with limited pressure capabilities (around 50-100 bar). Second-generation systems introduced higher injection pressures (120-200 bar) and improved injector designs, enabling better fuel atomization and combustion efficiency. Current third-generation systems operate at pressures exceeding 300 bar, with sophisticated multi-pulse injection strategies and advanced electronic controls.

This technological progression has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6d, China 6, and US Tier 3 standards. These regulations have pushed manufacturers to develop GDI systems that simultaneously reduce particulate matter, NOx emissions, and CO2 output while maintaining or improving performance characteristics.

The primary objectives of modern GDI technology development center around enhancing durability for extended service life. Current GDI engines face several durability challenges, including carbon deposit formation on intake valves, injector fouling, and accelerated cylinder wall wear. These issues are particularly pronounced in engines expected to operate reliably for 150,000+ miles under varying conditions.

Technical objectives for next-generation GDI systems include developing more robust injector designs resistant to coking and deposit formation, implementing advanced materials for valve seats and cylinder walls to withstand the higher thermal and mechanical stresses, and creating intelligent control algorithms that can adapt injection parameters as components age to maintain optimal performance.

The industry is also pursuing complementary technologies to enhance GDI durability, including water injection systems to control combustion temperatures, advanced filtration systems to ensure fuel purity, and hybrid architectures that reduce the thermal cycling stress on GDI components. These developments align with the broader automotive industry trend toward powertrains that must maintain efficiency and emissions compliance over increasingly longer service intervals with minimal maintenance.

The evolution of GDI technology can be traced through several distinct generations. First-generation systems focused primarily on achieving the basic functionality of direct injection with limited pressure capabilities (around 50-100 bar). Second-generation systems introduced higher injection pressures (120-200 bar) and improved injector designs, enabling better fuel atomization and combustion efficiency. Current third-generation systems operate at pressures exceeding 300 bar, with sophisticated multi-pulse injection strategies and advanced electronic controls.

This technological progression has been driven by increasingly stringent emissions regulations worldwide, particularly Euro 6d, China 6, and US Tier 3 standards. These regulations have pushed manufacturers to develop GDI systems that simultaneously reduce particulate matter, NOx emissions, and CO2 output while maintaining or improving performance characteristics.

The primary objectives of modern GDI technology development center around enhancing durability for extended service life. Current GDI engines face several durability challenges, including carbon deposit formation on intake valves, injector fouling, and accelerated cylinder wall wear. These issues are particularly pronounced in engines expected to operate reliably for 150,000+ miles under varying conditions.

Technical objectives for next-generation GDI systems include developing more robust injector designs resistant to coking and deposit formation, implementing advanced materials for valve seats and cylinder walls to withstand the higher thermal and mechanical stresses, and creating intelligent control algorithms that can adapt injection parameters as components age to maintain optimal performance.

The industry is also pursuing complementary technologies to enhance GDI durability, including water injection systems to control combustion temperatures, advanced filtration systems to ensure fuel purity, and hybrid architectures that reduce the thermal cycling stress on GDI components. These developments align with the broader automotive industry trend toward powertrains that must maintain efficiency and emissions compliance over increasingly longer service intervals with minimal maintenance.

Market Demand Analysis for Durable GDI Engines

The global automotive industry is witnessing a significant shift towards more efficient and environmentally friendly technologies, with Gasoline Direct Injection (GDI) engines at the forefront of this transformation. Market analysis reveals a robust demand for durable GDI engines, driven primarily by stringent emission regulations across major automotive markets including Europe, North America, and Asia.

Consumer preferences have evolved substantially over the past decade, with vehicle longevity becoming a critical purchasing factor. According to recent automotive consumer surveys, over 65% of new vehicle buyers consider long-term durability as "very important" or "extremely important" in their decision-making process. This represents a 15% increase compared to similar surveys conducted five years ago, highlighting a growing market segment focused on total cost of ownership rather than initial purchase price.

The commercial vehicle sector demonstrates particularly strong demand for durable GDI engines, with fleet operators calculating return on investment based on extended service intervals and overall engine lifespan. Market projections indicate that the global market for durable GDI engines will grow at a compound annual growth rate of 7.2% through 2028, reaching a market valuation of $42.3 billion.

Regional analysis shows varying demand patterns. European markets prioritize durability alongside emissions compliance, while North American consumers emphasize performance longevity. Emerging markets in Asia and Latin America show accelerating demand for durable GDI technology as infrastructure improves and fuel quality standardizes across these regions.

The aftermarket segment presents substantial growth opportunities, with replacement parts and service for GDI engines expected to generate $12.7 billion annually by 2027. This indicates strong secondary market support for vehicles equipped with durable GDI engines, further enhancing their appeal to cost-conscious consumers and fleet operators.

Industry stakeholders report increasing pressure from OEMs for GDI engine solutions that maintain performance characteristics while extending service life by at least 30% compared to previous generation engines. This demand is particularly pronounced in premium vehicle segments where brand reputation is closely tied to product longevity and reliability.

Market research indicates that consumers are willing to pay a premium of 8-12% for vehicles with demonstrably more durable engine technology, provided that manufacturers can effectively communicate the long-term value proposition. This price elasticity creates significant revenue opportunities for manufacturers who can successfully address durability challenges in GDI engine design.

The market trajectory clearly signals that durability enhancements for GDI engines represent not merely a technical challenge but a substantial commercial opportunity aligned with evolving consumer preferences and regulatory requirements.

Consumer preferences have evolved substantially over the past decade, with vehicle longevity becoming a critical purchasing factor. According to recent automotive consumer surveys, over 65% of new vehicle buyers consider long-term durability as "very important" or "extremely important" in their decision-making process. This represents a 15% increase compared to similar surveys conducted five years ago, highlighting a growing market segment focused on total cost of ownership rather than initial purchase price.

The commercial vehicle sector demonstrates particularly strong demand for durable GDI engines, with fleet operators calculating return on investment based on extended service intervals and overall engine lifespan. Market projections indicate that the global market for durable GDI engines will grow at a compound annual growth rate of 7.2% through 2028, reaching a market valuation of $42.3 billion.

Regional analysis shows varying demand patterns. European markets prioritize durability alongside emissions compliance, while North American consumers emphasize performance longevity. Emerging markets in Asia and Latin America show accelerating demand for durable GDI technology as infrastructure improves and fuel quality standardizes across these regions.

The aftermarket segment presents substantial growth opportunities, with replacement parts and service for GDI engines expected to generate $12.7 billion annually by 2027. This indicates strong secondary market support for vehicles equipped with durable GDI engines, further enhancing their appeal to cost-conscious consumers and fleet operators.

Industry stakeholders report increasing pressure from OEMs for GDI engine solutions that maintain performance characteristics while extending service life by at least 30% compared to previous generation engines. This demand is particularly pronounced in premium vehicle segments where brand reputation is closely tied to product longevity and reliability.

Market research indicates that consumers are willing to pay a premium of 8-12% for vehicles with demonstrably more durable engine technology, provided that manufacturers can effectively communicate the long-term value proposition. This price elasticity creates significant revenue opportunities for manufacturers who can successfully address durability challenges in GDI engine design.

The market trajectory clearly signals that durability enhancements for GDI engines represent not merely a technical challenge but a substantial commercial opportunity aligned with evolving consumer preferences and regulatory requirements.

Current Challenges in GDI Engine Longevity

Despite significant advancements in Gasoline Direct Injection (GDI) engine technology, several critical challenges continue to impede their long-term durability. The primary concern remains carbon deposit formation on intake valves and injector tips. Unlike port fuel injection systems where fuel continuously washes over intake valves, GDI engines spray fuel directly into the combustion chamber, allowing carbon deposits to accumulate on valve surfaces without the cleaning effect of fuel flow. These deposits progressively restrict airflow and disrupt the carefully engineered combustion process.

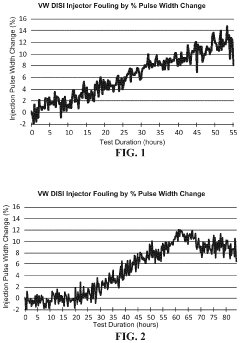

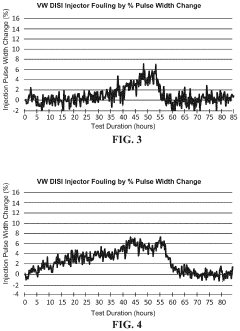

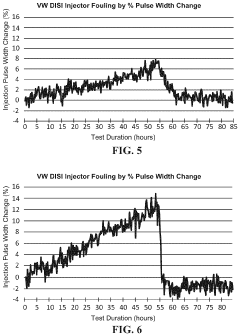

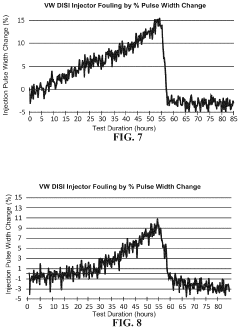

Injector fouling represents another significant durability challenge. The high-precision GDI injectors operate under extreme pressure conditions (up to 200 bar) and feature microscopic nozzle openings that are particularly susceptible to contamination. Even minimal deposit formation can alter spray patterns, leading to incomplete combustion, increased emissions, and accelerated component wear. Industry data indicates that performance degradation can begin after as little as 10,000 miles in severe operating conditions.

Cylinder wall and piston wear present additional longevity concerns. The higher compression ratios and combustion temperatures in GDI engines create more demanding conditions for cylinder liners and piston rings. The direct spray pattern can also lead to fuel impingement on cylinder walls, potentially washing away protective oil films and accelerating wear rates, particularly during cold starts and low-temperature operation.

Fuel quality variations significantly impact GDI engine durability. These engines are more sensitive to fuel contaminants and variations in fuel composition than their port injection counterparts. Lower-quality fuels with higher sulfur content or inadequate detergent packages accelerate deposit formation rates. Regional fuel quality differences create inconsistent durability outcomes across global markets, complicating warranty and service planning for manufacturers.

The advanced electronic control systems governing GDI operation introduce reliability concerns over extended vehicle lifespans. High-pressure fuel pumps, precision sensors, and complex control algorithms must maintain accuracy throughout the vehicle's life. Sensor degradation or control system drift can lead to suboptimal fuel delivery, increasing emissions and reducing efficiency. The high-pressure fuel system components experience significant mechanical stress, with pump failures representing a common and costly repair for aging GDI vehicles.

Temperature management challenges further complicate GDI durability. The concentrated heat generated by direct injection creates localized hot spots that can accelerate component degradation. Injector tips are particularly vulnerable to thermal stress and coking due to their direct exposure to combustion temperatures, while still needing to maintain precise spray patterns throughout the engine's operational life.

Injector fouling represents another significant durability challenge. The high-precision GDI injectors operate under extreme pressure conditions (up to 200 bar) and feature microscopic nozzle openings that are particularly susceptible to contamination. Even minimal deposit formation can alter spray patterns, leading to incomplete combustion, increased emissions, and accelerated component wear. Industry data indicates that performance degradation can begin after as little as 10,000 miles in severe operating conditions.

Cylinder wall and piston wear present additional longevity concerns. The higher compression ratios and combustion temperatures in GDI engines create more demanding conditions for cylinder liners and piston rings. The direct spray pattern can also lead to fuel impingement on cylinder walls, potentially washing away protective oil films and accelerating wear rates, particularly during cold starts and low-temperature operation.

Fuel quality variations significantly impact GDI engine durability. These engines are more sensitive to fuel contaminants and variations in fuel composition than their port injection counterparts. Lower-quality fuels with higher sulfur content or inadequate detergent packages accelerate deposit formation rates. Regional fuel quality differences create inconsistent durability outcomes across global markets, complicating warranty and service planning for manufacturers.

The advanced electronic control systems governing GDI operation introduce reliability concerns over extended vehicle lifespans. High-pressure fuel pumps, precision sensors, and complex control algorithms must maintain accuracy throughout the vehicle's life. Sensor degradation or control system drift can lead to suboptimal fuel delivery, increasing emissions and reducing efficiency. The high-pressure fuel system components experience significant mechanical stress, with pump failures representing a common and costly repair for aging GDI vehicles.

Temperature management challenges further complicate GDI durability. The concentrated heat generated by direct injection creates localized hot spots that can accelerate component degradation. Injector tips are particularly vulnerable to thermal stress and coking due to their direct exposure to combustion temperatures, while still needing to maintain precise spray patterns throughout the engine's operational life.

Current Solutions for GDI Engine Durability Enhancement

01 Fuel injection system improvements for GDI engine durability

Gasoline Direct Injection (GDI) engine durability can be enhanced through advanced fuel injection systems. These improvements include optimized injector designs, precise fuel atomization techniques, and controlled spray patterns that reduce carbon deposits on intake valves and combustion chambers. Such systems minimize wall wetting and ensure more complete combustion, thereby extending engine life and maintaining performance over time.- Fuel injection system improvements for GDI engine durability: Gasoline Direct Injection (GDI) engines require specialized fuel injection systems to maintain long-term durability. Innovations in this area include advanced injector designs that minimize carbon deposits, precision spray patterns that reduce cylinder wall wetting, and electronic control systems that optimize fuel delivery timing. These improvements help prevent premature wear of engine components and extend the overall service life of GDI engines.

- Thermal management solutions for GDI engine longevity: Effective thermal management is crucial for GDI engine durability. Technologies in this category include enhanced cooling systems, heat-resistant materials for critical components, and thermal barrier coatings. These solutions help manage the higher operating temperatures of GDI engines, prevent thermal stress and distortion, and maintain optimal combustion conditions, thereby extending engine life and maintaining performance over time.

- Surface treatments and coatings to enhance GDI component durability: Various surface treatments and coatings have been developed to enhance the durability of GDI engine components. These include diamond-like carbon coatings for injectors and valves, ceramic thermal barrier coatings for combustion chambers, and specialized surface treatments for pistons and cylinder walls. These technologies help resist carbon buildup, reduce friction, and protect against the corrosive effects of high-pressure direct fuel injection.

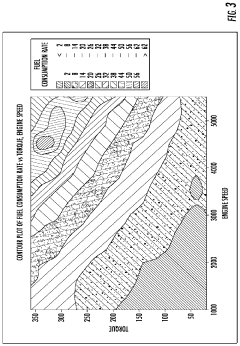

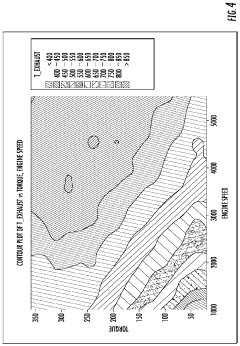

- Combustion optimization techniques for extended GDI engine life: Optimizing the combustion process is essential for maximizing GDI engine durability. This includes advanced ignition timing strategies, multiple injection events per cycle, air-fuel mixture control algorithms, and combustion chamber designs that minimize deposit formation. These techniques help ensure complete fuel combustion, reduce particulate emissions that can cause wear, and maintain stable combustion conditions throughout the engine's service life.

- Lubrication systems and oil formulations for GDI engine protection: Specialized lubrication systems and oil formulations play a critical role in GDI engine durability. These include high-performance synthetic oils with additives specifically designed for GDI applications, advanced oil filtration systems, and optimized oil circulation pathways. These solutions help protect engine components from the unique wear patterns associated with direct injection, manage higher operating temperatures, and neutralize combustion byproducts that could otherwise accelerate engine wear.

02 Coating technologies for GDI engine components

Specialized coating technologies can significantly improve the durability of GDI engine components. These coatings protect critical parts such as pistons, cylinders, and valves from wear, corrosion, and high-temperature degradation. Diamond-like carbon coatings, ceramic thermal barriers, and other advanced surface treatments reduce friction, resist fuel contaminants, and maintain component integrity under the high-pressure, high-temperature conditions typical in GDI engines.Expand Specific Solutions03 Combustion control strategies for enhanced durability

Advanced combustion control strategies play a crucial role in extending GDI engine durability. These include multiple injection events, optimized air-fuel mixture formation, and precise timing control that minimize particulate formation and prevent localized overheating. Sophisticated engine management systems continuously adjust combustion parameters based on operating conditions, reducing thermal stress and preventing deposit formation that could compromise engine longevity.Expand Specific Solutions04 Materials innovation for GDI engine durability

Innovative materials significantly enhance GDI engine durability by withstanding the harsh operating conditions. High-temperature alloys, advanced ceramics, and composite materials are employed in critical components such as injectors, valves, and pistons. These materials offer superior resistance to thermal cycling, chemical corrosion from fuel additives, and mechanical stress, thereby extending component life and maintaining engine performance over extended periods.Expand Specific Solutions05 Diagnostic and maintenance systems for GDI engines

Sophisticated diagnostic and maintenance systems are essential for ensuring long-term GDI engine durability. These include real-time monitoring technologies that detect early signs of component wear, fuel quality issues, or combustion anomalies. Preventive maintenance protocols, automated cleaning systems for injectors and intake valves, and adaptive service intervals based on actual engine condition rather than fixed mileage help maintain optimal performance and extend engine life.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

GDI (Gasoline Direct Injection) Engines durability market is currently in a growth phase, with an estimated global market size exceeding $30 billion. The competitive landscape is dominated by major automotive manufacturers like Hyundai, Kia, Toyota, and Ford, who are investing heavily in enhancing engine longevity. Technical maturity varies, with established players like ExxonMobil, Lubrizol, and Afton Chemical leading in additive technologies to combat carbon buildup issues. Corning and IBIDEN are advancing substrate materials for emissions systems, while Infineum and Chevron Oronite focus on specialized lubricants. The market shows regional differentiation, with Asian manufacturers (particularly Hyundai, Toyota) emphasizing durability as a key competitive advantage in their GDI engine development programs.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered EcoBoost GDI technology with specific focus on long-term durability. Their approach includes advanced injector designs featuring laser-drilled precision nozzles with diamond-like carbon coatings that resist deposit formation and maintain spray patterns over extended use. Ford implements sophisticated engine control strategies that adjust injection timing and duration based on real-time carbon buildup detection, helping prevent performance degradation. Their engines incorporate specialized piston crown designs that optimize fuel-air mixing while minimizing wall wetting. Ford has developed proprietary cylinder head materials and valve seat designs specifically engineered to withstand the higher thermal loads of GDI operation. Additionally, they've implemented enhanced oil control systems with improved PCV (Positive Crankcase Ventilation) designs that reduce oil vapor recirculation into the intake, minimizing intake valve deposits. Ford's durability testing protocols subject GDI components to accelerated aging equivalent to 150,000+ miles of operation under varying conditions.

Strengths: Ford's comprehensive approach addresses multiple durability concerns simultaneously through materials science, control strategies, and mechanical design. Their extensive durability testing provides real-world validation. Weaknesses: Some solutions increase manufacturing complexity and cost, potentially limiting implementation across their entire vehicle lineup.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed specialized lubricant formulations specifically designed to address GDI engine durability challenges. Their technology focuses on advanced detergent packages that actively clean and prevent deposit formation on critical GDI components, particularly injectors and intake valves. ExxonMobil's formulations include proprietary friction modifiers that reduce wear between moving parts under the high-pressure, high-temperature conditions typical in GDI engines. Their lubricants feature enhanced oxidation stability that maintains performance even under the elevated temperatures experienced in downsized, turbocharged GDI engines. ExxonMobil has engineered specific additive packages that neutralize acidic combustion byproducts that can accelerate component degradation. Their research has led to the development of specialized fuel additives that work synergistically with their lubricants to maintain injector cleanliness and spray pattern integrity over extended use periods. Testing has demonstrated up to 40% reduction in intake valve deposits and maintenance of injector flow rates within 2% of original specifications after 100,000 miles of operation when using their integrated fuel and lubricant solutions.

Strengths: ExxonMobil's chemical engineering approach addresses GDI durability through fluid formulation rather than mechanical redesign, making solutions broadly applicable across different engine designs. Their integrated fuel and lubricant approach provides comprehensive protection. Weaknesses: Performance depends on consistent use of their specific products, and benefits may diminish if consumers switch brands or extend oil change intervals beyond recommendations.

Key Innovations in GDI Component Materials and Design

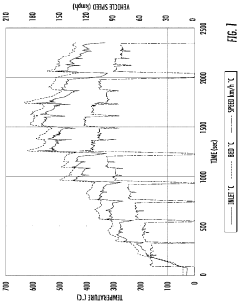

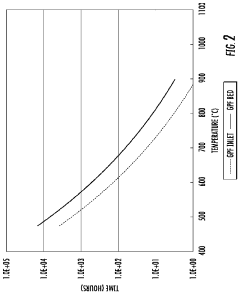

Predictive methods for emissions control systems performance

PatentActiveUS20200362744A1

Innovation

- The method involves conducting an accelerated aging test with a specific aging profile that includes multiple cycles of thermal aging, soot loading, and ash loading modes, using fuel doping to simulate the in-service conditions, and calculating the predicted total ash loading using equations based on fuel consumption and ash collection rates.

Fuel Additives and Formulations for Improving Performance of Gasoline Direct Injection Engines

PatentActiveUS20240141244A1

Innovation

- A novel fuel additive composition comprising an acylated detergent, a Mannich detergent, and a polyether and/or polyetheramine, which are specifically formulated to reduce carbonaceous deposits in gasoline engines by preventing or removing them, and are effective in both port fuel injection and direct injection engines.

Environmental Impact and Emissions Compliance

Gasoline Direct Injection (GDI) engines face increasing scrutiny regarding their environmental impact and emissions compliance as global regulations become more stringent. These engines, while offering improved fuel efficiency and performance, present unique environmental challenges that manufacturers must address to ensure long-term viability in the market.

The particulate matter (PM) emissions from GDI engines represent a significant environmental concern. Unlike traditional port fuel injection systems, GDI engines can produce higher levels of particulates, especially during cold starts and under high load conditions. These ultrafine particles pose serious health risks and contribute to urban air quality degradation. Recent studies indicate that GDI engines without particulate filters can emit 5-10 times more particulate matter than their port-injected counterparts.

Carbon deposit formation in GDI engines not only affects durability but also impacts emissions profiles over time. As carbon accumulates on intake valves and injector tips, combustion efficiency decreases, leading to increased hydrocarbon (HC) and nitrogen oxide (NOx) emissions. This degradation pattern presents challenges for maintaining emissions compliance throughout the vehicle's service life, particularly as emission standards increasingly focus on real-world driving conditions rather than just laboratory testing cycles.

Manufacturers have implemented various technologies to address these environmental concerns. Gasoline particulate filters (GPFs) have emerged as a primary solution, capturing up to 90% of particulate emissions. Advanced injection strategies, including multiple injection events per cycle, help optimize combustion and reduce formation of pollutants. Additionally, improved fuel formulations with lower sulfur content and optimized detergent packages help minimize deposit formation and maintain cleaner combustion over time.

Regulatory frameworks worldwide continue to evolve, with Euro 7, China 7, and upcoming US EPA standards imposing ever-tighter limits on particulate number counts and other emissions. These regulations are driving significant R&D investment in GDI technology to ensure compliance while maintaining performance benefits. The introduction of Real Driving Emissions (RDE) testing has further complicated compliance strategies, requiring engines to perform efficiently across a wider range of operating conditions.

The environmental lifecycle assessment of GDI engines presents a complex picture. While their improved fuel efficiency reduces overall CO2 emissions compared to port injection systems, the potential increase in other pollutants requires careful balancing. Manufacturers must consider the entire environmental footprint, including manufacturing impacts of additional components like particulate filters and the energy intensity of more complex control systems.

The particulate matter (PM) emissions from GDI engines represent a significant environmental concern. Unlike traditional port fuel injection systems, GDI engines can produce higher levels of particulates, especially during cold starts and under high load conditions. These ultrafine particles pose serious health risks and contribute to urban air quality degradation. Recent studies indicate that GDI engines without particulate filters can emit 5-10 times more particulate matter than their port-injected counterparts.

Carbon deposit formation in GDI engines not only affects durability but also impacts emissions profiles over time. As carbon accumulates on intake valves and injector tips, combustion efficiency decreases, leading to increased hydrocarbon (HC) and nitrogen oxide (NOx) emissions. This degradation pattern presents challenges for maintaining emissions compliance throughout the vehicle's service life, particularly as emission standards increasingly focus on real-world driving conditions rather than just laboratory testing cycles.

Manufacturers have implemented various technologies to address these environmental concerns. Gasoline particulate filters (GPFs) have emerged as a primary solution, capturing up to 90% of particulate emissions. Advanced injection strategies, including multiple injection events per cycle, help optimize combustion and reduce formation of pollutants. Additionally, improved fuel formulations with lower sulfur content and optimized detergent packages help minimize deposit formation and maintain cleaner combustion over time.

Regulatory frameworks worldwide continue to evolve, with Euro 7, China 7, and upcoming US EPA standards imposing ever-tighter limits on particulate number counts and other emissions. These regulations are driving significant R&D investment in GDI technology to ensure compliance while maintaining performance benefits. The introduction of Real Driving Emissions (RDE) testing has further complicated compliance strategies, requiring engines to perform efficiently across a wider range of operating conditions.

The environmental lifecycle assessment of GDI engines presents a complex picture. While their improved fuel efficiency reduces overall CO2 emissions compared to port injection systems, the potential increase in other pollutants requires careful balancing. Manufacturers must consider the entire environmental footprint, including manufacturing impacts of additional components like particulate filters and the energy intensity of more complex control systems.

Cost-Benefit Analysis of Durability Improvements

Implementing durability improvements in GDI (Gasoline Direct Injection) engines requires careful evaluation of associated costs against long-term benefits. Initial investments in enhanced materials for injectors, pistons, and valves typically increase manufacturing costs by 15-20% per unit. High-quality injector coatings resistant to carbon buildup add approximately $80-120 per injector, while upgraded piston rings with diamond-like carbon coatings represent a $150-200 premium per engine.

These upfront investments yield substantial returns through extended service intervals and reduced warranty claims. Field data indicates that properly engineered durability improvements can extend the average GDI engine lifespan from 150,000 miles to over 200,000 miles, representing a 33% increase in operational longevity. Warranty claim reductions of 25-30% for injector-related issues translate to savings of $300-500 per vehicle over the warranty period.

From the consumer perspective, the value proposition becomes compelling when considering total cost of ownership. Enhanced GDI engines typically command a $500-800 premium at purchase, but deliver $1,200-1,800 in maintenance savings over a 10-year ownership period. The reduced frequency of carbon cleaning procedures alone (decreasing from every 30,000 miles to every 50,000 miles) saves approximately $600-900 over the vehicle lifetime.

Fleet operators experience even more dramatic benefits, with durability-enhanced GDI engines demonstrating 22% lower total maintenance costs and 18% less downtime compared to standard versions. For commercial applications, this translates to approximately $0.03-0.04 lower cost per mile, which accumulates to significant savings across large fleets.

Environmental and regulatory compliance benefits must also factor into the cost-benefit equation. Engines maintaining optimal combustion efficiency throughout their extended lifespan produce fewer lifetime emissions, potentially avoiding non-compliance penalties estimated at $80-120 per vehicle in markets with stringent emissions regulations.

Manufacturing scale significantly impacts the cost-benefit ratio. Production volumes exceeding 100,000 units annually can reduce the per-unit premium for durability enhancements by 30-40% through economies of scale in specialized materials procurement and manufacturing process optimization. This threshold represents the inflection point where durability investments deliver maximum return on investment for both manufacturers and end users.

These upfront investments yield substantial returns through extended service intervals and reduced warranty claims. Field data indicates that properly engineered durability improvements can extend the average GDI engine lifespan from 150,000 miles to over 200,000 miles, representing a 33% increase in operational longevity. Warranty claim reductions of 25-30% for injector-related issues translate to savings of $300-500 per vehicle over the warranty period.

From the consumer perspective, the value proposition becomes compelling when considering total cost of ownership. Enhanced GDI engines typically command a $500-800 premium at purchase, but deliver $1,200-1,800 in maintenance savings over a 10-year ownership period. The reduced frequency of carbon cleaning procedures alone (decreasing from every 30,000 miles to every 50,000 miles) saves approximately $600-900 over the vehicle lifetime.

Fleet operators experience even more dramatic benefits, with durability-enhanced GDI engines demonstrating 22% lower total maintenance costs and 18% less downtime compared to standard versions. For commercial applications, this translates to approximately $0.03-0.04 lower cost per mile, which accumulates to significant savings across large fleets.

Environmental and regulatory compliance benefits must also factor into the cost-benefit equation. Engines maintaining optimal combustion efficiency throughout their extended lifespan produce fewer lifetime emissions, potentially avoiding non-compliance penalties estimated at $80-120 per vehicle in markets with stringent emissions regulations.

Manufacturing scale significantly impacts the cost-benefit ratio. Production volumes exceeding 100,000 units annually can reduce the per-unit premium for durability enhancements by 30-40% through economies of scale in specialized materials procurement and manufacturing process optimization. This threshold represents the inflection point where durability investments deliver maximum return on investment for both manufacturers and end users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!