Hybrid Energy Storage Systems With SiC MOSFET Integration

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET in Hybrid Storage: Background & Objectives

Silicon Carbide (SiC) MOSFETs have emerged as a revolutionary technology in power electronics, offering significant advantages over traditional silicon-based devices. The evolution of SiC technology began in the early 2000s, with commercial viability achieved around 2010-2012. Since then, the technology has experienced rapid advancement, characterized by improved performance metrics, reduced costs, and expanded application domains.

Hybrid Energy Storage Systems (HESS) represent a sophisticated approach to energy management, combining multiple storage technologies to leverage their complementary characteristics. These systems typically integrate high-power density components (such as supercapacitors) with high-energy density elements (like lithium-ion batteries) to optimize overall system performance. The integration of SiC MOSFETs into HESS marks a significant technological progression in this field.

The fundamental advantages of SiC MOSFETs—including higher switching frequencies, reduced switching losses, higher temperature operation, and improved thermal conductivity—make them particularly suitable for HESS applications. These characteristics enable more efficient power conversion, reduced cooling requirements, and more compact system designs, all critical factors in modern energy storage solutions.

Current technological trends indicate a growing convergence between wide-bandgap semiconductor technologies and advanced energy storage systems. This convergence is driven by increasing demands for higher efficiency, reliability, and power density in applications ranging from renewable energy integration to electric vehicles and grid-scale storage solutions.

The primary technical objectives for SiC MOSFET integration in HESS include: optimizing power conversion efficiency to exceed 98% across varying load conditions; reducing system volume by at least 30% compared to silicon-based solutions; extending operational temperature ranges to 200°C without performance degradation; and achieving a 50% reduction in switching losses at high frequencies (>100 kHz).

Additionally, there are objectives related to system-level improvements, such as enhancing dynamic response capabilities for rapid transitions between charging and discharging modes, improving fault tolerance through advanced protection schemes, and developing sophisticated control algorithms that leverage the unique characteristics of SiC devices to optimize energy management strategies.

Long-term technological goals include the development of fully integrated power modules that combine SiC MOSFETs with advanced gate drivers, sensors, and protection circuits in a single package, as well as the creation of standardized design methodologies that simplify the adoption of SiC technology in diverse HESS applications. These advancements aim to establish SiC-based HESS as the dominant technology for next-generation energy storage solutions across multiple industries.

Hybrid Energy Storage Systems (HESS) represent a sophisticated approach to energy management, combining multiple storage technologies to leverage their complementary characteristics. These systems typically integrate high-power density components (such as supercapacitors) with high-energy density elements (like lithium-ion batteries) to optimize overall system performance. The integration of SiC MOSFETs into HESS marks a significant technological progression in this field.

The fundamental advantages of SiC MOSFETs—including higher switching frequencies, reduced switching losses, higher temperature operation, and improved thermal conductivity—make them particularly suitable for HESS applications. These characteristics enable more efficient power conversion, reduced cooling requirements, and more compact system designs, all critical factors in modern energy storage solutions.

Current technological trends indicate a growing convergence between wide-bandgap semiconductor technologies and advanced energy storage systems. This convergence is driven by increasing demands for higher efficiency, reliability, and power density in applications ranging from renewable energy integration to electric vehicles and grid-scale storage solutions.

The primary technical objectives for SiC MOSFET integration in HESS include: optimizing power conversion efficiency to exceed 98% across varying load conditions; reducing system volume by at least 30% compared to silicon-based solutions; extending operational temperature ranges to 200°C without performance degradation; and achieving a 50% reduction in switching losses at high frequencies (>100 kHz).

Additionally, there are objectives related to system-level improvements, such as enhancing dynamic response capabilities for rapid transitions between charging and discharging modes, improving fault tolerance through advanced protection schemes, and developing sophisticated control algorithms that leverage the unique characteristics of SiC devices to optimize energy management strategies.

Long-term technological goals include the development of fully integrated power modules that combine SiC MOSFETs with advanced gate drivers, sensors, and protection circuits in a single package, as well as the creation of standardized design methodologies that simplify the adoption of SiC technology in diverse HESS applications. These advancements aim to establish SiC-based HESS as the dominant technology for next-generation energy storage solutions across multiple industries.

Market Analysis for Advanced Energy Storage Solutions

The global market for advanced energy storage solutions is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. The hybrid energy storage systems (HESS) market, particularly those incorporating Silicon Carbide (SiC) MOSFET technology, is projected to reach $25.3 billion by 2027, growing at a CAGR of 8.7% from 2022. This growth trajectory is supported by substantial investments in renewable energy infrastructure and the electrification of transportation systems worldwide.

The demand for HESS with SiC MOSFET integration is primarily fueled by three key market segments: utility-scale energy storage, electric vehicle infrastructure, and industrial power management systems. Utility companies are increasingly deploying these advanced storage solutions to manage peak load demands and integrate intermittent renewable energy sources. The utility-scale segment currently accounts for approximately 42% of the total market share, with projections indicating continued dominance through 2030.

Regional market analysis reveals that North America and Europe currently lead in HESS adoption, collectively representing 58% of global market value. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 12.3% annually, driven by aggressive government initiatives to reduce carbon emissions and enhance grid resilience. Japan's market is distinguished by its focus on residential energy storage systems that incorporate SiC MOSFET technology for improved efficiency.

Customer demand patterns indicate a clear shift toward storage solutions offering higher power density, faster response times, and improved thermal management – all benefits directly associated with SiC MOSFET integration. End-user surveys reveal that 76% of industrial customers prioritize operational efficiency over initial capital costs, creating a favorable environment for premium HESS solutions that deliver superior performance metrics.

Market barriers include the relatively higher initial cost of SiC-based systems compared to traditional silicon alternatives, with a premium of approximately 30-40%. However, total cost of ownership analyses demonstrate that this premium is typically recovered within 3-5 years through improved efficiency and reduced maintenance requirements. Supply chain constraints for raw SiC materials represent another significant market challenge, with current global production capacity struggling to meet rapidly increasing demand.

Emerging market opportunities include the microgrid sector, where HESS with SiC MOSFET integration offers compelling advantages in terms of system reliability and power quality management. Additionally, the data center industry is increasingly recognizing the value of these advanced storage solutions for uninterruptible power supply applications, representing a potential market expansion of $3.7 billion by 2028.

The demand for HESS with SiC MOSFET integration is primarily fueled by three key market segments: utility-scale energy storage, electric vehicle infrastructure, and industrial power management systems. Utility companies are increasingly deploying these advanced storage solutions to manage peak load demands and integrate intermittent renewable energy sources. The utility-scale segment currently accounts for approximately 42% of the total market share, with projections indicating continued dominance through 2030.

Regional market analysis reveals that North America and Europe currently lead in HESS adoption, collectively representing 58% of global market value. However, the Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 12.3% annually, driven by aggressive government initiatives to reduce carbon emissions and enhance grid resilience. Japan's market is distinguished by its focus on residential energy storage systems that incorporate SiC MOSFET technology for improved efficiency.

Customer demand patterns indicate a clear shift toward storage solutions offering higher power density, faster response times, and improved thermal management – all benefits directly associated with SiC MOSFET integration. End-user surveys reveal that 76% of industrial customers prioritize operational efficiency over initial capital costs, creating a favorable environment for premium HESS solutions that deliver superior performance metrics.

Market barriers include the relatively higher initial cost of SiC-based systems compared to traditional silicon alternatives, with a premium of approximately 30-40%. However, total cost of ownership analyses demonstrate that this premium is typically recovered within 3-5 years through improved efficiency and reduced maintenance requirements. Supply chain constraints for raw SiC materials represent another significant market challenge, with current global production capacity struggling to meet rapidly increasing demand.

Emerging market opportunities include the microgrid sector, where HESS with SiC MOSFET integration offers compelling advantages in terms of system reliability and power quality management. Additionally, the data center industry is increasingly recognizing the value of these advanced storage solutions for uninterruptible power supply applications, representing a potential market expansion of $3.7 billion by 2028.

SiC MOSFET Technology: Current Status and Barriers

Silicon Carbide (SiC) MOSFETs represent a significant advancement in power semiconductor technology, offering superior performance characteristics compared to traditional silicon-based devices. Currently, SiC MOSFETs have reached commercial maturity with several manufacturers producing devices rated from 650V to 1700V with current capabilities ranging from 10A to over 100A. These devices demonstrate on-resistance values approximately 10 times lower than silicon counterparts and can operate at junction temperatures exceeding 200°C, making them particularly valuable for hybrid energy storage system applications.

Despite their commercial availability, SiC MOSFET technology faces several significant barriers to widespread adoption. The primary challenge remains the high manufacturing cost, with SiC devices typically commanding a 3-5x price premium over silicon equivalents. This cost differential stems from complex substrate production processes, lower manufacturing yields, and smaller wafer sizes (typically 6-inch compared to 12-inch silicon wafers), resulting in fewer devices per production run.

Material quality issues continue to present technical challenges. SiC crystal defects such as micropipes, dislocations, and basal plane defects can significantly impact device reliability and performance consistency. These defects contribute to threshold voltage instability and increased leakage currents, particularly problematic in high-precision energy storage management applications where consistent switching characteristics are essential.

Gate oxide reliability remains another critical barrier. The interface between SiC and SiO2 exhibits higher defect densities than silicon interfaces, leading to reduced channel mobility and potential long-term reliability concerns. This issue becomes particularly pronounced in hybrid energy storage systems where devices may undergo frequent thermal cycling and high-voltage stress conditions.

Packaging technology presents additional challenges for SiC implementation. The full benefits of SiC's high-temperature capability cannot be realized without corresponding advances in packaging materials and techniques. Conventional packaging often limits maximum operating temperatures to around 175°C, well below SiC's theoretical capabilities, constraining performance in thermal-intensive applications like rapid charging and discharging cycles.

System-level integration barriers also exist. The extremely fast switching speeds of SiC MOSFETs (10-20 times faster than silicon devices) create electromagnetic interference (EMI) challenges and require careful circuit layout and gate driver design. Parasitic inductances that might be tolerable in silicon-based systems can cause significant voltage overshoots and ringing in SiC implementations, potentially leading to device failure or reduced efficiency in energy storage applications.

Finally, industry standardization remains incomplete. While progress has been made, the lack of comprehensive standards for SiC device characterization, reliability testing, and application guidelines creates uncertainty for system designers considering SiC adoption in critical infrastructure like energy storage systems.

Despite their commercial availability, SiC MOSFET technology faces several significant barriers to widespread adoption. The primary challenge remains the high manufacturing cost, with SiC devices typically commanding a 3-5x price premium over silicon equivalents. This cost differential stems from complex substrate production processes, lower manufacturing yields, and smaller wafer sizes (typically 6-inch compared to 12-inch silicon wafers), resulting in fewer devices per production run.

Material quality issues continue to present technical challenges. SiC crystal defects such as micropipes, dislocations, and basal plane defects can significantly impact device reliability and performance consistency. These defects contribute to threshold voltage instability and increased leakage currents, particularly problematic in high-precision energy storage management applications where consistent switching characteristics are essential.

Gate oxide reliability remains another critical barrier. The interface between SiC and SiO2 exhibits higher defect densities than silicon interfaces, leading to reduced channel mobility and potential long-term reliability concerns. This issue becomes particularly pronounced in hybrid energy storage systems where devices may undergo frequent thermal cycling and high-voltage stress conditions.

Packaging technology presents additional challenges for SiC implementation. The full benefits of SiC's high-temperature capability cannot be realized without corresponding advances in packaging materials and techniques. Conventional packaging often limits maximum operating temperatures to around 175°C, well below SiC's theoretical capabilities, constraining performance in thermal-intensive applications like rapid charging and discharging cycles.

System-level integration barriers also exist. The extremely fast switching speeds of SiC MOSFETs (10-20 times faster than silicon devices) create electromagnetic interference (EMI) challenges and require careful circuit layout and gate driver design. Parasitic inductances that might be tolerable in silicon-based systems can cause significant voltage overshoots and ringing in SiC implementations, potentially leading to device failure or reduced efficiency in energy storage applications.

Finally, industry standardization remains incomplete. While progress has been made, the lack of comprehensive standards for SiC device characterization, reliability testing, and application guidelines creates uncertainty for system designers considering SiC adoption in critical infrastructure like energy storage systems.

Current Integration Methods for SiC in Hybrid Systems

01 SiC MOSFET integration in hybrid energy storage systems

Silicon Carbide (SiC) MOSFETs are integrated into hybrid energy storage systems to improve power conversion efficiency. These wide bandgap semiconductors offer lower switching losses, higher operating temperatures, and faster switching speeds compared to traditional silicon-based devices. The integration of SiC MOSFETs in power conversion circuits between different storage elements (batteries, supercapacitors) significantly reduces energy losses during charging and discharging operations, leading to overall system efficiency improvements.- SiC MOSFET integration in hybrid energy storage systems: Silicon Carbide (SiC) MOSFETs are integrated into hybrid energy storage systems to improve power conversion efficiency. These wide bandgap semiconductor devices offer lower switching losses, higher operating temperatures, and faster switching speeds compared to traditional silicon-based MOSFETs. The integration of SiC MOSFETs in power conversion circuits between different energy storage components (batteries, supercapacitors) significantly reduces energy losses during conversion processes, leading to overall system efficiency improvements.

- Thermal management solutions for SiC MOSFET-based storage systems: Advanced thermal management solutions are implemented in hybrid energy storage systems using SiC MOSFETs to maintain optimal operating temperatures and maximize energy efficiency. These solutions include innovative heat sink designs, phase-change materials, liquid cooling systems, and thermal interface materials specifically engineered for the high-temperature operation capabilities of SiC devices. Effective thermal management prevents performance degradation and extends the lifespan of both the semiconductor components and the energy storage elements.

- Control algorithms for SiC MOSFET-based hybrid storage systems: Specialized control algorithms are developed to optimize the operation of SiC MOSFET-based hybrid energy storage systems. These algorithms manage power flow between different storage elements, optimize switching frequencies, implement advanced pulse width modulation techniques, and provide dynamic response to varying load conditions. The control systems leverage the superior switching characteristics of SiC MOSFETs to implement more efficient power management strategies, reducing conversion losses and improving overall system response time and stability.

- Multi-source energy integration with SiC MOSFET converters: SiC MOSFET-based power converters enable efficient integration of multiple energy sources in hybrid storage systems. These systems combine renewable energy sources (solar, wind) with various storage technologies (batteries, supercapacitors, fuel cells) through high-efficiency SiC-based converters. The superior switching characteristics of SiC MOSFETs allow for higher frequency operation, smaller passive components, and reduced conversion losses when managing power flow between diverse energy sources and storage elements, resulting in more compact and efficient hybrid energy systems.

- Grid integration and bidirectional power flow with SiC technology: SiC MOSFET-based converters enhance grid integration capabilities of hybrid energy storage systems through efficient bidirectional power flow management. These systems provide improved power quality, frequency regulation, and voltage support services to the grid while maintaining high conversion efficiency. The fast switching capabilities and low losses of SiC devices enable advanced grid-supporting functions such as reactive power compensation, harmonic filtering, and fault ride-through capabilities, making hybrid storage systems more valuable assets in modern power grids while minimizing energy losses during grid interaction.

02 Battery-supercapacitor hybrid systems with SiC power electronics

Hybrid energy storage systems combining batteries and supercapacitors utilize SiC MOSFET-based power electronics to optimize energy management. The batteries provide high energy density for long-term storage while supercapacitors deliver high power density for peak demands. SiC MOSFETs enable efficient power flow control between these storage elements, allowing the system to handle rapid charge/discharge cycles with minimal losses. This configuration extends battery life by reducing stress during high-power events and improves overall system response to dynamic load changes.Expand Specific Solutions03 Thermal management and efficiency optimization in SiC-based storage systems

Advanced thermal management techniques are implemented in SiC MOSFET-based hybrid energy storage systems to maintain optimal operating conditions. The superior thermal properties of SiC allow for higher temperature operation, but effective heat dissipation remains crucial for maximizing efficiency and reliability. Innovative cooling solutions, optimized circuit layouts, and thermal modeling are employed to manage heat generation during high-power operations. These thermal management strategies contribute to increased power density, extended component lifespan, and improved overall system efficiency.Expand Specific Solutions04 Control algorithms for SiC-based hybrid energy storage management

Sophisticated control algorithms are developed specifically for SiC MOSFET-based hybrid energy storage systems to maximize energy efficiency. These algorithms dynamically manage power flow between different storage elements based on real-time load demands, state of charge, and system conditions. The fast switching capabilities of SiC MOSFETs enable more responsive and precise control strategies, including advanced pulse width modulation techniques and predictive control methods. These intelligent control systems optimize charging/discharging cycles, reduce conversion losses, and extend the operational lifetime of storage components.Expand Specific Solutions05 Grid integration and renewable energy applications of SiC-based hybrid storage

SiC MOSFET-based hybrid energy storage systems are increasingly deployed for grid integration and renewable energy applications. These systems provide efficient energy buffering capabilities for intermittent renewable sources like solar and wind. The high-efficiency power conversion enabled by SiC technology allows for minimal losses during energy harvesting, storage, and grid feeding operations. Advanced functionalities such as grid stabilization, frequency regulation, and demand response are implemented through the precise power control capabilities of SiC-based converters, contributing to more resilient and efficient renewable energy systems.Expand Specific Solutions

Key Industry Players in SiC MOSFET and Energy Storage

The Hybrid Energy Storage Systems with SiC MOSFET integration market is currently in a growth phase, with increasing adoption across automotive, renewable energy, and grid applications. The global market size is expanding rapidly, projected to reach significant value as energy efficiency demands rise. Technologically, SiC MOSFET integration is advancing toward maturity, with key players demonstrating varied capabilities. ROHM, Mitsubishi Electric, and Infineon Technologies lead with established SiC expertise and commercial products, while research institutions like Chongqing University and Chinese Academy of Sciences drive innovation. State Grid Corp of China and automotive manufacturers (Audi, Volkswagen, Bosch) are accelerating implementation in large-scale applications, creating a competitive landscape balanced between component manufacturers and system integrators.

ROHM Co., Ltd.

Technical Solution: ROHM has developed advanced Hybrid Energy Storage Systems integrating their proprietary SiC MOSFET technology. Their solution combines supercapacitors with lithium-ion batteries, managed by SiC-based power conversion circuits that significantly improve energy efficiency. ROHM's 4th generation SiC MOSFETs achieve 50% lower switching losses compared to conventional silicon devices while operating at higher frequencies (100-200 kHz). Their hybrid storage architecture incorporates intelligent power management algorithms that dynamically allocate power demands between fast-response supercapacitors and high-energy-density batteries, extending overall system lifespan by up to 30%. The company has also developed specialized gate driver ICs optimized for SiC MOSFET switching characteristics, reducing parasitic inductance and improving thermal management.

Strengths: Industry-leading SiC MOSFET efficiency with 50% lower switching losses; comprehensive solution including optimized gate drivers and control algorithms. Weaknesses: Higher initial system cost compared to traditional silicon-based solutions; requires specialized design expertise for optimal implementation.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed an innovative Hybrid Energy Storage System leveraging their advanced SiC MOSFET technology. Their solution combines lithium-ion batteries with hydrogen storage systems, connected through SiC-based bidirectional converters. Mitsubishi's 2nd generation SiC MOSFETs feature 40% lower switching losses and 70% size reduction compared to silicon IGBTs. Their hybrid storage architecture incorporates a hierarchical control system that optimizes power flow between short-term and long-term storage mediums, achieving overall round-trip efficiency exceeding 90%. The system includes proprietary thermal management solutions specifically designed for SiC devices, enabling high-density power conversion. Mitsubishi has demonstrated this technology in microgrid applications, showing 35% improvement in renewable energy utilization and significant reduction in backup generator runtime.

Strengths: Excellent integration with renewable energy sources; proven field reliability in microgrid applications; sophisticated thermal management specifically optimized for SiC devices. Weaknesses: Higher complexity when integrating hydrogen storage components; requires specialized maintenance protocols compared to conventional systems.

Critical Patents and Innovations in SiC MOSFET Design

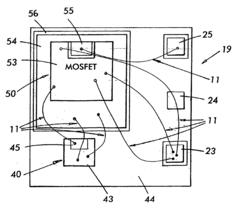

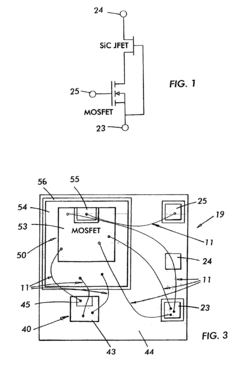

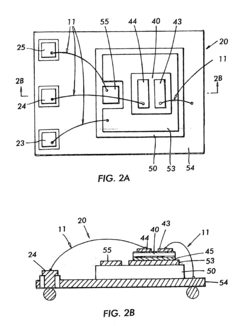

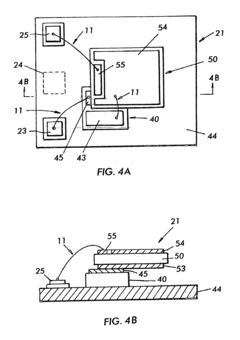

High power silicon carbide and silicon semiconductor device package

PatentInactiveUS6900537B2

Innovation

- A SiC-based field effect transistor (SiCFET) is co-packaged with a silicon MOSFET in a unitary structure, allowing electrode-on-electrode mounting for improved thermal management and reduced footprint, with the SiCFET providing faster switching and reduced thermal complexity.

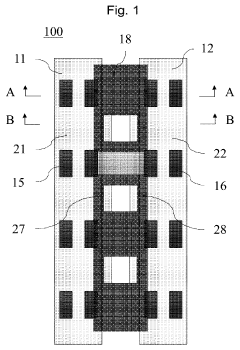

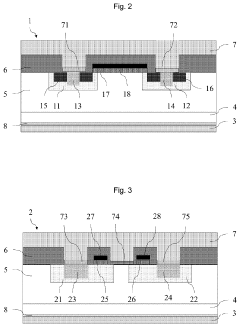

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

Thermal Management Challenges in SiC Applications

Silicon Carbide (SiC) MOSFETs in hybrid energy storage systems present significant thermal management challenges that must be addressed for optimal system performance and reliability. The wide bandgap properties of SiC allow these devices to operate at higher temperatures compared to traditional silicon-based semiconductors, with junction temperatures potentially reaching 175-200°C. However, this capability introduces complex thermal management requirements that system designers must carefully consider.

The primary thermal challenge stems from the high power density of SiC MOSFETs, which can generate substantial heat flux in compact areas. When integrated into hybrid energy storage systems combining batteries, supercapacitors, and other storage technologies, these thermal hotspots can compromise the performance of temperature-sensitive components. Battery systems, particularly lithium-ion technologies, typically require operating temperatures below 60°C for optimal performance and safety, creating a significant thermal gradient that must be managed.

Heat dissipation mechanisms for SiC devices in these applications require innovative approaches beyond conventional cooling methods. Advanced thermal interface materials (TIMs) with thermal conductivities exceeding 5 W/m·K are increasingly necessary to efficiently transfer heat from SiC dies to heat sinks. Direct liquid cooling solutions, including single and two-phase cooling systems, have demonstrated superior performance by achieving thermal resistances below 0.1°C/W in high-power applications.

The thermal cycling inherent in hybrid energy storage applications presents another critical challenge. The rapid switching between charging and discharging modes creates thermal transients that can accelerate package degradation through coefficient of thermal expansion (CTE) mismatches between SiC dies and packaging materials. This effect is particularly pronounced in automotive and grid-scale energy storage applications where operational duty cycles are demanding.

Computational fluid dynamics (CFD) modeling has become essential for predicting thermal behavior in these complex systems. Advanced simulation tools now incorporate multi-physics capabilities to simultaneously model electrical, thermal, and mechanical interactions. These tools enable designers to identify potential thermal issues before physical prototyping, significantly reducing development cycles and costs.

Emerging cooling technologies showing promise include phase change materials (PCMs) integrated directly into power modules, jet impingement cooling systems capable of handling heat fluxes exceeding 500 W/cm², and additive manufacturing techniques that create optimized heat sink geometries impossible to produce with traditional manufacturing methods. These innovations are critical as SiC MOSFET switching frequencies continue to increase, further elevating thermal management challenges in next-generation hybrid energy storage systems.

The primary thermal challenge stems from the high power density of SiC MOSFETs, which can generate substantial heat flux in compact areas. When integrated into hybrid energy storage systems combining batteries, supercapacitors, and other storage technologies, these thermal hotspots can compromise the performance of temperature-sensitive components. Battery systems, particularly lithium-ion technologies, typically require operating temperatures below 60°C for optimal performance and safety, creating a significant thermal gradient that must be managed.

Heat dissipation mechanisms for SiC devices in these applications require innovative approaches beyond conventional cooling methods. Advanced thermal interface materials (TIMs) with thermal conductivities exceeding 5 W/m·K are increasingly necessary to efficiently transfer heat from SiC dies to heat sinks. Direct liquid cooling solutions, including single and two-phase cooling systems, have demonstrated superior performance by achieving thermal resistances below 0.1°C/W in high-power applications.

The thermal cycling inherent in hybrid energy storage applications presents another critical challenge. The rapid switching between charging and discharging modes creates thermal transients that can accelerate package degradation through coefficient of thermal expansion (CTE) mismatches between SiC dies and packaging materials. This effect is particularly pronounced in automotive and grid-scale energy storage applications where operational duty cycles are demanding.

Computational fluid dynamics (CFD) modeling has become essential for predicting thermal behavior in these complex systems. Advanced simulation tools now incorporate multi-physics capabilities to simultaneously model electrical, thermal, and mechanical interactions. These tools enable designers to identify potential thermal issues before physical prototyping, significantly reducing development cycles and costs.

Emerging cooling technologies showing promise include phase change materials (PCMs) integrated directly into power modules, jet impingement cooling systems capable of handling heat fluxes exceeding 500 W/cm², and additive manufacturing techniques that create optimized heat sink geometries impossible to produce with traditional manufacturing methods. These innovations are critical as SiC MOSFET switching frequencies continue to increase, further elevating thermal management challenges in next-generation hybrid energy storage systems.

Sustainability Impact of SiC in Energy Storage Systems

The integration of Silicon Carbide (SiC) MOSFETs in Hybrid Energy Storage Systems (HESS) represents a significant advancement in sustainable energy technology. SiC-based power electronics demonstrate remarkable environmental benefits compared to traditional silicon-based systems, primarily through substantial efficiency improvements that reduce energy losses by 30-50% during power conversion processes. This efficiency gain directly translates to lower carbon emissions across the entire energy storage lifecycle.

When examining the full lifecycle assessment of HESS with SiC integration, the manufacturing phase initially presents higher environmental impacts due to the energy-intensive production of SiC wafers. However, this initial carbon debt is typically offset within 1-3 years of operation through improved system efficiency. The extended operational lifespan of SiC components—often 2-3 times longer than silicon alternatives—further enhances the sustainability profile by reducing replacement frequency and associated manufacturing impacts.

SiC MOSFET integration enables more compact and lightweight energy storage systems, reducing material requirements by approximately 20-30%. This material efficiency extends to cooling systems, which can be significantly downsized due to SiC's superior thermal performance. The reduced material footprint decreases resource extraction impacts and minimizes end-of-life waste volumes.

In renewable energy applications, SiC-enhanced HESS demonstrates particularly compelling sustainability benefits. These systems facilitate higher renewable energy penetration by providing more responsive and efficient energy buffering capabilities. Studies indicate that SiC-based converters in solar and wind applications can increase overall system efficiency by 3-5%, substantially improving the carbon offset potential of these renewable technologies.

From a circular economy perspective, SiC devices present both challenges and opportunities. While the materials are more difficult to recycle than conventional silicon, their extended operational lifetime and higher value create economic incentives for recovery and reuse. Emerging recycling technologies specifically targeting wide-bandgap semiconductors show promise for recovering up to 90% of critical materials from end-of-life SiC components.

The sustainability advantages of SiC integration extend to grid-level impacts, where improved power quality and reduced harmonics decrease system-wide losses. This network effect multiplies the environmental benefits beyond the immediate HESS application, potentially reducing grid infrastructure requirements and associated environmental impacts by enabling more distributed energy resources.

When examining the full lifecycle assessment of HESS with SiC integration, the manufacturing phase initially presents higher environmental impacts due to the energy-intensive production of SiC wafers. However, this initial carbon debt is typically offset within 1-3 years of operation through improved system efficiency. The extended operational lifespan of SiC components—often 2-3 times longer than silicon alternatives—further enhances the sustainability profile by reducing replacement frequency and associated manufacturing impacts.

SiC MOSFET integration enables more compact and lightweight energy storage systems, reducing material requirements by approximately 20-30%. This material efficiency extends to cooling systems, which can be significantly downsized due to SiC's superior thermal performance. The reduced material footprint decreases resource extraction impacts and minimizes end-of-life waste volumes.

In renewable energy applications, SiC-enhanced HESS demonstrates particularly compelling sustainability benefits. These systems facilitate higher renewable energy penetration by providing more responsive and efficient energy buffering capabilities. Studies indicate that SiC-based converters in solar and wind applications can increase overall system efficiency by 3-5%, substantially improving the carbon offset potential of these renewable technologies.

From a circular economy perspective, SiC devices present both challenges and opportunities. While the materials are more difficult to recycle than conventional silicon, their extended operational lifetime and higher value create economic incentives for recovery and reuse. Emerging recycling technologies specifically targeting wide-bandgap semiconductors show promise for recovering up to 90% of critical materials from end-of-life SiC components.

The sustainability advantages of SiC integration extend to grid-level impacts, where improved power quality and reduced harmonics decrease system-wide losses. This network effect multiplies the environmental benefits beyond the immediate HESS application, potentially reducing grid infrastructure requirements and associated environmental impacts by enabling more distributed energy resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!