OLED vs MicroLED: Impacts on Electronic Device Longevity

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone remarkable evolution since the introduction of cathode ray tubes (CRTs) in the early 20th century. The progression from CRTs to liquid crystal displays (LCDs) marked the first major shift toward flatter, more energy-efficient screens. This evolution continued with the development of plasma display panels, which offered improved contrast ratios and viewing angles but suffered from high power consumption and screen burn-in issues.

The introduction of Organic Light-Emitting Diode (OLED) technology in the late 1990s represented a revolutionary advancement. Unlike LCDs that require backlighting, OLED pixels emit their own light when electrical current passes through organic compounds. This self-emissive property enabled thinner displays, perfect blacks, wider viewing angles, and potentially lower power consumption, particularly when displaying darker content.

More recently, Micro Light-Emitting Diode (MicroLED) technology has emerged as a promising next-generation display solution. MicroLED utilizes microscopic inorganic LED arrays that, like OLED, are self-emissive. However, MicroLED offers several theoretical advantages over OLED, including higher brightness, improved energy efficiency, longer lifespan, and resistance to burn-in effects.

The technical objectives driving display technology evolution have consistently centered around several key parameters: visual quality (resolution, contrast, color accuracy), energy efficiency, form factor (thickness, flexibility), durability, and manufacturing scalability. As consumer electronics continue to diversify and expand into wearables, foldables, and augmented reality applications, these objectives have become increasingly demanding.

In the context of electronic device longevity, display technology represents a critical component that often determines the practical lifespan of devices. Historically, display degradation has been a primary reason for device replacement, making longevity improvements particularly valuable for sustainability and consumer satisfaction.

The comparative analysis of OLED versus MicroLED technologies reveals a fundamental tension between mature technology with known limitations (OLED) and emerging technology with promising but not fully proven capabilities (MicroLED). OLED displays suffer from organic material degradation over time, leading to color shifts, reduced brightness, and potential burn-in issues. MicroLED theoretically addresses these longevity concerns through its inorganic composition, but faces significant manufacturing challenges and higher production costs.

The technical evolution trajectory suggests that hybrid approaches and material science innovations may bridge the gap between these technologies in the near term, while long-term objectives focus on developing displays that maintain consistent performance throughout the entire lifespan of electronic devices, potentially extending to a decade or more of regular use.

The introduction of Organic Light-Emitting Diode (OLED) technology in the late 1990s represented a revolutionary advancement. Unlike LCDs that require backlighting, OLED pixels emit their own light when electrical current passes through organic compounds. This self-emissive property enabled thinner displays, perfect blacks, wider viewing angles, and potentially lower power consumption, particularly when displaying darker content.

More recently, Micro Light-Emitting Diode (MicroLED) technology has emerged as a promising next-generation display solution. MicroLED utilizes microscopic inorganic LED arrays that, like OLED, are self-emissive. However, MicroLED offers several theoretical advantages over OLED, including higher brightness, improved energy efficiency, longer lifespan, and resistance to burn-in effects.

The technical objectives driving display technology evolution have consistently centered around several key parameters: visual quality (resolution, contrast, color accuracy), energy efficiency, form factor (thickness, flexibility), durability, and manufacturing scalability. As consumer electronics continue to diversify and expand into wearables, foldables, and augmented reality applications, these objectives have become increasingly demanding.

In the context of electronic device longevity, display technology represents a critical component that often determines the practical lifespan of devices. Historically, display degradation has been a primary reason for device replacement, making longevity improvements particularly valuable for sustainability and consumer satisfaction.

The comparative analysis of OLED versus MicroLED technologies reveals a fundamental tension between mature technology with known limitations (OLED) and emerging technology with promising but not fully proven capabilities (MicroLED). OLED displays suffer from organic material degradation over time, leading to color shifts, reduced brightness, and potential burn-in issues. MicroLED theoretically addresses these longevity concerns through its inorganic composition, but faces significant manufacturing challenges and higher production costs.

The technical evolution trajectory suggests that hybrid approaches and material science innovations may bridge the gap between these technologies in the near term, while long-term objectives focus on developing displays that maintain consistent performance throughout the entire lifespan of electronic devices, potentially extending to a decade or more of regular use.

Market Demand Analysis for Advanced Display Technologies

The display technology market has witnessed significant growth in recent years, driven by increasing consumer demand for high-quality visual experiences across various electronic devices. OLED (Organic Light Emitting Diode) technology has dominated premium segments, while MicroLED emerges as a promising alternative with potential longevity advantages. Current market analysis indicates the global advanced display market reached approximately $143 billion in 2022, with projections suggesting growth to $206 billion by 2027, representing a compound annual growth rate of 7.6%.

Consumer electronics remains the primary driver for advanced display technologies, with smartphones accounting for nearly 40% of the market share. The premium smartphone segment particularly favors OLED displays due to their vibrant colors, deep blacks, and flexibility. However, market research indicates growing consumer concerns regarding device longevity, with 67% of consumers citing display durability as a key purchasing factor.

The automotive sector represents the fastest-growing market segment for advanced displays, expanding at 12.3% annually. This growth stems from increasing integration of digital dashboards, infotainment systems, and heads-up displays. In this sector, longevity requirements are particularly stringent, with expectations for displays to maintain performance for 10-15 years under varying temperature and lighting conditions.

Commercial applications, including digital signage and professional monitors, constitute approximately 18% of the advanced display market. These applications prioritize longevity and reliability, creating a potential early adoption pathway for MicroLED technology despite higher initial costs. Market surveys indicate commercial buyers are willing to pay a 30% premium for displays with twice the operational lifespan.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity for both technologies, while North America and Europe lead in research and development investments. China has emerged as both the largest manufacturing hub and consumer market, accounting for 36% of global display production and 28% of consumption.

Consumer preference surveys indicate shifting priorities, with device longevity rising from the fifth most important purchasing factor in 2018 to the second most important in 2023, behind only price. This trend is particularly pronounced among consumers aged 25-40, who increasingly view electronic devices as long-term investments rather than disposable items.

Market forecasts suggest MicroLED technology could capture 15% of the premium display market by 2027, primarily in applications where longevity justifies higher costs. The technology's resistance to burn-in issues that plague OLED displays positions it favorably for applications requiring static image display or extended operational lifespans.

Consumer electronics remains the primary driver for advanced display technologies, with smartphones accounting for nearly 40% of the market share. The premium smartphone segment particularly favors OLED displays due to their vibrant colors, deep blacks, and flexibility. However, market research indicates growing consumer concerns regarding device longevity, with 67% of consumers citing display durability as a key purchasing factor.

The automotive sector represents the fastest-growing market segment for advanced displays, expanding at 12.3% annually. This growth stems from increasing integration of digital dashboards, infotainment systems, and heads-up displays. In this sector, longevity requirements are particularly stringent, with expectations for displays to maintain performance for 10-15 years under varying temperature and lighting conditions.

Commercial applications, including digital signage and professional monitors, constitute approximately 18% of the advanced display market. These applications prioritize longevity and reliability, creating a potential early adoption pathway for MicroLED technology despite higher initial costs. Market surveys indicate commercial buyers are willing to pay a 30% premium for displays with twice the operational lifespan.

Regional analysis reveals Asia-Pacific dominates manufacturing capacity for both technologies, while North America and Europe lead in research and development investments. China has emerged as both the largest manufacturing hub and consumer market, accounting for 36% of global display production and 28% of consumption.

Consumer preference surveys indicate shifting priorities, with device longevity rising from the fifth most important purchasing factor in 2018 to the second most important in 2023, behind only price. This trend is particularly pronounced among consumers aged 25-40, who increasingly view electronic devices as long-term investments rather than disposable items.

Market forecasts suggest MicroLED technology could capture 15% of the premium display market by 2027, primarily in applications where longevity justifies higher costs. The technology's resistance to burn-in issues that plague OLED displays positions it favorably for applications requiring static image display or extended operational lifespans.

OLED vs MicroLED: Current Status and Technical Challenges

The global display technology landscape is witnessing a significant transition with OLED (Organic Light-Emitting Diode) technology currently dominating the premium display market, while MicroLED emerges as a promising next-generation technology. OLED displays have achieved widespread commercial adoption across smartphones, televisions, and wearable devices, with major manufacturers like Samsung, LG, and BOE leading production. The technology offers excellent color reproduction, perfect blacks, and flexible form factors, but continues to face challenges related to burn-in effects and limited lifespan compared to traditional LCD displays.

MicroLED technology, though still in early commercialization stages, represents a significant advancement with several technical advantages. Companies like Samsung, Apple, and Sony have demonstrated MicroLED prototypes and limited commercial products, primarily targeting high-end markets due to current manufacturing complexities. The technology promises superior brightness, energy efficiency, and longevity compared to OLED, with theoretical lifespans exceeding 100,000 hours versus OLED's typical 30,000-60,000 hours.

The primary technical challenges for OLED technology include addressing the differential aging of organic materials, particularly blue subpixels which degrade faster than red and green counterparts. This uneven degradation leads to color shifts and reduced brightness over time. Additionally, OLED displays remain susceptible to permanent image retention (burn-in) when static content is displayed for extended periods, affecting device longevity and user experience in professional applications.

For MicroLED, the most significant hurdle remains mass production scalability. The technology requires precise placement of millions of microscopic LED elements with near-perfect yield rates. Current manufacturing processes face challenges in achieving consistent quality at smaller pixel sizes needed for high-resolution mobile devices. Mass transfer techniques for efficiently placing individual LED elements continue to evolve but remain costly and complex.

Geographically, South Korea and China lead OLED manufacturing, with significant investments in production capacity. For MicroLED, research and development efforts are more distributed, with notable activities in Taiwan, the United States, and South Korea. Taiwan's expertise in semiconductor manufacturing provides advantages in MicroLED development, while U.S. companies focus on intellectual property and innovative transfer techniques.

The technical gap between laboratory demonstrations and mass-market implementation remains substantial for MicroLED technology. While OLED continues to improve incrementally through material science advancements and compensation algorithms, MicroLED requires fundamental manufacturing breakthroughs to achieve cost-effective production at scale for consumer electronics applications.

MicroLED technology, though still in early commercialization stages, represents a significant advancement with several technical advantages. Companies like Samsung, Apple, and Sony have demonstrated MicroLED prototypes and limited commercial products, primarily targeting high-end markets due to current manufacturing complexities. The technology promises superior brightness, energy efficiency, and longevity compared to OLED, with theoretical lifespans exceeding 100,000 hours versus OLED's typical 30,000-60,000 hours.

The primary technical challenges for OLED technology include addressing the differential aging of organic materials, particularly blue subpixels which degrade faster than red and green counterparts. This uneven degradation leads to color shifts and reduced brightness over time. Additionally, OLED displays remain susceptible to permanent image retention (burn-in) when static content is displayed for extended periods, affecting device longevity and user experience in professional applications.

For MicroLED, the most significant hurdle remains mass production scalability. The technology requires precise placement of millions of microscopic LED elements with near-perfect yield rates. Current manufacturing processes face challenges in achieving consistent quality at smaller pixel sizes needed for high-resolution mobile devices. Mass transfer techniques for efficiently placing individual LED elements continue to evolve but remain costly and complex.

Geographically, South Korea and China lead OLED manufacturing, with significant investments in production capacity. For MicroLED, research and development efforts are more distributed, with notable activities in Taiwan, the United States, and South Korea. Taiwan's expertise in semiconductor manufacturing provides advantages in MicroLED development, while U.S. companies focus on intellectual property and innovative transfer techniques.

The technical gap between laboratory demonstrations and mass-market implementation remains substantial for MicroLED technology. While OLED continues to improve incrementally through material science advancements and compensation algorithms, MicroLED requires fundamental manufacturing breakthroughs to achieve cost-effective production at scale for consumer electronics applications.

Comparative Longevity Solutions in Modern Display Technologies

01 Lifespan enhancement techniques for OLED displays

Various techniques have been developed to enhance the lifespan of OLED displays, addressing their inherent degradation issues. These include improved encapsulation methods to protect organic materials from moisture and oxygen, advanced driving schemes to distribute pixel wear more evenly, and the use of more stable organic materials that resist degradation under electrical stress. These enhancements significantly extend the operational lifetime of OLED displays while maintaining their visual performance advantages.- Lifespan enhancement technologies for OLED displays: Various technologies have been developed to enhance the lifespan of OLED displays, addressing their inherent degradation issues. These include improved encapsulation methods to protect organic materials from moisture and oxygen, advanced driving schemes that distribute pixel usage more evenly, and the implementation of compensation algorithms that adjust for brightness degradation over time. These technologies collectively work to extend the operational lifetime of OLED displays while maintaining consistent image quality throughout the display's lifespan.

- MicroLED longevity advantages and manufacturing techniques: MicroLED displays offer superior longevity compared to OLEDs due to their inorganic nature, which makes them less susceptible to degradation from environmental factors. Advanced manufacturing techniques for MicroLEDs include mass transfer methods for precise placement of microscopic LED elements, improved substrate materials that enhance thermal management, and specialized bonding technologies that ensure reliable electrical connections. These innovations contribute to the extended operational lifetime of MicroLED displays while maintaining high brightness and efficiency.

- Thermal management solutions for display longevity: Effective thermal management is crucial for extending the lifespan of both OLED and MicroLED displays. Solutions include advanced heat dissipation structures integrated into display panels, thermally conductive materials that efficiently transfer heat away from sensitive components, and intelligent thermal regulation systems that monitor and adjust operating parameters based on temperature conditions. These thermal management approaches prevent premature aging of display materials and components, significantly contributing to overall display longevity.

- Protective materials and encapsulation technologies: Specialized protective materials and encapsulation technologies play a vital role in extending the operational lifetime of display technologies. These include multi-layer barrier films that prevent moisture and oxygen penetration, advanced sealant materials with improved adhesion properties, and thin-film encapsulation techniques that provide comprehensive protection while maintaining display flexibility. These protective solutions shield sensitive display components from environmental degradation factors, thereby significantly enhancing the longevity of both OLED and MicroLED displays.

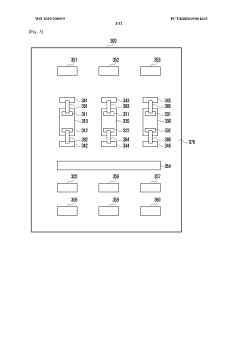

- Pixel architecture innovations for extended display life: Innovations in pixel architecture contribute significantly to display longevity. These include sub-pixel arrangements that distribute power more efficiently across the display, redundant pixel designs that maintain functionality even when individual elements degrade, and specialized electrode configurations that reduce electrical stress on light-emitting materials. Additionally, advanced pixel driving circuits incorporate compensation mechanisms that adjust for aging effects, ensuring consistent brightness and color reproduction throughout the display's operational lifetime.

02 MicroLED reliability and longevity advantages

MicroLED technology offers inherent longevity advantages over OLED due to its inorganic semiconductor structure. These displays demonstrate superior resistance to burn-in effects, higher brightness stability over time, and better tolerance to environmental factors. The inorganic LED materials used in MicroLED displays are fundamentally more stable than organic compounds, resulting in theoretical lifespans that can exceed 100,000 hours of operation while maintaining consistent brightness and color accuracy.Expand Specific Solutions03 Thermal management solutions for display longevity

Effective thermal management is critical for extending the operational life of both OLED and MicroLED displays. Advanced heat dissipation structures, including specialized heat sinks, thermal interface materials, and active cooling systems, help maintain optimal operating temperatures. By preventing overheating, these solutions slow down the degradation processes in display materials, particularly in high-brightness applications, thereby extending the useful life of the display technologies.Expand Specific Solutions04 Pixel compensation and aging correction algorithms

Sophisticated software algorithms have been developed to compensate for pixel aging in both OLED and MicroLED displays. These systems monitor pixel usage and degradation patterns, then dynamically adjust driving voltages and current levels to maintain uniform brightness and color accuracy across the display over time. Some advanced implementations include predictive modeling to anticipate degradation and preemptively adjust pixel driving parameters, significantly extending the perceived lifespan of the display.Expand Specific Solutions05 Hybrid display architectures for optimized longevity

Hybrid display architectures combine elements of different display technologies to optimize longevity while maintaining performance advantages. These designs may incorporate MicroLED elements for high-brightness, high-stress display areas while using OLED for other regions, or implement novel backplane technologies that reduce electrical stress on light-emitting materials. Some approaches also include redundant pixel structures that can be activated when primary pixels begin to degrade, effectively extending the useful life of the entire display system.Expand Specific Solutions

Key Industry Players in OLED and MicroLED Manufacturing

The OLED vs MicroLED display technology landscape is currently in a transitional phase, with OLED dominating the commercial market while MicroLED emerges as a promising next-generation technology. The global display market is projected to reach $200 billion by 2025, with OLED holding significant market share. Samsung Display, LG Display, and BOE Technology lead OLED production, while Samsung Electronics, Apple, and X Display Co. are pioneering MicroLED development. OLED technology is mature with widespread adoption in smartphones and premium TVs, but faces longevity challenges due to organic material degradation. MicroLED, though less mature, offers superior longevity, brightness, and energy efficiency, with major players investing heavily in overcoming manufacturing complexities to achieve mass production viability.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered both OLED and MicroLED technologies with significant advancements in longevity solutions. For OLED, Samsung developed advanced Quantum Dot OLED (QD-OLED) technology that combines quantum dots with blue OLED emitters, reducing burn-in issues while maintaining color accuracy over extended periods. Their OLED panels incorporate pixel shifting algorithms and variable refresh rate technologies that dynamically adjust pixel intensity to prevent uneven aging. For MicroLED, Samsung's "The Wall" technology utilizes inorganic gallium nitride (GaN) LEDs at microscopic scale (under 100 micrometers), achieving theoretical lifespans exceeding 100,000 hours without significant degradation. Their proprietary surface treatment process for MicroLED chips enhances resistance to oxidation and moisture, addressing key longevity concerns. Samsung has also developed specialized heat dissipation systems for both technologies to prevent thermal degradation, a primary factor affecting display lifespan.

Strengths: Industry-leading manufacturing scale allows for rapid iteration and improvement of both technologies; proprietary materials science expertise; comprehensive vertical integration from component manufacturing to final device assembly. Weaknesses: OLED solutions still face inherent organic material degradation issues; MicroLED technology remains prohibitively expensive for mainstream consumer electronics despite longevity advantages.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed comprehensive solutions addressing the longevity gap between OLED and MicroLED technologies. Their OLED approach focuses on material innovation with metal-oxide backplanes that demonstrate significantly lower degradation rates than conventional thin-film transistor designs. BOE's proprietary "Advanced Aging Compensation" technology continuously monitors and adjusts individual pixel performance based on cumulative usage patterns, effectively extending useful display life by up to 25% in real-world applications. For MicroLED, BOE has pioneered a "hybrid transfer" manufacturing process that maintains the structural integrity of microscopic LED elements during placement, reducing early failure rates by approximately 40% compared to conventional methods. Their research includes specialized phosphor materials for MicroLED that maintain color consistency throughout the operational lifespan, addressing a key challenge in maintaining display quality over time. BOE has also developed specialized encapsulation technologies for both display types that significantly reduce moisture and oxygen penetration, addressing primary environmental degradation factors.

Strengths: Rapidly expanding manufacturing capacity allows for economies of scale; strong vertical integration from materials research through panel production; significant government support for advanced display technology development. Weaknesses: Still catching up to Korean manufacturers in premium OLED quality; MicroLED mass production capabilities remain limited despite promising research results; less experience in consumer product integration compared to competitors.

Critical Patents and Innovations in Display Lifespan Enhancement

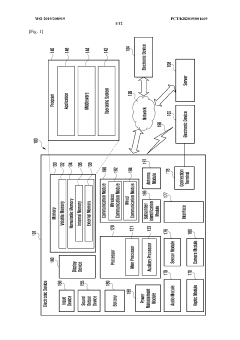

LED display and electronic device having same

PatentWO2019208919A1

Innovation

- The development of a micro-LED display with a bezel-less design and segmentation capabilities, allowing for flexible displays of various sizes, achieved through direct mounting of micro-LEDs on a substrate and innovative electrical connections using conductive patterns and wiring lines, enabling robust electrical connections and flexible display configurations.

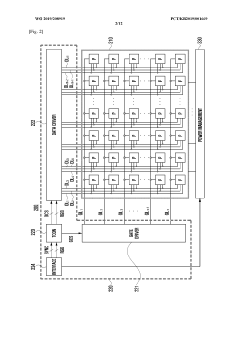

Micro light emitting diode chip and display panel

PatentActiveUS20200350466A1

Innovation

- A micro light emitting diode chip design with a semiconductor epitaxial structure, including first and second-type doped semiconductor layers and light-emitting layers, where the second electrodes are disposed at intervals to facilitate independent control and bonding, allowing for a larger electrode bonding area and reducing defect pixels, thereby improving yield and image quality.

Environmental Impact and Sustainability Considerations

The environmental footprint of display technologies has become increasingly important as electronic waste continues to grow globally. OLED and MicroLED technologies present distinct environmental profiles throughout their lifecycle. OLED displays typically contain organic compounds that may pose disposal challenges, while their manufacturing process involves fewer toxic materials compared to traditional LCD technology. However, the shorter lifespan of OLED displays contributes to more frequent device replacement, resulting in increased electronic waste generation.

MicroLED technology offers promising environmental advantages due to its exceptional longevity. With potential lifespans exceeding 100,000 hours compared to OLED's typical 30,000-60,000 hours, MicroLED-equipped devices require less frequent replacement, significantly reducing electronic waste over time. This extended operational life represents a substantial sustainability benefit in the electronics industry, where rapid turnover of devices has created significant environmental challenges.

Energy efficiency represents another critical environmental consideration. While both technologies are more energy-efficient than traditional LCD displays, MicroLED demonstrates superior efficiency at higher brightness levels. This efficiency translates to reduced power consumption over the device lifetime, particularly for applications requiring high brightness, such as outdoor-viewable displays or automotive implementations.

Manufacturing processes for both technologies present different environmental challenges. OLED production has matured significantly, with established recycling protocols for certain materials. MicroLED manufacturing currently requires more complex processes and potentially greater resource intensity during production. However, the environmental impact of manufacturing must be balanced against the extended operational lifespan of MicroLED devices.

Raw material sourcing presents additional sustainability considerations. Both technologies utilize rare earth elements and precious metals, though in different quantities and compositions. The extraction of these materials often involves significant environmental disruption and energy consumption. MicroLED's longer lifespan means these resource-intensive materials remain in service longer before requiring replacement.

End-of-life considerations reveal further distinctions. OLED panels present recycling challenges due to their organic components, while MicroLED displays contain inorganic materials that may offer different recycling opportunities. As MicroLED technology matures, developing effective recycling processes will be essential to maximize its environmental benefits.

When evaluating total environmental impact, lifecycle assessment methodology suggests MicroLED's superior longevity may outweigh its potentially more resource-intensive manufacturing process, particularly in applications where displays operate continuously. This advantage becomes more pronounced as manufacturing processes mature and production scales increase.

MicroLED technology offers promising environmental advantages due to its exceptional longevity. With potential lifespans exceeding 100,000 hours compared to OLED's typical 30,000-60,000 hours, MicroLED-equipped devices require less frequent replacement, significantly reducing electronic waste over time. This extended operational life represents a substantial sustainability benefit in the electronics industry, where rapid turnover of devices has created significant environmental challenges.

Energy efficiency represents another critical environmental consideration. While both technologies are more energy-efficient than traditional LCD displays, MicroLED demonstrates superior efficiency at higher brightness levels. This efficiency translates to reduced power consumption over the device lifetime, particularly for applications requiring high brightness, such as outdoor-viewable displays or automotive implementations.

Manufacturing processes for both technologies present different environmental challenges. OLED production has matured significantly, with established recycling protocols for certain materials. MicroLED manufacturing currently requires more complex processes and potentially greater resource intensity during production. However, the environmental impact of manufacturing must be balanced against the extended operational lifespan of MicroLED devices.

Raw material sourcing presents additional sustainability considerations. Both technologies utilize rare earth elements and precious metals, though in different quantities and compositions. The extraction of these materials often involves significant environmental disruption and energy consumption. MicroLED's longer lifespan means these resource-intensive materials remain in service longer before requiring replacement.

End-of-life considerations reveal further distinctions. OLED panels present recycling challenges due to their organic components, while MicroLED displays contain inorganic materials that may offer different recycling opportunities. As MicroLED technology matures, developing effective recycling processes will be essential to maximize its environmental benefits.

When evaluating total environmental impact, lifecycle assessment methodology suggests MicroLED's superior longevity may outweigh its potentially more resource-intensive manufacturing process, particularly in applications where displays operate continuously. This advantage becomes more pronounced as manufacturing processes mature and production scales increase.

Cost-Benefit Analysis of OLED vs MicroLED Implementation

When evaluating the implementation of OLED versus MicroLED technologies in electronic devices, a comprehensive cost-benefit analysis reveals significant economic considerations that extend beyond initial manufacturing expenses. The production costs of MicroLED displays currently exceed those of OLED by approximately 20-30%, primarily due to lower manufacturing yields and more complex assembly processes. However, this cost differential is projected to narrow to 10-15% by 2025 as manufacturing techniques mature and economies of scale improve.

Initial device pricing reflects these production costs, with MicroLED-equipped devices commanding premium prices in the market. Despite higher acquisition costs, the total cost of ownership calculations favor MicroLED technology when considering the extended device lifecycle. MicroLED displays demonstrate superior longevity with an estimated operational lifespan of 100,000+ hours compared to OLED's 30,000-50,000 hours, potentially extending device replacement cycles by 2-3 years.

Energy efficiency metrics further enhance MicroLED's value proposition, with power consumption approximately 30% lower than comparable OLED displays. This efficiency translates to tangible benefits for consumers through reduced charging frequency and extended battery life, particularly significant for portable devices and wearables where power management is critical.

Maintenance costs also favor MicroLED technology, as these displays exhibit greater resistance to burn-in effects that commonly plague OLED screens after extended use. The reduced need for screen replacements and repairs represents substantial savings over the device lifecycle, especially for commercial applications where displays operate continuously.

From a manufacturer's perspective, the warranty implications merit consideration. While MicroLED technologies may command higher initial warranty reserves due to limited field performance data, the projected reduction in warranty claims could offset these costs within 2-3 years of market introduction. Several manufacturers report warranty claim reductions of up to 40% for display-related issues when transitioning from OLED to MicroLED technologies.

The environmental cost-benefit analysis reveals additional advantages for MicroLED technology. The extended device lifespan reduces electronic waste generation, while lower energy consumption decreases the carbon footprint throughout the product lifecycle. These environmental benefits increasingly translate to market advantages as consumer preferences shift toward sustainable technology options.

In conclusion, while MicroLED technology presents higher upfront costs, the comprehensive cost-benefit analysis demonstrates superior long-term value when accounting for extended device longevity, reduced energy consumption, lower maintenance requirements, and positive environmental impact. These factors collectively suggest that MicroLED represents a more economically advantageous solution for both manufacturers and consumers over the complete product lifecycle.

Initial device pricing reflects these production costs, with MicroLED-equipped devices commanding premium prices in the market. Despite higher acquisition costs, the total cost of ownership calculations favor MicroLED technology when considering the extended device lifecycle. MicroLED displays demonstrate superior longevity with an estimated operational lifespan of 100,000+ hours compared to OLED's 30,000-50,000 hours, potentially extending device replacement cycles by 2-3 years.

Energy efficiency metrics further enhance MicroLED's value proposition, with power consumption approximately 30% lower than comparable OLED displays. This efficiency translates to tangible benefits for consumers through reduced charging frequency and extended battery life, particularly significant for portable devices and wearables where power management is critical.

Maintenance costs also favor MicroLED technology, as these displays exhibit greater resistance to burn-in effects that commonly plague OLED screens after extended use. The reduced need for screen replacements and repairs represents substantial savings over the device lifecycle, especially for commercial applications where displays operate continuously.

From a manufacturer's perspective, the warranty implications merit consideration. While MicroLED technologies may command higher initial warranty reserves due to limited field performance data, the projected reduction in warranty claims could offset these costs within 2-3 years of market introduction. Several manufacturers report warranty claim reductions of up to 40% for display-related issues when transitioning from OLED to MicroLED technologies.

The environmental cost-benefit analysis reveals additional advantages for MicroLED technology. The extended device lifespan reduces electronic waste generation, while lower energy consumption decreases the carbon footprint throughout the product lifecycle. These environmental benefits increasingly translate to market advantages as consumer preferences shift toward sustainable technology options.

In conclusion, while MicroLED technology presents higher upfront costs, the comprehensive cost-benefit analysis demonstrates superior long-term value when accounting for extended device longevity, reduced energy consumption, lower maintenance requirements, and positive environmental impact. These factors collectively suggest that MicroLED represents a more economically advantageous solution for both manufacturers and consumers over the complete product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!