OLED vs MicroLED: Opportunities in Aerospace Applications

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Display Technology Evolution and Objectives

Display technology has undergone significant evolution since the introduction of cathode ray tubes (CRTs) in the early 20th century. The progression from CRTs to liquid crystal displays (LCDs) marked the first major shift toward thinner, more energy-efficient display solutions. This evolution continued with the development of plasma display panels (PDPs), which offered improved contrast ratios and viewing angles but suffered from high power consumption and heat generation issues.

The introduction of Organic Light-Emitting Diode (OLED) technology in the late 1990s represented a revolutionary advancement in display technology. Unlike LCDs that require backlighting, OLED displays generate light within organic compounds when electricity is applied, enabling thinner form factors, deeper blacks, and significantly improved power efficiency. These characteristics have made OLED displays increasingly prevalent in consumer electronics and, more recently, in specialized applications such as aerospace.

Micro Light-Emitting Diode (MicroLED) technology represents the latest frontier in display evolution. Developed in the early 2000s but only recently approaching commercial viability, MicroLED utilizes arrays of microscopic LEDs to create pixels that are individually addressable. This architecture offers several theoretical advantages over OLED, including higher brightness, improved durability, and even greater energy efficiency.

In aerospace applications, display technology faces unique challenges and requirements that differ substantially from consumer electronics. These include the need for exceptional reliability under extreme conditions, resistance to temperature fluctuations, vibration tolerance, and the ability to maintain visibility under varying lighting conditions from direct sunlight to complete darkness. Additionally, aerospace displays must meet stringent certification requirements while minimizing weight and power consumption.

The technical objectives for next-generation aerospace displays center around several key parameters: enhanced durability in extreme environments, reduced weight and power consumption, improved brightness and contrast ratios, wider viewing angles, and longer operational lifespans. Both OLED and MicroLED technologies offer promising pathways to meet these objectives, albeit with different strengths and limitations.

Current research trends indicate a growing interest in flexible and conformable displays that can be integrated into non-traditional surfaces within aircraft and spacecraft interiors. This direction aligns with broader industry goals of maximizing usable space and improving ergonomics for both pilots and passengers. Additionally, there is significant focus on developing display technologies that can maintain performance integrity during rapid pressure changes and exposure to cosmic radiation.

The evolution trajectory suggests that while OLED technology currently holds advantages in terms of manufacturing maturity and cost-effectiveness, MicroLED displays may ultimately offer superior performance characteristics for the most demanding aerospace applications, particularly as production techniques advance and costs decrease over the next decade.

The introduction of Organic Light-Emitting Diode (OLED) technology in the late 1990s represented a revolutionary advancement in display technology. Unlike LCDs that require backlighting, OLED displays generate light within organic compounds when electricity is applied, enabling thinner form factors, deeper blacks, and significantly improved power efficiency. These characteristics have made OLED displays increasingly prevalent in consumer electronics and, more recently, in specialized applications such as aerospace.

Micro Light-Emitting Diode (MicroLED) technology represents the latest frontier in display evolution. Developed in the early 2000s but only recently approaching commercial viability, MicroLED utilizes arrays of microscopic LEDs to create pixels that are individually addressable. This architecture offers several theoretical advantages over OLED, including higher brightness, improved durability, and even greater energy efficiency.

In aerospace applications, display technology faces unique challenges and requirements that differ substantially from consumer electronics. These include the need for exceptional reliability under extreme conditions, resistance to temperature fluctuations, vibration tolerance, and the ability to maintain visibility under varying lighting conditions from direct sunlight to complete darkness. Additionally, aerospace displays must meet stringent certification requirements while minimizing weight and power consumption.

The technical objectives for next-generation aerospace displays center around several key parameters: enhanced durability in extreme environments, reduced weight and power consumption, improved brightness and contrast ratios, wider viewing angles, and longer operational lifespans. Both OLED and MicroLED technologies offer promising pathways to meet these objectives, albeit with different strengths and limitations.

Current research trends indicate a growing interest in flexible and conformable displays that can be integrated into non-traditional surfaces within aircraft and spacecraft interiors. This direction aligns with broader industry goals of maximizing usable space and improving ergonomics for both pilots and passengers. Additionally, there is significant focus on developing display technologies that can maintain performance integrity during rapid pressure changes and exposure to cosmic radiation.

The evolution trajectory suggests that while OLED technology currently holds advantages in terms of manufacturing maturity and cost-effectiveness, MicroLED displays may ultimately offer superior performance characteristics for the most demanding aerospace applications, particularly as production techniques advance and costs decrease over the next decade.

Aerospace Market Requirements Analysis

The aerospace industry presents unique and demanding requirements for display technologies, significantly different from consumer electronics markets. These requirements are primarily driven by extreme operating conditions, mission-critical reliability needs, and specialized functional demands that conventional display technologies struggle to meet.

Environmental resilience stands as a paramount concern, with aerospace displays needing to function reliably across temperature extremes ranging from -65°C to +125°C during typical flight operations. Displays must withstand intense vibration profiles during launch and flight, high-altitude radiation exposure, and rapid pressure changes without performance degradation or failure.

Power efficiency represents another critical requirement, particularly for space applications where energy resources are severely constrained. Every watt saved in display power consumption translates to extended mission capabilities or reduced battery and solar panel requirements, directly impacting mission economics and feasibility.

Longevity requirements in aerospace far exceed consumer expectations, with typical aerospace systems designed for 15-25 year operational lifespans without the possibility of replacement or significant maintenance. This demands display technologies with exceptional resistance to degradation mechanisms like pixel burnout or luminance decay.

Visual performance requirements are equally stringent, with displays needing to maintain readability under extreme lighting conditions ranging from direct sunlight (100,000+ lux) to complete darkness. High contrast ratios (minimum 1000:1) are essential for information visibility during critical flight phases, while wide viewing angles ensure information accessibility for multiple crew members simultaneously.

Form factor considerations are increasingly important as aerospace systems trend toward miniaturization. Displays must achieve maximum information density while minimizing weight, thickness, and power draw – each gram saved in cockpit instrumentation can translate to significant operational cost savings over an aircraft's lifetime.

Reliability metrics for aerospace displays typically demand mean time between failures (MTBF) exceeding 50,000 hours, with redundancy systems and graceful degradation pathways to prevent catastrophic information loss during critical operations. Certification requirements add additional complexity, with displays needing to meet stringent standards like DO-160 for environmental conditions and DO-254 for hardware reliability.

The market increasingly demands displays capable of advanced functionality including touchscreen operation with gloved hands, night vision compatibility, augmented reality overlays for pilot assistance, and seamless integration with existing avionics systems – all while maintaining backward compatibility with legacy systems.

Environmental resilience stands as a paramount concern, with aerospace displays needing to function reliably across temperature extremes ranging from -65°C to +125°C during typical flight operations. Displays must withstand intense vibration profiles during launch and flight, high-altitude radiation exposure, and rapid pressure changes without performance degradation or failure.

Power efficiency represents another critical requirement, particularly for space applications where energy resources are severely constrained. Every watt saved in display power consumption translates to extended mission capabilities or reduced battery and solar panel requirements, directly impacting mission economics and feasibility.

Longevity requirements in aerospace far exceed consumer expectations, with typical aerospace systems designed for 15-25 year operational lifespans without the possibility of replacement or significant maintenance. This demands display technologies with exceptional resistance to degradation mechanisms like pixel burnout or luminance decay.

Visual performance requirements are equally stringent, with displays needing to maintain readability under extreme lighting conditions ranging from direct sunlight (100,000+ lux) to complete darkness. High contrast ratios (minimum 1000:1) are essential for information visibility during critical flight phases, while wide viewing angles ensure information accessibility for multiple crew members simultaneously.

Form factor considerations are increasingly important as aerospace systems trend toward miniaturization. Displays must achieve maximum information density while minimizing weight, thickness, and power draw – each gram saved in cockpit instrumentation can translate to significant operational cost savings over an aircraft's lifetime.

Reliability metrics for aerospace displays typically demand mean time between failures (MTBF) exceeding 50,000 hours, with redundancy systems and graceful degradation pathways to prevent catastrophic information loss during critical operations. Certification requirements add additional complexity, with displays needing to meet stringent standards like DO-160 for environmental conditions and DO-254 for hardware reliability.

The market increasingly demands displays capable of advanced functionality including touchscreen operation with gloved hands, night vision compatibility, augmented reality overlays for pilot assistance, and seamless integration with existing avionics systems – all while maintaining backward compatibility with legacy systems.

OLED and MicroLED Technical Challenges

Both OLED and MicroLED technologies face significant technical challenges that impact their adoption in aerospace applications. OLED displays currently struggle with limited operational lifespans, typically ranging from 30,000 to 100,000 hours depending on usage patterns and color requirements. This limitation is particularly problematic for aerospace systems that demand extended service periods without replacement.

Brightness degradation represents another critical challenge for OLED technology. The organic materials experience uneven aging, with blue subpixels deteriorating faster than red and green counterparts, resulting in color shift over time. In aerospace environments where display accuracy is mission-critical, this degradation pattern raises reliability concerns.

Environmental sensitivity further complicates OLED implementation in aerospace settings. The organic materials are highly susceptible to moisture and oxygen, requiring sophisticated encapsulation techniques. Despite advances in thin-film encapsulation, achieving the hermetic sealing necessary for extreme aerospace conditions remains challenging, particularly with temperature variations from -65°C to +85°C common in aviation environments.

MicroLED technology, while promising, faces its own set of technical hurdles. Mass transfer yield represents the most significant manufacturing challenge, as the process requires precisely placing millions of microscopic LED chips onto substrates with near-perfect accuracy. Current yield rates below 99.999% result in visible defects, unacceptable for high-reliability aerospace applications.

Miniaturization constraints also limit MicroLED advancement. As manufacturers push toward higher resolution displays, LED chip sizes must decrease to sub-10μm dimensions. This miniaturization introduces quantum efficiency challenges and increased current density requirements, potentially compromising longevity and performance stability.

Color consistency across MicroLED panels presents another technical obstacle. The epitaxial growth processes used to create red, green, and blue LEDs result in varying efficiency levels and wavelength characteristics. Achieving uniform color performance across large displays requires sophisticated compensation algorithms and precise manufacturing controls not yet fully mature.

Heat management represents a shared challenge for both technologies in aerospace applications. OLED displays generate heat during operation that can accelerate material degradation, while MicroLED's higher brightness capabilities produce significant thermal loads requiring advanced cooling solutions. The confined spaces and weight restrictions in aerospace systems complicate thermal management approaches.

Power efficiency trade-offs also impact implementation decisions. While both technologies offer advantages over traditional LCD displays, OLED's efficiency decreases at higher brightness levels, whereas MicroLED maintains better efficiency at peak luminance—a critical factor for cockpit displays that must remain readable in direct sunlight conditions.

Brightness degradation represents another critical challenge for OLED technology. The organic materials experience uneven aging, with blue subpixels deteriorating faster than red and green counterparts, resulting in color shift over time. In aerospace environments where display accuracy is mission-critical, this degradation pattern raises reliability concerns.

Environmental sensitivity further complicates OLED implementation in aerospace settings. The organic materials are highly susceptible to moisture and oxygen, requiring sophisticated encapsulation techniques. Despite advances in thin-film encapsulation, achieving the hermetic sealing necessary for extreme aerospace conditions remains challenging, particularly with temperature variations from -65°C to +85°C common in aviation environments.

MicroLED technology, while promising, faces its own set of technical hurdles. Mass transfer yield represents the most significant manufacturing challenge, as the process requires precisely placing millions of microscopic LED chips onto substrates with near-perfect accuracy. Current yield rates below 99.999% result in visible defects, unacceptable for high-reliability aerospace applications.

Miniaturization constraints also limit MicroLED advancement. As manufacturers push toward higher resolution displays, LED chip sizes must decrease to sub-10μm dimensions. This miniaturization introduces quantum efficiency challenges and increased current density requirements, potentially compromising longevity and performance stability.

Color consistency across MicroLED panels presents another technical obstacle. The epitaxial growth processes used to create red, green, and blue LEDs result in varying efficiency levels and wavelength characteristics. Achieving uniform color performance across large displays requires sophisticated compensation algorithms and precise manufacturing controls not yet fully mature.

Heat management represents a shared challenge for both technologies in aerospace applications. OLED displays generate heat during operation that can accelerate material degradation, while MicroLED's higher brightness capabilities produce significant thermal loads requiring advanced cooling solutions. The confined spaces and weight restrictions in aerospace systems complicate thermal management approaches.

Power efficiency trade-offs also impact implementation decisions. While both technologies offer advantages over traditional LCD displays, OLED's efficiency decreases at higher brightness levels, whereas MicroLED maintains better efficiency at peak luminance—a critical factor for cockpit displays that must remain readable in direct sunlight conditions.

Current Implementation Solutions

01 OLED display structure and materials

Organic Light Emitting Diode (OLED) displays utilize organic compounds that emit light when an electric current is applied. These displays feature multiple layers including cathode, emissive layer, conductive layer, and anode. The technology offers advantages such as flexibility, thinness, and superior contrast ratios. Various materials and structures are employed to enhance efficiency, color accuracy, and lifespan of OLED displays.- OLED display structure and materials: Organic Light Emitting Diode (OLED) displays utilize organic compounds that emit light when electricity is applied. These displays feature multiple layers including cathode, organic layers, and anode. The organic materials can be engineered for different colors and brightness levels. OLED technology offers advantages such as flexibility, thinness, and high contrast ratios. Recent innovations focus on improving efficiency, lifespan, and reducing power consumption through novel material compositions and structural designs.

- MicroLED fabrication and integration: MicroLED technology involves the integration of microscopic LED arrays to create displays with superior brightness, efficiency, and longevity. The fabrication process includes transfer techniques to position tiny LED chips onto display substrates. Innovations in this field focus on mass transfer methods, defect management, and integration with driving circuits. MicroLED displays offer advantages including higher brightness, better energy efficiency, and longer lifespans compared to traditional display technologies.

- Display driving and control systems: Advanced driving and control systems are essential for both OLED and MicroLED displays. These systems include pixel driving circuits, timing controllers, and power management solutions. Innovations focus on reducing power consumption, improving refresh rates, and enhancing image quality. The driving architecture must address challenges specific to each technology, such as current uniformity in OLEDs and individual pixel addressing in MicroLEDs. Recent developments include compensation circuits for aging effects and temperature variations.

- Flexible and foldable display technologies: Flexible and foldable displays represent a significant advancement in both OLED and MicroLED technologies. These displays incorporate specialized substrates, encapsulation methods, and mechanical designs to enable bending without damage. Innovations focus on reducing the bending radius, improving durability during repeated folding, and maintaining display quality at the fold areas. Applications include smartphones, wearables, and other portable devices where form factor flexibility provides significant advantages.

- Thermal management and efficiency improvements: Thermal management is critical for both OLED and MicroLED displays to ensure optimal performance and longevity. Heat dissipation techniques include specialized materials, structural designs, and active cooling systems. Efficiency improvements focus on reducing power consumption while maintaining or enhancing brightness and color accuracy. Recent innovations address challenges such as thermal degradation of organic materials in OLEDs and heat concentration in high-brightness MicroLED displays. Advanced thermal management solutions contribute to extended device lifespans and improved reliability.

02 MicroLED fabrication and integration

MicroLED technology involves the integration of microscopic LED arrays to create high-resolution displays. The fabrication process includes transfer techniques to position tiny LED elements onto display substrates. These displays offer high brightness, energy efficiency, and long lifespans. Advanced manufacturing methods address challenges in mass transfer, alignment precision, and yield rates to enable commercial viability of MicroLED displays.Expand Specific Solutions03 Display driving and control systems

Specialized driving and control systems are essential for both OLED and MicroLED displays. These include pixel driving circuits, backplane technologies, and timing controllers that manage refresh rates and power consumption. Advanced control systems enable features like variable refresh rates, local dimming, and adaptive brightness. The driving architecture significantly impacts display performance, power efficiency, and image quality.Expand Specific Solutions04 Flexible and foldable display technologies

Innovations in flexible and foldable displays leverage the inherent advantages of OLED and MicroLED technologies. These displays incorporate specialized substrates, encapsulation methods, and mechanical structures to enable bending without damage. Flexible displays can be integrated into curved surfaces or foldable devices, opening new form factors for consumer electronics. Special attention is given to stress distribution and durability at fold points.Expand Specific Solutions05 Display enhancement technologies

Various enhancement technologies improve the performance of OLED and MicroLED displays. These include quantum dot integration for color enhancement, optical films for improved light extraction, and specialized coatings for reduced reflection. Additional enhancements focus on power efficiency, thermal management, and ambient light adaptation. These technologies collectively contribute to superior image quality, extended battery life, and improved user experience in various lighting conditions.Expand Specific Solutions

Key Industry Players and Ecosystem

The OLED vs MicroLED aerospace application market is in an early growth phase, with increasing adoption driven by demands for lightweight, energy-efficient displays in cockpits and cabin systems. The market is projected to expand significantly as aerospace manufacturers seek advanced visualization technologies. Technologically, OLED is more mature with established players like BOE Technology, Samsung, and Universal Display Corporation leading commercial deployment, while MicroLED represents the emerging frontier with companies like Lumileds, Airbus, and CSEM advancing development. Honeywell and Barco are leveraging both technologies for specialized aerospace applications. The competitive landscape shows traditional display manufacturers competing with aerospace systems integrators, with Asian manufacturers dominating production capacity while Western companies focus on specialized aerospace-grade implementations.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed specialized OLED display solutions for aerospace applications, focusing on flexible and rigid OLED panels that address the unique requirements of aircraft cockpits and cabin entertainment systems. Their aerospace OLED technology features high-resolution displays (up to 4K) with pixel densities exceeding 300 PPI, while maintaining power efficiency through advanced OLED materials and driving schemes. BOE's aerospace OLEDs incorporate specialized encapsulation technology that extends operational lifetime to over 50,000 hours while protecting against moisture and oxygen degradation in variable cabin pressure environments. The displays achieve brightness levels of 600-800 nits with high contrast ratios (over 100,000:1) and implement specialized optical treatments to minimize reflections in cockpit environments. BOE has also developed temperature-compensated OLED driving schemes that maintain consistent performance across the wide temperature ranges experienced in aerospace applications (-20°C to +70°C). Their flexible OLED solutions enable curved and conformable displays that can be integrated into space-constrained cockpit environments while reducing overall weight compared to traditional LCD systems.

Strengths: Excellent color reproduction and infinite contrast ratio beneficial for detailed instrumentation displays; lower power consumption than LCD alternatives; lightweight and thin form factors allowing for space and weight savings in aircraft; flexibility enabling curved display implementations in ergonomic cockpit designs. Weaknesses: Susceptibility to burn-in with static cockpit display elements; shorter lifespan compared to MicroLED alternatives; brightness limitations in direct sunlight conditions; more complex thermal management requirements in aerospace environments.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has pioneered hybrid display solutions for aerospace applications that strategically implement both OLED and MicroLED technologies based on specific cockpit and cabin requirements. Their primary innovation is the Honeywell Advanced Display System (HADS) that utilizes OLED technology for primary flight displays requiring superior contrast and color reproduction, while implementing MicroLED for high-brightness applications such as head-up displays (HUDs) and external vision systems. Honeywell's aerospace display solutions feature specialized optical bonding techniques that enhance readability in variable lighting conditions while improving impact resistance to meet DO-160 environmental standards. Their MicroLED implementations achieve brightness levels exceeding 3,000 nits while maintaining power efficiency through adaptive brightness control systems that respond to ambient light conditions. Honeywell has developed proprietary redundant display architectures that ensure critical flight information remains visible even in partial display failure scenarios, with mean time between failures (MTBF) exceeding 50,000 hours. Their displays incorporate specialized EMI shielding to prevent interference with critical avionics systems while maintaining compliance with stringent aerospace certification requirements including DO-254 and DO-178C.

Strengths: Comprehensive integration with existing avionics systems; proven certification pathway through established aerospace relationships; hybrid approach maximizes benefits of both technologies; extensive experience with aerospace environmental requirements and certification processes. Weaknesses: Higher system complexity when implementing hybrid display solutions; increased integration costs compared to single-technology approaches; potential weight penalties from redundant systems; longer certification timelines for novel display technologies in safety-critical applications.

Critical Patents and Technical Innovations

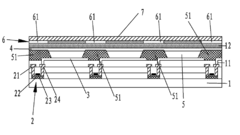

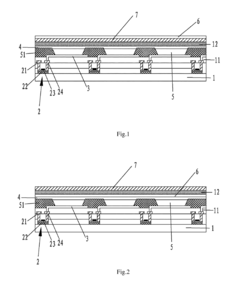

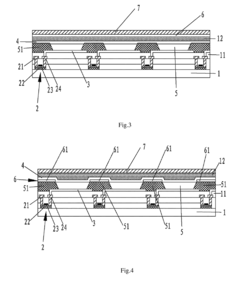

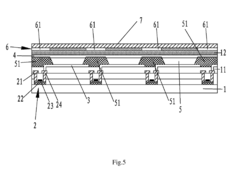

Micro light-emitting diode display device and micro light-emitting diode driving circuit

PatentActiveUS10680035B1

Innovation

- A micro light-emitting diode display device with a driving transistor featuring a gate insulator thickness of less than or equal to 500 angstroms and a micro light-emitting diode with a current injection channel and an active layer portion in contact with the channel, reducing the light-emitting area and avoiding surface recombination, thereby lowering the voltage required to activate the diode.

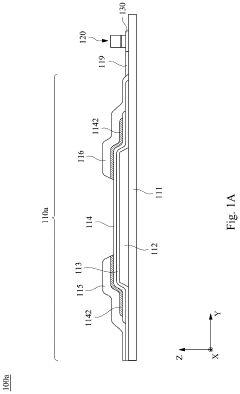

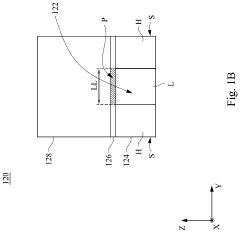

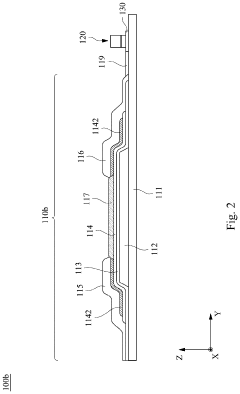

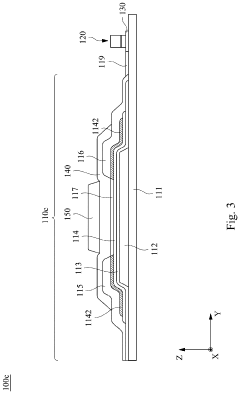

Organic light-emitting diode (OLED) device and display device

PatentActiveUS9905625B2

Innovation

- Incorporating a light-blocking layer, made of materials like ZnO, IGZO, TiO2, or TiO2, between the organic light-emitting layer and the cathode, or at the light-exiting side of the OLED device to block UV light, thereby preventing performance degradation.

Reliability and Environmental Testing

Reliability and environmental testing represents a critical evaluation domain for both OLED and MicroLED technologies in aerospace applications, where operating conditions are exceptionally demanding. These technologies must withstand extreme temperature fluctuations ranging from -65°C during high-altitude flight to over 125°C in certain equipment compartments, requiring robust thermal cycling tests to validate performance stability.

Vacuum exposure testing reveals significant differences between these display technologies. OLEDs demonstrate vulnerability to outgassing in vacuum environments, potentially compromising display integrity during extended space missions. Conversely, MicroLED exhibits superior vacuum stability due to its inorganic composition, presenting a distinct advantage for spacecraft applications where vacuum exposure is inevitable.

Radiation hardness testing indicates MicroLED's superior resilience to cosmic radiation compared to OLED. Testing protocols typically subject displays to cumulative radiation doses of 100 krad or higher, simulating years of space exposure. MicroLED consistently maintains performance parameters with minimal degradation, while OLEDs show more pronounced color shift and luminance reduction under equivalent conditions.

Vibration and shock testing protocols, adhering to MIL-STD-810 standards, reveal structural advantages of MicroLED. The technology's solid-state construction withstands mechanical stresses exceeding 20G without pixel failure. OLED displays, with their more complex layer structure, demonstrate higher susceptibility to delamination and pixel damage under identical test conditions.

Accelerated lifetime testing under aerospace-specific conditions shows MicroLED maintaining 90% brightness after 50,000 operating hours, significantly outperforming OLED's typical 30,000-hour performance threshold before reaching 80% brightness. This extended operational lifespan directly translates to reduced maintenance requirements for aerospace systems.

Humidity and pressure variation tests demonstrate both technologies can be effectively sealed against moisture ingress, though MicroLED exhibits better long-term barrier properties. When subjected to rapid pressure changes simulating altitude variations between sea level and 40,000 feet, MicroLED displays maintain consistent performance parameters with minimal stress-induced degradation.

These comprehensive testing protocols reveal MicroLED's superior overall environmental resilience for aerospace applications, though OLED maintains advantages in specific operational scenarios where weight and power efficiency are prioritized over environmental extremes. The selection between these technologies ultimately depends on mission-specific requirements and the particular environmental challenges anticipated.

Vacuum exposure testing reveals significant differences between these display technologies. OLEDs demonstrate vulnerability to outgassing in vacuum environments, potentially compromising display integrity during extended space missions. Conversely, MicroLED exhibits superior vacuum stability due to its inorganic composition, presenting a distinct advantage for spacecraft applications where vacuum exposure is inevitable.

Radiation hardness testing indicates MicroLED's superior resilience to cosmic radiation compared to OLED. Testing protocols typically subject displays to cumulative radiation doses of 100 krad or higher, simulating years of space exposure. MicroLED consistently maintains performance parameters with minimal degradation, while OLEDs show more pronounced color shift and luminance reduction under equivalent conditions.

Vibration and shock testing protocols, adhering to MIL-STD-810 standards, reveal structural advantages of MicroLED. The technology's solid-state construction withstands mechanical stresses exceeding 20G without pixel failure. OLED displays, with their more complex layer structure, demonstrate higher susceptibility to delamination and pixel damage under identical test conditions.

Accelerated lifetime testing under aerospace-specific conditions shows MicroLED maintaining 90% brightness after 50,000 operating hours, significantly outperforming OLED's typical 30,000-hour performance threshold before reaching 80% brightness. This extended operational lifespan directly translates to reduced maintenance requirements for aerospace systems.

Humidity and pressure variation tests demonstrate both technologies can be effectively sealed against moisture ingress, though MicroLED exhibits better long-term barrier properties. When subjected to rapid pressure changes simulating altitude variations between sea level and 40,000 feet, MicroLED displays maintain consistent performance parameters with minimal stress-induced degradation.

These comprehensive testing protocols reveal MicroLED's superior overall environmental resilience for aerospace applications, though OLED maintains advantages in specific operational scenarios where weight and power efficiency are prioritized over environmental extremes. The selection between these technologies ultimately depends on mission-specific requirements and the particular environmental challenges anticipated.

Power Efficiency and Weight Considerations

In aerospace applications, power efficiency and weight considerations are paramount factors that directly impact mission capabilities, operational costs, and overall system performance. When comparing OLED and MicroLED technologies for aerospace implementation, these considerations become critical decision points that can determine the viability of either technology.

OLED displays currently demonstrate superior power efficiency in dark or black-dominant content scenarios due to their self-emissive pixel architecture, where inactive pixels consume virtually no power. This characteristic is particularly advantageous for aerospace applications where cockpit displays often feature dark backgrounds with critical information highlighted. Testing data indicates that OLEDs can achieve up to 40% power savings compared to traditional LCD displays in these specific use cases.

However, MicroLED technology is rapidly closing this efficiency gap while offering significant advantages in bright-content scenarios. Recent advancements have improved MicroLED efficiency by approximately 30% over the past three years, with laboratory prototypes demonstrating power consumption reductions of up to 50% compared to first-generation implementations. This efficiency curve suggests MicroLED may surpass OLED in overall power efficiency within the next development cycle.

Weight considerations heavily favor both technologies over conventional aerospace display systems, but MicroLED holds a distinct advantage. The structural simplicity of MicroLED displays—requiring fewer substrate layers and no color filters—results in approximately 25-30% weight reduction compared to equivalent OLED panels. For aerospace applications, this translates to potential weight savings of 3-5kg in a typical cockpit display configuration, with corresponding fuel efficiency improvements.

Thermal management requirements further differentiate these technologies. OLEDs typically operate at lower temperatures but demonstrate accelerated degradation when subjected to temperature extremes common in aerospace environments. MicroLED displays exhibit superior thermal stability, maintaining performance integrity across a wider temperature range (-65°C to +125°C compared to OLED's -40°C to +85°C), potentially eliminating the need for additional thermal management systems that add weight and complexity.

Power supply integration presents another consideration, with MicroLED's higher voltage requirements potentially necessitating more complex power conditioning circuits. However, this disadvantage is offset by MicroLED's longer operational lifespan, which reduces replacement frequency and associated maintenance weight penalties over the aircraft lifecycle.

When evaluating total system impact, MicroLED technology demonstrates a projected 15-20% advantage in the power-to-weight ratio over comparable OLED implementations in aerospace applications, particularly for displays with mixed content requirements and extended operational lifespans exceeding 30,000 hours.

OLED displays currently demonstrate superior power efficiency in dark or black-dominant content scenarios due to their self-emissive pixel architecture, where inactive pixels consume virtually no power. This characteristic is particularly advantageous for aerospace applications where cockpit displays often feature dark backgrounds with critical information highlighted. Testing data indicates that OLEDs can achieve up to 40% power savings compared to traditional LCD displays in these specific use cases.

However, MicroLED technology is rapidly closing this efficiency gap while offering significant advantages in bright-content scenarios. Recent advancements have improved MicroLED efficiency by approximately 30% over the past three years, with laboratory prototypes demonstrating power consumption reductions of up to 50% compared to first-generation implementations. This efficiency curve suggests MicroLED may surpass OLED in overall power efficiency within the next development cycle.

Weight considerations heavily favor both technologies over conventional aerospace display systems, but MicroLED holds a distinct advantage. The structural simplicity of MicroLED displays—requiring fewer substrate layers and no color filters—results in approximately 25-30% weight reduction compared to equivalent OLED panels. For aerospace applications, this translates to potential weight savings of 3-5kg in a typical cockpit display configuration, with corresponding fuel efficiency improvements.

Thermal management requirements further differentiate these technologies. OLEDs typically operate at lower temperatures but demonstrate accelerated degradation when subjected to temperature extremes common in aerospace environments. MicroLED displays exhibit superior thermal stability, maintaining performance integrity across a wider temperature range (-65°C to +125°C compared to OLED's -40°C to +85°C), potentially eliminating the need for additional thermal management systems that add weight and complexity.

Power supply integration presents another consideration, with MicroLED's higher voltage requirements potentially necessitating more complex power conditioning circuits. However, this disadvantage is offset by MicroLED's longer operational lifespan, which reduces replacement frequency and associated maintenance weight penalties over the aircraft lifecycle.

When evaluating total system impact, MicroLED technology demonstrates a projected 15-20% advantage in the power-to-weight ratio over comparable OLED implementations in aerospace applications, particularly for displays with mixed content requirements and extended operational lifespans exceeding 30,000 hours.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!