Optimizing Efficiency In Variable Frequency Drives With SiC MOSFETs

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET VFD Technology Background and Objectives

Variable Frequency Drives (VFDs) have evolved significantly since their introduction in the 1960s, transforming from simple motor speed controllers to sophisticated power conversion systems. The integration of Silicon Carbide (SiC) MOSFETs represents a pivotal advancement in this technological trajectory, marking a transition from traditional silicon-based power semiconductors to wide bandgap materials with superior performance characteristics.

The evolution of VFD technology has been driven by increasing demands for energy efficiency, power density, and system reliability across industrial applications. Early VFDs utilized silicon-based IGBTs and MOSFETs, which presented inherent limitations in switching frequency, thermal performance, and power handling capabilities. These constraints have become increasingly problematic as industries push toward more compact, efficient, and reliable motor drive systems.

SiC MOSFETs emerged in the commercial market during the early 2010s, offering a revolutionary alternative with significantly reduced switching losses, higher temperature operation, and improved thermal conductivity. The wide bandgap properties of silicon carbide enable these devices to operate at higher voltages, frequencies, and temperatures compared to their silicon counterparts, directly addressing the fundamental limitations of conventional VFD technology.

Market adoption of SiC technology in VFDs has accelerated in recent years, driven by decreasing component costs and increasing emphasis on energy efficiency regulations worldwide. The compound annual growth rate for SiC power devices exceeds 30% in some market segments, indicating strong momentum toward widespread implementation in variable frequency drive applications.

The primary technical objective of SiC MOSFET integration in VFDs is to achieve substantial improvements in system efficiency, with potential energy savings of 2-3% at full load and up to 10% at partial load conditions compared to conventional silicon-based solutions. This efficiency enhancement directly translates to reduced operational costs and smaller carbon footprints for industrial operations.

Secondary objectives include significant reductions in system size and weight through higher switching frequencies that enable smaller passive components. Current research indicates potential volume reductions of 30-40% for equivalent power ratings, creating opportunities for more compact industrial installations and mobile applications.

Reliability enhancement represents another critical objective, with SiC MOSFETs demonstrating superior robustness under thermal cycling and surge conditions. The technology aims to extend mean time between failures (MTBF) by 25-50% compared to silicon-based VFDs, reducing maintenance requirements and improving overall system availability.

Looking forward, the technology roadmap for SiC MOSFET VFDs includes further advancements in device packaging, gate driver optimization, and system-level integration to fully capitalize on the inherent advantages of wide bandgap semiconductors. The ultimate goal is to establish a new performance standard for variable frequency drives that delivers unprecedented efficiency, power density, and reliability across diverse industrial applications.

The evolution of VFD technology has been driven by increasing demands for energy efficiency, power density, and system reliability across industrial applications. Early VFDs utilized silicon-based IGBTs and MOSFETs, which presented inherent limitations in switching frequency, thermal performance, and power handling capabilities. These constraints have become increasingly problematic as industries push toward more compact, efficient, and reliable motor drive systems.

SiC MOSFETs emerged in the commercial market during the early 2010s, offering a revolutionary alternative with significantly reduced switching losses, higher temperature operation, and improved thermal conductivity. The wide bandgap properties of silicon carbide enable these devices to operate at higher voltages, frequencies, and temperatures compared to their silicon counterparts, directly addressing the fundamental limitations of conventional VFD technology.

Market adoption of SiC technology in VFDs has accelerated in recent years, driven by decreasing component costs and increasing emphasis on energy efficiency regulations worldwide. The compound annual growth rate for SiC power devices exceeds 30% in some market segments, indicating strong momentum toward widespread implementation in variable frequency drive applications.

The primary technical objective of SiC MOSFET integration in VFDs is to achieve substantial improvements in system efficiency, with potential energy savings of 2-3% at full load and up to 10% at partial load conditions compared to conventional silicon-based solutions. This efficiency enhancement directly translates to reduced operational costs and smaller carbon footprints for industrial operations.

Secondary objectives include significant reductions in system size and weight through higher switching frequencies that enable smaller passive components. Current research indicates potential volume reductions of 30-40% for equivalent power ratings, creating opportunities for more compact industrial installations and mobile applications.

Reliability enhancement represents another critical objective, with SiC MOSFETs demonstrating superior robustness under thermal cycling and surge conditions. The technology aims to extend mean time between failures (MTBF) by 25-50% compared to silicon-based VFDs, reducing maintenance requirements and improving overall system availability.

Looking forward, the technology roadmap for SiC MOSFET VFDs includes further advancements in device packaging, gate driver optimization, and system-level integration to fully capitalize on the inherent advantages of wide bandgap semiconductors. The ultimate goal is to establish a new performance standard for variable frequency drives that delivers unprecedented efficiency, power density, and reliability across diverse industrial applications.

Market Analysis for SiC-Based Variable Frequency Drives

The global market for SiC-based Variable Frequency Drives (VFDs) is experiencing robust growth, driven by increasing demand for energy-efficient motor control systems across various industries. The market size was valued at approximately $1.2 billion in 2022 and is projected to reach $3.5 billion by 2028, representing a compound annual growth rate (CAGR) of 19.6% during the forecast period.

Industrial automation remains the largest application segment, accounting for over 40% of the total market share. This dominance is attributed to the critical need for precise motor control and energy efficiency in manufacturing processes. The HVAC sector follows closely, representing about 25% of the market, as building energy efficiency regulations become more stringent globally.

Regionally, Asia-Pacific leads the market with approximately 38% share, primarily due to rapid industrialization in China, Japan, and South Korea. North America and Europe collectively account for 45% of the market, driven by technological advancements and stringent energy efficiency standards. The Middle East and Africa region, though currently holding a smaller share, is expected to witness the fastest growth rate of 22.3% through 2028.

End-user analysis reveals that manufacturing industries constitute the largest consumer segment (35%), followed by utilities (20%) and building automation (18%). The oil and gas sector, despite representing only 12% of current demand, is showing accelerated adoption rates due to the harsh operating environments where SiC MOSFETs' temperature resilience provides significant advantages.

Price sensitivity varies significantly across market segments. While initial adoption was limited to premium applications due to the higher cost of SiC components compared to traditional silicon alternatives, the price gap has narrowed by approximately 30% over the past five years. This trend has expanded the addressable market considerably.

Customer requirements are evolving toward more compact designs, with 65% of surveyed end-users citing size reduction as a primary consideration. Additionally, 78% of customers prioritize total cost of ownership over initial acquisition costs, recognizing the long-term energy savings provided by SiC-based VFDs.

Distribution channels are also transforming, with direct sales to OEMs representing 55% of transactions, while system integrators account for 30%. The remaining 15% flows through specialized industrial electronics distributors. This distribution structure highlights the technical complexity of SiC-based VFDs and the need for specialized knowledge in system design and implementation.

Industrial automation remains the largest application segment, accounting for over 40% of the total market share. This dominance is attributed to the critical need for precise motor control and energy efficiency in manufacturing processes. The HVAC sector follows closely, representing about 25% of the market, as building energy efficiency regulations become more stringent globally.

Regionally, Asia-Pacific leads the market with approximately 38% share, primarily due to rapid industrialization in China, Japan, and South Korea. North America and Europe collectively account for 45% of the market, driven by technological advancements and stringent energy efficiency standards. The Middle East and Africa region, though currently holding a smaller share, is expected to witness the fastest growth rate of 22.3% through 2028.

End-user analysis reveals that manufacturing industries constitute the largest consumer segment (35%), followed by utilities (20%) and building automation (18%). The oil and gas sector, despite representing only 12% of current demand, is showing accelerated adoption rates due to the harsh operating environments where SiC MOSFETs' temperature resilience provides significant advantages.

Price sensitivity varies significantly across market segments. While initial adoption was limited to premium applications due to the higher cost of SiC components compared to traditional silicon alternatives, the price gap has narrowed by approximately 30% over the past five years. This trend has expanded the addressable market considerably.

Customer requirements are evolving toward more compact designs, with 65% of surveyed end-users citing size reduction as a primary consideration. Additionally, 78% of customers prioritize total cost of ownership over initial acquisition costs, recognizing the long-term energy savings provided by SiC-based VFDs.

Distribution channels are also transforming, with direct sales to OEMs representing 55% of transactions, while system integrators account for 30%. The remaining 15% flows through specialized industrial electronics distributors. This distribution structure highlights the technical complexity of SiC-based VFDs and the need for specialized knowledge in system design and implementation.

Current Challenges in SiC MOSFET Implementation for VFDs

Despite the promising advantages of Silicon Carbide (SiC) MOSFETs in Variable Frequency Drives (VFDs), several significant challenges impede their widespread implementation. The primary obstacle remains the high cost of SiC devices compared to traditional silicon-based alternatives. Current market analysis indicates that SiC MOSFETs can cost 3-5 times more than their silicon counterparts, creating a substantial barrier to adoption, particularly for cost-sensitive industrial applications where immediate ROI is prioritized over long-term efficiency gains.

Manufacturing complexities further exacerbate implementation challenges. The production of high-quality SiC wafers involves sophisticated processes including crystal growth at extremely high temperatures (over 2000°C) and precise doping control. These manufacturing intricacies result in lower yields and contribute to elevated costs, while also creating supply chain vulnerabilities that can affect production schedules for VFD manufacturers.

Technical integration issues present another significant hurdle. SiC MOSFETs operate at higher switching frequencies and exhibit faster switching transients than silicon IGBTs, necessitating careful gate driver design to prevent parasitic oscillations and electromagnetic interference (EMI). The higher dv/dt rates (typically 10-50 V/ns compared to 2-5 V/ns for silicon devices) can cause voltage spikes and insulation stress in motor windings, potentially reducing motor lifespan if not properly addressed.

Thermal management represents a critical challenge in SiC MOSFET implementation. While SiC devices can operate at higher temperatures (up to 200°C junction temperature versus 150°C for silicon), they require specialized packaging solutions and thermal interface materials to effectively dissipate heat. The higher power density achievable with SiC MOSFETs demands more sophisticated cooling strategies, adding complexity to VFD design.

Reliability concerns persist within the industry, particularly regarding gate oxide stability and threshold voltage drift under long-term operation. SiC MOSFETs have thinner gate oxides than silicon devices, making them potentially more susceptible to dielectric breakdown under high-stress conditions. Limited long-term field data on SiC MOSFET performance in industrial VFD applications creates uncertainty about device lifetime in real-world environments.

System-level design challenges also emerge when implementing SiC MOSFETs in VFDs. Engineers must redesign control algorithms and protection schemes to accommodate the faster switching characteristics of SiC devices. Additionally, the higher operating frequencies enabled by SiC MOSFETs require careful consideration of PCB layout to minimize parasitic inductances and capacitances that could trigger oscillations or voltage overshoots.

Standardization issues further complicate adoption, as SiC MOSFET specifications and testing protocols are still evolving. The lack of universally accepted reliability qualification standards specific to SiC power devices creates uncertainty for VFD manufacturers when selecting components and designing for specific lifetime requirements.

Manufacturing complexities further exacerbate implementation challenges. The production of high-quality SiC wafers involves sophisticated processes including crystal growth at extremely high temperatures (over 2000°C) and precise doping control. These manufacturing intricacies result in lower yields and contribute to elevated costs, while also creating supply chain vulnerabilities that can affect production schedules for VFD manufacturers.

Technical integration issues present another significant hurdle. SiC MOSFETs operate at higher switching frequencies and exhibit faster switching transients than silicon IGBTs, necessitating careful gate driver design to prevent parasitic oscillations and electromagnetic interference (EMI). The higher dv/dt rates (typically 10-50 V/ns compared to 2-5 V/ns for silicon devices) can cause voltage spikes and insulation stress in motor windings, potentially reducing motor lifespan if not properly addressed.

Thermal management represents a critical challenge in SiC MOSFET implementation. While SiC devices can operate at higher temperatures (up to 200°C junction temperature versus 150°C for silicon), they require specialized packaging solutions and thermal interface materials to effectively dissipate heat. The higher power density achievable with SiC MOSFETs demands more sophisticated cooling strategies, adding complexity to VFD design.

Reliability concerns persist within the industry, particularly regarding gate oxide stability and threshold voltage drift under long-term operation. SiC MOSFETs have thinner gate oxides than silicon devices, making them potentially more susceptible to dielectric breakdown under high-stress conditions. Limited long-term field data on SiC MOSFET performance in industrial VFD applications creates uncertainty about device lifetime in real-world environments.

System-level design challenges also emerge when implementing SiC MOSFETs in VFDs. Engineers must redesign control algorithms and protection schemes to accommodate the faster switching characteristics of SiC devices. Additionally, the higher operating frequencies enabled by SiC MOSFETs require careful consideration of PCB layout to minimize parasitic inductances and capacitances that could trigger oscillations or voltage overshoots.

Standardization issues further complicate adoption, as SiC MOSFET specifications and testing protocols are still evolving. The lack of universally accepted reliability qualification standards specific to SiC power devices creates uncertainty for VFD manufacturers when selecting components and designing for specific lifetime requirements.

Current SiC MOSFET Integration Solutions for VFDs

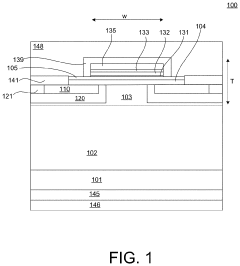

01 SiC MOSFET device structure optimization

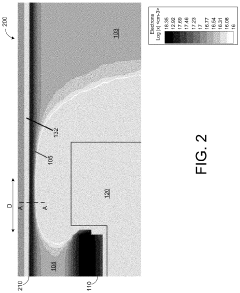

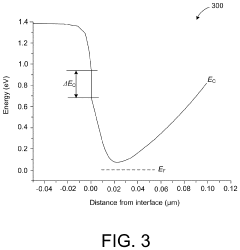

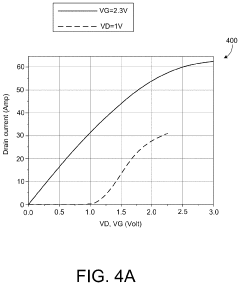

Silicon Carbide (SiC) MOSFET efficiency can be improved through structural optimizations of the device. These optimizations include refining the gate structure, optimizing the channel design, and enhancing the drift region. By modifying these structural elements, key electrical parameters such as on-resistance, switching speed, and thermal performance can be significantly improved, leading to higher overall efficiency in power conversion applications.- Device structure optimization for SiC MOSFETs: Optimizing the structure of SiC MOSFETs can significantly improve their efficiency. This includes designing better gate structures, optimizing channel regions, and improving the interface between SiC and gate oxide. Structural improvements can reduce on-resistance, minimize parasitic capacitances, and enhance carrier mobility, all contributing to higher efficiency and performance in power conversion applications.

- Gate drive optimization techniques: Advanced gate drive techniques can enhance the switching performance and efficiency of SiC MOSFETs. These include optimized gate drive circuits, intelligent gate drivers with adaptive control, and resonant gate drive methods. Proper gate drive design can reduce switching losses, mitigate voltage overshoots, and enable faster switching speeds, ultimately improving the overall efficiency of power conversion systems using SiC MOSFETs.

- Thermal management solutions: Effective thermal management is crucial for maintaining high efficiency in SiC MOSFETs. Advanced cooling techniques, improved packaging designs, and thermal interface materials help dissipate heat more efficiently. Better thermal management prevents performance degradation at high temperatures, extends device lifetime, and allows SiC MOSFETs to operate at higher power densities while maintaining optimal efficiency levels.

- Power converter topology optimization: Optimizing power converter topologies specifically for SiC MOSFETs can maximize their efficiency benefits. This includes developing novel circuit configurations, implementing soft-switching techniques, and designing resonant converters tailored to SiC characteristics. These specialized topologies leverage the fast switching capabilities and low losses of SiC devices while mitigating their challenges, resulting in higher overall system efficiency.

- Material and manufacturing process improvements: Advancements in SiC material quality and manufacturing processes directly impact MOSFET efficiency. This includes improved substrate growth techniques, enhanced epitaxial layer formation, better channel mobility, and reduced defect density. Manufacturing innovations like optimized implantation processes and annealing techniques lead to more consistent device characteristics and higher efficiency through reduced conduction and switching losses.

02 Gate driver and control techniques

Advanced gate driver circuits and control techniques specifically designed for SiC MOSFETs can substantially improve efficiency. These techniques include optimized gate voltage levels, precise timing control, and specialized driving waveforms that account for the unique switching characteristics of SiC devices. Proper gate control reduces switching losses and enables the full utilization of SiC MOSFET's high-speed switching capabilities.Expand Specific Solutions03 Thermal management solutions

Effective thermal management is crucial for maintaining SiC MOSFET efficiency at high power levels. Advanced cooling techniques, improved packaging designs, and thermally optimized layouts help dissipate heat more efficiently. These solutions prevent performance degradation due to elevated temperatures and allow SiC MOSFETs to operate at higher power densities while maintaining high efficiency levels.Expand Specific Solutions04 Power converter topology optimization

Specialized power converter topologies designed to leverage the unique characteristics of SiC MOSFETs can significantly enhance system efficiency. These topologies include resonant and soft-switching circuits that minimize switching losses, as well as multilevel converter designs that reduce stress on individual devices. By matching the converter topology to SiC MOSFET capabilities, overall system efficiency can be maximized across various operating conditions.Expand Specific Solutions05 SiC MOSFET manufacturing process improvements

Advancements in manufacturing processes for SiC MOSFETs directly impact device efficiency. Improved substrate quality, enhanced epitaxial growth techniques, and refined doping profiles lead to devices with better electrical characteristics. Additionally, innovations in edge termination structures and surface passivation methods reduce parasitic effects and leakage currents, resulting in more efficient and reliable SiC MOSFETs for power applications.Expand Specific Solutions

Key Industry Players in SiC MOSFET and VFD Markets

The SiC MOSFET-based variable frequency drive market is in a growth phase, with increasing adoption driven by efficiency demands across industrial and automotive sectors. The market is projected to reach significant scale as SiC technology matures from early commercial deployment to mainstream adoption. Leading academic institutions like University of Electronic Science & Technology of China, Xi'an Jiaotong University, and Beihang University are advancing fundamental research, while companies including Global Power Technology, Yangzhou Yangjie Electronic Technology, and Hunan Guoxin Semiconductor are commercializing SiC solutions. State Grid entities and NXP Semiconductors represent established players integrating these technologies into power systems, creating a competitive landscape where collaboration between research institutions and industry is accelerating technology maturation and market penetration.

Hunan Guoxin Semiconductor Technology Co., Ltd.

Technical Solution: Hunan Guoxin has developed specialized SiC MOSFETs for VFD applications featuring a unique trench structure that reduces on-resistance while maintaining high breakdown voltage. Their devices employ a proprietary termination structure that enhances reliability under high dv/dt conditions commonly encountered in VFD applications. The company's SiC modules incorporate advanced sintered silver die-attach technology that improves thermal cycling capability by over 300% compared to traditional solder methods, critical for the thermal cycling demands of industrial VFDs. Their solution includes integrated temperature and current sensing capabilities with direct digital interfaces to motor control MCUs, enabling more precise protection and efficiency optimization. Hunan Guoxin's latest generation devices feature optimized gate oxide structures with enhanced reliability under high-temperature operation, maintaining stable threshold voltage characteristics even after extended operation at junction temperatures exceeding 175°C.

Strengths: Excellent reliability under harsh industrial conditions; competitive pricing compared to international competitors while maintaining performance specifications. Weaknesses: More limited ecosystem support compared to larger international semiconductor companies; less extensive application engineering resources for customer design support.

Global Power Technology (Beijing) Co. Ltd.

Technical Solution: Global Power Technology has developed a comprehensive SiC MOSFET solution specifically optimized for high-efficiency VFD applications. Their approach features a unique split-gate design that enables precise control of switching transients, reducing EMI while maintaining fast switching speeds. The company's modules incorporate advanced thermal interface materials that reduce junction-to-case thermal resistance by approximately 25% compared to conventional packaging. Their VFD solution implements a hybrid switching strategy that dynamically adjusts switching frequency based on motor operating conditions, maximizing efficiency across the entire speed range. Global Power Technology's gate driver solution features integrated isolation with common-mode transient immunity exceeding 100 kV/μs, essential for reliable operation in industrial VFD environments with high dv/dt. Their latest generation devices achieve specific on-resistance below 2.3 mΩ·cm² while maintaining short-circuit withstand capability exceeding 4μs at rated voltage.

Strengths: Excellent system-level optimization for VFD applications; strong focus on EMI performance while maintaining high efficiency. Weaknesses: More limited production capacity compared to larger semiconductor manufacturers; narrower product portfolio focusing primarily on medium-voltage applications.

Critical Patents and Innovations in SiC MOSFET Technology

Silicon carbide field-effect transistors

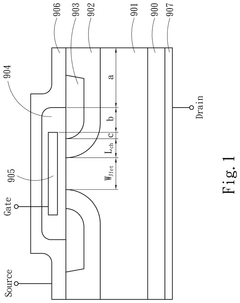

PatentActiveUS20220013661A1

Innovation

- A silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) design incorporating a substrate, drift region, spreading layer, body region, and source region with a gate structure that includes a gate oxide layer, aluminum nitride, and p-type gallium nitride layers, achieving low on-state specific resistance and high threshold voltage.

Silicon carbide semiconductor device

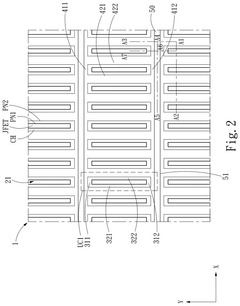

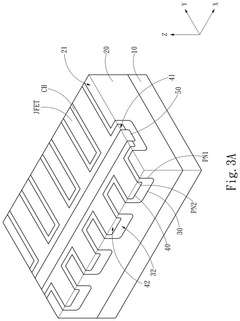

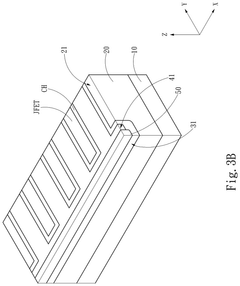

PatentPendingUS20240347599A1

Innovation

- A silicon carbide semiconductor device with a specific doped region configuration, including first, second, and third doped regions, and a gate insulator and source electrode structure, which increases channel width density without increasing contact resistance, allowing for a smaller cell pitch without compromising breakdown voltage.

Thermal Management Strategies for SiC MOSFET Applications

Effective thermal management is critical for maximizing the performance and reliability of SiC MOSFETs in variable frequency drive applications. The superior thermal conductivity of silicon carbide (approximately 3-4 times that of silicon) provides inherent advantages, but also presents unique challenges due to the higher power densities and switching frequencies these devices enable.

Traditional cooling methods such as forced air convection often prove insufficient for SiC MOSFET applications in variable frequency drives. Advanced liquid cooling solutions, including direct liquid cooling and cold plates with optimized microchannel designs, have demonstrated superior thermal performance by reducing junction-to-ambient thermal resistance by up to 40% compared to conventional approaches.

Phase-change materials (PCMs) represent an emerging thermal management strategy for SiC MOSFETs. These materials absorb heat during phase transition, effectively dampening temperature spikes during transient operations. Recent studies indicate that PCM-based solutions can reduce temperature fluctuations by 15-20% in high-frequency switching applications, extending device lifetime and improving reliability.

Advanced thermal interface materials (TIMs) with enhanced thermal conductivity are essential components in SiC MOSFET cooling systems. Metal-based TIMs and graphene-enhanced compounds have shown promising results, reducing thermal resistance at critical interfaces by up to 30% compared to conventional silicone-based materials.

Integrated power modules with optimized thermal designs specifically for SiC MOSFETs represent another significant advancement. These modules incorporate direct bonded copper (DBC) substrates and advanced die-attach materials like silver sintering, which offers 3-5 times better thermal conductivity than traditional solder materials while providing superior reliability under thermal cycling conditions.

Active cooling techniques, including thermoelectric coolers and vapor compression refrigeration systems, are being explored for extreme performance requirements. Though more complex and energy-intensive, these approaches can maintain junction temperatures within optimal ranges even under the most demanding operating conditions, potentially increasing power density by up to 40%.

Computational fluid dynamics (CFD) modeling and finite element analysis (FEA) have become indispensable tools for thermal management design optimization. These simulation techniques enable engineers to predict hotspots, optimize heat sink geometries, and evaluate cooling strategies before physical prototyping, reducing development cycles by up to 60% while improving thermal performance.

The integration of temperature sensors and adaptive cooling control systems represents the frontier of thermal management for SiC MOSFETs in variable frequency drives. These systems dynamically adjust cooling parameters based on real-time temperature monitoring, optimizing energy efficiency while ensuring reliable operation across varying load conditions.

Traditional cooling methods such as forced air convection often prove insufficient for SiC MOSFET applications in variable frequency drives. Advanced liquid cooling solutions, including direct liquid cooling and cold plates with optimized microchannel designs, have demonstrated superior thermal performance by reducing junction-to-ambient thermal resistance by up to 40% compared to conventional approaches.

Phase-change materials (PCMs) represent an emerging thermal management strategy for SiC MOSFETs. These materials absorb heat during phase transition, effectively dampening temperature spikes during transient operations. Recent studies indicate that PCM-based solutions can reduce temperature fluctuations by 15-20% in high-frequency switching applications, extending device lifetime and improving reliability.

Advanced thermal interface materials (TIMs) with enhanced thermal conductivity are essential components in SiC MOSFET cooling systems. Metal-based TIMs and graphene-enhanced compounds have shown promising results, reducing thermal resistance at critical interfaces by up to 30% compared to conventional silicone-based materials.

Integrated power modules with optimized thermal designs specifically for SiC MOSFETs represent another significant advancement. These modules incorporate direct bonded copper (DBC) substrates and advanced die-attach materials like silver sintering, which offers 3-5 times better thermal conductivity than traditional solder materials while providing superior reliability under thermal cycling conditions.

Active cooling techniques, including thermoelectric coolers and vapor compression refrigeration systems, are being explored for extreme performance requirements. Though more complex and energy-intensive, these approaches can maintain junction temperatures within optimal ranges even under the most demanding operating conditions, potentially increasing power density by up to 40%.

Computational fluid dynamics (CFD) modeling and finite element analysis (FEA) have become indispensable tools for thermal management design optimization. These simulation techniques enable engineers to predict hotspots, optimize heat sink geometries, and evaluate cooling strategies before physical prototyping, reducing development cycles by up to 60% while improving thermal performance.

The integration of temperature sensors and adaptive cooling control systems represents the frontier of thermal management for SiC MOSFETs in variable frequency drives. These systems dynamically adjust cooling parameters based on real-time temperature monitoring, optimizing energy efficiency while ensuring reliable operation across varying load conditions.

Cost-Benefit Analysis of SiC Implementation in VFD Systems

The implementation of Silicon Carbide (SiC) MOSFETs in Variable Frequency Drive (VFD) systems represents a significant investment decision that requires thorough economic analysis. Initial acquisition costs for SiC-based VFDs typically exceed those of traditional silicon-based systems by 30-40%, presenting a substantial barrier to adoption despite the technical advantages.

When evaluating the total cost of ownership (TCO), energy savings emerge as the primary financial benefit. SiC MOSFETs demonstrate 30-50% lower switching losses compared to silicon IGBTs, translating to overall system efficiency improvements of 2-3%. For industrial applications operating continuously, these efficiency gains can yield energy cost reductions of $5,000-$15,000 annually for medium-sized drives (50-200kW), enabling ROI achievement within 2-4 years.

Maintenance costs also factor significantly into the cost-benefit equation. SiC-based VFDs typically operate at lower temperatures, reducing thermal stress on components and extending system lifespan by an estimated 20-30%. This translates to fewer replacement parts and maintenance interventions, with some manufacturers reporting maintenance cost reductions of 15-25% over a five-year operational period.

Space utilization presents another economic advantage. The higher power density of SiC-based systems allows for approximately 30% smaller footprints compared to silicon equivalents. In industrial settings where space carries premium value, this compact design can yield indirect cost benefits of $1,000-$3,000 per square meter of freed floor space.

Performance improvements also deliver quantifiable economic benefits. SiC-based VFDs offer superior dynamic response, enabling more precise motor control that can reduce mechanical wear on driven equipment. Manufacturing operations report 5-10% reductions in mechanical maintenance costs for end equipment when utilizing SiC-based motor drives.

Environmental considerations increasingly influence cost-benefit analyses through carbon taxation and incentive programs. The reduced energy consumption of SiC-based systems can decrease carbon emissions by 20-30 tons annually for medium-sized industrial applications, potentially qualifying for carbon credits or avoiding carbon taxes valued at $25-$50 per ton in various jurisdictions.

Market differentiation represents a less quantifiable but strategically significant benefit. Manufacturers implementing SiC technology in their VFD offerings can command premium pricing of 15-25% above market averages, with early adopters reporting sales growth 1.5-2 times industry averages in high-performance application segments.

When evaluating the total cost of ownership (TCO), energy savings emerge as the primary financial benefit. SiC MOSFETs demonstrate 30-50% lower switching losses compared to silicon IGBTs, translating to overall system efficiency improvements of 2-3%. For industrial applications operating continuously, these efficiency gains can yield energy cost reductions of $5,000-$15,000 annually for medium-sized drives (50-200kW), enabling ROI achievement within 2-4 years.

Maintenance costs also factor significantly into the cost-benefit equation. SiC-based VFDs typically operate at lower temperatures, reducing thermal stress on components and extending system lifespan by an estimated 20-30%. This translates to fewer replacement parts and maintenance interventions, with some manufacturers reporting maintenance cost reductions of 15-25% over a five-year operational period.

Space utilization presents another economic advantage. The higher power density of SiC-based systems allows for approximately 30% smaller footprints compared to silicon equivalents. In industrial settings where space carries premium value, this compact design can yield indirect cost benefits of $1,000-$3,000 per square meter of freed floor space.

Performance improvements also deliver quantifiable economic benefits. SiC-based VFDs offer superior dynamic response, enabling more precise motor control that can reduce mechanical wear on driven equipment. Manufacturing operations report 5-10% reductions in mechanical maintenance costs for end equipment when utilizing SiC-based motor drives.

Environmental considerations increasingly influence cost-benefit analyses through carbon taxation and incentive programs. The reduced energy consumption of SiC-based systems can decrease carbon emissions by 20-30 tons annually for medium-sized industrial applications, potentially qualifying for carbon credits or avoiding carbon taxes valued at $25-$50 per ton in various jurisdictions.

Market differentiation represents a less quantifiable but strategically significant benefit. Manufacturers implementing SiC technology in their VFD offerings can command premium pricing of 15-25% above market averages, with early adopters reporting sales growth 1.5-2 times industry averages in high-performance application segments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!