SiC MOSFET Applications In Harsh Industrial Environments

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Performance Targets

Silicon Carbide (SiC) MOSFET technology has undergone significant evolution since its initial development in the early 1990s. The first commercial SiC MOSFETs emerged around 2001 with relatively high on-resistance and limited performance capabilities. These early devices operated at voltages of 600-1200V with current ratings below 10A, exhibiting switching frequencies under 50kHz and junction temperature capabilities limited to approximately 150°C.

By 2010, second-generation devices demonstrated substantial improvements, with on-resistance reduced by 50% and current ratings reaching 20-30A. The temperature handling capability increased to around 175°C, while switching frequencies improved to 100kHz range, marking a significant advancement for industrial applications requiring operation in elevated temperature environments.

The period between 2015-2020 saw third-generation SiC MOSFETs with dramatically enhanced performance metrics. On-resistance decreased to less than 20 mΩ for 1200V devices, current ratings expanded to 50-100A, and junction temperature capabilities reached 200°C. These improvements enabled SiC MOSFETs to operate reliably in harsh industrial environments characterized by extreme temperatures, high humidity, and significant electromagnetic interference.

Current state-of-the-art SiC MOSFETs (2020-2023) feature on-resistance below 10 mΩ for 1200V devices, current ratings exceeding 100A, and junction temperature capabilities approaching 225°C. Switching frequencies have increased to 200-300kHz, enabling more compact power conversion systems with higher efficiency.

Looking forward, the performance targets for next-generation SiC MOSFETs focus on several critical parameters. Junction temperature capabilities are expected to reach 250-300°C by 2025-2027, enabling operation in extremely harsh industrial environments without additional cooling infrastructure. On-resistance is projected to decrease further to 5 mΩ or lower for 1200V devices, while current ratings may exceed 200A for standard packages.

Reliability targets include radiation hardness improvements to withstand 300 krad or higher, critical for applications in nuclear facilities and space environments. Humidity resistance is expected to improve with enhanced packaging technologies, targeting 85% RH at 85°C for 1000+ hours without performance degradation. Manufacturers are also working toward extending operational lifetimes to 20+ years under harsh conditions, compared to the current 10-15 year expectations.

These evolutionary improvements and performance targets are driving SiC MOSFET adoption in harsh industrial applications including high-temperature motor drives, power conversion systems in oil and gas exploration, electric vehicle powertrains operating in extreme climates, and grid infrastructure exposed to severe environmental conditions.

By 2010, second-generation devices demonstrated substantial improvements, with on-resistance reduced by 50% and current ratings reaching 20-30A. The temperature handling capability increased to around 175°C, while switching frequencies improved to 100kHz range, marking a significant advancement for industrial applications requiring operation in elevated temperature environments.

The period between 2015-2020 saw third-generation SiC MOSFETs with dramatically enhanced performance metrics. On-resistance decreased to less than 20 mΩ for 1200V devices, current ratings expanded to 50-100A, and junction temperature capabilities reached 200°C. These improvements enabled SiC MOSFETs to operate reliably in harsh industrial environments characterized by extreme temperatures, high humidity, and significant electromagnetic interference.

Current state-of-the-art SiC MOSFETs (2020-2023) feature on-resistance below 10 mΩ for 1200V devices, current ratings exceeding 100A, and junction temperature capabilities approaching 225°C. Switching frequencies have increased to 200-300kHz, enabling more compact power conversion systems with higher efficiency.

Looking forward, the performance targets for next-generation SiC MOSFETs focus on several critical parameters. Junction temperature capabilities are expected to reach 250-300°C by 2025-2027, enabling operation in extremely harsh industrial environments without additional cooling infrastructure. On-resistance is projected to decrease further to 5 mΩ or lower for 1200V devices, while current ratings may exceed 200A for standard packages.

Reliability targets include radiation hardness improvements to withstand 300 krad or higher, critical for applications in nuclear facilities and space environments. Humidity resistance is expected to improve with enhanced packaging technologies, targeting 85% RH at 85°C for 1000+ hours without performance degradation. Manufacturers are also working toward extending operational lifetimes to 20+ years under harsh conditions, compared to the current 10-15 year expectations.

These evolutionary improvements and performance targets are driving SiC MOSFET adoption in harsh industrial applications including high-temperature motor drives, power conversion systems in oil and gas exploration, electric vehicle powertrains operating in extreme climates, and grid infrastructure exposed to severe environmental conditions.

Market Demand for Harsh Environment Power Electronics

The global market for harsh environment power electronics is experiencing robust growth, driven primarily by the increasing demand for reliable and efficient power management solutions in extreme operating conditions. Industries such as aerospace, automotive, oil and gas, mining, and heavy manufacturing require power electronic systems that can withstand high temperatures, intense vibration, corrosive environments, and radiation exposure. The market value for harsh environment electronics reached approximately $2.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028.

Silicon Carbide (SiC) MOSFET technology has emerged as a critical solution in this market segment due to its superior performance characteristics compared to traditional silicon-based devices. The inherent properties of SiC, including wider bandgap, higher thermal conductivity, and greater electric field strength, make it particularly suitable for harsh industrial applications where conventional silicon devices fail to deliver optimal performance.

The automotive sector represents one of the largest market segments for harsh environment power electronics, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The powertrain systems in these vehicles operate under high-temperature conditions and require power electronic components that can maintain efficiency and reliability. Market research indicates that the automotive segment accounts for approximately 35% of the total harsh environment power electronics market.

Industrial automation and control systems constitute another significant market segment, valued at approximately $580 million in 2022. Manufacturing facilities with extreme temperature variations, high electromagnetic interference, and continuous operation requirements are increasingly adopting SiC-based power solutions to enhance system reliability and reduce downtime costs.

The renewable energy sector presents a rapidly growing market opportunity for harsh environment power electronics. Solar inverters and wind power converters operate in challenging outdoor conditions and must maintain high efficiency over decades of service life. This segment is expected to grow at a CAGR of 9.2% through 2028, outpacing the overall market growth rate.

Regional analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization in countries like China and India, coupled with increasing investments in renewable energy infrastructure and electric vehicle manufacturing.

Customer requirements in this market emphasize long-term reliability, extended temperature range operation (typically -55°C to +225°C), resistance to mechanical shock and vibration, and reduced size and weight. These demands are driving innovation in packaging technologies, thermal management solutions, and system integration approaches for SiC MOSFET applications.

Silicon Carbide (SiC) MOSFET technology has emerged as a critical solution in this market segment due to its superior performance characteristics compared to traditional silicon-based devices. The inherent properties of SiC, including wider bandgap, higher thermal conductivity, and greater electric field strength, make it particularly suitable for harsh industrial applications where conventional silicon devices fail to deliver optimal performance.

The automotive sector represents one of the largest market segments for harsh environment power electronics, particularly with the rapid expansion of electric vehicles (EVs) and hybrid electric vehicles (HEVs). The powertrain systems in these vehicles operate under high-temperature conditions and require power electronic components that can maintain efficiency and reliability. Market research indicates that the automotive segment accounts for approximately 35% of the total harsh environment power electronics market.

Industrial automation and control systems constitute another significant market segment, valued at approximately $580 million in 2022. Manufacturing facilities with extreme temperature variations, high electromagnetic interference, and continuous operation requirements are increasingly adopting SiC-based power solutions to enhance system reliability and reduce downtime costs.

The renewable energy sector presents a rapidly growing market opportunity for harsh environment power electronics. Solar inverters and wind power converters operate in challenging outdoor conditions and must maintain high efficiency over decades of service life. This segment is expected to grow at a CAGR of 9.2% through 2028, outpacing the overall market growth rate.

Regional analysis reveals that North America currently holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the fastest growth due to rapid industrialization in countries like China and India, coupled with increasing investments in renewable energy infrastructure and electric vehicle manufacturing.

Customer requirements in this market emphasize long-term reliability, extended temperature range operation (typically -55°C to +225°C), resistance to mechanical shock and vibration, and reduced size and weight. These demands are driving innovation in packaging technologies, thermal management solutions, and system integration approaches for SiC MOSFET applications.

SiC MOSFET Technology Status and Barriers

Silicon Carbide (SiC) MOSFET technology has reached significant maturity in recent years, with commercial devices now widely available from multiple manufacturers. The current state-of-the-art SiC MOSFETs offer blocking voltages ranging from 650V to 1700V, with some experimental devices reaching up to 10kV. These devices demonstrate superior performance compared to silicon counterparts, with on-resistance values approximately 10 times lower and switching speeds 3-5 times faster at equivalent voltage ratings.

Despite these advancements, SiC MOSFET technology still faces several critical barriers, particularly for harsh industrial environment applications. The primary challenge remains the gate oxide reliability under extreme temperature conditions. While SiC MOSFETs can theoretically operate at temperatures exceeding 200°C, the gate oxide degradation accelerates significantly above 175°C, leading to threshold voltage instability and increased leakage currents that compromise long-term reliability.

Manufacturing consistency presents another significant barrier. Current fabrication processes still struggle with wafer defect densities approximately 10-100 times higher than mature silicon processes. These defects, including micropipes, stacking faults, and basal plane dislocations, directly impact device yield and reliability, particularly under the thermal cycling common in harsh industrial environments.

The interface quality between SiC and SiO2 remains problematic, with interface trap densities typically one order of magnitude higher than in silicon devices. This results in reduced channel mobility and increased on-resistance, particularly at lower temperatures, creating a performance bottleneck that limits efficiency gains in industrial applications.

Cost factors continue to impede widespread adoption, with SiC MOSFETs typically commanding a 2-3x price premium over silicon alternatives. While this gap has narrowed from the 5-10x premium seen five years ago, it still presents a significant barrier for cost-sensitive industrial applications where immediate performance benefits may not justify the increased component cost.

Packaging technology for harsh environments represents another critical challenge. Standard plastic packages are inadequate for the extreme temperature, vibration, and corrosive conditions found in many industrial settings. Advanced packaging solutions using high-temperature die-attach materials, specialized wire bonding, and hermetic sealing add significant cost and complexity to SiC MOSFET implementation.

Globally, SiC MOSFET technology development shows geographic concentration, with major advancements coming from the United States, Japan, and increasingly from Europe and China. This distribution has implications for supply chain resilience and technology access for industrial applications worldwide.

Despite these advancements, SiC MOSFET technology still faces several critical barriers, particularly for harsh industrial environment applications. The primary challenge remains the gate oxide reliability under extreme temperature conditions. While SiC MOSFETs can theoretically operate at temperatures exceeding 200°C, the gate oxide degradation accelerates significantly above 175°C, leading to threshold voltage instability and increased leakage currents that compromise long-term reliability.

Manufacturing consistency presents another significant barrier. Current fabrication processes still struggle with wafer defect densities approximately 10-100 times higher than mature silicon processes. These defects, including micropipes, stacking faults, and basal plane dislocations, directly impact device yield and reliability, particularly under the thermal cycling common in harsh industrial environments.

The interface quality between SiC and SiO2 remains problematic, with interface trap densities typically one order of magnitude higher than in silicon devices. This results in reduced channel mobility and increased on-resistance, particularly at lower temperatures, creating a performance bottleneck that limits efficiency gains in industrial applications.

Cost factors continue to impede widespread adoption, with SiC MOSFETs typically commanding a 2-3x price premium over silicon alternatives. While this gap has narrowed from the 5-10x premium seen five years ago, it still presents a significant barrier for cost-sensitive industrial applications where immediate performance benefits may not justify the increased component cost.

Packaging technology for harsh environments represents another critical challenge. Standard plastic packages are inadequate for the extreme temperature, vibration, and corrosive conditions found in many industrial settings. Advanced packaging solutions using high-temperature die-attach materials, specialized wire bonding, and hermetic sealing add significant cost and complexity to SiC MOSFET implementation.

Globally, SiC MOSFET technology development shows geographic concentration, with major advancements coming from the United States, Japan, and increasingly from Europe and China. This distribution has implications for supply chain resilience and technology access for industrial applications worldwide.

Current SiC Solutions for Extreme Operating Conditions

01 SiC MOSFET structure and fabrication

Silicon Carbide (SiC) MOSFETs have unique structural features and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel formations, and doping profiles that contribute to improved electrical properties. Advanced fabrication techniques are employed to create high-quality SiC/oxide interfaces, which are critical for reducing interface trap densities and enhancing carrier mobility in the channel region.- SiC MOSFET Structure and Fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel formations, and doping profiles that contribute to their high-voltage handling capabilities. The fabrication process often involves specific thermal oxidation techniques to create high-quality gate oxides on SiC substrates, which is critical for device reliability and performance.

- Power Conversion Applications: SiC MOSFETs are extensively used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system efficiency improvements and size reductions.

- Gate Drive and Control Techniques: Specialized gate drive circuits and control techniques are essential for optimizing SiC MOSFET performance. These include advanced gate driver designs that address the unique switching characteristics of SiC devices, such as faster switching speeds and higher gate threshold voltages. Control strategies often incorporate techniques to mitigate switching transients, reduce electromagnetic interference, and protect against overcurrent and overvoltage conditions, ensuring reliable operation in demanding applications.

- Thermal Management and Reliability: Effective thermal management is crucial for SiC MOSFET reliability and performance. Various packaging technologies and cooling solutions are employed to handle the high power densities and operating temperatures of these devices. Reliability enhancement techniques include specialized die-attach materials, encapsulation methods, and package designs that minimize thermal resistance and mechanical stress. These approaches extend device lifetime and maintain performance under extreme operating conditions.

- Integration and System Design: SiC MOSFETs are increasingly integrated into complex power electronic systems and modules. This integration involves specialized circuit topologies, protection schemes, and parasitic management techniques tailored to the unique characteristics of SiC devices. System-level design considerations include optimized PCB layouts, bus structures, and passive component selection to fully leverage the high-frequency operation capabilities of SiC MOSFETs while maintaining system stability and reliability.

02 SiC MOSFET power applications

SiC MOSFETs are widely used in power electronic applications due to their superior performance at high voltages and temperatures. These devices enable more efficient power conversion systems, including inverters, converters, and motor drives. The implementation of SiC MOSFETs in power applications results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to more compact and efficient power electronic systems.Expand Specific Solutions03 SiC MOSFET gate drive technology

Gate drive circuits for SiC MOSFETs require specialized designs to fully leverage the high-speed switching capabilities while managing parasitic effects. These circuits incorporate advanced features such as optimized gate resistors, voltage clamping mechanisms, and isolation techniques. The gate drive technology addresses challenges related to high dv/dt and di/dt rates, gate oscillations, and electromagnetic interference, ensuring reliable operation of SiC MOSFETs in various applications.Expand Specific Solutions04 SiC MOSFET reliability and ruggedness

Reliability and ruggedness are critical aspects of SiC MOSFETs that determine their long-term performance and ability to withstand harsh operating conditions. Various design and manufacturing techniques are employed to enhance the device's resistance to phenomena such as short circuit events, avalanche breakdown, and gate oxide degradation. Testing methodologies and lifetime prediction models are developed to evaluate and improve the reliability of SiC MOSFETs under different stress conditions.Expand Specific Solutions05 SiC MOSFET packaging and thermal management

Advanced packaging technologies and thermal management solutions are essential for maximizing the performance of SiC MOSFETs. These include innovative die-attach materials, interconnection methods, and encapsulation techniques that minimize parasitic inductances and thermal resistances. Effective thermal management strategies, such as optimized heat sink designs and cooling methods, are implemented to handle the high power densities and ensure reliable operation at elevated temperatures.Expand Specific Solutions

Leading SiC MOSFET Manufacturers and Competitors

The SiC MOSFET market for harsh industrial environments is in a growth phase, with increasing adoption driven by demands for higher efficiency and reliability in extreme conditions. The market is projected to expand significantly as industries transition from silicon-based to wide bandgap semiconductor technologies. Leading players include established power semiconductor manufacturers like Infineon Technologies, ROHM, and Mitsubishi Electric, who have mature SiC MOSFET product lines. Emerging competitors such as BASiC Semiconductor and Fuji Electric are rapidly advancing their technological capabilities. Chinese entities, including the Institute of Microelectronics of CAS and Yangjie Electronic Technology, are investing heavily in R&D to close the technology gap with international leaders, particularly focusing on high-temperature, high-voltage applications for industrial power systems.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered SiC MOSFET technology specifically engineered for harsh industrial environments. Their 2nd generation SiC power modules feature an optimized chip design with improved gate oxide reliability and reduced on-resistance, enabling operation at junction temperatures up to 175°C[1]. Mitsubishi's unique package design incorporates direct liquid cooling capabilities and high-reliability solder materials that withstand extreme thermal cycling conditions found in industrial settings. Their modules employ advanced silicone gel encapsulation with enhanced resistance to humidity and corrosive environments[2]. For industrial motor drives and power conversion systems, Mitsubishi has developed specialized gate driver solutions with integrated protection features including short-circuit detection with response times under 2μs and robust noise immunity for factory environments. Their SiC devices undergo rigorous qualification testing including HTRB (High Temperature Reverse Bias) testing at elevated temperatures and H3TRB (High Humidity High Temperature Reverse Bias) testing to ensure long-term reliability in harsh conditions[3].

Strengths: Excellent thermal cycling capability with advanced packaging technology; comprehensive protection features integrated into driver solutions; proven reliability in high-humidity industrial environments. Weaknesses: Higher cost structure compared to some competitors; more limited product portfolio in certain voltage ranges; requires specialized cooling solutions for maximum performance in extreme environments.

Fuji Electric Co., Ltd.

Technical Solution: Fuji Electric has developed specialized SiC MOSFET solutions targeting harsh industrial environments. Their All-SiC modules feature direct copper bonding (DCB) substrate technology with optimized thermal cycling capability, demonstrating less than 2% change in thermal resistance after 30,000 power cycles[1]. Fuji's devices incorporate a proprietary trench gate structure that reduces on-resistance while maintaining high short-circuit withstand capability—critical for industrial applications with unpredictable load conditions. Their modules employ a specialized silicone gel encapsulation formulation with enhanced resistance to humidity and industrial contaminants, maintaining integrity even after 1,000 hours of high-temperature high-humidity bias testing (85°C/85% RH)[2]. For industrial power conversion systems, Fuji has developed intelligent power modules (IPMs) with integrated temperature sensors and protection circuits specifically calibrated for SiC MOSFET characteristics. Their industrial SiC solutions undergo extended qualification testing including power cycling at ΔTj = 100°C for reliability verification and vibration testing at up to 10G to ensure mechanical robustness in factory environments[3].

Strengths: Superior power cycling capability ideal for applications with frequent load changes; excellent short-circuit withstand time enhancing system reliability; comprehensive protection features in IPM configurations. Weaknesses: More limited voltage range offerings compared to some competitors; higher thermal resistance in some package options; requires more complex gate drive design for optimal switching performance.

Key Patents and Breakthroughs in SiC Device Reliability

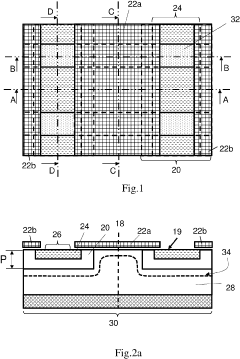

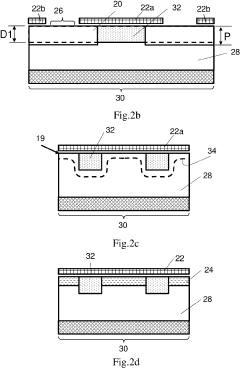

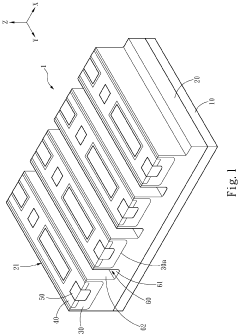

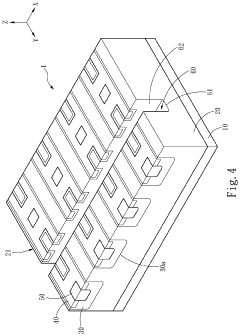

Sic mosfet with transverse p+ region

PatentActiveUS20230053874A1

Innovation

- The design incorporates a silicon carbide MOSFET structure with specific doping layers and geometries, including a polysilicon gate layer, to enhance the protection of the gate oxide without increasing the MOSFET cell area, utilizing epitaxy and ion implantation processes to create N+ and P+ regions that act as shields, ensuring adequate body diode performance and channel mobility.

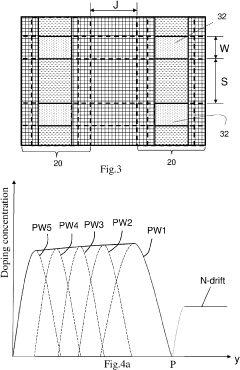

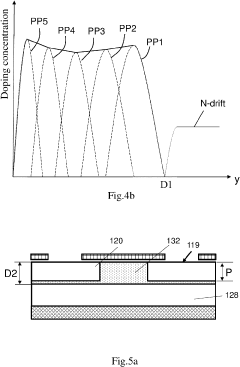

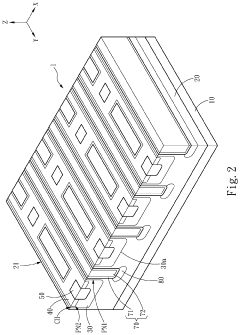

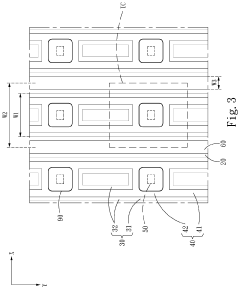

Silicon carbide semiconductor device

PatentPendingUS20240234569A9

Innovation

- A silicon carbide semiconductor device with a hybrid gate structure featuring a trench gate configuration that reduces JFET resistance and parasitic gate-to-drain capacitance, enhancing switching performance by increasing channel width density and optimizing the layout of doped regions and trenches.

Thermal Management Strategies for SiC Industrial Applications

Thermal management is a critical aspect of SiC MOSFET implementation in harsh industrial environments, where operating temperatures can regularly exceed 200°C. Unlike traditional silicon-based devices, SiC MOSFETs can function at higher temperatures but still require sophisticated thermal management to maximize reliability and performance. The fundamental challenge lies in efficiently dissipating the heat generated during high-power switching operations while maintaining junction temperatures within safe operating limits.

Advanced cooling technologies have emerged as essential components of SiC thermal management strategies. Liquid cooling systems, particularly those utilizing dielectric fluids, offer superior thermal conductivity compared to traditional air cooling methods. These systems can remove heat at rates 2-3 times higher than conventional approaches, making them ideal for high-density power applications in industrial settings. Direct immersion cooling, where SiC devices are submerged in cooling fluid, represents the cutting edge of this technology, enabling even greater power density.

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Novel composite materials incorporating graphene, boron nitride, and metal-matrix composites have demonstrated thermal conductivities exceeding 25 W/m·K, significantly reducing thermal resistance between SiC devices and heat sinks. These advanced TIMs maintain performance integrity even under the extreme temperature cycling common in industrial applications.

Integrated thermal design approaches have gained prominence, where thermal considerations are incorporated from the earliest stages of system development. Three-dimensional thermal modeling and computational fluid dynamics simulations enable precise prediction of hotspots and thermal gradients, allowing engineers to optimize component placement and cooling channel design. This holistic approach has demonstrated up to 40% improvement in thermal performance compared to traditional design methodologies.

Active thermal management systems utilizing temperature sensors and microcontroller-based feedback loops represent another significant advancement. These systems dynamically adjust cooling parameters based on real-time operating conditions, optimizing energy consumption while maintaining safe operating temperatures. In industrial environments with variable load profiles, such adaptive systems have shown energy efficiency improvements of 15-30% compared to static cooling solutions.

Package-level innovations, including direct bonded copper (DBC) substrates and silver sintering die-attach technologies, have substantially reduced thermal resistance within SiC MOSFET modules. These technologies enable better heat spreading and improved thermal cycling capability, critical for applications experiencing frequent power cycling. Recent developments in double-sided cooling architectures have further enhanced thermal performance by providing additional pathways for heat dissipation.

Advanced cooling technologies have emerged as essential components of SiC thermal management strategies. Liquid cooling systems, particularly those utilizing dielectric fluids, offer superior thermal conductivity compared to traditional air cooling methods. These systems can remove heat at rates 2-3 times higher than conventional approaches, making them ideal for high-density power applications in industrial settings. Direct immersion cooling, where SiC devices are submerged in cooling fluid, represents the cutting edge of this technology, enabling even greater power density.

Thermal interface materials (TIMs) play a crucial role in the thermal management stack. Novel composite materials incorporating graphene, boron nitride, and metal-matrix composites have demonstrated thermal conductivities exceeding 25 W/m·K, significantly reducing thermal resistance between SiC devices and heat sinks. These advanced TIMs maintain performance integrity even under the extreme temperature cycling common in industrial applications.

Integrated thermal design approaches have gained prominence, where thermal considerations are incorporated from the earliest stages of system development. Three-dimensional thermal modeling and computational fluid dynamics simulations enable precise prediction of hotspots and thermal gradients, allowing engineers to optimize component placement and cooling channel design. This holistic approach has demonstrated up to 40% improvement in thermal performance compared to traditional design methodologies.

Active thermal management systems utilizing temperature sensors and microcontroller-based feedback loops represent another significant advancement. These systems dynamically adjust cooling parameters based on real-time operating conditions, optimizing energy consumption while maintaining safe operating temperatures. In industrial environments with variable load profiles, such adaptive systems have shown energy efficiency improvements of 15-30% compared to static cooling solutions.

Package-level innovations, including direct bonded copper (DBC) substrates and silver sintering die-attach technologies, have substantially reduced thermal resistance within SiC MOSFET modules. These technologies enable better heat spreading and improved thermal cycling capability, critical for applications experiencing frequent power cycling. Recent developments in double-sided cooling architectures have further enhanced thermal performance by providing additional pathways for heat dissipation.

Cost-Performance Analysis of SiC vs Silicon Technologies

When evaluating SiC MOSFETs against traditional silicon technologies for harsh industrial environments, cost-performance analysis reveals significant trade-offs that influence implementation decisions. Initial acquisition costs for SiC MOSFETs typically range 3-5 times higher than their silicon counterparts, presenting a substantial barrier to entry for many industrial applications. However, this cost premium must be evaluated against the comprehensive performance benefits that directly impact total cost of ownership.

The superior thermal conductivity of SiC (approximately 3 times that of silicon) enables more efficient heat dissipation, reducing cooling system requirements and associated costs. This becomes particularly valuable in harsh industrial settings where ambient temperatures may already stress conventional silicon solutions. Performance testing in high-temperature environments (175°C+) demonstrates that SiC MOSFETs maintain stable switching characteristics where silicon devices would require significant derating or fail entirely.

Energy efficiency represents another critical cost-performance factor. SiC MOSFETs exhibit switching losses 75-80% lower than silicon IGBTs at comparable voltage ratings, translating to energy savings of 15-30% in typical industrial power conversion systems. For continuous operation applications like factory automation, steel processing, or oil and gas equipment, these efficiency gains accumulate substantial operational cost savings that typically offset the higher initial investment within 1-3 years.

Reliability metrics further strengthen the SiC value proposition in harsh environments. Accelerated life testing shows SiC devices maintain performance integrity under thermal cycling conditions that would degrade silicon alternatives, resulting in mean time between failures (MTBF) improvements of 2-3x. This extended operational lifespan reduces maintenance intervals and replacement costs, particularly valuable in remote or difficult-to-service industrial installations.

System-level cost reductions must also be considered. SiC's higher frequency operation capabilities (typically 50-100 kHz versus 5-20 kHz for silicon) enable smaller passive components, reducing overall system size by 30-50%. In industrial applications where space constraints exist or where equipment mobility matters, this miniaturization delivers both direct material cost savings and indirect benefits through reduced installation and transportation expenses.

The manufacturing maturity gap between silicon and SiC technologies continues to narrow, with SiC wafer production costs decreasing approximately 10-15% annually. This trend suggests that the cost-performance equation will increasingly favor SiC solutions for harsh industrial environments, particularly as economies of scale improve and manufacturing processes mature. Forward-looking cost models predict price parity for certain application segments within 5-7 years, potentially accelerating adoption across broader industrial use cases.

The superior thermal conductivity of SiC (approximately 3 times that of silicon) enables more efficient heat dissipation, reducing cooling system requirements and associated costs. This becomes particularly valuable in harsh industrial settings where ambient temperatures may already stress conventional silicon solutions. Performance testing in high-temperature environments (175°C+) demonstrates that SiC MOSFETs maintain stable switching characteristics where silicon devices would require significant derating or fail entirely.

Energy efficiency represents another critical cost-performance factor. SiC MOSFETs exhibit switching losses 75-80% lower than silicon IGBTs at comparable voltage ratings, translating to energy savings of 15-30% in typical industrial power conversion systems. For continuous operation applications like factory automation, steel processing, or oil and gas equipment, these efficiency gains accumulate substantial operational cost savings that typically offset the higher initial investment within 1-3 years.

Reliability metrics further strengthen the SiC value proposition in harsh environments. Accelerated life testing shows SiC devices maintain performance integrity under thermal cycling conditions that would degrade silicon alternatives, resulting in mean time between failures (MTBF) improvements of 2-3x. This extended operational lifespan reduces maintenance intervals and replacement costs, particularly valuable in remote or difficult-to-service industrial installations.

System-level cost reductions must also be considered. SiC's higher frequency operation capabilities (typically 50-100 kHz versus 5-20 kHz for silicon) enable smaller passive components, reducing overall system size by 30-50%. In industrial applications where space constraints exist or where equipment mobility matters, this miniaturization delivers both direct material cost savings and indirect benefits through reduced installation and transportation expenses.

The manufacturing maturity gap between silicon and SiC technologies continues to narrow, with SiC wafer production costs decreasing approximately 10-15% annually. This trend suggests that the cost-performance equation will increasingly favor SiC solutions for harsh industrial environments, particularly as economies of scale improve and manufacturing processes mature. Forward-looking cost models predict price parity for certain application segments within 5-7 years, potentially accelerating adoption across broader industrial use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!