SiC MOSFET Benefits In Smart Home Energy Systems

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Implementation Goals

Silicon Carbide (SiC) MOSFET technology has evolved significantly since its initial development in the early 1990s. The journey began with rudimentary devices exhibiting high on-resistance and limited reliability, primarily confined to laboratory environments. By the early 2000s, commercial viability started to emerge as manufacturers like Cree (now Wolfspeed) and Rohm introduced the first generation of SiC MOSFETs with improved performance characteristics, though still at prohibitively high costs for mass adoption.

The mid-2010s marked a pivotal turning point when second-generation devices achieved substantial improvements in switching performance and thermal stability, enabling operation at higher temperatures than traditional silicon alternatives. This period saw the expansion of SiC MOSFET applications beyond niche military and aerospace sectors into automotive and industrial power conversion systems.

Recent technological advancements have focused on reducing defect densities in SiC wafers, enhancing channel mobility, and optimizing gate oxide reliability. These improvements have resulted in third-generation devices with significantly lower RDS(on) values, faster switching speeds, and enhanced ruggedness under fault conditions, all while manufacturing costs have steadily decreased.

The implementation goals for SiC MOSFETs in smart home energy systems center on several key objectives. Primary among these is achieving higher energy efficiency across the entire power conversion chain, from grid connection to individual appliance control. Current targets aim for efficiency improvements of 15-20% compared to silicon-based alternatives, particularly in applications such as solar inverters, battery management systems, and intelligent load controllers.

Size reduction represents another critical goal, with designs targeting 40-60% smaller footprints for power conversion modules. This miniaturization enables more compact and aesthetically pleasing smart home installations while reducing material costs and installation complexity.

Thermal management simplification constitutes a third major objective, leveraging SiC's superior thermal conductivity and high-temperature operation capability to reduce cooling requirements. Implementation roadmaps project a 30-50% reduction in heatsink size and potentially eliminating certain active cooling components entirely in specific applications.

Long-term reliability under variable load conditions typical in residential environments remains a persistent focus area. Current implementation targets specify 15+ year operational lifespans with minimal performance degradation, even under challenging conditions such as frequent power cycling, voltage fluctuations, and occasional grid anomalies.

Cost reduction trajectories aim to achieve price parity with advanced silicon solutions by 2025-2027, primarily through manufacturing scale economies, improved yield rates, and innovations in packaging technology. This economic threshold represents a critical inflection point for widespread adoption in consumer-grade smart home energy systems.

The mid-2010s marked a pivotal turning point when second-generation devices achieved substantial improvements in switching performance and thermal stability, enabling operation at higher temperatures than traditional silicon alternatives. This period saw the expansion of SiC MOSFET applications beyond niche military and aerospace sectors into automotive and industrial power conversion systems.

Recent technological advancements have focused on reducing defect densities in SiC wafers, enhancing channel mobility, and optimizing gate oxide reliability. These improvements have resulted in third-generation devices with significantly lower RDS(on) values, faster switching speeds, and enhanced ruggedness under fault conditions, all while manufacturing costs have steadily decreased.

The implementation goals for SiC MOSFETs in smart home energy systems center on several key objectives. Primary among these is achieving higher energy efficiency across the entire power conversion chain, from grid connection to individual appliance control. Current targets aim for efficiency improvements of 15-20% compared to silicon-based alternatives, particularly in applications such as solar inverters, battery management systems, and intelligent load controllers.

Size reduction represents another critical goal, with designs targeting 40-60% smaller footprints for power conversion modules. This miniaturization enables more compact and aesthetically pleasing smart home installations while reducing material costs and installation complexity.

Thermal management simplification constitutes a third major objective, leveraging SiC's superior thermal conductivity and high-temperature operation capability to reduce cooling requirements. Implementation roadmaps project a 30-50% reduction in heatsink size and potentially eliminating certain active cooling components entirely in specific applications.

Long-term reliability under variable load conditions typical in residential environments remains a persistent focus area. Current implementation targets specify 15+ year operational lifespans with minimal performance degradation, even under challenging conditions such as frequent power cycling, voltage fluctuations, and occasional grid anomalies.

Cost reduction trajectories aim to achieve price parity with advanced silicon solutions by 2025-2027, primarily through manufacturing scale economies, improved yield rates, and innovations in packaging technology. This economic threshold represents a critical inflection point for widespread adoption in consumer-grade smart home energy systems.

Smart Home Energy Management Market Analysis

The smart home energy management market is experiencing unprecedented growth, driven by increasing consumer awareness of energy efficiency, rising electricity costs, and governmental regulations promoting sustainable energy practices. Current market valuations indicate the global smart home energy management sector reached approximately 5.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 17.2% through 2030.

Consumer demand patterns reveal a significant shift toward integrated energy solutions that offer both cost savings and environmental benefits. Market research indicates that over 65% of homeowners consider energy efficiency a primary factor when upgrading home systems, with particular interest in solutions that provide real-time monitoring and automated optimization capabilities.

Regional analysis shows North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid urbanization, increasing disposable income, and government initiatives promoting smart grid technologies.

The market segmentation reveals distinct consumer categories: early adopters focused on cutting-edge technology regardless of price (approximately 15% of the market), value-oriented consumers seeking demonstrable ROI on energy investments (approximately 45%), and sustainability-focused consumers prioritizing environmental impact (approximately 25%).

Key market drivers include the proliferation of IoT devices, decreasing costs of sensor technologies, increasing smart grid implementations, and growing consumer familiarity with home automation systems. The integration of SiC MOSFET technology in energy management systems represents a significant value proposition, particularly in power conversion efficiency and system miniaturization.

Market challenges include interoperability issues between different manufacturers' systems, consumer concerns about data privacy and security, and the relatively high initial investment costs for comprehensive smart energy management systems. The average payback period for such systems currently ranges from 2-4 years, depending on regional energy costs and usage patterns.

Future market trends indicate movement toward AI-powered predictive energy management, increased integration with renewable energy sources, and expansion of demand-response capabilities that interact with utility companies' smart grid initiatives. The potential market for SiC MOSFET-based energy management systems is particularly promising, with an estimated addressable market of 2.1 billion USD by 2025.

Consumer demand patterns reveal a significant shift toward integrated energy solutions that offer both cost savings and environmental benefits. Market research indicates that over 65% of homeowners consider energy efficiency a primary factor when upgrading home systems, with particular interest in solutions that provide real-time monitoring and automated optimization capabilities.

Regional analysis shows North America currently leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid urbanization, increasing disposable income, and government initiatives promoting smart grid technologies.

The market segmentation reveals distinct consumer categories: early adopters focused on cutting-edge technology regardless of price (approximately 15% of the market), value-oriented consumers seeking demonstrable ROI on energy investments (approximately 45%), and sustainability-focused consumers prioritizing environmental impact (approximately 25%).

Key market drivers include the proliferation of IoT devices, decreasing costs of sensor technologies, increasing smart grid implementations, and growing consumer familiarity with home automation systems. The integration of SiC MOSFET technology in energy management systems represents a significant value proposition, particularly in power conversion efficiency and system miniaturization.

Market challenges include interoperability issues between different manufacturers' systems, consumer concerns about data privacy and security, and the relatively high initial investment costs for comprehensive smart energy management systems. The average payback period for such systems currently ranges from 2-4 years, depending on regional energy costs and usage patterns.

Future market trends indicate movement toward AI-powered predictive energy management, increased integration with renewable energy sources, and expansion of demand-response capabilities that interact with utility companies' smart grid initiatives. The potential market for SiC MOSFET-based energy management systems is particularly promising, with an estimated addressable market of 2.1 billion USD by 2025.

SiC MOSFET Technical Barriers and Global Development

Despite the promising advantages of SiC MOSFETs in smart home energy systems, several significant technical barriers impede their widespread adoption. The primary challenge remains the high manufacturing cost compared to traditional silicon-based devices, with SiC MOSFETs typically costing 3-5 times more. This cost differential stems from complex manufacturing processes, lower yields, and expensive substrate materials, creating a substantial barrier for mass-market smart home applications.

Material quality issues present another critical challenge. SiC wafers exhibit higher defect densities than silicon, including micropipes, dislocations, and basal plane defects. These imperfections negatively impact device performance and reliability, particularly problematic for smart home systems requiring long operational lifetimes with minimal maintenance.

Gate oxide reliability represents a persistent technical hurdle. The interface between SiC and silicon dioxide contains significantly higher trap densities than silicon-based devices, leading to threshold voltage instability and reduced channel mobility. This instability can compromise the efficiency gains that make SiC attractive for energy management applications in smart homes.

Packaging technology limitations further constrain SiC MOSFET implementation. Traditional packaging materials cannot fully withstand the higher operating temperatures of SiC devices (potentially exceeding 200°C), necessitating advanced packaging solutions that add cost and complexity to the final product.

From a global development perspective, SiC MOSFET technology shows distinct regional patterns. North America, particularly the United States, leads in fundamental research and intellectual property, with companies like Wolfspeed, ON Semiconductor, and academic institutions driving innovation. Europe focuses on industrial applications and automotive implementations, with STMicroelectronics and Infineon Technologies as major players.

Asia, especially Japan and China, has rapidly expanded manufacturing capacity, with companies like ROHM Semiconductor and Mitsubishi Electric in Japan, and CRRC and Sanan IC in China making significant investments. China's government has designated SiC technology as strategically important in its semiconductor roadmap, providing substantial funding for development.

The global supply chain remains concentrated, with limited suppliers of high-quality SiC substrates creating potential bottlenecks. Recent geopolitical tensions have accelerated efforts to develop regionalized supply chains, particularly in Europe and Asia, to reduce dependence on specific geographic sources.

Standardization efforts are progressing but remain fragmented across regions, complicating global adoption in consumer applications like smart home energy systems. This technical and geographical landscape presents both challenges and opportunities for companies seeking to leverage SiC MOSFETs in next-generation smart home energy management solutions.

Material quality issues present another critical challenge. SiC wafers exhibit higher defect densities than silicon, including micropipes, dislocations, and basal plane defects. These imperfections negatively impact device performance and reliability, particularly problematic for smart home systems requiring long operational lifetimes with minimal maintenance.

Gate oxide reliability represents a persistent technical hurdle. The interface between SiC and silicon dioxide contains significantly higher trap densities than silicon-based devices, leading to threshold voltage instability and reduced channel mobility. This instability can compromise the efficiency gains that make SiC attractive for energy management applications in smart homes.

Packaging technology limitations further constrain SiC MOSFET implementation. Traditional packaging materials cannot fully withstand the higher operating temperatures of SiC devices (potentially exceeding 200°C), necessitating advanced packaging solutions that add cost and complexity to the final product.

From a global development perspective, SiC MOSFET technology shows distinct regional patterns. North America, particularly the United States, leads in fundamental research and intellectual property, with companies like Wolfspeed, ON Semiconductor, and academic institutions driving innovation. Europe focuses on industrial applications and automotive implementations, with STMicroelectronics and Infineon Technologies as major players.

Asia, especially Japan and China, has rapidly expanded manufacturing capacity, with companies like ROHM Semiconductor and Mitsubishi Electric in Japan, and CRRC and Sanan IC in China making significant investments. China's government has designated SiC technology as strategically important in its semiconductor roadmap, providing substantial funding for development.

The global supply chain remains concentrated, with limited suppliers of high-quality SiC substrates creating potential bottlenecks. Recent geopolitical tensions have accelerated efforts to develop regionalized supply chains, particularly in Europe and Asia, to reduce dependence on specific geographic sources.

Standardization efforts are progressing but remain fragmented across regions, complicating global adoption in consumer applications like smart home energy systems. This technical and geographical landscape presents both challenges and opportunities for companies seeking to leverage SiC MOSFETs in next-generation smart home energy management solutions.

Current SiC MOSFET Integration Solutions

01 Higher Breakdown Voltage and Power Density

Silicon Carbide (SiC) MOSFETs offer significantly higher breakdown voltage capabilities compared to traditional silicon-based MOSFETs, allowing them to withstand higher voltages without failure. This property enables the design of more compact power electronics with increased power density. The wide bandgap nature of SiC material (approximately 3 times wider than silicon) contributes to this enhanced voltage handling capability, making these devices ideal for high-voltage applications in power conversion systems.- Higher breakdown voltage and power efficiency: Silicon Carbide (SiC) MOSFETs offer significantly higher breakdown voltage capabilities compared to traditional silicon-based MOSFETs, allowing them to withstand higher voltages without failure. This property, combined with lower on-resistance, results in superior power efficiency and reduced power losses during operation. These characteristics make SiC MOSFETs particularly valuable in high-voltage and high-power applications where energy efficiency is critical.

- Enhanced thermal performance and reliability: SiC MOSFETs demonstrate excellent thermal conductivity and can operate efficiently at much higher temperatures than silicon devices. This superior thermal performance reduces cooling requirements and allows for more compact designs. Additionally, SiC MOSFETs exhibit greater reliability under extreme conditions, including high-temperature environments, contributing to extended device lifespans and improved system reliability in demanding applications.

- Faster switching speeds and reduced switching losses: The wide bandgap properties of Silicon Carbide enable SiC MOSFETs to achieve significantly faster switching speeds compared to conventional silicon devices. This characteristic results in reduced switching losses and allows for higher frequency operation, which in turn enables the design of smaller passive components and more compact power conversion systems. The improved switching performance makes SiC MOSFETs ideal for applications requiring high-frequency operation.

- Improved power density and miniaturization: SiC MOSFETs enable higher power density in electronic systems due to their superior electrical properties and thermal performance. This allows for significant miniaturization of power electronic systems without compromising performance. The reduced size and weight of SiC-based power systems make them particularly valuable in space-constrained applications such as automotive systems, aerospace, and portable electronics where size and weight reductions provide substantial benefits.

- Enhanced performance in specific applications: SiC MOSFETs offer particular advantages in specialized applications such as electric vehicles, renewable energy systems, and industrial power supplies. In electric vehicles, they improve efficiency in traction inverters and onboard chargers. In renewable energy systems, they enhance the performance of solar inverters and wind power converters. Their superior characteristics also make them valuable in industrial power supplies, uninterruptible power supplies (UPS), and motor drives, where they contribute to overall system efficiency and reliability improvements.

02 Superior Thermal Performance and Efficiency

SiC MOSFETs demonstrate excellent thermal conductivity (approximately 3 times higher than silicon), allowing for more efficient heat dissipation during operation. This superior thermal performance enables these devices to operate at higher temperatures (up to 200°C) without degradation in performance. The improved thermal characteristics result in higher efficiency power conversion systems with reduced cooling requirements, leading to smaller overall system size and lower operational costs in high-power applications.Expand Specific Solutions03 Faster Switching Speeds and Lower Switching Losses

SiC MOSFETs can switch at significantly higher frequencies than traditional silicon devices due to their superior electron mobility and lower parasitic capacitances. This faster switching capability enables the design of more efficient power conversion systems with reduced switching losses. The high-frequency operation also allows for the use of smaller passive components (inductors and capacitors) in power electronic circuits, contributing to overall system miniaturization while maintaining or improving performance metrics.Expand Specific Solutions04 Enhanced Reliability in Harsh Environments

The robust material properties of Silicon Carbide make SiC MOSFETs highly reliable in harsh operating environments. These devices demonstrate superior resistance to radiation effects, chemical corrosion, and mechanical stress compared to silicon alternatives. The inherent stability of SiC crystal structure contributes to longer device lifetimes and consistent performance under extreme conditions, making them particularly valuable in aerospace, automotive, and industrial applications where reliability is critical.Expand Specific Solutions05 Reduced System Size and Total Cost of Ownership

While SiC MOSFETs typically have higher initial component costs than silicon alternatives, they enable significant system-level benefits that reduce the total cost of ownership. The higher efficiency reduces energy consumption during operation, while the higher temperature capability and power density allow for smaller cooling systems and overall device footprints. Additionally, the higher reliability reduces maintenance costs and extends system lifetime. These combined benefits make SiC MOSFETs increasingly economical for high-performance power applications despite their premium price point.Expand Specific Solutions

Leading SiC MOSFET Manufacturers and Competitors

The SiC MOSFET market in smart home energy systems is experiencing rapid growth, currently transitioning from early adoption to mainstream implementation. The market is projected to expand significantly as energy efficiency demands increase in residential applications. Leading players like ROHM, ON Semiconductor, and Mitsubishi Electric have established strong technological foundations, while companies such as StarPower Semiconductor, Fuji Electric, and Toshiba are advancing commercial applications. Emerging competitors including Huawei Digital Power, BYD, and Gree Electric are leveraging their consumer electronics expertise to integrate SiC MOSFETs into smart home solutions. Academic institutions like University of Electronic Science & Technology of China and Nanjing University of Posts & Telecommunications are contributing to technological innovation through research partnerships with industry players, accelerating the technology's maturity and adoption curve.

ROHM Co., Ltd.

Technical Solution: ROHM has developed advanced 4th generation SiC MOSFETs specifically optimized for smart home energy systems. Their technology features industry-leading low on-resistance with 40% reduction compared to previous generations, enabling higher efficiency power conversion in residential solar inverters, energy storage systems, and smart appliances. ROHM's SiC MOSFETs operate at switching frequencies up to 100kHz while maintaining high reliability through enhanced short-circuit withstand capability (over 4μs) and gate oxide reliability. Their devices incorporate built-in protection features against surge voltages and implement trench gate structures that minimize switching losses. For smart home applications, ROHM offers compact packages with optimized thermal performance, allowing for smaller power supply designs in home energy management systems while achieving efficiency ratings exceeding 98% in DC-AC conversion stages.

Strengths: Superior power density and thermal performance enable compact designs ideal for space-constrained residential applications. Industry-leading reliability metrics ensure long-term operation in consumer environments. Weaknesses: Higher initial component cost compared to silicon alternatives may impact adoption in cost-sensitive consumer markets. Requires more sophisticated gate driver designs than traditional MOSFETs.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has pioneered a comprehensive SiC MOSFET solution for smart home energy systems centered around their N-series SiC power modules. These modules feature proprietary packaging technology that reduces thermal resistance by approximately 30% compared to conventional modules, enabling higher power density in residential energy storage systems and heat pumps. Their SiC MOSFETs employ a unique planar gate structure with optimized cell design that balances low on-resistance (achieving <10mΩ·cm²) with high short-circuit capability essential for residential applications. Mitsubishi's smart home energy solution integrates their SiC devices with intelligent power management algorithms that dynamically adjust switching parameters based on load conditions, reducing EMI emissions by up to 40% while maintaining peak efficiency above 97%. Their technology enables bidirectional power flow in home energy systems, facilitating grid-interactive functions like peak shaving and demand response with minimal conversion losses.

Strengths: Exceptional thermal management capabilities allow for passive cooling in many residential applications, reducing system complexity and noise. Comprehensive ecosystem approach with compatible gate drivers and protection circuits simplifies implementation. Weaknesses: Higher upfront cost compared to silicon alternatives. Requires more sophisticated control algorithms to fully leverage performance benefits in residential settings.

Key Patents and Innovations in SiC Power Electronics

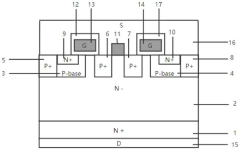

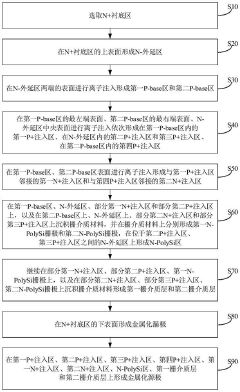

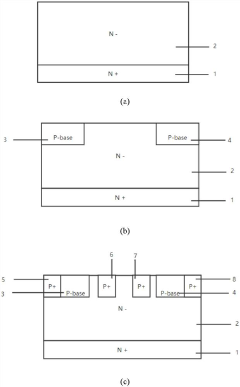

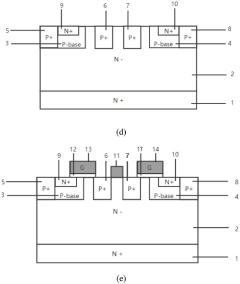

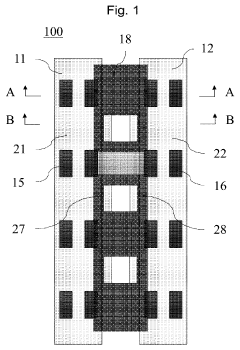

SiC DMOSFET device integrated with HJD and preparation method thereof

PatentPendingCN115842056A

Innovation

- Design a SiC DMOSFET device with an integrated heterojunction diode (HJD). By setting the heterojunction contact between the N-PolySi region and the N-epitaxial region inside the device, it replaces the traditional SBD or JBS structure and adopts a split gate structure. , reduce the gate capacitance.

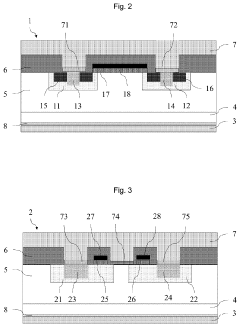

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

Energy Efficiency Regulations Impact Assessment

Energy efficiency regulations are increasingly shaping the landscape for smart home energy systems, with SiC MOSFETs positioned as a key enabling technology for compliance. The European Union's Ecodesign Directive (2009/125/EC) has established stringent efficiency requirements for various household appliances and electronic devices, with amendments in 2021 further tightening these standards. Smart home energy systems incorporating SiC MOSFETs can achieve efficiency improvements of 20-30% compared to traditional silicon-based systems, directly supporting compliance with these regulations.

In the United States, the Department of Energy's appliance and equipment standards program has been progressively increasing minimum efficiency requirements. The ENERGY STAR certification program has also raised its qualification thresholds, with the latest specifications requiring power supplies in smart home systems to achieve 90%+ efficiency at multiple load points. SiC MOSFET-based power conversion systems typically operate at 92-98% efficiency ranges, providing manufacturers with significant headroom above regulatory minimums.

The economic impact assessment of these regulations reveals substantial benefits. According to the International Energy Agency, energy efficiency regulations could reduce global electricity consumption by approximately 3,000 TWh annually by 2030. For smart home manufacturers, the initial 15-25% cost premium for SiC MOSFET implementation is offset by avoiding non-compliance penalties, which can reach up to 4% of annual turnover in some jurisdictions.

Consumer impact analysis shows mixed results. While end-users benefit from reduced energy bills (estimated at $120-180 annually for a typical smart home), the higher initial product costs are passed down to consumers. However, the payback period for this premium has decreased from 4-5 years to 2-3 years as SiC MOSFET production has scaled and efficiency benefits have increased.

Regulatory compliance timelines present challenges for manufacturers. The EU's Ecodesign requirements for smart home energy management systems will tighten by an additional 10% in 2025, while California's Title 24 Building Energy Efficiency Standards now mandate smart capabilities for certain home systems. SiC MOSFET technology adoption provides a future-proofing strategy against this regulatory evolution, as their performance characteristics exceed even forthcoming requirements.

Regional variations in regulations create complexity for global manufacturers. China's Energy Efficiency Top Runner program and Japan's Top Runner standards have different technical specifications than Western markets. SiC MOSFET-based designs offer the flexibility to meet these diverse requirements through software adjustments rather than hardware redesigns, providing significant manufacturing and inventory management advantages in a fragmented regulatory landscape.

In the United States, the Department of Energy's appliance and equipment standards program has been progressively increasing minimum efficiency requirements. The ENERGY STAR certification program has also raised its qualification thresholds, with the latest specifications requiring power supplies in smart home systems to achieve 90%+ efficiency at multiple load points. SiC MOSFET-based power conversion systems typically operate at 92-98% efficiency ranges, providing manufacturers with significant headroom above regulatory minimums.

The economic impact assessment of these regulations reveals substantial benefits. According to the International Energy Agency, energy efficiency regulations could reduce global electricity consumption by approximately 3,000 TWh annually by 2030. For smart home manufacturers, the initial 15-25% cost premium for SiC MOSFET implementation is offset by avoiding non-compliance penalties, which can reach up to 4% of annual turnover in some jurisdictions.

Consumer impact analysis shows mixed results. While end-users benefit from reduced energy bills (estimated at $120-180 annually for a typical smart home), the higher initial product costs are passed down to consumers. However, the payback period for this premium has decreased from 4-5 years to 2-3 years as SiC MOSFET production has scaled and efficiency benefits have increased.

Regulatory compliance timelines present challenges for manufacturers. The EU's Ecodesign requirements for smart home energy management systems will tighten by an additional 10% in 2025, while California's Title 24 Building Energy Efficiency Standards now mandate smart capabilities for certain home systems. SiC MOSFET technology adoption provides a future-proofing strategy against this regulatory evolution, as their performance characteristics exceed even forthcoming requirements.

Regional variations in regulations create complexity for global manufacturers. China's Energy Efficiency Top Runner program and Japan's Top Runner standards have different technical specifications than Western markets. SiC MOSFET-based designs offer the flexibility to meet these diverse requirements through software adjustments rather than hardware redesigns, providing significant manufacturing and inventory management advantages in a fragmented regulatory landscape.

Thermal Management Considerations for Smart Home Applications

Silicon Carbide (SiC) MOSFETs generate significant heat during operation in smart home energy systems, necessitating comprehensive thermal management strategies. The thermal characteristics of SiC devices differ substantially from traditional silicon counterparts, with SiC MOSFETs capable of operating at junction temperatures up to 200°C compared to silicon's typical 150°C limit. This higher temperature tolerance creates both opportunities and challenges for smart home applications.

Effective thermal management begins with proper device selection and placement. SiC MOSFETs should be positioned to maximize natural airflow and minimize thermal coupling between components. In compact smart home devices such as energy storage systems and advanced HVAC controllers, thermal simulation during the design phase becomes critical to identify potential hotspots before physical prototyping.

Heat dissipation solutions vary based on application requirements. Passive cooling methods utilizing aluminum or copper heatsinks remain popular for lower-power smart home applications like intelligent lighting controllers and smart plugs. For higher-power applications such as home energy management systems and EV chargers, active cooling solutions incorporating fans or liquid cooling may be necessary to maintain optimal operating temperatures.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer efficiency between SiC MOSFETs and cooling structures. Advanced ceramic-filled silicone compounds and phase-change materials offer superior thermal conductivity compared to traditional thermal greases, reducing thermal resistance at critical junctions. The selection of appropriate TIMs must account for the specific power cycling profiles typical in smart home environments.

Temperature monitoring and adaptive control systems represent another essential aspect of thermal management. Implementing temperature sensors near SiC MOSFETs allows smart home systems to dynamically adjust operating parameters based on thermal conditions. This might include reducing switching frequencies during peak load periods or implementing soft-start procedures to minimize thermal stress during system initialization.

The physical layout of printed circuit boards significantly impacts thermal performance. Utilizing thicker copper layers (2oz or greater) and thermal vias beneath SiC devices helps distribute heat more effectively. Advanced PCB materials with enhanced thermal conductivity, though more expensive, can provide substantial benefits in high-density smart home applications where space constraints limit conventional cooling options.

Environmental considerations also affect thermal management strategies. Smart home devices installed in attics, utility closets, or outdoor enclosures face more extreme temperature variations than those in climate-controlled living spaces. Thermal management solutions must account for these installation scenarios, potentially incorporating additional thermal headroom or environmental sealing to maintain reliability across diverse operating conditions.

Effective thermal management begins with proper device selection and placement. SiC MOSFETs should be positioned to maximize natural airflow and minimize thermal coupling between components. In compact smart home devices such as energy storage systems and advanced HVAC controllers, thermal simulation during the design phase becomes critical to identify potential hotspots before physical prototyping.

Heat dissipation solutions vary based on application requirements. Passive cooling methods utilizing aluminum or copper heatsinks remain popular for lower-power smart home applications like intelligent lighting controllers and smart plugs. For higher-power applications such as home energy management systems and EV chargers, active cooling solutions incorporating fans or liquid cooling may be necessary to maintain optimal operating temperatures.

Thermal interface materials (TIMs) play a crucial role in maximizing heat transfer efficiency between SiC MOSFETs and cooling structures. Advanced ceramic-filled silicone compounds and phase-change materials offer superior thermal conductivity compared to traditional thermal greases, reducing thermal resistance at critical junctions. The selection of appropriate TIMs must account for the specific power cycling profiles typical in smart home environments.

Temperature monitoring and adaptive control systems represent another essential aspect of thermal management. Implementing temperature sensors near SiC MOSFETs allows smart home systems to dynamically adjust operating parameters based on thermal conditions. This might include reducing switching frequencies during peak load periods or implementing soft-start procedures to minimize thermal stress during system initialization.

The physical layout of printed circuit boards significantly impacts thermal performance. Utilizing thicker copper layers (2oz or greater) and thermal vias beneath SiC devices helps distribute heat more effectively. Advanced PCB materials with enhanced thermal conductivity, though more expensive, can provide substantial benefits in high-density smart home applications where space constraints limit conventional cooling options.

Environmental considerations also affect thermal management strategies. Smart home devices installed in attics, utility closets, or outdoor enclosures face more extreme temperature variations than those in climate-controlled living spaces. Thermal management solutions must account for these installation scenarios, potentially incorporating additional thermal headroom or environmental sealing to maintain reliability across diverse operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!