SiC MOSFET Implementation In Industrial Motor Drives

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Implementation Goals

Silicon Carbide (SiC) MOSFET technology has evolved significantly since its inception in the early 1990s, transforming from a laboratory curiosity to a commercial reality that is revolutionizing power electronics. The journey began with rudimentary devices exhibiting high on-resistance and reliability issues, progressing through various technological breakthroughs in material quality, device design, and manufacturing processes. Early SiC MOSFETs suffered from poor channel mobility and oxide interface quality, limiting their practical applications despite their theoretical advantages over silicon.

The evolution accelerated in the 2000s with improvements in SiC wafer quality and size, moving from 2-inch to 4-inch and eventually to today's 6-inch and 8-inch wafers, significantly reducing production costs. Concurrently, device structures evolved from planar to trench designs, enabling better performance characteristics and higher power density. The introduction of advanced packaging technologies further enhanced thermal management capabilities, a critical factor for industrial motor drive applications.

By the 2010s, commercial viability was achieved with devices offering blocking voltages from 650V to 1700V, making them suitable for industrial motor drives. Recent developments have focused on reducing specific on-resistance, improving short-circuit capability, and enhancing gate oxide reliability – all crucial parameters for robust industrial applications. The technology has now reached a maturity level where widespread adoption in motor drives is not only feasible but increasingly economical.

The implementation goals for SiC MOSFETs in industrial motor drives are multifaceted, addressing both technical performance and economic considerations. Primarily, there is a push to achieve higher power density, enabling more compact and efficient motor drive systems. This is particularly valuable in space-constrained industrial environments and for applications requiring high power-to-weight ratios, such as material handling equipment and industrial robots.

Energy efficiency stands as another critical goal, with targets to reduce switching and conduction losses by at least 50% compared to silicon-based solutions. This translates directly to operational cost savings and contributes to sustainability objectives across industrial sectors. Additionally, implementation aims include extending the operational temperature range to 200°C or beyond, eliminating the need for complex cooling systems in harsh industrial environments.

Reliability improvement represents a fundamental implementation goal, with efforts directed toward achieving failure rates comparable to or better than silicon IGBTs, despite operating at higher temperatures and switching frequencies. This includes enhancing robustness against short circuits, voltage spikes, and thermal cycling – all common stress factors in industrial motor drives. Finally, cost reduction remains a persistent goal, with targets to achieve price parity with silicon alternatives on a system level, accounting for the reduced need for passive components and cooling infrastructure.

The evolution accelerated in the 2000s with improvements in SiC wafer quality and size, moving from 2-inch to 4-inch and eventually to today's 6-inch and 8-inch wafers, significantly reducing production costs. Concurrently, device structures evolved from planar to trench designs, enabling better performance characteristics and higher power density. The introduction of advanced packaging technologies further enhanced thermal management capabilities, a critical factor for industrial motor drive applications.

By the 2010s, commercial viability was achieved with devices offering blocking voltages from 650V to 1700V, making them suitable for industrial motor drives. Recent developments have focused on reducing specific on-resistance, improving short-circuit capability, and enhancing gate oxide reliability – all crucial parameters for robust industrial applications. The technology has now reached a maturity level where widespread adoption in motor drives is not only feasible but increasingly economical.

The implementation goals for SiC MOSFETs in industrial motor drives are multifaceted, addressing both technical performance and economic considerations. Primarily, there is a push to achieve higher power density, enabling more compact and efficient motor drive systems. This is particularly valuable in space-constrained industrial environments and for applications requiring high power-to-weight ratios, such as material handling equipment and industrial robots.

Energy efficiency stands as another critical goal, with targets to reduce switching and conduction losses by at least 50% compared to silicon-based solutions. This translates directly to operational cost savings and contributes to sustainability objectives across industrial sectors. Additionally, implementation aims include extending the operational temperature range to 200°C or beyond, eliminating the need for complex cooling systems in harsh industrial environments.

Reliability improvement represents a fundamental implementation goal, with efforts directed toward achieving failure rates comparable to or better than silicon IGBTs, despite operating at higher temperatures and switching frequencies. This includes enhancing robustness against short circuits, voltage spikes, and thermal cycling – all common stress factors in industrial motor drives. Finally, cost reduction remains a persistent goal, with targets to achieve price parity with silicon alternatives on a system level, accounting for the reduced need for passive components and cooling infrastructure.

Market Demand Analysis for Industrial Motor Drives

The industrial motor drives market is experiencing a significant shift towards more efficient and high-performance solutions, creating substantial demand for Silicon Carbide (SiC) MOSFET technology. Current market analysis indicates that industrial motor drives account for approximately 30% of global electricity consumption, highlighting the critical need for energy-efficient alternatives. The transition to SiC MOSFETs is primarily driven by stringent energy efficiency regulations worldwide, including the EU's IE4 and IE5 motor efficiency standards and similar frameworks in North America and Asia.

Market research reveals that the industrial SiC power device market is growing at a compound annual growth rate of 25%, significantly outpacing traditional silicon-based solutions. This accelerated adoption is particularly evident in high-power industrial applications where the benefits of SiC technology—including higher switching frequencies, reduced cooling requirements, and smaller form factors—translate directly to operational cost savings.

End-user industries demonstrating the strongest demand include manufacturing automation, HVAC systems, water treatment facilities, and renewable energy integration systems. These sectors prioritize total cost of ownership over initial investment, making them ideal early adopters for SiC MOSFET motor drives despite the higher upfront costs. The market shows a clear segmentation between high-power applications (>100kW) where SiC adoption is accelerating rapidly, and low-power applications where traditional silicon solutions remain competitive due to cost considerations.

Regional analysis indicates that Europe currently leads SiC MOSFET adoption in industrial drives, followed closely by North America and East Asia. Emerging economies are showing increasing interest as manufacturing sectors modernize and energy costs rise, creating new market opportunities. The industrial retrofit market represents a particularly promising segment, as upgrading existing motor systems with SiC-based drives offers compelling return on investment through energy savings.

Supply chain considerations are increasingly influencing market dynamics, with recent semiconductor shortages highlighting the strategic importance of securing SiC wafer supply. This has prompted several major industrial drive manufacturers to form strategic partnerships with SiC substrate and device manufacturers to ensure component availability.

Customer surveys indicate that key purchasing factors include energy efficiency improvements, system reliability, power density, and total cost of ownership. Interestingly, maintenance cost reduction is emerging as a significant secondary benefit, as SiC-based systems typically require less frequent maintenance due to reduced thermal stress and component count.

The market forecast suggests that by 2026, SiC MOSFETs will become the dominant technology in new industrial drive installations above 50kW, with penetration into lower power ranges accelerating as manufacturing economies of scale reduce component costs. This transition represents a fundamental shift in the industrial drives market, creating opportunities for manufacturers who can effectively integrate SiC technology into their product portfolios.

Market research reveals that the industrial SiC power device market is growing at a compound annual growth rate of 25%, significantly outpacing traditional silicon-based solutions. This accelerated adoption is particularly evident in high-power industrial applications where the benefits of SiC technology—including higher switching frequencies, reduced cooling requirements, and smaller form factors—translate directly to operational cost savings.

End-user industries demonstrating the strongest demand include manufacturing automation, HVAC systems, water treatment facilities, and renewable energy integration systems. These sectors prioritize total cost of ownership over initial investment, making them ideal early adopters for SiC MOSFET motor drives despite the higher upfront costs. The market shows a clear segmentation between high-power applications (>100kW) where SiC adoption is accelerating rapidly, and low-power applications where traditional silicon solutions remain competitive due to cost considerations.

Regional analysis indicates that Europe currently leads SiC MOSFET adoption in industrial drives, followed closely by North America and East Asia. Emerging economies are showing increasing interest as manufacturing sectors modernize and energy costs rise, creating new market opportunities. The industrial retrofit market represents a particularly promising segment, as upgrading existing motor systems with SiC-based drives offers compelling return on investment through energy savings.

Supply chain considerations are increasingly influencing market dynamics, with recent semiconductor shortages highlighting the strategic importance of securing SiC wafer supply. This has prompted several major industrial drive manufacturers to form strategic partnerships with SiC substrate and device manufacturers to ensure component availability.

Customer surveys indicate that key purchasing factors include energy efficiency improvements, system reliability, power density, and total cost of ownership. Interestingly, maintenance cost reduction is emerging as a significant secondary benefit, as SiC-based systems typically require less frequent maintenance due to reduced thermal stress and component count.

The market forecast suggests that by 2026, SiC MOSFETs will become the dominant technology in new industrial drive installations above 50kW, with penetration into lower power ranges accelerating as manufacturing economies of scale reduce component costs. This transition represents a fundamental shift in the industrial drives market, creating opportunities for manufacturers who can effectively integrate SiC technology into their product portfolios.

SiC MOSFET Technology Status and Challenges

Silicon Carbide (SiC) MOSFET technology has reached a significant level of maturity in recent years, with commercial products now widely available from multiple manufacturers. The current global landscape shows that Japan, United States, and Europe lead in SiC device manufacturing, with China rapidly expanding its capabilities. Major industrial players like Wolfspeed, Infineon, ROHM, and STMicroelectronics have established robust production lines with increasing capacity to meet growing demand.

Despite this progress, several critical challenges persist in SiC MOSFET technology. The gate oxide reliability remains a primary concern, as the interface between SiC and SiO2 contains higher defect densities compared to traditional silicon devices. These defects can lead to threshold voltage instability and reduced lifetime, particularly problematic for industrial motor drives that require long operational lifetimes under harsh conditions.

Manufacturing costs continue to be significantly higher than silicon alternatives, with SiC wafers costing approximately 5-10 times more than silicon wafers of comparable size. The complex manufacturing process, including epitaxial growth and specialized implantation techniques, contributes to this cost premium, creating barriers to widespread adoption in cost-sensitive industrial applications.

Channel mobility in SiC MOSFETs remains lower than theoretical predictions, typically achieving only 10-20% of the bulk mobility. This limitation directly impacts on-resistance and switching performance, which are critical parameters for efficient motor drive operation. Research efforts are focused on novel channel engineering techniques and alternative crystal orientations to address this constraint.

Packaging technology presents another significant challenge, as SiC devices operate at higher temperatures and switching frequencies than silicon counterparts. Traditional packaging materials and techniques often cannot fully exploit SiC's inherent advantages, with thermal management and parasitic inductance becoming limiting factors in high-performance industrial drives.

The supply chain for SiC materials and devices remains relatively concentrated, creating potential vulnerabilities for industrial motor drive manufacturers. Limited substrate availability and specialized processing requirements have created bottlenecks that impact production scalability and cost reduction trajectories.

Standardization across the industry is still evolving, with variations in device characteristics, driving requirements, and reliability testing protocols between manufacturers. This lack of standardization complicates the design process for industrial motor drive systems and increases engineering overhead for implementation.

Recent advancements in third-generation SiC MOSFETs have demonstrated improved ruggedness and reliability, with enhanced short-circuit withstand capabilities crucial for industrial motor drive applications. However, the technology still requires further refinement to achieve the robustness levels necessary for the most demanding industrial environments.

Despite this progress, several critical challenges persist in SiC MOSFET technology. The gate oxide reliability remains a primary concern, as the interface between SiC and SiO2 contains higher defect densities compared to traditional silicon devices. These defects can lead to threshold voltage instability and reduced lifetime, particularly problematic for industrial motor drives that require long operational lifetimes under harsh conditions.

Manufacturing costs continue to be significantly higher than silicon alternatives, with SiC wafers costing approximately 5-10 times more than silicon wafers of comparable size. The complex manufacturing process, including epitaxial growth and specialized implantation techniques, contributes to this cost premium, creating barriers to widespread adoption in cost-sensitive industrial applications.

Channel mobility in SiC MOSFETs remains lower than theoretical predictions, typically achieving only 10-20% of the bulk mobility. This limitation directly impacts on-resistance and switching performance, which are critical parameters for efficient motor drive operation. Research efforts are focused on novel channel engineering techniques and alternative crystal orientations to address this constraint.

Packaging technology presents another significant challenge, as SiC devices operate at higher temperatures and switching frequencies than silicon counterparts. Traditional packaging materials and techniques often cannot fully exploit SiC's inherent advantages, with thermal management and parasitic inductance becoming limiting factors in high-performance industrial drives.

The supply chain for SiC materials and devices remains relatively concentrated, creating potential vulnerabilities for industrial motor drive manufacturers. Limited substrate availability and specialized processing requirements have created bottlenecks that impact production scalability and cost reduction trajectories.

Standardization across the industry is still evolving, with variations in device characteristics, driving requirements, and reliability testing protocols between manufacturers. This lack of standardization complicates the design process for industrial motor drive systems and increases engineering overhead for implementation.

Recent advancements in third-generation SiC MOSFETs have demonstrated improved ruggedness and reliability, with enhanced short-circuit withstand capabilities crucial for industrial motor drive applications. However, the technology still requires further refinement to achieve the robustness levels necessary for the most demanding industrial environments.

Current SiC MOSFET Integration Solutions

01 SiC MOSFET Structure and Fabrication

Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel formations, and doping profiles that contribute to their high-voltage handling capabilities. The fabrication process often involves specific thermal oxidation techniques to create high-quality gate oxides on SiC substrates, which is critical for reducing interface defects and improving channel mobility.- SiC MOSFET Structure and Fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel formations, and doping profiles that contribute to improved electrical properties. Advanced fabrication techniques address challenges specific to SiC materials, such as interface quality and defect management, resulting in devices with superior high-temperature and high-voltage capabilities.

- Power Conversion Applications: SiC MOSFETs are extensively used in power conversion systems due to their high efficiency and switching performance. These devices enable more compact and efficient power supplies, inverters, and converters across various applications including renewable energy systems, electric vehicles, and industrial equipment. Their ability to operate at higher frequencies allows for smaller passive components and overall system size reduction while maintaining or improving efficiency.

- Thermal Management and Reliability: Thermal management is critical for SiC MOSFETs due to their high power density and operating temperatures. Various packaging technologies and cooling solutions have been developed to address heat dissipation challenges. Reliability enhancements include specialized die attach materials, encapsulation methods, and structural designs that mitigate thermal stress and improve device lifetime under extreme operating conditions.

- Gate Drive and Control Techniques: SiC MOSFETs require specialized gate drive circuits and control strategies to fully leverage their fast switching capabilities while managing parasitic effects. Advanced gate driver designs incorporate features like adjustable drive strength, protection mechanisms, and isolation techniques suitable for the higher voltages and faster switching speeds of SiC devices. These control techniques optimize switching performance while minimizing losses and electromagnetic interference.

- Integration and System Design: Integration of SiC MOSFETs into power electronic systems requires specialized design approaches to maximize their benefits. This includes optimized circuit layouts to minimize parasitic inductances, advanced protection schemes, and system-level considerations for EMI mitigation. Novel topologies and control algorithms specifically designed for SiC devices enable higher operating frequencies and power densities while maintaining system reliability and performance.

02 Power Conversion Applications

SiC MOSFETs are widely used in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system miniaturization and enhanced energy efficiency.Expand Specific Solutions03 Gate Drive and Control Techniques

Specialized gate drive and control techniques are essential for optimizing the performance of SiC MOSFETs. These techniques address the unique switching characteristics and gate voltage requirements of SiC devices. Advanced gate driver circuits incorporate features such as adjustable slew rates, protection mechanisms against voltage spikes, and temperature compensation. Proper gate control strategies help minimize switching losses, reduce electromagnetic interference, and extend the operational lifetime of SiC MOSFET-based systems.Expand Specific Solutions04 Thermal Management and Reliability

Effective thermal management is crucial for ensuring the reliability and longevity of SiC MOSFETs. Despite their ability to operate at higher temperatures compared to silicon devices, SiC MOSFETs still require careful thermal design considerations. Advanced packaging technologies, heat dissipation structures, and thermal interface materials are employed to manage the heat generated during high-power operation. Reliability enhancement techniques include specialized passivation layers, robust interconnections, and stress-relief structures to mitigate failure mechanisms under extreme operating conditions.Expand Specific Solutions05 Integration and System Design

The integration of SiC MOSFETs into power electronic systems requires specialized design approaches to fully leverage their performance advantages. System-level considerations include optimized PCB layouts to minimize parasitic inductances, custom cooling solutions, and compatible passive components rated for high-frequency operation. Advanced protection circuits and isolation techniques are implemented to ensure safe operation under various fault conditions. The system design also accounts for the unique driving requirements and switching behavior of SiC devices to achieve optimal efficiency and reliability in the final application.Expand Specific Solutions

Key SiC MOSFET Manufacturers and Competitors

The SiC MOSFET implementation in industrial motor drives market is currently in a growth phase, with increasing adoption driven by demands for higher efficiency and power density. The global market size is expanding rapidly, projected to reach significant value as industrial applications embrace wide-bandgap semiconductors. Technologically, SiC MOSFETs are approaching maturity, with companies like ROHM, Huawei Digital Power, and Yangzhou Yangjie Electronic leading commercial deployment. Research institutions including Xi'an Jiaotong University and Huazhong University of Science & Technology are advancing fundamental technologies, while companies such as Inventchip Technology and GTA Semiconductor are developing specialized industrial applications. State Grid and China Southern Power Grid are implementing these technologies at scale, indicating growing industry confidence in SiC MOSFET reliability for motor drive applications.

Huawei Digital Power Technologies Co Ltd

Technical Solution: 华为数字能源在SiC MOSFET工业电机驱动领域开发了全栈式解决方案,结合自主研发的SiC功率模块与智能控制算法。其技术方案采用平面+沟槽混合MOSFET结构,实现了更低的导通电阻(Rds(on)降低约30%)和更高的开关频率(可达100kHz)。华为的SiC MOSFET驱动方案特别关注EMI优化,通过专利的栅极驱动技术控制dv/dt和di/dt速率,有效抑制电磁干扰。系统集成了AI自适应控制算法,可根据负载特性自动调整开关参数,在保证效率的同时延长器件寿命。华为还开发了数字孪生技术,实时监测SiC MOSFET的健康状态,预测可能的故障。该方案已在数据中心电源、新能源汽车充电和工业变频器等领域实现规模化应用,相比传统硅基方案,能效提升15-20%,系统体积减小35%。

优势:拥有强大的研发能力和完整的产业链整合能力,技术方案结合了硬件和软件的创新;系统级优化能力强,可提供端到端解决方案。劣势:在SiC晶圆制造方面依赖外部供应商;相比专业半导体厂商,在SiC MOSFET核心工艺上的积累相对较短。

ROHM Co., Ltd.

Technical Solution: ROHM作为SiC MOSFET领域的先驱企业,开发了第四代SiC MOSFET技术,采用独特的双沟槽结构(Double-Trench Structure),显著降低了导通电阻并提高了短路耐受能力。其SiC MOSFET模块专为工业电机驱动设计,工作电压范围650V-1700V,具有业界领先的低开关损耗特性。ROHM的解决方案集成了先进的栅极驱动电路和保护功能,能在高温环境(最高200°C)下稳定运行。公司还开发了专用的电机驱动控制算法,优化了SiC MOSFET在变频器中的性能,使电机驱动系统效率提升约50%,同时体积减小40%。ROHM的SiC MOSFET模块已在电动汽车充电桩、工业变频器和太阳能逆变器等领域得到广泛应用。

优势:拥有完整的SiC MOSFET供应链和制造工艺,产品可靠性高,开关损耗低,高温性能优异;提供全面的应用支持和参考设计。劣势:产品价格相对较高,对于成本敏感的应用场景可能缺乏竞争力;在中国市场的本地化服务和技术支持相对有限。

Critical Patents and Innovations in SiC Technology

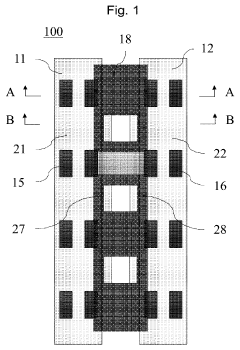

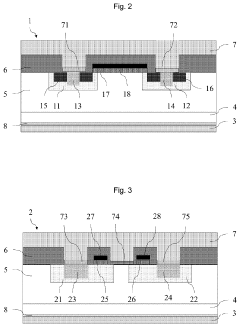

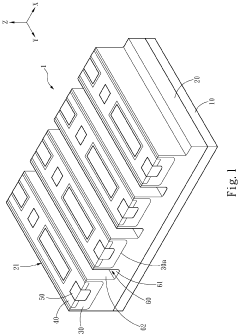

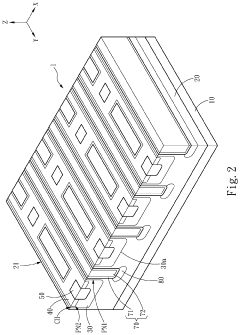

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

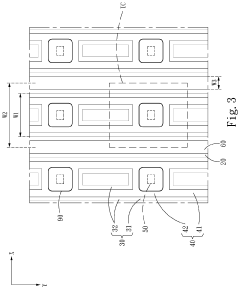

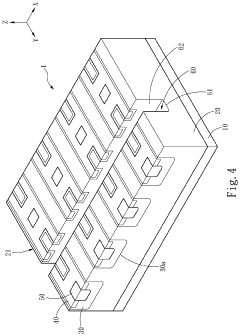

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

Silicon carbide semiconductor device

PatentPendingUS20240234569A9

Innovation

- A silicon carbide semiconductor device with a hybrid gate structure featuring a trench gate configuration that reduces JFET resistance and parasitic gate-to-drain capacitance, enhancing switching performance by increasing channel width density and optimizing the layout of doped regions and trenches.

Thermal Management Strategies for SiC Devices

Thermal management is a critical aspect of SiC MOSFET implementation in industrial motor drives due to the high power density and switching frequencies these devices operate at. While SiC MOSFETs offer superior thermal conductivity compared to silicon counterparts (approximately 3-4 times higher), they still generate significant heat during operation that must be effectively dissipated to maintain reliability and performance.

Conventional cooling methods such as forced-air cooling remain applicable but often insufficient for high-power SiC applications. Advanced liquid cooling systems have emerged as preferred solutions, offering thermal resistance values as low as 0.1°C/W compared to 0.3-0.5°C/W for air-cooled systems. Direct liquid cooling, where coolant directly contacts the device or its substrate, has demonstrated up to 40% improvement in heat dissipation compared to indirect methods.

Double-sided cooling architectures represent another significant advancement, allowing heat extraction from both sides of the SiC die. This approach can increase cooling efficiency by 30-50% compared to single-sided cooling and is particularly valuable in high-current applications where thermal management becomes the limiting factor for power density.

Novel thermal interface materials (TIMs) specifically designed for wide bandgap semiconductors have been developed with thermal conductivities exceeding 10 W/m·K. Silver-sintered interfaces have shown particular promise, offering up to 5 times better thermal performance than conventional solder while maintaining excellent reliability under thermal cycling conditions typical in industrial drive applications.

Integration of temperature sensors and dynamic thermal management systems has become increasingly important. Advanced SiC MOSFET modules now incorporate embedded temperature monitoring with response times under 1ms, enabling real-time thermal management strategies. These systems can dynamically adjust switching frequencies or implement selective derating to maintain optimal thermal conditions without compromising overall system performance.

Thermal modeling and simulation tools have evolved to address the unique challenges of SiC devices. Multi-physics simulation platforms now accurately predict junction temperatures with error margins below 5%, allowing designers to optimize thermal solutions before physical prototyping. These tools have become essential for managing the complex thermal transients that occur during the rapid switching typical of SiC-based motor drives.

Industry data indicates that effective thermal management can extend SiC MOSFET lifetime by 2-3 times compared to poorly managed implementations. As industrial motor drives continue to push power density boundaries, integrated cooling solutions that combine multiple approaches—such as microfluidic cooling channels with advanced TIMs and dynamic thermal management—are emerging as the most promising path forward.

Conventional cooling methods such as forced-air cooling remain applicable but often insufficient for high-power SiC applications. Advanced liquid cooling systems have emerged as preferred solutions, offering thermal resistance values as low as 0.1°C/W compared to 0.3-0.5°C/W for air-cooled systems. Direct liquid cooling, where coolant directly contacts the device or its substrate, has demonstrated up to 40% improvement in heat dissipation compared to indirect methods.

Double-sided cooling architectures represent another significant advancement, allowing heat extraction from both sides of the SiC die. This approach can increase cooling efficiency by 30-50% compared to single-sided cooling and is particularly valuable in high-current applications where thermal management becomes the limiting factor for power density.

Novel thermal interface materials (TIMs) specifically designed for wide bandgap semiconductors have been developed with thermal conductivities exceeding 10 W/m·K. Silver-sintered interfaces have shown particular promise, offering up to 5 times better thermal performance than conventional solder while maintaining excellent reliability under thermal cycling conditions typical in industrial drive applications.

Integration of temperature sensors and dynamic thermal management systems has become increasingly important. Advanced SiC MOSFET modules now incorporate embedded temperature monitoring with response times under 1ms, enabling real-time thermal management strategies. These systems can dynamically adjust switching frequencies or implement selective derating to maintain optimal thermal conditions without compromising overall system performance.

Thermal modeling and simulation tools have evolved to address the unique challenges of SiC devices. Multi-physics simulation platforms now accurately predict junction temperatures with error margins below 5%, allowing designers to optimize thermal solutions before physical prototyping. These tools have become essential for managing the complex thermal transients that occur during the rapid switching typical of SiC-based motor drives.

Industry data indicates that effective thermal management can extend SiC MOSFET lifetime by 2-3 times compared to poorly managed implementations. As industrial motor drives continue to push power density boundaries, integrated cooling solutions that combine multiple approaches—such as microfluidic cooling channels with advanced TIMs and dynamic thermal management—are emerging as the most promising path forward.

Cost-Benefit Analysis of SiC Implementation

The implementation of Silicon Carbide (SiC) MOSFETs in industrial motor drives represents a significant investment decision that requires thorough cost-benefit analysis. Initial acquisition costs of SiC devices typically range 2-3 times higher than traditional silicon-based alternatives, presenting a substantial barrier to adoption. However, this premium must be evaluated against the comprehensive system-level benefits that accumulate over the operational lifetime.

Energy efficiency improvements of 20-30% can be realized through SiC implementation, translating to substantial operational cost savings, particularly in high-power industrial applications where motors operate continuously. For a 100kW industrial drive, annual energy savings can exceed $5,000 depending on local electricity rates and duty cycles, potentially enabling ROI within 2-3 years of deployment.

System miniaturization represents another significant economic advantage. SiC-based drives can achieve 40-60% reduction in heatsink requirements and 30-50% reduction in passive component sizes. This translates to approximately 25-35% reduction in overall system volume and weight, yielding savings in installation space, transportation costs, and supporting infrastructure requirements.

Maintenance economics also favor SiC implementation. The higher temperature tolerance (up to 200°C vs. 150°C for silicon) and greater reliability under thermal cycling reduce cooling system requirements and extend mean time between failures. Studies indicate maintenance cost reductions of 15-25% over system lifetime, with particular benefits in harsh industrial environments where traditional silicon solutions require more frequent service interventions.

Production scaling effects are progressively improving the SiC value proposition. Manufacturing advancements have reduced SiC device costs by approximately 10-15% annually over the past five years, narrowing the price gap with silicon alternatives. Industry projections suggest price parity for certain power ratings could be achieved within 5-7 years, fundamentally altering adoption economics.

Environmental compliance benefits must also factor into comprehensive cost analysis. SiC drives' higher efficiency directly translates to reduced carbon emissions, potentially qualifying for carbon credits or regulatory incentives in jurisdictions with strict environmental regulations. The estimated carbon reduction can range from 15-25 tons annually for a typical industrial motor drive system, representing both environmental and potential financial value.

Energy efficiency improvements of 20-30% can be realized through SiC implementation, translating to substantial operational cost savings, particularly in high-power industrial applications where motors operate continuously. For a 100kW industrial drive, annual energy savings can exceed $5,000 depending on local electricity rates and duty cycles, potentially enabling ROI within 2-3 years of deployment.

System miniaturization represents another significant economic advantage. SiC-based drives can achieve 40-60% reduction in heatsink requirements and 30-50% reduction in passive component sizes. This translates to approximately 25-35% reduction in overall system volume and weight, yielding savings in installation space, transportation costs, and supporting infrastructure requirements.

Maintenance economics also favor SiC implementation. The higher temperature tolerance (up to 200°C vs. 150°C for silicon) and greater reliability under thermal cycling reduce cooling system requirements and extend mean time between failures. Studies indicate maintenance cost reductions of 15-25% over system lifetime, with particular benefits in harsh industrial environments where traditional silicon solutions require more frequent service interventions.

Production scaling effects are progressively improving the SiC value proposition. Manufacturing advancements have reduced SiC device costs by approximately 10-15% annually over the past five years, narrowing the price gap with silicon alternatives. Industry projections suggest price parity for certain power ratings could be achieved within 5-7 years, fundamentally altering adoption economics.

Environmental compliance benefits must also factor into comprehensive cost analysis. SiC drives' higher efficiency directly translates to reduced carbon emissions, potentially qualifying for carbon credits or regulatory incentives in jurisdictions with strict environmental regulations. The estimated carbon reduction can range from 15-25 tons annually for a typical industrial motor drive system, representing both environmental and potential financial value.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!