SiC MOSFET Use In MRI And CT Power Electronics

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Evolution and Applications in Medical Imaging

Silicon Carbide (SiC) MOSFET technology has undergone remarkable evolution since its initial development in the early 1990s. The first commercial SiC MOSFETs emerged around 2001, offering limited performance capabilities compared to today's standards. These early devices operated at relatively low voltages and suffered from reliability issues, particularly regarding gate oxide stability and high on-resistance.

The mid-2000s marked a significant advancement period when manufacturers like Cree (now Wolfspeed) and Rohm introduced second-generation devices with improved channel mobility and reduced defect density. These improvements enabled higher blocking voltages exceeding 1200V while maintaining reasonable switching characteristics, making them viable for specialized high-power applications.

Between 2010-2015, the technology matured substantially with third-generation devices featuring dramatically reduced on-resistance, enhanced thermal performance, and improved reliability. This generation established SiC MOSFETs as serious contenders in power electronics applications requiring high efficiency and power density.

The medical imaging sector began adopting SiC MOSFETs around 2015, initially in CT scanner power supplies where their high-frequency operation capabilities enabled more compact designs. MRI systems followed shortly after, leveraging SiC technology to improve gradient amplifier performance and reduce cooling requirements.

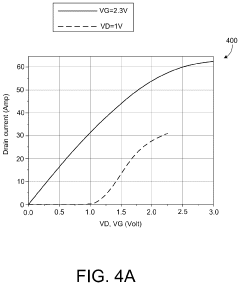

Current generation SiC MOSFETs (2018-present) feature blocking voltages ranging from 650V to 1700V with significantly enhanced ruggedness and reliability. These devices demonstrate on-resistance values approaching theoretical limits for SiC material and switching frequencies exceeding 100 kHz in practical applications, enabling unprecedented power density in medical imaging equipment.

In MRI applications, SiC MOSFETs have revolutionized gradient amplifier design by enabling faster switching speeds and reduced power losses, resulting in improved image resolution and reduced scan times. The superior thermal performance of SiC devices has also minimized cooling requirements, contributing to more compact and energy-efficient MRI systems.

For CT scanners, SiC technology has enabled the development of more precise and stable high-voltage power supplies, critical for X-ray generation. The fast switching capability and low losses of SiC MOSFETs have facilitated higher rotation speeds and improved image quality while reducing the overall system footprint.

Recent developments include trench-structure SiC MOSFETs with even lower on-resistance and improved short-circuit capability, addressing reliability concerns in critical medical applications. Additionally, advanced packaging technologies specifically designed for SiC devices have emerged, optimizing thermal management and reducing parasitic inductances crucial for medical imaging equipment reliability.

The mid-2000s marked a significant advancement period when manufacturers like Cree (now Wolfspeed) and Rohm introduced second-generation devices with improved channel mobility and reduced defect density. These improvements enabled higher blocking voltages exceeding 1200V while maintaining reasonable switching characteristics, making them viable for specialized high-power applications.

Between 2010-2015, the technology matured substantially with third-generation devices featuring dramatically reduced on-resistance, enhanced thermal performance, and improved reliability. This generation established SiC MOSFETs as serious contenders in power electronics applications requiring high efficiency and power density.

The medical imaging sector began adopting SiC MOSFETs around 2015, initially in CT scanner power supplies where their high-frequency operation capabilities enabled more compact designs. MRI systems followed shortly after, leveraging SiC technology to improve gradient amplifier performance and reduce cooling requirements.

Current generation SiC MOSFETs (2018-present) feature blocking voltages ranging from 650V to 1700V with significantly enhanced ruggedness and reliability. These devices demonstrate on-resistance values approaching theoretical limits for SiC material and switching frequencies exceeding 100 kHz in practical applications, enabling unprecedented power density in medical imaging equipment.

In MRI applications, SiC MOSFETs have revolutionized gradient amplifier design by enabling faster switching speeds and reduced power losses, resulting in improved image resolution and reduced scan times. The superior thermal performance of SiC devices has also minimized cooling requirements, contributing to more compact and energy-efficient MRI systems.

For CT scanners, SiC technology has enabled the development of more precise and stable high-voltage power supplies, critical for X-ray generation. The fast switching capability and low losses of SiC MOSFETs have facilitated higher rotation speeds and improved image quality while reducing the overall system footprint.

Recent developments include trench-structure SiC MOSFETs with even lower on-resistance and improved short-circuit capability, addressing reliability concerns in critical medical applications. Additionally, advanced packaging technologies specifically designed for SiC devices have emerged, optimizing thermal management and reducing parasitic inductances crucial for medical imaging equipment reliability.

Market Demand for Advanced Power Electronics in MRI/CT Systems

The medical imaging market is experiencing significant growth, with MRI and CT systems at the forefront of diagnostic technology. These advanced imaging modalities require increasingly sophisticated power electronics to deliver precise, reliable performance while meeting stringent medical safety standards. The global medical imaging equipment market, valued at approximately $37.5 billion in 2021, is projected to reach $50.2 billion by 2028, with power electronics components representing a crucial segment of this expansion.

MRI and CT systems specifically demand high-performance power electronics to manage their substantial energy requirements. Modern MRI machines operate at field strengths of 1.5T to 7T, consuming between 20-100 kW during operation, while CT scanners require precise power control for X-ray generation systems that operate at 80-140 kV. These demanding specifications create a specialized market for advanced power electronics solutions.

Healthcare providers are increasingly prioritizing energy efficiency in imaging equipment, driven by both operational cost concerns and sustainability initiatives. A typical hospital's imaging department can account for 10-15% of the facility's total energy consumption. This has created market demand for power electronics that can reduce energy losses and improve thermal management, directly impacting operational expenses in healthcare settings.

The trend toward portable and point-of-care imaging systems is further driving demand for compact, efficient power electronics. Mobile CT units and transportable MRI systems require power solutions that maximize efficiency while minimizing size and weight, creating new market opportunities for SiC MOSFET technology that offers superior power density compared to traditional silicon-based alternatives.

Reliability requirements in medical imaging create another significant market driver. Downtime for MRI and CT systems can cost healthcare facilities between $3,000-$10,000 per hour in lost revenue, not including repair costs. This has intensified demand for power electronics with enhanced reliability, longer service intervals, and reduced failure rates – all areas where SiC MOSFETs demonstrate advantages over conventional technologies.

Regulatory factors are also shaping market demand, with IEC 60601 medical electrical equipment standards and electromagnetic compatibility requirements becoming increasingly stringent. Power electronics that can meet these standards while delivering improved performance command premium pricing in the medical imaging market, with manufacturers willing to invest in advanced solutions that simplify compliance.

The shift toward value-based healthcare has created demand for imaging systems with lower total cost of ownership, where the initial premium for advanced power electronics can be justified through energy savings, improved reliability, and extended equipment lifespan. This market dynamic favors SiC MOSFET adoption despite higher initial component costs.

MRI and CT systems specifically demand high-performance power electronics to manage their substantial energy requirements. Modern MRI machines operate at field strengths of 1.5T to 7T, consuming between 20-100 kW during operation, while CT scanners require precise power control for X-ray generation systems that operate at 80-140 kV. These demanding specifications create a specialized market for advanced power electronics solutions.

Healthcare providers are increasingly prioritizing energy efficiency in imaging equipment, driven by both operational cost concerns and sustainability initiatives. A typical hospital's imaging department can account for 10-15% of the facility's total energy consumption. This has created market demand for power electronics that can reduce energy losses and improve thermal management, directly impacting operational expenses in healthcare settings.

The trend toward portable and point-of-care imaging systems is further driving demand for compact, efficient power electronics. Mobile CT units and transportable MRI systems require power solutions that maximize efficiency while minimizing size and weight, creating new market opportunities for SiC MOSFET technology that offers superior power density compared to traditional silicon-based alternatives.

Reliability requirements in medical imaging create another significant market driver. Downtime for MRI and CT systems can cost healthcare facilities between $3,000-$10,000 per hour in lost revenue, not including repair costs. This has intensified demand for power electronics with enhanced reliability, longer service intervals, and reduced failure rates – all areas where SiC MOSFETs demonstrate advantages over conventional technologies.

Regulatory factors are also shaping market demand, with IEC 60601 medical electrical equipment standards and electromagnetic compatibility requirements becoming increasingly stringent. Power electronics that can meet these standards while delivering improved performance command premium pricing in the medical imaging market, with manufacturers willing to invest in advanced solutions that simplify compliance.

The shift toward value-based healthcare has created demand for imaging systems with lower total cost of ownership, where the initial premium for advanced power electronics can be justified through energy savings, improved reliability, and extended equipment lifespan. This market dynamic favors SiC MOSFET adoption despite higher initial component costs.

Technical Challenges and Current State of SiC MOSFETs

Silicon Carbide (SiC) MOSFETs represent a significant advancement in power electronics technology, offering superior performance characteristics compared to traditional silicon-based devices. However, their implementation in medical imaging equipment such as MRI and CT scanners presents unique technical challenges that must be addressed for successful integration.

The current state of SiC MOSFETs in medical imaging power electronics is characterized by promising developments alongside persistent limitations. These devices offer higher switching frequencies, reduced switching losses, and improved thermal conductivity compared to silicon alternatives, which are particularly valuable in the high-power density requirements of medical imaging systems. However, the adoption rate remains constrained by several factors.

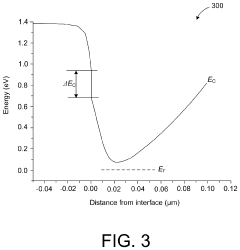

One primary challenge is the gate oxide reliability in SiC MOSFETs. The interface between SiC and SiO2 contains higher defect densities than silicon-based counterparts, leading to threshold voltage instability and reduced lifetime under the high-stress operating conditions typical in medical imaging equipment. This issue becomes particularly critical in MRI environments where device reliability is paramount for patient safety.

Electromagnetic interference (EMI) presents another significant hurdle. The faster switching speeds of SiC MOSFETs, while beneficial for efficiency, generate higher frequency electromagnetic noise that can interfere with the sensitive detection systems in both MRI and CT scanners. Developing effective EMI shielding and filtering solutions without compromising the performance advantages of SiC technology remains challenging.

Cost factors continue to impede widespread adoption. Current manufacturing processes for SiC wafers and devices involve higher complexity and lower yields compared to silicon, resulting in substantially higher component costs. For medical imaging OEMs operating in cost-sensitive healthcare markets, this presents a significant barrier despite the performance benefits.

The radiation environment in CT scanners poses unique challenges for SiC MOSFETs. While these devices generally demonstrate better radiation hardness than silicon alternatives, their long-term reliability under repeated radiation exposure requires further validation, particularly regarding charge trapping effects in the gate oxide.

Thermal management systems must also be redesigned to fully leverage SiC capabilities. Although SiC MOSFETs can operate at higher temperatures, the surrounding components in medical imaging power supplies often cannot, necessitating comprehensive thermal redesign approaches.

Current research efforts focus on addressing these challenges through improved manufacturing processes, enhanced packaging technologies, and specialized circuit designs tailored to medical imaging applications. Progress has been made in reducing defect densities and developing more robust gate oxide structures, but significant work remains before SiC MOSFETs can fully replace silicon devices in mainstream medical imaging equipment.

The current state of SiC MOSFETs in medical imaging power electronics is characterized by promising developments alongside persistent limitations. These devices offer higher switching frequencies, reduced switching losses, and improved thermal conductivity compared to silicon alternatives, which are particularly valuable in the high-power density requirements of medical imaging systems. However, the adoption rate remains constrained by several factors.

One primary challenge is the gate oxide reliability in SiC MOSFETs. The interface between SiC and SiO2 contains higher defect densities than silicon-based counterparts, leading to threshold voltage instability and reduced lifetime under the high-stress operating conditions typical in medical imaging equipment. This issue becomes particularly critical in MRI environments where device reliability is paramount for patient safety.

Electromagnetic interference (EMI) presents another significant hurdle. The faster switching speeds of SiC MOSFETs, while beneficial for efficiency, generate higher frequency electromagnetic noise that can interfere with the sensitive detection systems in both MRI and CT scanners. Developing effective EMI shielding and filtering solutions without compromising the performance advantages of SiC technology remains challenging.

Cost factors continue to impede widespread adoption. Current manufacturing processes for SiC wafers and devices involve higher complexity and lower yields compared to silicon, resulting in substantially higher component costs. For medical imaging OEMs operating in cost-sensitive healthcare markets, this presents a significant barrier despite the performance benefits.

The radiation environment in CT scanners poses unique challenges for SiC MOSFETs. While these devices generally demonstrate better radiation hardness than silicon alternatives, their long-term reliability under repeated radiation exposure requires further validation, particularly regarding charge trapping effects in the gate oxide.

Thermal management systems must also be redesigned to fully leverage SiC capabilities. Although SiC MOSFETs can operate at higher temperatures, the surrounding components in medical imaging power supplies often cannot, necessitating comprehensive thermal redesign approaches.

Current research efforts focus on addressing these challenges through improved manufacturing processes, enhanced packaging technologies, and specialized circuit designs tailored to medical imaging applications. Progress has been made in reducing defect densities and developing more robust gate oxide structures, but significant work remains before SiC MOSFETs can fully replace silicon devices in mainstream medical imaging equipment.

Current Implementation Solutions for MRI/CT Power Systems

01 SiC MOSFET structure and fabrication

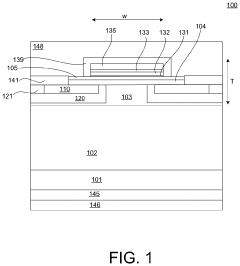

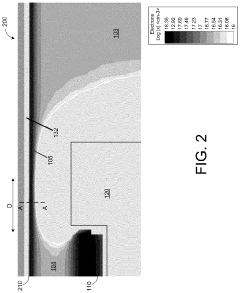

Silicon Carbide (SiC) MOSFETs have unique structural features and fabrication methods that enhance their performance characteristics. These include specialized gate structures, channel designs, and manufacturing techniques that improve electron mobility and reduce on-resistance. The fabrication process typically involves epitaxial growth of SiC layers, precise doping profiles, and specialized annealing treatments to minimize interface defects between the SiC and gate oxide.- SiC MOSFET Structure and Fabrication: Silicon Carbide (SiC) MOSFETs feature unique structural designs and fabrication methods that enhance their performance characteristics. These devices typically include specialized gate structures, channel formations, and doping profiles that contribute to their high-voltage handling capabilities. The fabrication process often involves specific thermal oxidation techniques, ion implantation methods, and annealing processes to create high-quality interfaces between SiC and gate dielectrics, which are crucial for reliable device operation.

- Power Conversion Applications: SiC MOSFETs are widely implemented in power conversion systems due to their superior switching characteristics and high-temperature operation capabilities. These devices enable more efficient power conversion in applications such as inverters, converters, and power supplies. The implementation of SiC MOSFETs in these systems results in reduced switching losses, higher operating frequencies, and improved thermal management, leading to overall system miniaturization and enhanced energy efficiency.

- Gate Drive and Control Techniques: Specialized gate drive circuits and control techniques are essential for optimizing SiC MOSFET performance. These include advanced gate driver designs that address the unique switching characteristics of SiC devices, such as faster switching speeds and higher gate threshold voltages. Control methodologies often incorporate protection features against voltage spikes, current overshoots, and thermal runaway conditions, ensuring reliable operation under various load conditions while maximizing the benefits of SiC technology.

- Thermal Management and Reliability: Effective thermal management solutions are critical for SiC MOSFETs to maintain reliability at high operating temperatures. These include advanced packaging technologies, heat dissipation structures, and thermal interface materials specifically designed for SiC devices. Reliability enhancement techniques address common failure modes such as gate oxide degradation, threshold voltage instability, and body diode performance, extending the operational lifetime of SiC MOSFETs in demanding applications.

- Integration with Other Power Devices: SiC MOSFETs are increasingly integrated with other power semiconductor devices to create hybrid or multi-chip power modules. These integrated solutions combine the advantages of different semiconductor technologies to optimize overall system performance. Integration approaches include co-packaging with silicon devices, GaN components, or passive components, as well as monolithic integration techniques. These integrated solutions address specific application requirements such as bidirectional power flow, multi-level conversion, and wide operating temperature ranges.

02 SiC MOSFET power applications and circuits

SiC MOSFETs are widely used in power electronic applications due to their superior performance at high voltages and temperatures. These devices are incorporated into various circuit topologies including inverters, converters, and power supply units. The implementation of SiC MOSFETs in these circuits results in higher efficiency, reduced switching losses, and smaller form factors compared to traditional silicon-based solutions.Expand Specific Solutions03 Thermal management and reliability of SiC MOSFETs

Effective thermal management is crucial for SiC MOSFETs operating at high power densities. Various cooling techniques and packaging solutions have been developed to dissipate heat efficiently and maintain device reliability. These include advanced die-attach materials, improved thermal interface materials, and optimized package designs. Additionally, reliability testing methodologies specific to SiC MOSFETs have been established to evaluate their long-term performance under various stress conditions.Expand Specific Solutions04 Gate drive optimization for SiC MOSFETs

Gate drive circuits for SiC MOSFETs require special consideration due to the unique switching characteristics of these devices. Optimized gate drive designs include features such as adjustable gate voltage levels, controlled slew rates, and protection against voltage spikes. These specialized gate drivers help maximize the switching performance of SiC MOSFETs while ensuring safe operation within their specified limits.Expand Specific Solutions05 SiC MOSFET integration with other semiconductor technologies

Integration of SiC MOSFETs with other semiconductor technologies enables advanced hybrid power systems. These integrations include combining SiC MOSFETs with silicon devices, GaN components, or various sensing and control circuits. Such hybrid approaches leverage the strengths of each technology to create optimized power systems for specific applications, balancing performance, cost, and reliability considerations.Expand Specific Solutions

Key Manufacturers and Competitors in SiC MOSFET Market

The SiC MOSFET market for MRI and CT power electronics is in a growth phase, with increasing adoption driven by demands for higher efficiency and power density in medical imaging equipment. The market is expanding at approximately 25-30% annually, reaching an estimated $150-200 million specifically for medical applications. Leading players include established power semiconductor manufacturers like Mitsubishi Electric and ROHM, who offer mature commercial SiC MOSFET solutions, while Huawei Digital Power and Mornsun are developing specialized medical-grade power modules. Chinese institutions including Xidian University and State Grid research centers are advancing domestic SiC technology capabilities. The technology has reached commercial maturity for standard applications, though specialized medical implementations still require optimization for electromagnetic compatibility and reliability in sensitive healthcare environments.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed advanced SiC MOSFET modules specifically optimized for medical imaging equipment power supplies. Their technology features a unique hybrid structure combining planar and trench gate designs that achieves switching frequencies exceeding 100kHz while maintaining efficiency above 98% under high-voltage conditions required for MRI and CT systems. The company's proprietary packaging technology reduces parasitic inductance by approximately 60% compared to conventional modules, enabling faster switching transitions and lower EMI emissions - critical for sensitive medical diagnostic equipment. Mitsubishi's SiC MOSFETs incorporate enhanced short-circuit protection mechanisms and thermal management solutions specifically designed to meet the reliability requirements of medical-grade power electronics with expected operational lifespans of 10+ years.

Strengths: Industry-leading power density and efficiency metrics; comprehensive medical certification compliance; proven reliability in high-voltage applications. Weaknesses: Higher initial cost compared to silicon alternatives; requires specialized gate driver circuits; limited availability of smaller power ratings for compact medical systems.

ROHM Co., Ltd.

Technical Solution: ROHM has pioneered specialized SiC MOSFET solutions for medical imaging equipment with their fourth-generation technology featuring trench gate structures that achieve industry-leading RDS(on) values below 80mΩ at 1200V ratings. Their proprietary "double-trench" structure minimizes on-resistance while maintaining high short-circuit withstand capability exceeding 5μs - critical for protecting expensive medical equipment. For MRI applications specifically, ROHM has developed magnetically-optimized packaging that reduces ferromagnetic materials by over 95%, minimizing interference with imaging quality. Their SiC devices incorporate specialized gate oxide screening processes that enhance long-term reliability under the high-voltage switching conditions typical in CT power supplies, with demonstrated MTTF (Mean Time To Failure) exceeding 100 million hours at operating temperatures.

Strengths: Superior magnetic compatibility for MRI environments; exceptional reliability metrics; comprehensive design support ecosystem including specialized gate drivers. Weaknesses: Premium pricing structure limits adoption in cost-sensitive applications; requires more complex thermal management solutions; limited manufacturing capacity compared to silicon alternatives.

Critical Patents and Innovations in SiC MOSFET Technology

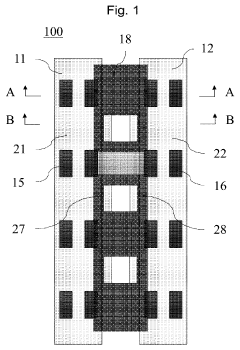

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

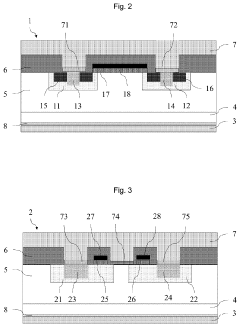

Silicon carbide field-effect transistors

PatentActiveUS11894454B2

Innovation

- The development of a silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) with a gate structure comprising a gate oxide layer, an aluminum nitride layer, and a p-type gallium nitride layer, which includes a lateral built-in channel with a p-type AlGaN gate and an AlN buffer layer, providing high threshold voltage and low interface trap density, enabling efficient operation with low on-state resistance.

Thermal Management Strategies for SiC in Medical Environments

Thermal management is a critical consideration for SiC MOSFETs in medical imaging equipment like MRI and CT scanners. These devices operate at significantly higher temperatures than traditional silicon-based components, with junction temperatures reaching up to 200°C compared to silicon's 150°C limit. This thermal characteristic necessitates specialized cooling strategies tailored to the unique medical environment requirements.

In medical settings, conventional cooling methods must be adapted to address the specific challenges posed by SiC devices. Liquid cooling systems have emerged as particularly effective for MRI and CT power electronics, offering superior heat dissipation capabilities while maintaining electromagnetic compatibility. Advanced coolants with high thermal conductivity and dielectric properties are increasingly utilized to maximize cooling efficiency without introducing electromagnetic interference.

Heat sink design has evolved significantly for SiC applications in medical imaging equipment. Novel materials such as aluminum nitride and boron nitride composites provide enhanced thermal conductivity while maintaining electrical isolation. These advanced heat sinks often incorporate microchannels or pin-fin structures to increase surface area and improve convection cooling performance within the confined spaces of medical equipment.

Thermal interface materials (TIMs) play a crucial role in SiC MOSFET cooling systems for medical applications. Recent developments include phase-change materials and metal-based TIMs that offer thermal conductivity values exceeding 20 W/m·K while maintaining compliance with medical equipment standards. These materials significantly reduce thermal resistance at the critical junction between SiC devices and cooling structures.

Active cooling technologies, including thermoelectric coolers and micro-pumped cooling loops, are being integrated into newer medical imaging systems. These solutions provide precise temperature control for SiC power electronics, ensuring optimal performance during extended operational periods typical in clinical settings. The ability to maintain consistent junction temperatures improves both reliability and efficiency of the power conversion systems.

Thermal simulation and modeling have become essential tools in developing cooling strategies for medical SiC applications. Computational fluid dynamics coupled with electrothermal modeling enables engineers to predict hotspots and optimize cooling system designs before physical prototyping. These simulation approaches have reduced development cycles while improving thermal management effectiveness in the final medical products.

Noise considerations represent a unique challenge for thermal management in medical environments. Cooling solutions must maintain low acoustic profiles to avoid disrupting sensitive diagnostic procedures or patient comfort. This has led to the development of specialized low-noise fans and pumps with advanced vibration isolation features specifically designed for medical imaging equipment.

In medical settings, conventional cooling methods must be adapted to address the specific challenges posed by SiC devices. Liquid cooling systems have emerged as particularly effective for MRI and CT power electronics, offering superior heat dissipation capabilities while maintaining electromagnetic compatibility. Advanced coolants with high thermal conductivity and dielectric properties are increasingly utilized to maximize cooling efficiency without introducing electromagnetic interference.

Heat sink design has evolved significantly for SiC applications in medical imaging equipment. Novel materials such as aluminum nitride and boron nitride composites provide enhanced thermal conductivity while maintaining electrical isolation. These advanced heat sinks often incorporate microchannels or pin-fin structures to increase surface area and improve convection cooling performance within the confined spaces of medical equipment.

Thermal interface materials (TIMs) play a crucial role in SiC MOSFET cooling systems for medical applications. Recent developments include phase-change materials and metal-based TIMs that offer thermal conductivity values exceeding 20 W/m·K while maintaining compliance with medical equipment standards. These materials significantly reduce thermal resistance at the critical junction between SiC devices and cooling structures.

Active cooling technologies, including thermoelectric coolers and micro-pumped cooling loops, are being integrated into newer medical imaging systems. These solutions provide precise temperature control for SiC power electronics, ensuring optimal performance during extended operational periods typical in clinical settings. The ability to maintain consistent junction temperatures improves both reliability and efficiency of the power conversion systems.

Thermal simulation and modeling have become essential tools in developing cooling strategies for medical SiC applications. Computational fluid dynamics coupled with electrothermal modeling enables engineers to predict hotspots and optimize cooling system designs before physical prototyping. These simulation approaches have reduced development cycles while improving thermal management effectiveness in the final medical products.

Noise considerations represent a unique challenge for thermal management in medical environments. Cooling solutions must maintain low acoustic profiles to avoid disrupting sensitive diagnostic procedures or patient comfort. This has led to the development of specialized low-noise fans and pumps with advanced vibration isolation features specifically designed for medical imaging equipment.

Reliability and Safety Standards for Medical Power Electronics

Medical power electronics in MRI and CT systems must adhere to stringent reliability and safety standards due to their critical role in patient care. IEC 60601-1 serves as the foundational standard for medical electrical equipment, establishing essential requirements for basic safety and performance. For SiC MOSFET implementations specifically, compliance with IEC 60601-1-2 regarding electromagnetic compatibility is crucial, as these devices operate at higher switching frequencies that could potentially introduce electromagnetic interference in sensitive diagnostic equipment.

The FDA's regulatory framework imposes additional requirements for medical devices incorporating SiC MOSFET technology, including comprehensive risk management documentation according to ISO 14971. This standard necessitates thorough identification, evaluation, and mitigation of potential failure modes specific to SiC MOSFET power electronics in imaging environments.

Reliability testing protocols for SiC MOSFETs in medical applications exceed those of standard industrial applications. Accelerated life testing under medical-specific conditions must simulate the unique thermal cycling, humidity variations, and operational patterns encountered in MRI and CT environments. The JEDEC standards, particularly JESD22-A108 for temperature cycling and JESD22-A110 for highly accelerated temperature and humidity stress tests, have been adapted with more stringent acceptance criteria for medical implementations.

Safety isolation requirements present significant design challenges for SiC MOSFET integration. Medical power supplies utilizing this technology must maintain reinforced insulation with creepage and clearance distances that exceed standard industrial specifications by 1.5-2 times. The IEC 60601-1 standard mandates two means of patient protection (MOPP) with voltage withstand capabilities of 4000V AC for primary circuits.

Fault tolerance mechanisms represent another critical aspect of medical power electronics standards. Systems incorporating SiC MOSFETs must implement redundancy architectures and fail-safe modes that ensure continued operation or safe shutdown during component failure. This includes overvoltage, overcurrent, and thermal protection circuits specifically designed to accommodate the faster switching characteristics and higher operating temperatures of SiC devices.

Traceability and documentation requirements for medical-grade SiC MOSFETs exceed standard commercial practices. Each component must have comprehensive manufacturing records, batch testing data, and qualification reports available for regulatory review. This documentation burden increases development costs but ensures the highest levels of reliability and safety for critical medical imaging applications.

The FDA's regulatory framework imposes additional requirements for medical devices incorporating SiC MOSFET technology, including comprehensive risk management documentation according to ISO 14971. This standard necessitates thorough identification, evaluation, and mitigation of potential failure modes specific to SiC MOSFET power electronics in imaging environments.

Reliability testing protocols for SiC MOSFETs in medical applications exceed those of standard industrial applications. Accelerated life testing under medical-specific conditions must simulate the unique thermal cycling, humidity variations, and operational patterns encountered in MRI and CT environments. The JEDEC standards, particularly JESD22-A108 for temperature cycling and JESD22-A110 for highly accelerated temperature and humidity stress tests, have been adapted with more stringent acceptance criteria for medical implementations.

Safety isolation requirements present significant design challenges for SiC MOSFET integration. Medical power supplies utilizing this technology must maintain reinforced insulation with creepage and clearance distances that exceed standard industrial specifications by 1.5-2 times. The IEC 60601-1 standard mandates two means of patient protection (MOPP) with voltage withstand capabilities of 4000V AC for primary circuits.

Fault tolerance mechanisms represent another critical aspect of medical power electronics standards. Systems incorporating SiC MOSFETs must implement redundancy architectures and fail-safe modes that ensure continued operation or safe shutdown during component failure. This includes overvoltage, overcurrent, and thermal protection circuits specifically designed to accommodate the faster switching characteristics and higher operating temperatures of SiC devices.

Traceability and documentation requirements for medical-grade SiC MOSFETs exceed standard commercial practices. Each component must have comprehensive manufacturing records, batch testing data, and qualification reports available for regulatory review. This documentation burden increases development costs but ensures the highest levels of reliability and safety for critical medical imaging applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!