What Are The Testing Challenges For Automotive-Grade SiC MOSFETs?

SEP 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SiC MOSFET Testing Background and Objectives

Silicon Carbide (SiC) MOSFETs have emerged as revolutionary power semiconductor devices, particularly in automotive applications where high temperature operation, efficiency, and reliability are paramount. The evolution of SiC technology began in the early 2000s, with significant acceleration in development occurring over the past decade as automotive manufacturers sought more efficient power electronics solutions for electric vehicles and advanced driver assistance systems.

The automotive industry's transition toward electrification has created unprecedented demand for power semiconductors capable of operating under extreme conditions while maintaining high efficiency. SiC MOSFETs, with their wide bandgap properties, offer substantial advantages over traditional silicon-based devices, including higher breakdown voltage, faster switching speeds, and superior thermal conductivity.

Testing methodologies for these devices, however, have not kept pace with their rapid technological advancement. Traditional silicon-based testing protocols prove inadequate for evaluating the unique characteristics and failure modes of SiC MOSFETs, particularly those destined for automotive applications where reliability requirements are exceptionally stringent.

The primary objective of SiC MOSFET testing is to ensure these devices can withstand the harsh automotive environment while maintaining performance throughout the vehicle's operational lifetime. This includes validation of their ability to function reliably under extreme temperature cycling, humidity, mechanical stress, and electromagnetic interference—all while meeting the automotive industry's AEC-Q101 qualification standards.

Current testing approaches face significant limitations in accurately predicting long-term reliability, particularly regarding gate oxide integrity, threshold voltage stability, and body diode degradation under repeated switching conditions. These challenges are compounded by the higher operating voltages and temperatures characteristic of SiC devices.

The technology trajectory indicates a continued miniaturization of SiC MOSFETs alongside increasing power density requirements, which will further intensify testing challenges. As die sizes decrease and current densities increase, identifying potential failure mechanisms becomes increasingly complex, necessitating more sophisticated testing methodologies.

Industry projections suggest the SiC power semiconductor market will grow at a CAGR exceeding 30% through 2026, with automotive applications representing the largest segment. This growth trajectory underscores the urgent need for standardized, comprehensive testing protocols specifically designed for automotive-grade SiC MOSFETs.

The technical goals for advancing SiC MOSFET testing include developing accelerated life testing methods that accurately correlate with real-world performance, establishing standardized protocols for evaluating SiC-specific failure modes, and creating automated testing systems capable of high-throughput screening while maintaining precision in parameter measurement across temperature and voltage extremes.

The automotive industry's transition toward electrification has created unprecedented demand for power semiconductors capable of operating under extreme conditions while maintaining high efficiency. SiC MOSFETs, with their wide bandgap properties, offer substantial advantages over traditional silicon-based devices, including higher breakdown voltage, faster switching speeds, and superior thermal conductivity.

Testing methodologies for these devices, however, have not kept pace with their rapid technological advancement. Traditional silicon-based testing protocols prove inadequate for evaluating the unique characteristics and failure modes of SiC MOSFETs, particularly those destined for automotive applications where reliability requirements are exceptionally stringent.

The primary objective of SiC MOSFET testing is to ensure these devices can withstand the harsh automotive environment while maintaining performance throughout the vehicle's operational lifetime. This includes validation of their ability to function reliably under extreme temperature cycling, humidity, mechanical stress, and electromagnetic interference—all while meeting the automotive industry's AEC-Q101 qualification standards.

Current testing approaches face significant limitations in accurately predicting long-term reliability, particularly regarding gate oxide integrity, threshold voltage stability, and body diode degradation under repeated switching conditions. These challenges are compounded by the higher operating voltages and temperatures characteristic of SiC devices.

The technology trajectory indicates a continued miniaturization of SiC MOSFETs alongside increasing power density requirements, which will further intensify testing challenges. As die sizes decrease and current densities increase, identifying potential failure mechanisms becomes increasingly complex, necessitating more sophisticated testing methodologies.

Industry projections suggest the SiC power semiconductor market will grow at a CAGR exceeding 30% through 2026, with automotive applications representing the largest segment. This growth trajectory underscores the urgent need for standardized, comprehensive testing protocols specifically designed for automotive-grade SiC MOSFETs.

The technical goals for advancing SiC MOSFET testing include developing accelerated life testing methods that accurately correlate with real-world performance, establishing standardized protocols for evaluating SiC-specific failure modes, and creating automated testing systems capable of high-throughput screening while maintaining precision in parameter measurement across temperature and voltage extremes.

Automotive Market Requirements for SiC Power Devices

The automotive industry is undergoing a significant transformation with the electrification of vehicles, creating stringent requirements for power semiconductor devices. Silicon Carbide (SiC) MOSFETs have emerged as critical components in this evolution due to their superior performance characteristics compared to traditional silicon-based devices. Automotive applications demand exceptional reliability, efficiency, and performance under extreme conditions, establishing a unique set of market requirements for SiC power devices.

Vehicle manufacturers require SiC MOSFETs that can operate reliably across a wide temperature range, typically from -40°C to 175°C or higher. This temperature resilience is essential for under-hood applications where thermal management presents significant challenges. Additionally, these components must demonstrate robustness against thermal cycling, as automotive systems frequently experience temperature fluctuations during normal operation.

Reliability standards for automotive-grade SiC devices are exceptionally rigorous, with expected operational lifetimes of 15+ years and failure rates below 10 parts per billion. The Automotive Electronics Council (AEC) qualification standards, particularly AEC-Q101 for discrete semiconductors, establish baseline requirements that SiC MOSFETs must meet or exceed to be considered for automotive applications.

Energy efficiency represents another critical market requirement, with automotive manufacturers seeking SiC devices that minimize power losses to extend electric vehicle range. The higher switching frequencies enabled by SiC technology (typically 50-100 kHz compared to 20 kHz for silicon devices) allow for smaller passive components, reducing overall system size and weight—key considerations in vehicle design.

Cost considerations remain significant despite SiC's performance advantages. While automotive manufacturers recognize the value proposition of SiC technology, they continue to pressure suppliers for cost reductions to enable broader adoption across vehicle platforms. Current SiC solutions command a premium over silicon alternatives, though this gap is narrowing as manufacturing volumes increase.

Standardization and second-source availability have become increasingly important requirements as automotive manufacturers seek to mitigate supply chain risks. The industry prefers SiC MOSFETs with standardized footprints and electrical characteristics to enable multi-vendor sourcing strategies, reducing dependency on single suppliers.

Automotive applications also demand SiC devices with enhanced short-circuit withstand capability, typically requiring survival times of 2-5 microseconds under fault conditions. This requirement stems from the need to protect expensive power electronics systems and ensure passenger safety in the event of electrical faults.

Vehicle manufacturers require SiC MOSFETs that can operate reliably across a wide temperature range, typically from -40°C to 175°C or higher. This temperature resilience is essential for under-hood applications where thermal management presents significant challenges. Additionally, these components must demonstrate robustness against thermal cycling, as automotive systems frequently experience temperature fluctuations during normal operation.

Reliability standards for automotive-grade SiC devices are exceptionally rigorous, with expected operational lifetimes of 15+ years and failure rates below 10 parts per billion. The Automotive Electronics Council (AEC) qualification standards, particularly AEC-Q101 for discrete semiconductors, establish baseline requirements that SiC MOSFETs must meet or exceed to be considered for automotive applications.

Energy efficiency represents another critical market requirement, with automotive manufacturers seeking SiC devices that minimize power losses to extend electric vehicle range. The higher switching frequencies enabled by SiC technology (typically 50-100 kHz compared to 20 kHz for silicon devices) allow for smaller passive components, reducing overall system size and weight—key considerations in vehicle design.

Cost considerations remain significant despite SiC's performance advantages. While automotive manufacturers recognize the value proposition of SiC technology, they continue to pressure suppliers for cost reductions to enable broader adoption across vehicle platforms. Current SiC solutions command a premium over silicon alternatives, though this gap is narrowing as manufacturing volumes increase.

Standardization and second-source availability have become increasingly important requirements as automotive manufacturers seek to mitigate supply chain risks. The industry prefers SiC MOSFETs with standardized footprints and electrical characteristics to enable multi-vendor sourcing strategies, reducing dependency on single suppliers.

Automotive applications also demand SiC devices with enhanced short-circuit withstand capability, typically requiring survival times of 2-5 microseconds under fault conditions. This requirement stems from the need to protect expensive power electronics systems and ensure passenger safety in the event of electrical faults.

Current Testing Limitations and Technical Barriers

Despite significant advancements in SiC MOSFET technology, current testing methodologies face substantial limitations when evaluating automotive-grade devices. Traditional testing approaches developed for silicon-based power devices prove inadequate for accurately assessing the unique characteristics and failure modes of SiC MOSFETs. The higher operating temperatures, faster switching speeds, and different physical properties of SiC material create fundamental challenges for existing test equipment and protocols.

One critical limitation is the insufficient bandwidth of conventional test equipment. SiC MOSFETs operate at significantly higher switching frequencies (often exceeding 100 kHz) compared to silicon counterparts, requiring test equipment with bandwidth capabilities beyond what is commonly available in standard testing facilities. This limitation prevents accurate characterization of dynamic parameters and switching losses under realistic operating conditions.

Temperature-dependent testing represents another major barrier. While automotive applications demand reliable operation across extreme temperature ranges (-40°C to 175°C or higher), most testing equipment struggles to maintain stable measurement accuracy across this wide temperature spectrum. The thermal conductivity differences between SiC and Si further complicate the development of standardized thermal testing methodologies that accurately reflect real-world performance.

Gate oxide reliability testing faces particular challenges due to the fundamentally different interface properties between SiC and SiO2. Current accelerated lifetime testing protocols developed for silicon devices fail to accurately predict long-term reliability issues specific to SiC MOSFETs, such as threshold voltage instability and gate oxide degradation mechanisms that manifest differently in SiC-based structures.

Avalanche and short-circuit testing methodologies also require significant adaptation. The higher critical electric field strength of SiC enables devices to withstand substantially higher voltage stresses, but existing test equipment often lacks sufficient energy capacity to properly evaluate these limits. Additionally, the extremely fast short-circuit current rise times in SiC MOSFETs (often <100ns) exceed the response capabilities of many protection circuits in test systems.

Standardization presents another significant barrier. Unlike silicon power devices with well-established testing standards developed over decades, SiC MOSFETs lack comprehensive, universally accepted qualification standards specifically designed for automotive applications. This creates inconsistencies in how manufacturers report device parameters and reliability data, making direct comparisons challenging for automotive system designers.

Finally, accelerated lifetime testing faces fundamental limitations. The exceptional theoretical lifetime of SiC devices makes traditional acceleration factors less effective, requiring either extremely harsh test conditions that may introduce unrealistic failure modes or prohibitively long test durations that impede time-to-market requirements for automotive qualification.

One critical limitation is the insufficient bandwidth of conventional test equipment. SiC MOSFETs operate at significantly higher switching frequencies (often exceeding 100 kHz) compared to silicon counterparts, requiring test equipment with bandwidth capabilities beyond what is commonly available in standard testing facilities. This limitation prevents accurate characterization of dynamic parameters and switching losses under realistic operating conditions.

Temperature-dependent testing represents another major barrier. While automotive applications demand reliable operation across extreme temperature ranges (-40°C to 175°C or higher), most testing equipment struggles to maintain stable measurement accuracy across this wide temperature spectrum. The thermal conductivity differences between SiC and Si further complicate the development of standardized thermal testing methodologies that accurately reflect real-world performance.

Gate oxide reliability testing faces particular challenges due to the fundamentally different interface properties between SiC and SiO2. Current accelerated lifetime testing protocols developed for silicon devices fail to accurately predict long-term reliability issues specific to SiC MOSFETs, such as threshold voltage instability and gate oxide degradation mechanisms that manifest differently in SiC-based structures.

Avalanche and short-circuit testing methodologies also require significant adaptation. The higher critical electric field strength of SiC enables devices to withstand substantially higher voltage stresses, but existing test equipment often lacks sufficient energy capacity to properly evaluate these limits. Additionally, the extremely fast short-circuit current rise times in SiC MOSFETs (often <100ns) exceed the response capabilities of many protection circuits in test systems.

Standardization presents another significant barrier. Unlike silicon power devices with well-established testing standards developed over decades, SiC MOSFETs lack comprehensive, universally accepted qualification standards specifically designed for automotive applications. This creates inconsistencies in how manufacturers report device parameters and reliability data, making direct comparisons challenging for automotive system designers.

Finally, accelerated lifetime testing faces fundamental limitations. The exceptional theoretical lifetime of SiC devices makes traditional acceleration factors less effective, requiring either extremely harsh test conditions that may introduce unrealistic failure modes or prohibitively long test durations that impede time-to-market requirements for automotive qualification.

Standard Testing Protocols for Automotive-Grade SiC MOSFETs

01 High-temperature and high-voltage testing challenges

SiC MOSFETs require specialized testing under extreme conditions due to their high-temperature and high-voltage operating capabilities. Testing equipment must be designed to handle these conditions safely while accurately measuring device performance parameters. The challenges include developing test fixtures that can withstand high temperatures without degradation and implementing proper isolation techniques for high-voltage testing to ensure accurate measurements and operator safety.- High-temperature testing challenges for SiC MOSFETs: Silicon Carbide (SiC) MOSFETs require specialized testing at elevated temperatures to evaluate their performance characteristics and reliability. The high-temperature testing presents unique challenges including thermal management, accurate measurement of electrical parameters under extreme conditions, and assessment of device degradation mechanisms. Testing methodologies must account for the wide bandgap semiconductor properties and their behavior at temperatures exceeding those of traditional silicon devices.

- Gate oxide reliability testing methods: Testing the reliability of gate oxides in SiC MOSFETs presents significant challenges due to the interface between SiC and SiO2. Specialized testing protocols are required to evaluate threshold voltage stability, channel mobility degradation, and oxide breakdown characteristics. These methods include bias temperature stress tests, time-dependent dielectric breakdown measurements, and charge trapping analysis to ensure long-term reliability of the devices under various operating conditions.

- Switching performance characterization techniques: Characterizing the switching performance of SiC MOSFETs requires advanced testing techniques due to their fast switching speeds and high dv/dt and di/dt rates. Testing challenges include accurate measurement of switching losses, evaluation of parasitic inductances, and assessment of dynamic on-resistance. Specialized equipment with high bandwidth and low parasitic elements is necessary to capture the rapid transitions and accurately measure switching parameters under various load conditions.

- Automated test systems for SiC device qualification: Developing automated test systems for SiC MOSFET qualification presents challenges in terms of test sequence design, data acquisition, and analysis. These systems must integrate multiple test types including static parameter measurements, dynamic characterization, and reliability stress testing. The automation needs to handle high-voltage, high-temperature conditions while maintaining measurement accuracy and ensuring safety protocols during the qualification process.

- Short-circuit and avalanche ruggedness testing: Testing the ruggedness of SiC MOSFETs under short-circuit and avalanche conditions requires specialized methodologies to evaluate device failure modes and safe operating areas. These tests must accurately control energy dissipation while monitoring critical parameters such as temperature, current, and voltage during extreme stress conditions. The challenges include developing non-destructive test methods, establishing standardized test protocols, and correlating test results with actual application requirements to ensure reliable operation in power electronic systems.

02 Gate oxide reliability testing methods

Testing the reliability of gate oxide in SiC MOSFETs presents unique challenges due to the interface between SiC and SiO2. Specialized testing protocols are needed to evaluate threshold voltage stability, bias temperature instability, and time-dependent dielectric breakdown. These tests must account for the different defect mechanisms in SiC compared to traditional silicon devices, requiring longer test durations and more sophisticated measurement techniques to accurately predict device lifetime and performance degradation.Expand Specific Solutions03 Dynamic characterization and switching performance evaluation

Evaluating the dynamic performance of SiC MOSFETs requires specialized test setups to accurately measure fast switching transients and high dv/dt and di/dt rates. Testing challenges include minimizing parasitic inductances in test fixtures, implementing precise gate drive circuits, and developing measurement systems with sufficient bandwidth. Advanced techniques are needed to characterize switching losses, ringing phenomena, and short-circuit behavior under various operating conditions.Expand Specific Solutions04 Automated test systems for SiC device qualification

Developing automated test systems for SiC MOSFET qualification requires specialized hardware and software solutions. These systems must integrate high-temperature testing capabilities, precise measurement instruments, and robust safety mechanisms. Challenges include designing test sequences that comprehensively evaluate all critical parameters, implementing efficient data collection and analysis methods, and ensuring test repeatability across different production batches to maintain quality standards.Expand Specific Solutions05 Reliability and accelerated lifetime testing methodologies

Developing effective accelerated lifetime testing methodologies for SiC MOSFETs presents significant challenges due to their inherent reliability and different failure mechanisms compared to silicon devices. Testing must account for unique degradation modes related to the SiC/SiO2 interface, body diode reliability, and package-related issues. Challenges include determining appropriate acceleration factors, correlating accelerated test results with real-world performance, and developing standardized test protocols that accurately predict long-term reliability under various operating conditions.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The SiC MOSFET automotive testing market is experiencing rapid growth in an early maturity phase, driven by electric vehicle adoption and demand for high-efficiency power electronics. Market size is projected to expand significantly as automotive manufacturers increasingly integrate SiC technology into powertrains and charging systems. Leading companies like Wolfspeed, ROHM, and Mitsubishi Electric have established strong technological positions, while newer entrants such as Huawei and Chinese manufacturers are gaining ground. Testing challenges remain around reliability verification, thermal performance, and gate oxide stability. Academic-industry partnerships between universities like Chongqing University and companies like Bosch are accelerating testing methodology development to address the unique requirements of automotive-grade qualification for wide bandgap semiconductors.

Wolfspeed, Inc.

Technical Solution: Wolfspeed has developed comprehensive testing methodologies specifically for automotive-grade SiC MOSFETs that address the unique challenges of these devices. Their approach includes accelerated lifetime testing protocols that simulate extreme operating conditions, including high-temperature gate bias (HTGB) and high-temperature reverse bias (HTRB) tests to evaluate long-term reliability. Wolfspeed implements specialized threshold voltage stability testing to address the Vth drift issues common in SiC devices, using advanced measurement techniques that can detect subtle changes over thousands of operating hours. Their testing infrastructure incorporates custom-designed automated test equipment capable of characterizing devices across the full automotive temperature range (-40°C to 175°C) while simultaneously monitoring multiple electrical parameters. Additionally, Wolfspeed has pioneered short-circuit withstand time (SCWT) testing methodologies that accurately assess device robustness under fault conditions, which is critical for automotive safety applications.

Strengths: Industry-leading expertise in SiC technology with vertically integrated manufacturing allowing for comprehensive quality control throughout the testing process. Their testing protocols exceed AEC-Q101 requirements, providing higher reliability assurance. Weaknesses: Their rigorous testing approaches can increase time-to-market and production costs compared to competitors with less stringent methodologies.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has developed a sophisticated testing framework for automotive-grade SiC MOSFETs that addresses the unique challenges associated with these wide bandgap devices. Their approach includes enhanced gate oxide reliability testing using specialized time-dependent dielectric breakdown (TDDB) methodologies calibrated specifically for SiC's material properties and higher electric field strengths. Mitsubishi implements advanced threshold voltage stability monitoring using automated measurement systems that can detect subtle shifts over extended test periods under various bias and temperature conditions. Their testing protocols include comprehensive body diode characterization to evaluate forward voltage stability during repeated switching cycles, addressing a common reliability concern in SiC devices. Mitsubishi has developed custom test equipment for short-circuit evaluation that can precisely control energy dissipation during fault events while monitoring multiple device parameters at high temporal resolution. Additionally, they conduct extensive switching performance characterization under various inductive load conditions to assess robustness against voltage overshoots and ringing effects that are more pronounced with SiC's faster switching capabilities. Their testing infrastructure includes specialized power cycling equipment designed to evaluate module-level reliability, with particular attention to die-attach integrity and interconnect reliability under automotive thermal cycling conditions.

Strengths: Extensive experience in power semiconductor manufacturing with specialized knowledge in automotive applications. Their testing approach combines traditional qualification methods with application-specific stress testing tailored to automotive requirements. Weaknesses: Their testing methodologies may be more focused on module-level reliability rather than discrete device characterization, potentially overlooking some device-level failure mechanisms.

Critical Testing Parameters and Reliability Assessment

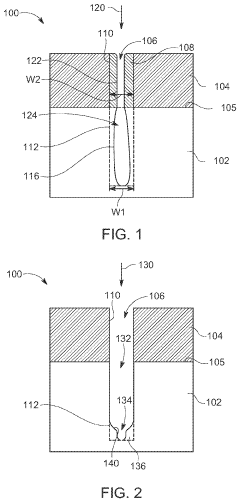

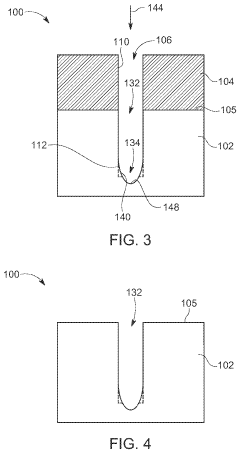

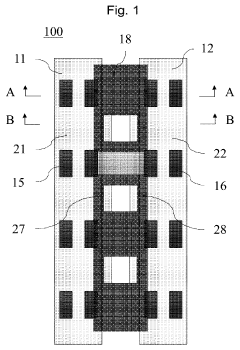

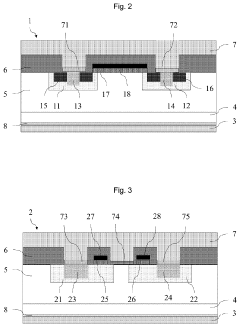

SiC MOSFET Including Trench with Rounded Corners

PatentPendingUS20240079236A1

Innovation

- An ion implantation process is used to increase the etch rate of a central portion of the SiC layer, followed by a dual-etch process to create a U-shape trench with a flat bottom, involving a masking layer, sidewall spacer, and selective ion implantation to form an implant region, which enhances etch rate and trench shaping.

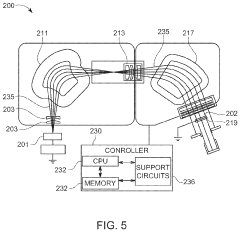

Silicon carbide metal oxide semiconductor field effect transistor and manufacturing method of silicon carbide metal oxide semiconductor field effect transistor

PatentPendingUS20230378341A1

Innovation

- The design incorporates alternating cells with specific well regions, source regions, and contact layers, including ohmic and Schottky contacts, to reduce channel density, enhance short-circuit tolerance, and minimize reverse leakage current and forward voltage drop, while maintaining the transistor's size and functionality.

Automotive Safety Standards and Compliance Requirements

Automotive safety standards play a crucial role in the qualification and implementation of SiC MOSFETs in vehicle applications. The automotive industry adheres to stringent safety requirements defined by standards such as ISO 26262, which establishes the Automotive Safety Integrity Levels (ASIL) framework for functional safety. For SiC MOSFET testing, compliance with these standards necessitates comprehensive validation procedures that exceed those of standard power semiconductors.

The AEC-Q101 qualification standard specifically addresses discrete semiconductors for automotive applications, outlining rigorous testing protocols for SiC MOSFETs. These include temperature cycling, high-temperature reverse bias, high-temperature gate bias, and various environmental stress tests. SiC MOSFETs must demonstrate reliability under these extreme conditions to achieve qualification status.

Beyond AEC-Q101, manufacturers must consider additional standards like ISO/TS 16949 for quality management systems and IEC 60747 for semiconductor device specifications. The challenge lies in adapting these established standards to address the unique characteristics of SiC technology, as many were originally developed for silicon-based devices.

Compliance with EMC (Electromagnetic Compatibility) requirements presents another significant challenge. SiC MOSFETs operate at higher switching frequencies than traditional silicon devices, potentially generating increased electromagnetic interference. Testing must verify compliance with standards such as CISPR 25 and ISO 11452 to ensure these devices do not compromise vehicle electronic systems.

Functional safety validation requires demonstrating that SiC MOSFETs maintain safe operation even under fault conditions. This includes analyzing failure modes, effects, and diagnostic coverage according to ISO 26262 methodologies. Manufacturers must establish safety goals, perform hazard analyses, and implement appropriate safety mechanisms to achieve the required ASIL levels.

The automotive industry's trend toward higher voltage systems (48V, 400V, and 800V architectures) introduces additional compliance challenges. Standards like LV 123 and LV 148 define specific requirements for high-voltage components in electric vehicles. SiC MOSFET testing must verify isolation capabilities, creepage and clearance distances, and performance under high-voltage transient conditions.

Cybersecurity considerations are increasingly important as vehicles become more connected. Standards like ISO/SAE 21434 establish requirements for cybersecurity engineering, which may impact the testing of power electronics systems incorporating SiC MOSFETs, particularly in battery management and powertrain control applications.

The AEC-Q101 qualification standard specifically addresses discrete semiconductors for automotive applications, outlining rigorous testing protocols for SiC MOSFETs. These include temperature cycling, high-temperature reverse bias, high-temperature gate bias, and various environmental stress tests. SiC MOSFETs must demonstrate reliability under these extreme conditions to achieve qualification status.

Beyond AEC-Q101, manufacturers must consider additional standards like ISO/TS 16949 for quality management systems and IEC 60747 for semiconductor device specifications. The challenge lies in adapting these established standards to address the unique characteristics of SiC technology, as many were originally developed for silicon-based devices.

Compliance with EMC (Electromagnetic Compatibility) requirements presents another significant challenge. SiC MOSFETs operate at higher switching frequencies than traditional silicon devices, potentially generating increased electromagnetic interference. Testing must verify compliance with standards such as CISPR 25 and ISO 11452 to ensure these devices do not compromise vehicle electronic systems.

Functional safety validation requires demonstrating that SiC MOSFETs maintain safe operation even under fault conditions. This includes analyzing failure modes, effects, and diagnostic coverage according to ISO 26262 methodologies. Manufacturers must establish safety goals, perform hazard analyses, and implement appropriate safety mechanisms to achieve the required ASIL levels.

The automotive industry's trend toward higher voltage systems (48V, 400V, and 800V architectures) introduces additional compliance challenges. Standards like LV 123 and LV 148 define specific requirements for high-voltage components in electric vehicles. SiC MOSFET testing must verify isolation capabilities, creepage and clearance distances, and performance under high-voltage transient conditions.

Cybersecurity considerations are increasingly important as vehicles become more connected. Standards like ISO/SAE 21434 establish requirements for cybersecurity engineering, which may impact the testing of power electronics systems incorporating SiC MOSFETs, particularly in battery management and powertrain control applications.

Cost-Benefit Analysis of Advanced Testing Solutions

The implementation of advanced testing methodologies for SiC MOSFETs in automotive applications necessitates a thorough cost-benefit analysis to justify the significant investment required. Initial setup costs for specialized SiC testing equipment can range from $500,000 to over $2 million, depending on the comprehensiveness of the testing suite and automation capabilities. This substantial capital expenditure must be evaluated against the long-term benefits and risk mitigation potential.

When analyzing operational expenses, advanced testing solutions typically increase per-unit testing costs by 15-30% compared to traditional silicon MOSFET testing. However, these higher costs must be contextualized within the automotive qualification framework, where field failures can result in exponentially higher expenses through recalls, warranty claims, and brand damage. Studies indicate that detecting a defect during component testing costs approximately 10x less than finding it during system integration, and 100x less than addressing it post-production.

The economic benefits of comprehensive testing become particularly evident when considering the high-reliability requirements of automotive applications. Advanced testing solutions that can accurately predict SiC MOSFET performance under extreme conditions and over extended lifetimes provide significant value through reduced field failure rates. Industry data suggests that improving defect detection rates by just 5% can result in warranty cost reductions exceeding $10 million annually for high-volume automotive manufacturers.

Return on investment calculations must account for both tangible and intangible benefits. While the direct cost savings from reduced field failures and warranty claims are quantifiable, the competitive advantage gained through enhanced reliability reputation represents a significant but less easily measured benefit. Market analysis indicates that automotive OEMs increasingly prioritize suppliers with proven reliability testing capabilities, potentially translating to premium pricing opportunities and preferred supplier status.

The scalability of testing solutions also impacts the cost-benefit equation. Modular testing platforms that can be expanded or reconfigured as testing requirements evolve offer better long-term value despite higher initial costs. Additionally, testing solutions with data analytics capabilities provide valuable insights for continuous improvement, potentially reducing future testing costs while enhancing effectiveness.

For automotive manufacturers considering in-house versus outsourced testing, the analysis must include facility requirements, personnel expertise, and utilization rates. Third-party testing services may offer cost advantages for lower-volume manufacturers, while high-volume producers typically benefit from establishing internal capabilities despite the higher fixed costs.

When analyzing operational expenses, advanced testing solutions typically increase per-unit testing costs by 15-30% compared to traditional silicon MOSFET testing. However, these higher costs must be contextualized within the automotive qualification framework, where field failures can result in exponentially higher expenses through recalls, warranty claims, and brand damage. Studies indicate that detecting a defect during component testing costs approximately 10x less than finding it during system integration, and 100x less than addressing it post-production.

The economic benefits of comprehensive testing become particularly evident when considering the high-reliability requirements of automotive applications. Advanced testing solutions that can accurately predict SiC MOSFET performance under extreme conditions and over extended lifetimes provide significant value through reduced field failure rates. Industry data suggests that improving defect detection rates by just 5% can result in warranty cost reductions exceeding $10 million annually for high-volume automotive manufacturers.

Return on investment calculations must account for both tangible and intangible benefits. While the direct cost savings from reduced field failures and warranty claims are quantifiable, the competitive advantage gained through enhanced reliability reputation represents a significant but less easily measured benefit. Market analysis indicates that automotive OEMs increasingly prioritize suppliers with proven reliability testing capabilities, potentially translating to premium pricing opportunities and preferred supplier status.

The scalability of testing solutions also impacts the cost-benefit equation. Modular testing platforms that can be expanded or reconfigured as testing requirements evolve offer better long-term value despite higher initial costs. Additionally, testing solutions with data analytics capabilities provide valuable insights for continuous improvement, potentially reducing future testing costs while enhancing effectiveness.

For automotive manufacturers considering in-house versus outsourced testing, the analysis must include facility requirements, personnel expertise, and utilization rates. Third-party testing services may offer cost advantages for lower-volume manufacturers, while high-volume producers typically benefit from establishing internal capabilities despite the higher fixed costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!