An installation tool for a compressor vane ring and a method for using the same

An installation tool and a technology for stator blade rings, which are applied in the field of installation tools for compressor stator blade rings, can solve the problems of low installation efficiency of stator blade rings, and achieve the effects of high work efficiency and simple use methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

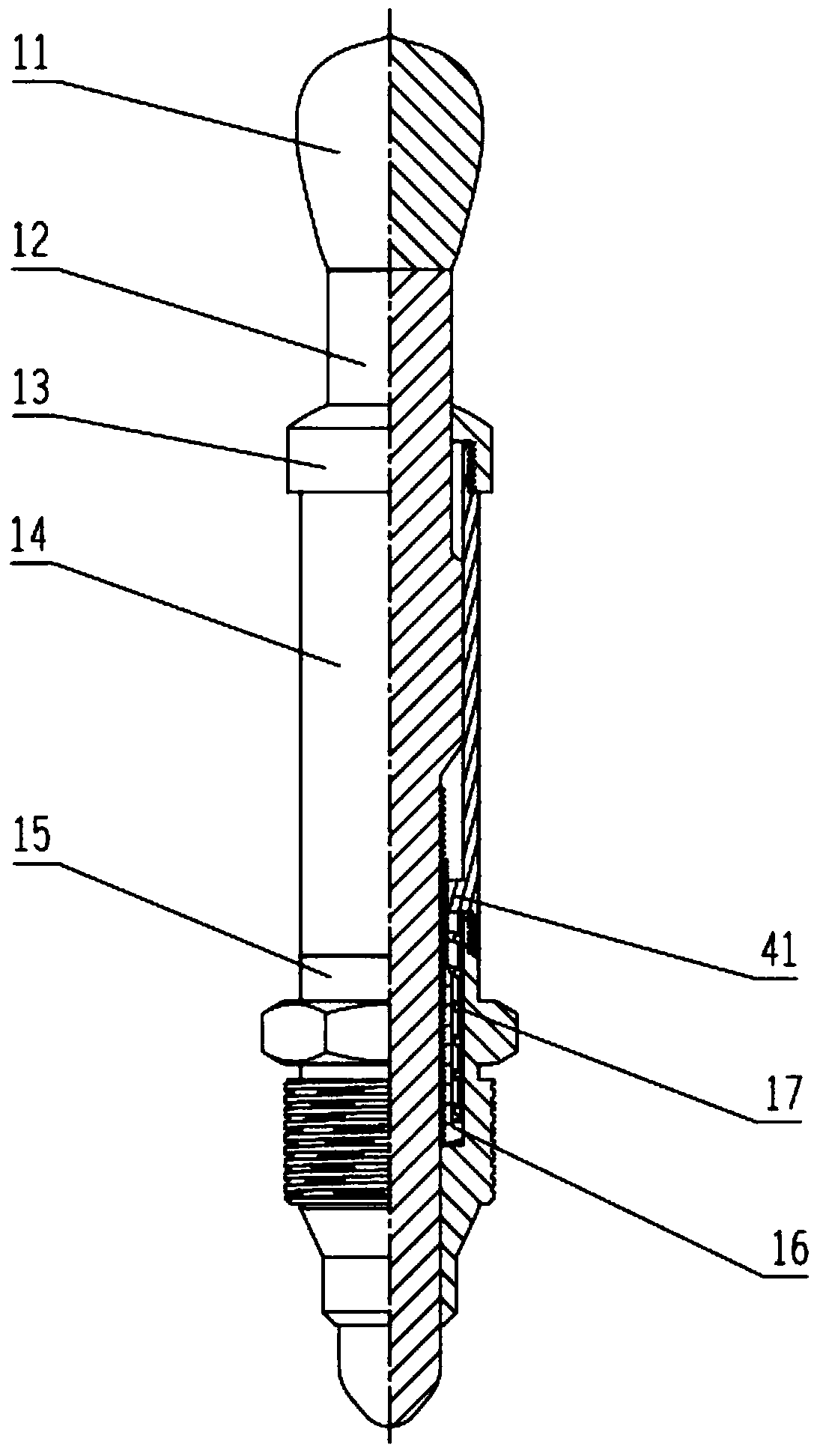

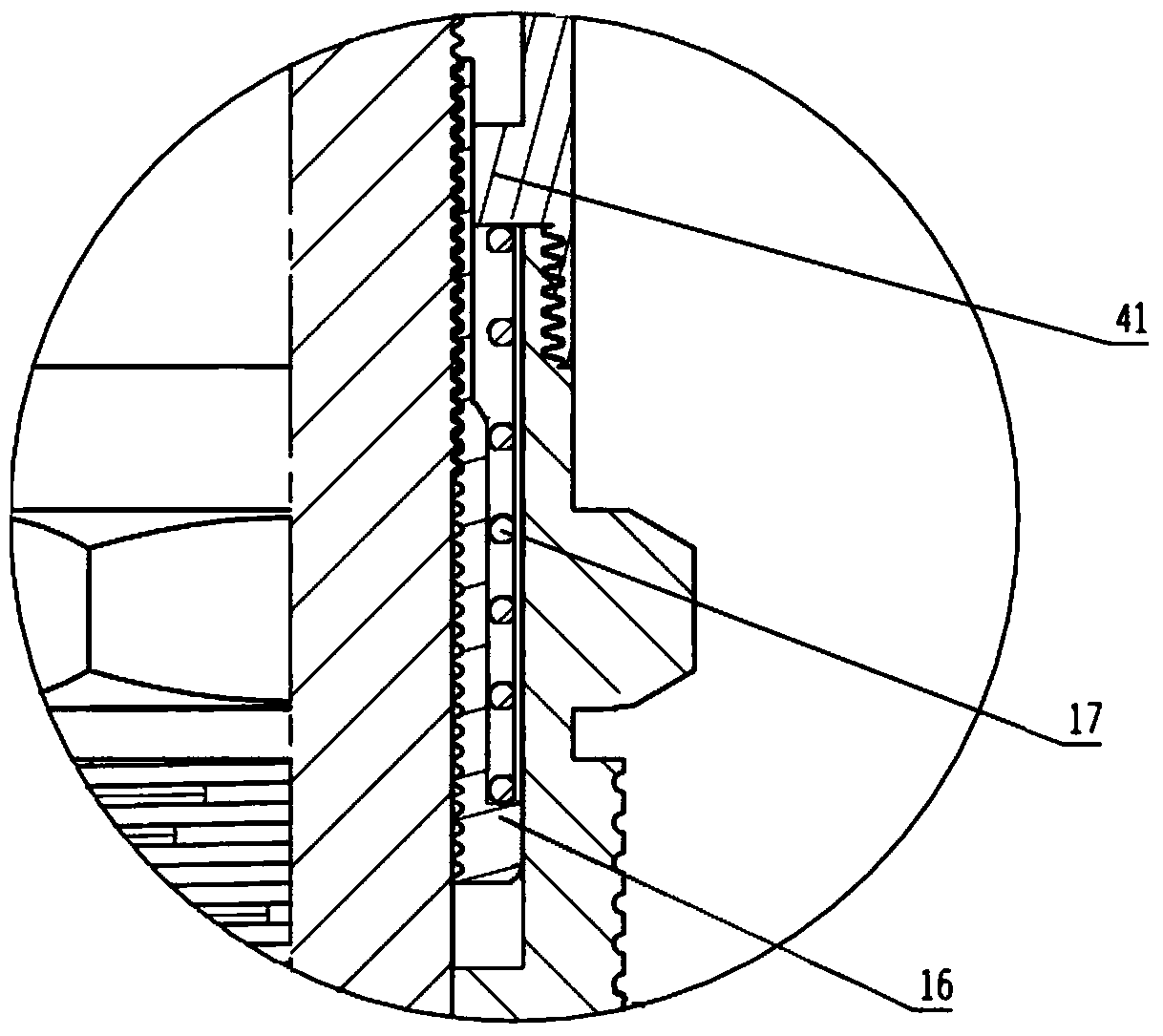

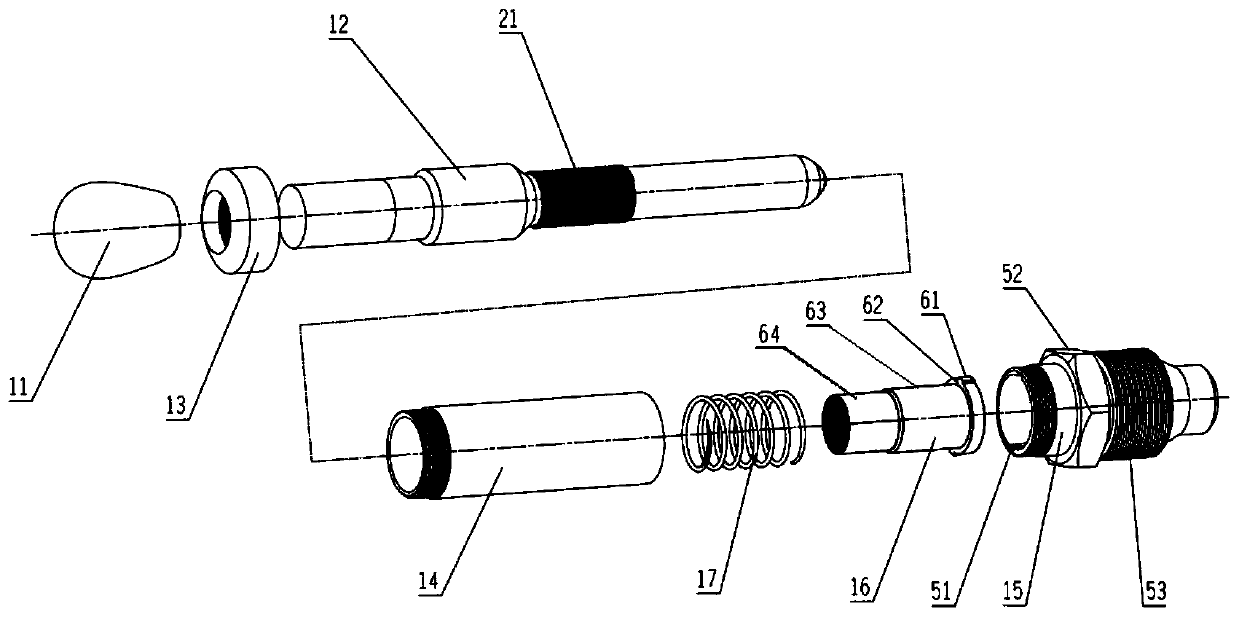

[0044] Such as Figure 1-3 As shown, the installation tool for the compressor vane ring provided by the embodiment of the present invention includes a thimble 12 , a cover 13 , a first sleeve 14 , a second sleeve 15 and a moving ring 16 arranged coaxially.

[0045] The cover 13, the first sleeve 14, and the second sleeve 15 are sequentially connected from top to bottom, the bottom inner wall of the cover 13 and the bottom inner wall of the first sleeve 14 are provided with internal threads, and the top of the first sleeve 14 The outer wall and the top outer wall of the second sleeve 15 are provided with external threads, so that the cover 13, the first sleeve 14 and the second sleeve 15 can be threaded in sequence. The thimble 12 passes through the cover 13, the first sleeve 14, the second sleeve 15 and the moving ring 16, and the moving ring 16 is inserted in the inner cavity of the first sleeve 14 and the second sleeve 15, and the thimble 12 is installed The corresponding p...

Embodiment 2

[0054] An embodiment of the present invention provides a method for using an installation tool for a compressor vane ring, such as Figure 4 shown, including the following steps:

[0055] S1. Rotate the handle 11, retract the thimble 12 into the second sleeve 15, then insert the second sleeve 15 into the radial hole of the compressor casing 2 where the vane ring section 3 needs to be installed and fix it; The method for fixing the second sleeve 15 on the radial hole is to twist the fixing portion 52 on the second sleeve 15 so that the external thread 53 on the second sleeve 15 cooperates with the compressor housing 2 .

[0056] S2. Insert the stationary vane ring segment 3 to be installed into the ring groove of the compressor casing 2, slide the stationary vane ring segment 3, and stop sliding when the slip ring of the stationary vane ring segment 3 completely covers the radial hole. Dynamic and static leaf ring segment 3;

[0057] S3. Rotate the handle 11 to move the thimb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com