Method for Determining Outline Dimensions of Stretch Bending Die

A technology for drawing and bending molds and determining methods, which is applied in the direction of instruments, geometric CAD, calculations, etc., can solve problems such as inaccurate outline size design, and achieve the effects of shortening the development cycle, improving accuracy, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

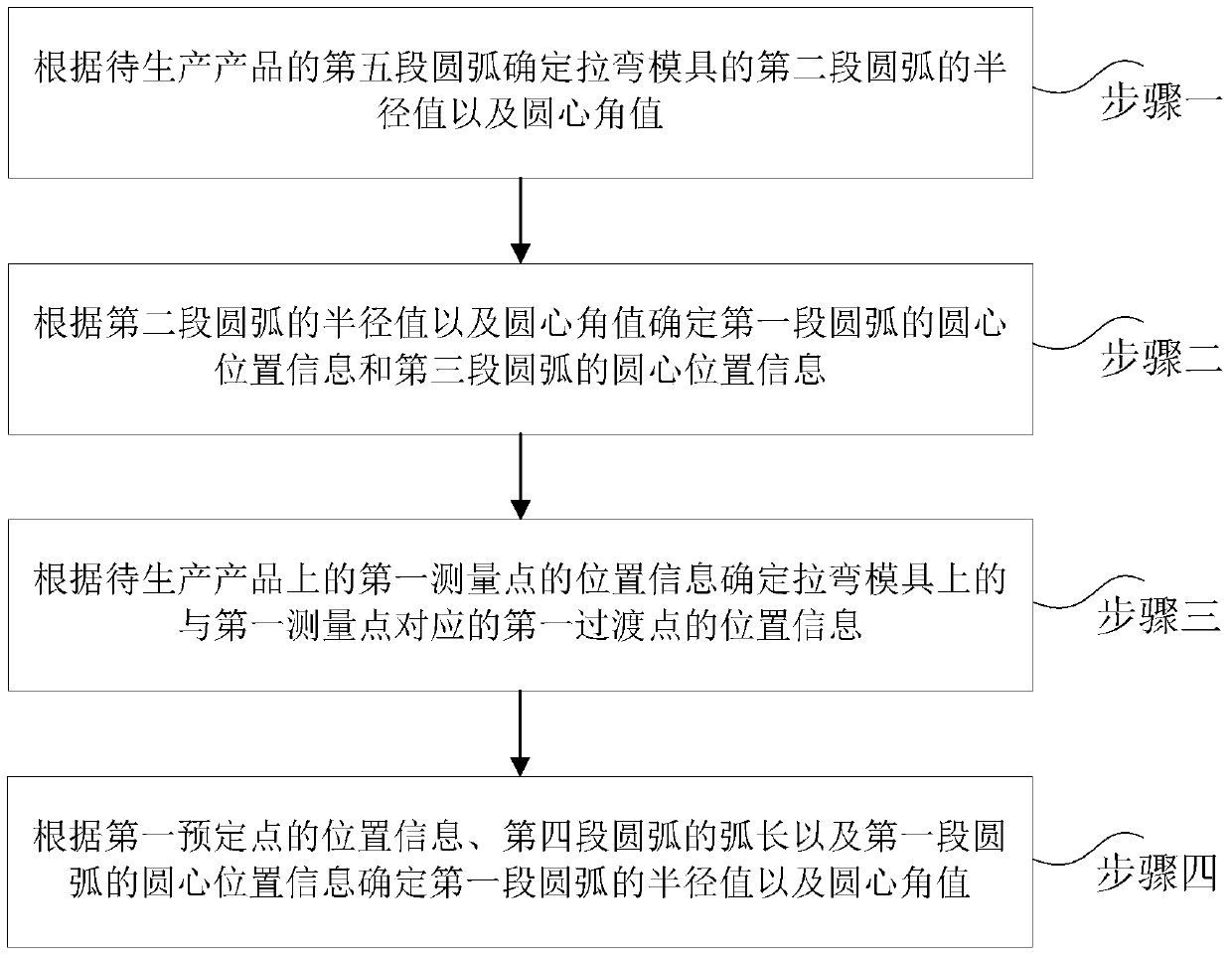

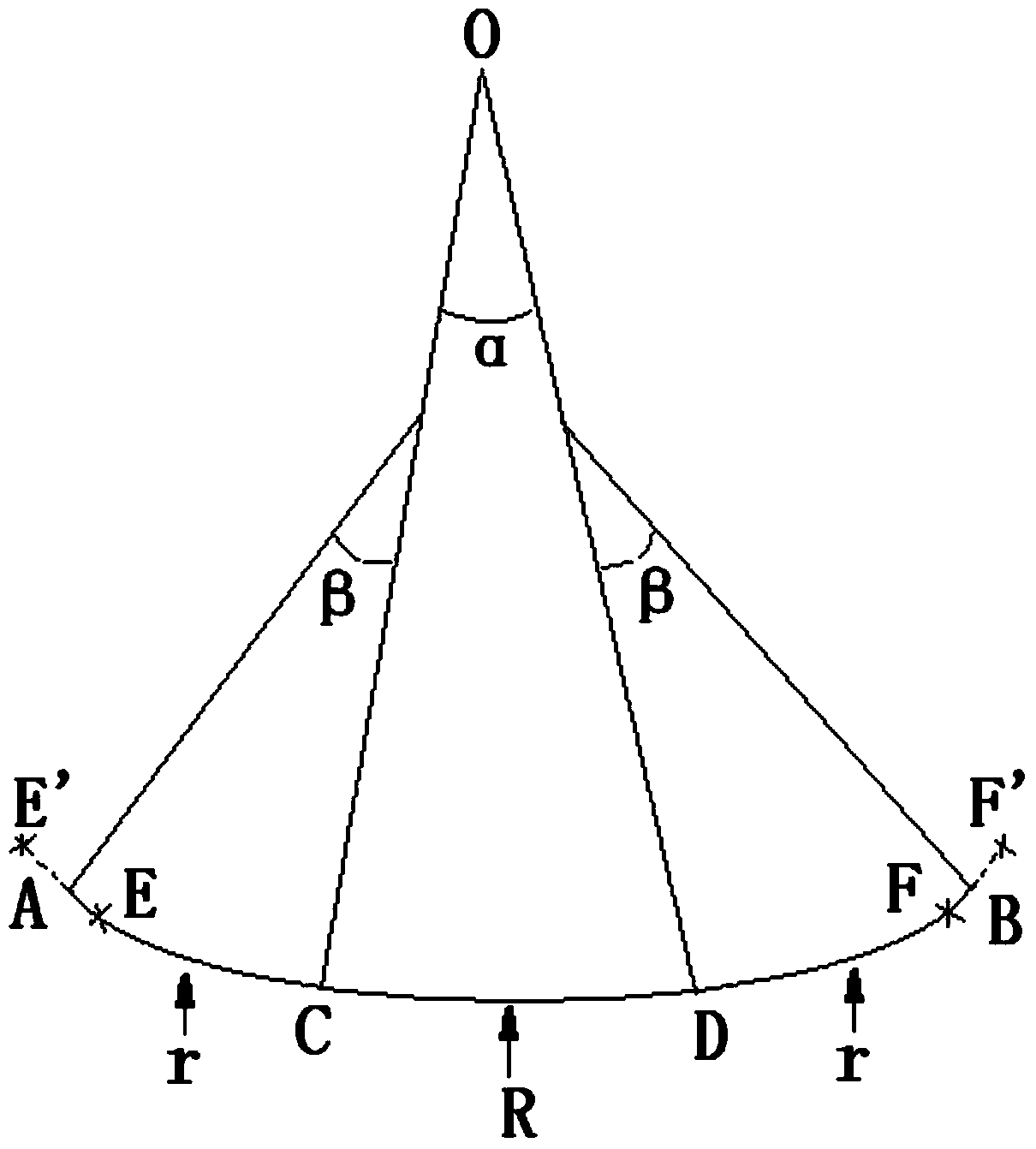

[0027] Such as figure 1 As shown, the embodiment of the present invention is a method for determining the contour size of a stretch bending die. Since the product to be produced is a three-segment arc, when designing the die, it is also designed to be a three-segment arc. Specifically, the stretch-bending die includes a first section of arc, a second section of arc and a third section of arc connected in sequence, the structure of the first section of the stretch-bending mold and the structure of the third section of the stretch-bending mold The arcs have the same structure, that is, the radius and central angle of the first segment of the arc of the stretch bending die are the same as the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com