Full-automatic lock body

A fully automatic, lock-body technology, applied in the field of door locks, can solve the problems of uneven quality of lithium batteries, high power consumption, uneven quality, etc., and achieve the effect of high degree of automation, compact size and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

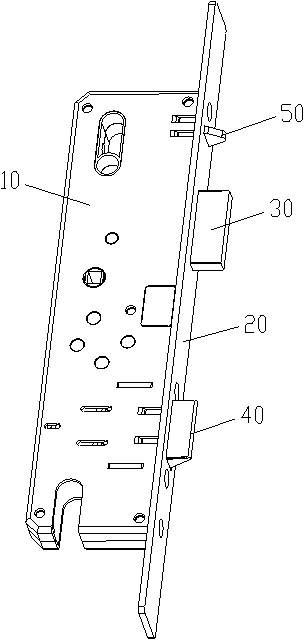

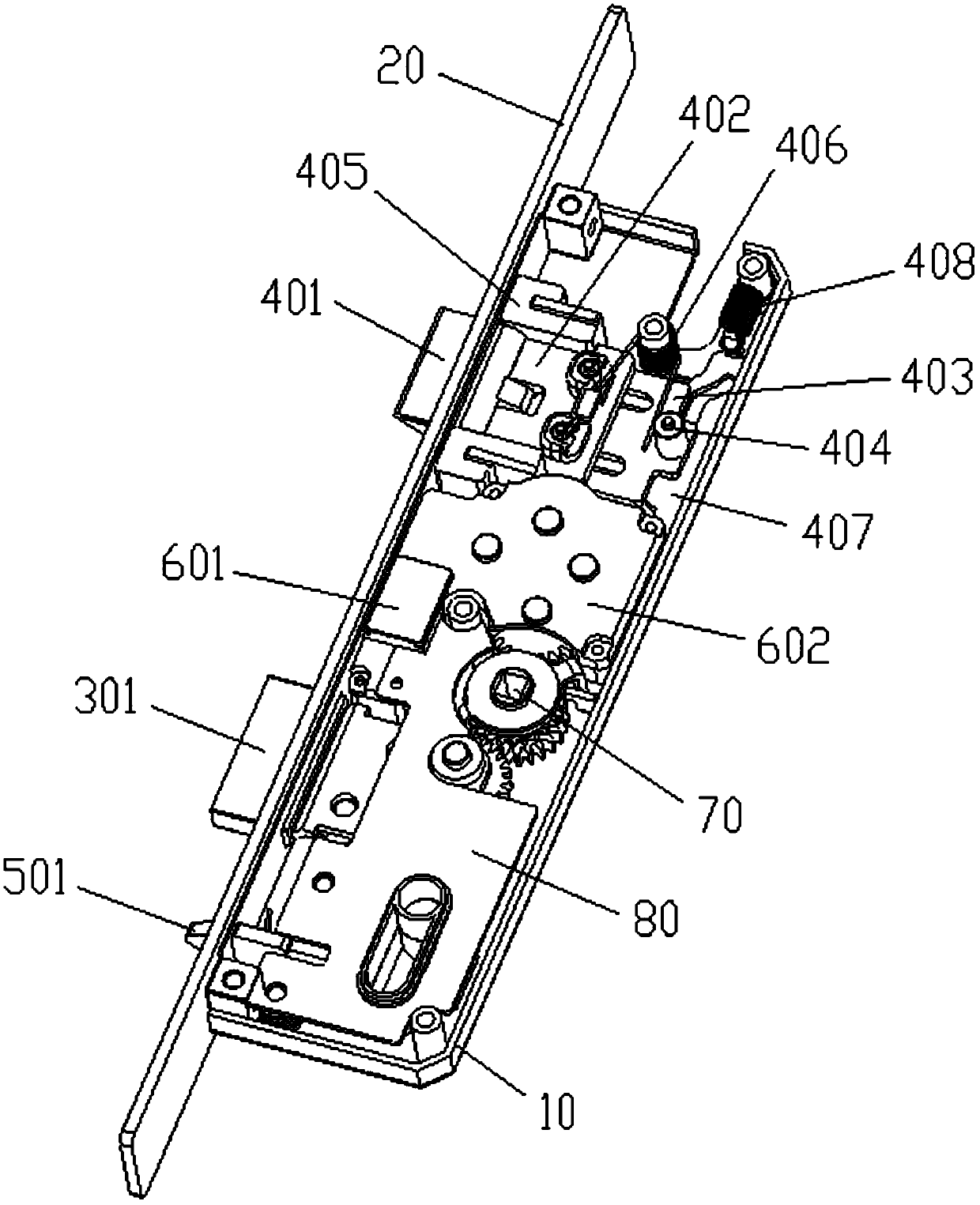

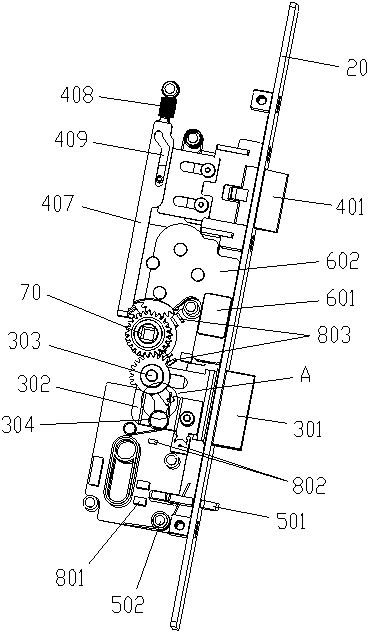

[0037] Such as Figure 1~3As shown, the present invention provides a fully automatic lock body, which includes a lock housing 10, a lock body side plate 20, a main tongue assembly 30, a rolling tongue assembly 40, a detection assembly 50, a driving device 60, a logic gear set 70 and a programmable Among them, the control circuit board 80, the lock body side plate 20 is placed on the side of the lock housing 10 for the installation of the lock body; the main tongue assembly 30 is placed inside the lock body 10 for locking the door body; the rolling tongue assembly 40 is placed One side of the main tongue assembly 30 is used to assist the main tongue assembly 30 to lock the door body; the detection assembly 50 is placed on the other side of the main tongue assembly 30 for detecting the position of the main tongue assembly 30 when it is in a stable state; the driving device 60 is placed between the main tongue assembly 30 and the rolling tongue assembly 40 to provide power for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com