High-power LED (light emitting diode) light emitting device package structure

A light-emitting device packaging and high-power technology, applied in the direction of electric solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of difficult control of consistency, loss of light efficiency, complex process, etc., to overcome poor consistency and simplify the process and the effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

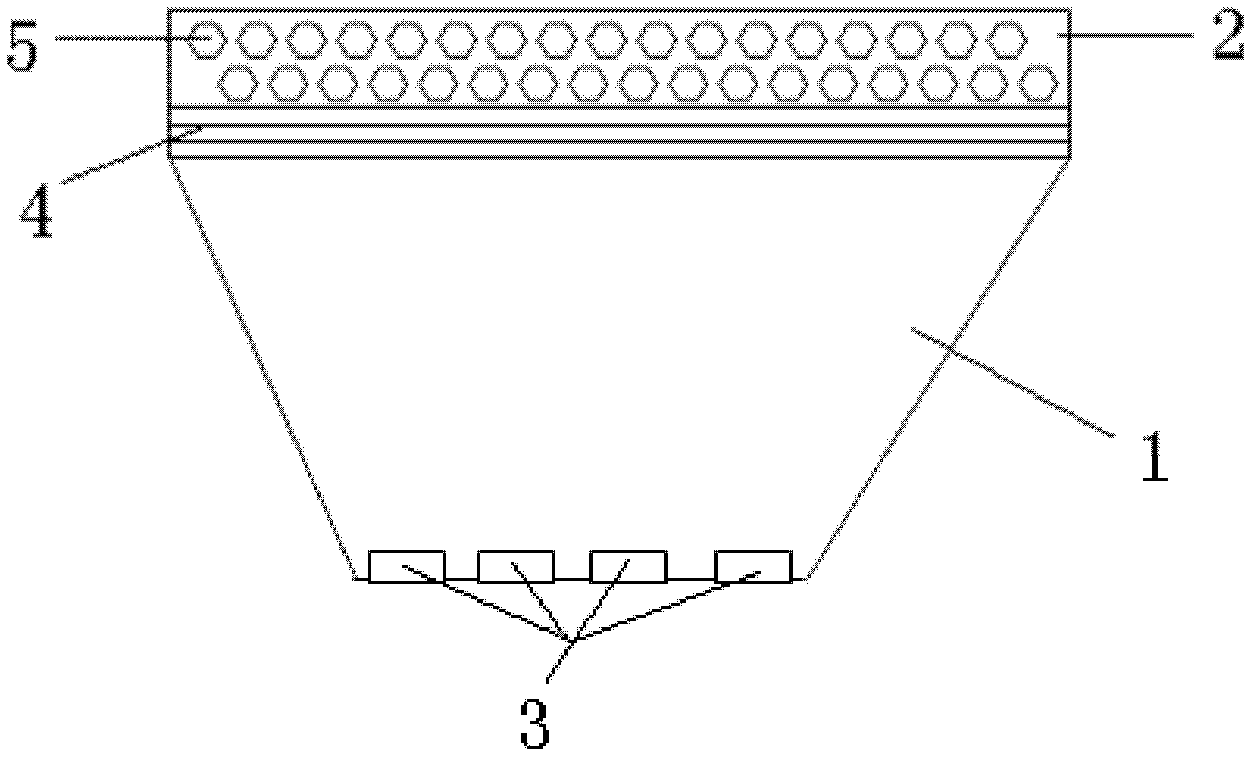

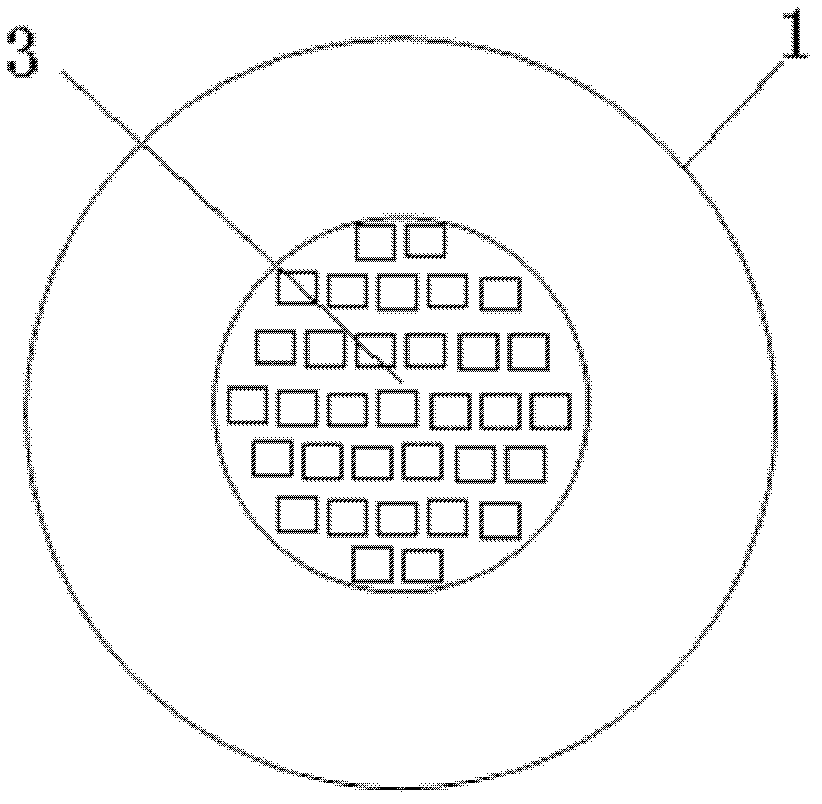

[0018] Embodiment 1: The packaging structure of a high-power LED light-emitting device includes a blue-light chip module, a reflective cup, and fluorescent glass. The blue light chip module is obtained by integrating 33 blue light LED chips. The reflective cup can optimize the light path effect. The yellow fluorescent substance is evenly distributed inside the fluorescent glass. Through this packaging method, white light can be realized, and the distance between the fluorescent glass and the blue light chip module can be adjusted through threads. A comprehensive optical test of the light-emitting device through an integrating sphere shows that its color temperature is 3000K-8000K.

Embodiment 2

[0019] Embodiment 2: The packaging structure of the high-power LED light-emitting device includes a blue-light chip module, a reflective cup, and fluorescent glass. The blue light chip module is obtained by integrating one blue light LED chip. The reflective cup can optimize the light path effect, and the yellow and red fluorescent substances are evenly distributed inside the fluorescent glass. Through this packaging method, white light with high color rendering can be realized, and the fluorescent light can be adjusted through threads The distance between the glass and the blue light chip module, the comprehensive optical test of the light emitting device through the integrating sphere shows that its color temperature is 3000K-8000K.

Embodiment 3

[0020] Embodiment 3: The packaging structure of the high-power LED light-emitting device includes a blue-light chip module, a reflective cup, and fluorescent glass. The blue light chip module is obtained by integrating 55 blue light LED chips. The reflective cup can optimize the light path effect. The green and red fluorescent substances are evenly distributed inside the fluorescent glass. Through this packaging method, the white light of the three primary colors can be realized. The fluorescent glass and the fluorescent glass can be adjusted through threads. The distance between the blue light chip modules, the comprehensive optical test of the light emitting device through the integrating sphere shows that its color temperature is 3000K-8000K.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com