Screen printing head, method of screen printing and printing blade

A technology of screen printing, screen printing machine, applied in the direction of screen printing machine, printing, printing machine, etc., can solve the problems of reducing deposit transfer efficiency, low area ratio, reducing printing medium and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

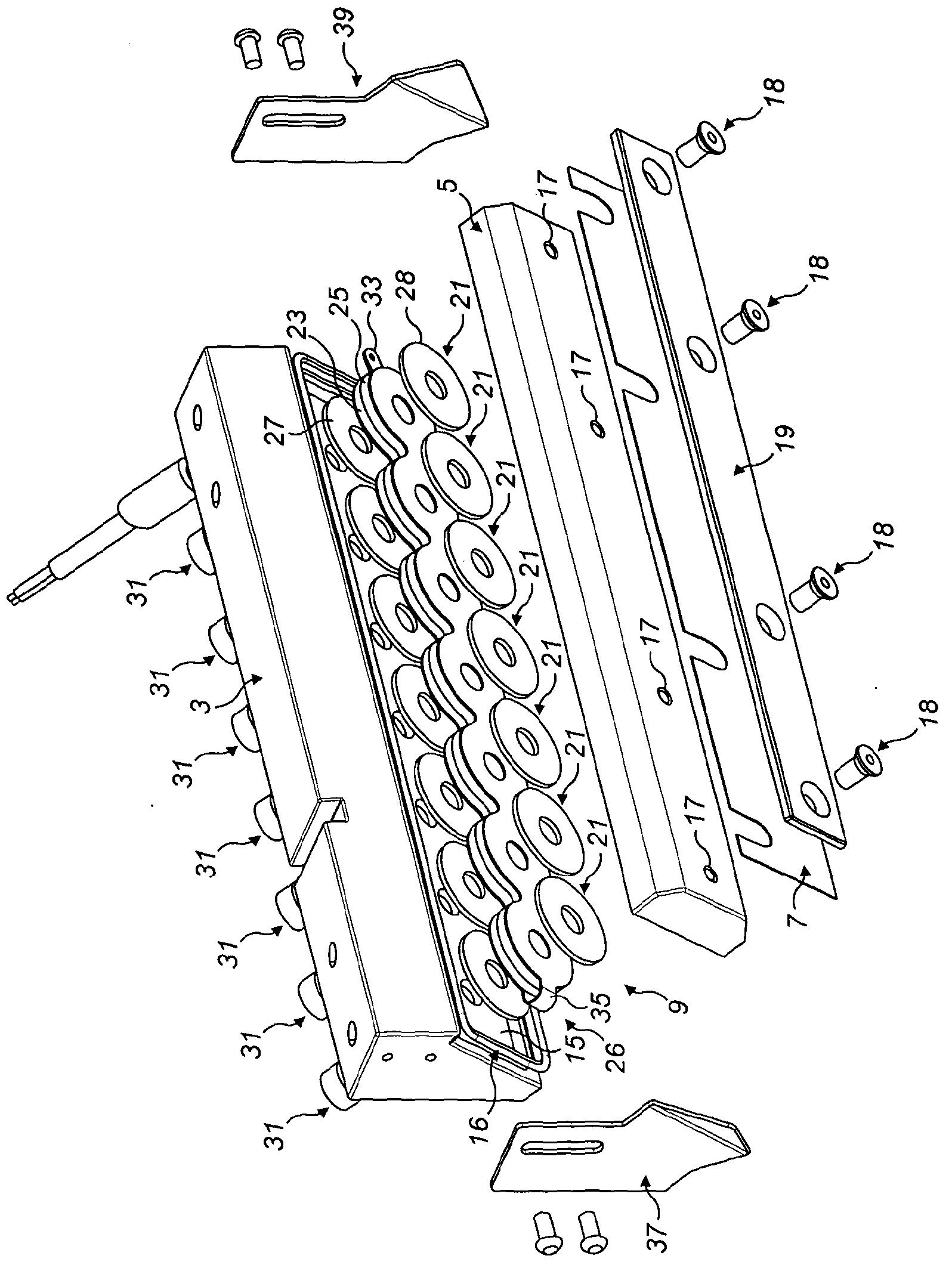

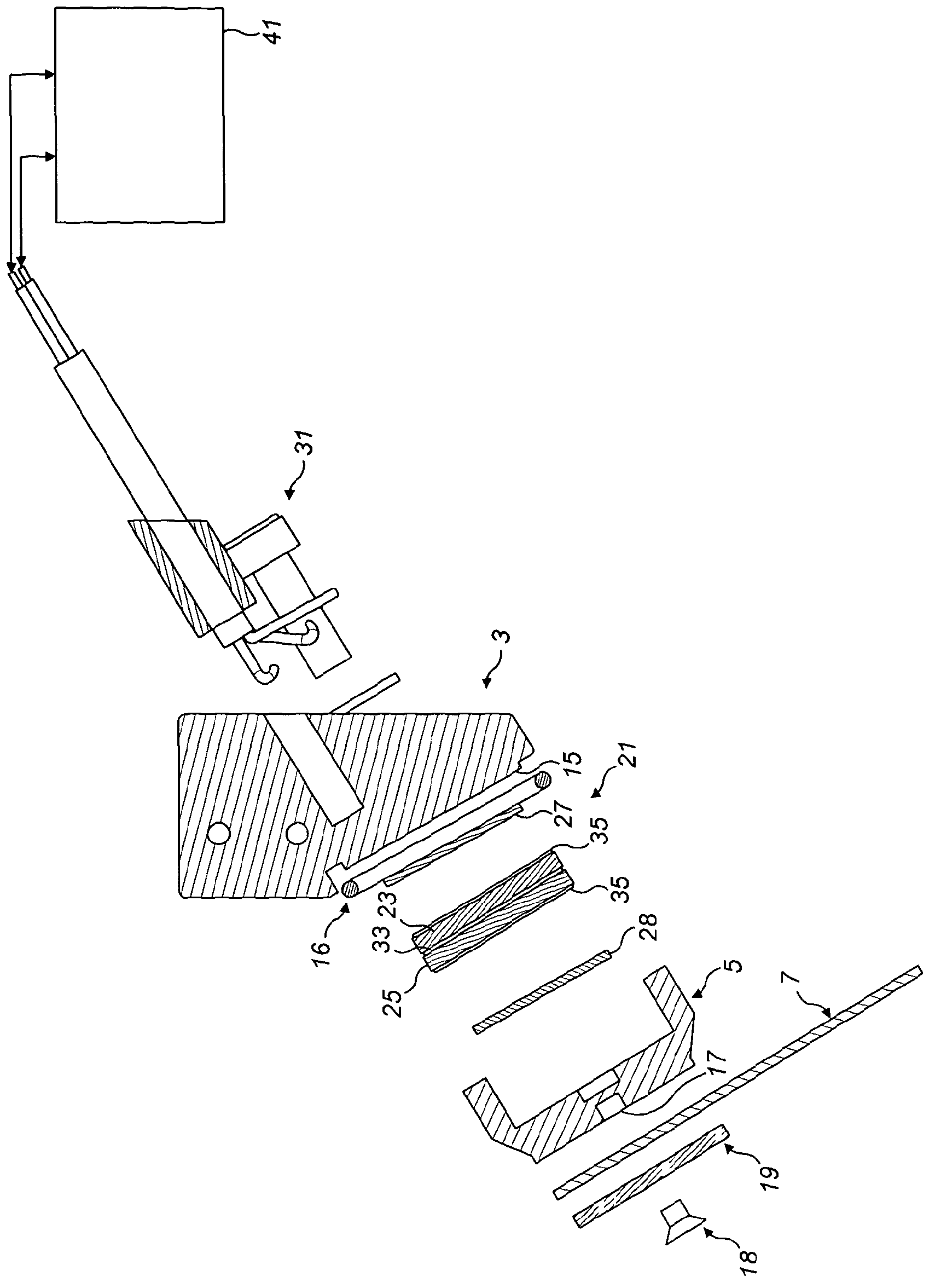

[0025] Figures 1 to 4 A screen printing head according to a first embodiment of the present invention is shown.

[0026] The screen printing head comprises a main support 3, which in this embodiment is an elongated block, formed of stainless steel, is intended to be attached to the printing head of a screen printing machine, a support element 5 and a vibrating unit 9. a transport mechanism (not shown) operable to move the print head over the printing screen S positioned over the workpiece W and to print a deposit of the print medium via the pattern of holes in the printing screen to the workpiece W; in this embodiment the support element 5 is an elongated element to which the printing blade 7 is attached; the vibration unit 9 couples the support element 5 to the main body 3 to provide the support element 5 and thus the printing blade 7 vibration.

[0027] As will be discussed in more detail below, the vibration of the printing blade 7 applies energy to the printing medium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com